FDR and GBS Specification 04_01_07

advertisement

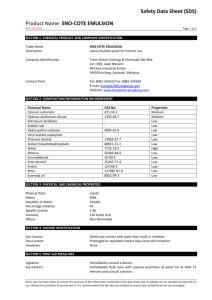

January, 2007 ASPHALT EMULSION FULL DEPTH RECLAMATION (FDR) AND GRANULAR BASE STABILIZATION (GBS) PART 1 1.1. GENERAL SECTION INCLUDES A. Pulverize the existing in-place material with a reclaimer to obtain required depth and width. B. Mix with asphalt emulsion; water shall be added as needed. C. Place to line, grade and compact. 1.2. PAYMENT PROCEDURES A. Asphalt Emulsion Full Depth Reclamation Bid 1. pay separately a. For bidding purposes use an emulsion content of 4.5% for FDR or 5.5% for GBS by weight of the material. b. Asphalt emulsion is measured by the gallon or ton. B. Mobilization is a lump sum. C. Traffic control is a lump sum. D. FDR / GBS work is measured by the square yard of the completed sections for the depth specified. Includes the reclaiming of the existing road, furnishing, preparing, hauling and placing new materials, such as water and aggregate; all freight involved; all manipulations, including blading and rolling; all labor, tools, equipment and incidentals necessary to complete the work; and quality control. 1.3. REFERENCES A. AASHTO T-322: Determining the Creep Compliance and Strength of HotMix Asphalt (HMA) Using the Indirect Tensile Test Device B. ASTM C 117: Standard Test Method for Materials Finer than 75-æm (No. 200) Sieve in Mineral Aggregates by Washing C. ASTM C 136: Standard Test Method for Sieve Analysis of Fine and Coarse Aggregates 1 January, 2007 D. ASTM D 244: Standard Test Methods and Practices for Emulsified Asphalts E. ASTM D 1452: Standard Practice for Soil Investigation and Sampling by Auger Borings F. ASTM D 1556: Standard Test Method for Density and Unit Weight of Soil in Place by the Sand-Cone Method G. ASTM D 1557: Standard Test Methods for Laboratory Compaction Characteristics of Soil Using Modified Effort H. ASTM D 1560: Standard Test Methods for Resistance to Deformation and Cohesion of Bituminous Mixtures by Means of Hveem Apparatus I. ASTM D 2041: Standard Test Method for Theoretical Maximum Specific Gravity and Density of Bituminous Paving Mixtures J. ASTM D 2419: Standard Test Method for Sand Equivalent Value of Soils and Fine Aggregate K. ASTM D 2726: Standard Test Method for Bulk Specific Gravity and Density of Non-Absorptive Compacted Bituminous Mixtures L. ASTM D 2950: Standard Test Method for Density of Bituminous Concrete in Place by Nuclear Methods M. ASTM D 4123: Indirect Tension Test for Resilient Modulus of Bituminous Mixtures N. ASTM D 4643 Standard Test Method for Determination of Water (Moisture) Content of Soil by the Microwave Oven Method O. ASTM D 4867 Standard Test Method for Effect of Moisture on Asphalt Concrete Paving Mixtures P. ASTM D 6752 Standard Test Method for Bulk Specific Gravity and Density of Compacted Bituminous Mixtures Using Automatic Vacuum Sealing Method 1.4. A. SUBMITTALS Submit mix design for Engineer’s approval 10 working days prior to commencing cold recycling operation. 2 January, 2007 PART 2 2.1. PRODUCTS MATERIALS A. The asphalt emulsion will conform to requirements of Table 1. Determine the properties of the emulsion according to the mix design. B. The reclaimed material at the recommended emulsion content shall meet the properties in Table 1. The properties and quantity of asphalt emulsion, add rock, and water shall be determined by the mixture design. C. Use Additives if necessary. In the case that an additive is used, the type and allowable usage percentage must be described in the submitted design and approved by the engineer. Table 1(FDR) – For mixtures containing <8 percent passing No. 200 150 mm diameter specimens shall be prepared in a Superpave gyratory compactor Property Superpave gyratory compaction, 1.25° angle, 600 kPa, gyrations Short-term strength test, 1 hour – modified cohesiometer, ASTM D 1560-92 (Part 13), g/25mm of width (see Appendix 2 for modifications) Indirect tensile strength (ITS), ASTM D 4867 Part 8.11.1, 25°C, psi Conditioned ITS, ASTM D 4867, psi Resilient modulus, ASTM D 4123, 25°C, psi x 1000 Thermal cracking (IDT), AASHTO T-322 (Based on LTPPBind for climate)* Criteria 30 175 min. 40 min. 25 min. 150 min. See note in appendix Table 1(GBS) – For mixtures containing >8 percent passing No. 200 or for all granular mixtures 150 mm diameter specimens shall be prepared in a Superpave gyratory compactor Property Criteria Superpave gyratory compaction, 1.25° angle, 600 kPa, gyrations 30 Short-term strength test, 1 hour – modified cohesiometer, ASTM D 1560-92 150 min. (Part 13), g/25mm of width (see Appendix 2 for modifications) Indirect tensile strength (ITS), ASTM D 4867 Part 8.11.1, 25°C, psi 35 min. Conditioned ITS, ASTM D 4867, psi 20 min. Resilient modulus, ASTM D 4123, 25°C, psi x 1000 120 min. Thermal cracking (IDT), AASHTO T-322 (Based on LTPPBind for climate)* See note in appendix * Optional if project is in -20°C or warmer climate (98% reliability) 2.2. A. MIX DESIGN Sampling and Processing 1. Use auger borings (ASTM D 1452), cores, and / or other data (i.e. pavement records, FWD deflection data, etc.) to determine if more than one mix design is needed 3 January, 2007 a. 2. 3. 