Mineral oil and natural gas

advertisement

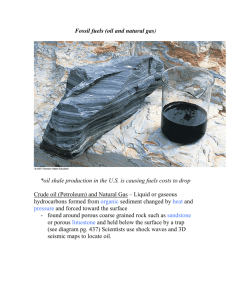

Mineral oil and natural gas 1. Mineral oil and natural gas were formed 150 to 400 millions of years ago from plankton. Dead organisms formed mud at the bottom of shallow seas. This mud was later covered by layers of sand and stone during geological processes. High temperature and high pressure and the absence of air promoted the formation of hydrocarbons from the organic compounds originally present. Due to the pressure and higher density of rock strata oil, gas and water migrated upwards until stopped by a non-permeable layer. Upward folding of strata and formation of faults led to the building of deposits called traps. There, water, oil and gas are filled in the rocks’ pores like water in a sponge. Due to their high energy content hydrocarbons are excellent fuels. Besides, mineral oil fractions consisting of larger molecules are ideal lubricants and the black residue called bitumen may be used for paving roads. Moreover, hydrocarbons are highly suitable as raw materials for any number of organic syntheses yielding plastics, detergents, pharmaceuticals, cosmetics, dyes and pigments, solvents, agrochemicals ……………. That is why man has been exploiting oil and gas deposits for about one hundred years now. As deposits are running low, engineers and researchers get more and more inventive in finding out, where oil is and how it may be brought to the surface. Oil wells may be found from the earth surface to depths of more than 10 kilometres and they may be below the desert or offshore. They are in regions with long winters like Alaska or even in the Antarctic. However, not every oil well merits exploitation. EROEI “Energy Returned on Energy Invested” is an important factor: Whether an oil field brings profit or not depends on the quality of oil and the situation of the field. mud shallow to promote compound density to migrate permeable deposit trap sponge slime chem. Verbindung to travel Lagerstätte Fossil fuels –Information text fraction lubricant residue detergent dye pigment solvent to exploit inventive to merit part, portion Schmiermittel Farbstoff ausbeuten to earn 1/6 Oil rich in gasoline and diesel that is found on dry land, in moderate depths and in regions with clement climatic conditions is however no longer an option. “Peak Oil” means the maximum in the oil exploitation curve. We seem to be about to reach it or might even have passed it by … That means that offer and demand of oil are drifting apart rendering the black gold more and more expensive. 2. To find oil first of all geological data are needed. They are based on satellite recordings and direct investigation. To get a geological profile of the earth surface seismology is the most important method. It is based on the reflection of shock waves from the rock strata. Regions where gas and oil traps might probably be can thus be designated. Only by drilling an unambiguous result can be obtained. The picture shows a drilling rig for a rotary drilling system. This means that the whole drill string, consisting of pipes of 10 metres each is kept rotating during the drilling process. gasoline diesel moderate dry land clement offer demand Festland Angebot Nachfrage Fossil fuels –Information text investigation demand to designate unambiguous drilling rig pipe drill string Untersuchung Bohrgestänge 2/6 The drilling hole needs casing to prevent it from collapsing and besides the drilling mud must be able to circulate and thus be moved to the surface. In order to accomplish this and to keep up constant pressure, water is pumped into the hole. The derrick is more than 30 metres high. When the drill string has to be drawn up in order to exchange the drill, the pipes are stored in units of three in the derrick. Oil drilling is performed down to depths of approximately 10 kilometres now. Depending on the constitution of the rock layers this process may take more than a year. Imagine the amount of work and energy it takes to perform such an enterprise, when realizing that the overall success of drilling is less than 20 %! If drilling is successful additional derricks have to be placed to find out the size of the field. Modern drilling methods include horizontal drilling techniques that allow reaching areas unattainable by vertical drilling and are also more efficient for subsequent extraction. 3. Oil is a more or less viscous liquid – but even relatively thin oil is a sticky liquid more viscous than water. Therefore, only at the very beginning oil will surface spontaneously. To extract about 50 % of the oil in a deposit different techniques are used: The most conventional method is using pumps creating a suction that draws oil up. Enhanced oil recovery is brought about by: o Injecting gases into the hole to increase pressure (natural gas or carbon dioxide are used); o Injecting detergents to lower viscosity; o Injecting hot steam to increase pressure and lower viscosity by elevating the temperature; drilling hole casing to collapse drilling mud to accomplish derrick constitution to elevate Gehäuse Bohrschlamm to bring about state, composition to raise Fossil fuels –Information text enterprise unattainable subsequent viscous spontaneous suction to enhance not to be reached following Sog to heighten 3/6 o In situ combustion to increase pressure and lower viscosity by elevating the temperature. Crude oil has to be transported to a refinery in order to separate its components and transform them to the desired products. This is done by tank ships or pipelines. 