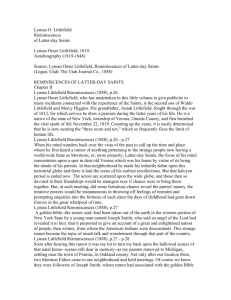

Littlefield-061606-lecture

advertisement

MULTIDISCIPLINARY ANALYSIS, INVERSE DESIGN, ROBUST OPTIMIZATION AND CONTROL (MAIDROC) LABORATORY DEPARTMENT OF MECHANICAL AND MATERIALS ENGINEERING Presents an Invited Lecture MODELING CONTACT IN MULTI-MATERIAL FRAMEWORKS Professor David L. Littlefield Department of Mechanical engineering The University of Alabama at Birmingham, Birmingham AL 35294 littlefield@uab.edu Date: Time: Room: June 16, 2006 (FRIDAY) 1:15 p.m. EC 3327 - MME Conference Room Realistic and accurate modeling of contact in the presence of large deformations and severe distortions is beset with many computational challenges. Relevant applications where this situation arises include vehicle crash dynamics, ballistic penetration and perforation, structure-blast interaction, warhead fracture and fragmentation, and orbital debris impact. The natural framework for description of surfaces afforded by Lagrangian finite element methods makes it the method of choice for many applications in this class. However, the large distortions often result in elements that develop large aspect ratios, twist, or even invert; making the application of traditional finite element approaches impossible in many cases. Due to this deficiency, Eulerian and arbitrary Lagrangian-Eulerian (ALE) methods have become popular, particularly in the last decade. The tradeoff with Eulerian or ALE approaches is the added complexity associated with permitting multiple materials to occupy a single finite element. One of the difficulties associated with allowing multiple materials in a single element is satisfying contact constraints at the interface between the materials. Historically this problem has been sidestepped by replacing the materials present in the element with an equivalent single material. The heuristic techniques applied to determine the material properties of this fictitious material usually have little or nothing to do with contact and as a result, often result in unphysical behavior. Recently several researchers have investigated alternatives in an attempt to correct this deficiency. The simplest technique is to set the shear stresses at interfaces equal to zero [1] which, in effect, replaces the contact boundary with a fluid layer one element wide. Benson [2] developed a mixture theory approach that accounts for friction at the interface by introducing additional internal state variables to describe the slip. A third alternative [3], demonstrated for rigid objects penetrating deforming bodies, uses a penalty method to prevent the Eulerian material from penetrating the rigid body. A common feature to all these approaches is the use of a single velocity field for all deforming materials. This limits applicability to contact problems, which by their very nature require distinct velocity fields for each material. An alternative approach, recently introduced by the author [4,5], uses distinct velocity fields for each material. No mixed-element thermodynamic or constitutive models are used in the formulation. Instead, the governing equations are solved for each material, with the appropriate inequality constraints applied at intermediate locations within the elements. What arises from this is a set of coupled equations that are approximated by an uncoupled, reduced form. Recent results from development of this technique will be presented in this talk. REFERENCES [1] Walker, J. D. and Anderson, C. E., “Multi-material velocities for mixed cells”, High Pressure Science and Technology – 1993, American Institute of Physics Press, pp. 1773–1776, 1994. [2] Benson, D. J., “A mixture theory for contact in multi-material Eulerian formulations”, Comput. Methods Appl. Mech. Engng., 140, pp. 59 – 86, 1997. [3] Benson, D. J. and Okazawa, S., “Contact in a multi-material Eulerian finite element formulation”, Comput. Methods Appl. Mech. Engng., 193, pp. 4277 – 4298, 2004. [4] Littlefield, D. L., “A method for treatment of dynamic contact-impact in multi-material frameworks”, Proceedings of the Fifth World Congress on Computational Mechanics, Jul 7 – 12, Vienna Austria, 2002. [5] Littlefield, D. L. “A technique for modeling interfaces in multi-material CSM applications”, presented at the Seventh U.S. National Congress on Computational Mechanics, Jul 27 – 31, Albuquerque NM, 2003. A Biographical Sketch of the Invited Lecturer: David Littlefield is professor of Mechanical Engineering at the University of Alabama at Birmingham (UAB). He is also the Functional Area Point-of-Contact (FAPOC) for Computational Structural Mechanics (CSM) for the Programming Environment and Training (PET) Program sponsored by the Department of Defense High Performance Computing Modernization Program (DoD HPCMP). Dr. Littlefield’s primary technical interests are in the areas of computational solid mechanics and computational magnetohydrodynamics. He has authored or co-authored over 100 papers and technical reports in these areas. In his role as FAPOC in the PET program, Dr. Littlefield leads a team of university researchers, scientists and DoD laboratory on-site personnel that is tasked with technology transfer of computer modeling applications, algorithms, methods, and tools into the user community. He has participated in both material and managerial roles on many projects since assuming the role of FAPOC in July 2002. Technical work he has been involved in includes advanced finite element methods, global error estimation and adaptive mesh refinement, goal-oriented error estimation, code coupling algorithms, improved interface tracking methods, and equations of state for energetic materials. Dr. Littlefield’s graduate studies were in Mechanical Engineering. He received his MSME degree from Georgia Institute of Technology in 1984. His Ph.D. in Mechanical Engineering was awarded in 1989, also from Georgia Institute of Technology. Dr. Littlefield as a member of the American Society of Mechanical Engineers, and was elected to fellow grade in 2002. He is also a member of the United States Association for Computational Mechanics, the Hypervelocity Impact Society and the National Defense Industrial Association. For further information please contact Prof. Dulikravich at (305) 348-7016 or at dulikrav@fiu.edu.