4. At the refinery crude oil is separated into fractions containing compounds of similar boiling points. This is done by distillation. The oil is heated to a temperature of approximately 350°C so that most of it evaporates. The hot steam rises through a chimneylike construction (called the distillation – column) that has sieve–bottoms in it, where the portions that liquefy due to the decrease in temperature collect and may be drawn. The most important fractions are: gasoline, kerosene, diesel and fuel oil. Crude oil contains also substantial amounts of dissolved natural gas that collects at the top of the column. The residue is distilled a second time under reduced pressure (vacuum distillation) so that boiling points decrease. The main fraction of this second distillation is called vacuum gas oil. It’s a valuable raw material for gaining additional gasoline by cracking. The residue of the vacuum distillation process is bitumen. The compounds composing the fractions differ in the size of the molecules: Small hydrocarbons with short chains (few carbon atoms) have low boiling points. The boiling points increase with increasing size of the molecules. combustion crude oil refinery boiling point to evaporate sieve burning verdampfen Fossil fuels –Information text to liquefy fuel oil substantial to dissolve raw material size make/get liquid important lösen 4/6 5. The fractions of mineral oil have then to be purified e. g. to be desulphurized. Afterwards chemical conversion is performed. The most important processes are cracking and reforming. While the former helps to increase the amount of gasoline that can be derived from crude oil the latter increases the quality of gasoline (octane number). Cracking indicates a process where long hydrocarbon chains consisting of 15 to 20 carbon atoms (and – of course – the necessary hydrogen atoms as well) are broken to chains of about half the original length. To obtain saturated hydrocarbons hydrogen has to be added. That is why this process is called hydro-cracking. Otherwise unsaturated hydrocarbons are obtained: Unsaturated hydrocarbons are very important raw materials of the petroleum processing industry, e. g. for the synthesis of polymers like polyethene – but they are undesirable in fuels. Reforming is done to improve the quality of gasoline with respect to its ability to withstand self-ignition. Self-ignition is called knocking. It happens prematurely, before the piston in the cylinder has reached the top dead centre, i. e. the maximum compression. Normally, ignition is caused by the spark plug at the top of each cylinder. Knocking reduces the engines output and de-synchronises the cylinders of the engine – thus causing a characteristic sound that has given its name to the phenomenon. Branched and cyclic hydrocarbons are less prone to knocking than simple chains. Reforming is a process to rearrange molecules so that the number of branched and cyclic molecules increases. to purify to desulphurize conversion to indicate saturated to withstand self-ignition anti-knock-quality polymers make free of sulphur to mean, to denote gesättigt Klopffestigkeit Fossil fuels –Information text prematurely piston dead centre spark plug output prone to rearrange petroleum processing undesirable early Totpunkt geneigt, anfällig umlagern Erdölverarbeitung not wanted 5/6 2,2,4-Trimethylpentane, called iso-octane is the compound with the highest anti-knock quality of all saturated hydrocarbons in gasoline. It has given its name to the octane number that is a measure for the anti-knock-quality of gasoline. Pure iso-octane has an octane number of 100. If the desired octane-number cannot be reached by reforming, anti knock additives are added. There are many other additives in gasoline and diesel that are all synthesized at the refinery. Tasks: Add the missing expressions in the word tables at the end of each page! Look for other words you don’t understand! Treat each section separately by studying it carefully and condensing its content to 3 - 4 sentences! Look for technical expressions that are not contained in the word tables and make sure you know their meaning. (Consult the key word tables!) Together with a partner a) draft a dialogue between a journalist and an expert about the benefits of oil and the problems ahead as supplies are running low or b) write an article for a newspaper about our oil dependent world. additive to condense benefit supplies to run low Vorräte advantage Fossil fuels –Information text 6/6