4. FDR projects with more than a 2-inch difference in bituminous surface between sections shall have separate designs performed. A minimum sample size of 350 pounds of representative material is required for each mix design. If cores or slabs are received, determine the individual and average thickness values. If the bituminous materials are the primary component of the mix design, measure the density of four cores or two slabs for emulsion rate calculations. Crush bituminous materials to the gradation below before blending with the aggregate. If bituminous materials only consist of a chip seal crush to 100% passing the 1-inch sieve. Sieve Size 1.25 in. (31.25 mm) 1 in. (25 mm) ¾ in. (19 mm) No. 4 (4.75 mm) No. 30 (0.6 mm) 5. B. All specimens prepared for mix design must have a maximum size passing the 1.25 in. (31.25 mm) screen. Material Evaluation 1. Perform and the report gradations (ASTM C 117 and C 136) and Sand equivalent (ASTM D 2419, method B) on: a. Base rock (Washed gradation) b. RAP (dry or Washed gradation) c. Blend (washed gradation) 2. C. Gradation 100 90 to 100 80 to 97 30 to 55 5 to 15 Perform Modified Proctor compaction according to ASTM D 1557, Method C to determine optimum moisture content (OMC) at peak dry density. a. Define OMC by a best-fit curve from a minimum of four points. b. If the material has 20% or more passing No. 200, mix at target moisture, seal, and set aside a minimum of 12 hours. If a material contains less than 4 percent passing No. 200, then this testing is not required. All other material shall be set aside a minimum of 3 hours. Selection of Water Content for Design 1. Use a water content of 50 to 75 percent of OMC if Sand equivalent value (SE) 30 or 40 to 65 percent of OMC if SE > 30. SE is from the combined materials. 4 January, 2007 2. 3. If a material contains less than 4 percent passing No. 200 or if no peak develops with the OMC curve, fix the moisture content between 2 and 3 percent. Mix specimens with the required amount of water before the addition of emulsion. Mix and allow it to sit sealed according to the same guidelines used for Modified Proctor specimens (Section 2.2.C.2.b). D. Number of Specimens / Mixing 1. Before adding water or emulsion to the mix, weigh sufficient material into individual pans to produce 70 to 80 mm tall compacted specimens (except for IDT testing) 2. Choose four emulsion contents that will bracket the design emulsion content. 3. Prepare the following specimens a. Two specimens at each of four emulsion contents for shortterm strength testing b. Four specimens at each of four emulsion contents for the strength and retained strength tests c. Two specimens for maximum specific gravity d. Four specimens at 120 to 140 mm tall at the design emulsion for thermal cracking testing (IDT) 4. Use a mechanical mixer that has a bowl of 10 to 12 inches in diameter that rotates on its axis at 50 to 75 revolutions per minute. In addition to a mixing paddle which makes contact with the bottom and side of the bowl rotating on its axis in the opposite direction at twice the bowl rotation rate. 5. Mix the aggregate and emulsion at a temperature of 20 to 26°C. 6. Mix in the water for 60 seconds. 7. Mix in the emulsion 60 seconds. 8. If other materials are added, such as lime or cement, introduce it in a similar manner, as they will be on the project. For example, if lime is incorporated a day or more before emulsion addition, then add it to the wet aggregate a day or more before mixing with emulsion. If lime is incorporated as slurry, then add it as slurry in the laboratory. E. Curing Before Compaction 1. Cure loose specimens individually at 40°C for 30 to 45 ( 3) minutes in plastic containers of 4 to 7 inches (100 to 180 mm) height and 6 inches (150 mm) diameter. No further mixing or aeration shall occur during this time. F. Compaction 1. Specimens shall be compacted in a Superpave gyratory compactor (SGC) at a vertical pressure of 600 kPa, an angle of 1.25°, and a mold 5 January, 2007 of 150 mm diameter for 30 gyrations. After the last gyration, 600 kPa pressure shall be applied for 10 seconds. The mold shall not be heated. G. Short-Term Strength (STS) Test 1. Use a modified Hveem cohesiometer apparatus to test early strength (1 hour). This apparatus and procedure generally conforms to ASTM D 1560 Section 10 with the following exceptions: a. It shall have the capability of testing 150 mm diameter specimens. b. It shall have a shot flow rate of 2700 50 g/minute. c. Specimens shall be cured before compaction according to Section 5, and cure each specimen at each emulsion content for 60 5 minutes at 25°C and 10 to 70 percent humidity after compaction and before testing. d. See Appendix 2 for further details of the equipment and operation. H. Curing After Compaction 1. Cure specimens (except STS specimens) for 72 hours at 40°C. Rest the specimens on racks with slots or holes for air circulation. After curing, cool specimens for moisture conditioning at ambient temperature, for a maximum of 24 hours. a. Cool specimens for dry strength at ambient temperature or 25°C and test at the same time as moisture-conditioned specimens. b. Cure specimens for maximum specific gravity at the same conditions as the compacted specimens, except they can be tested after cooling a maximum of 24 hours. I. Volumetric Measurements 1. Perform bulk specific gravity of the specimens according to ASTM D 6752. Keep specimens in bags until testing or vacuum saturation is performed. Perform ASTM D 2726 (one minute soak) if absorption is less than 2 percent. 2. Perform maximum specific gravity measurements according to ASTM D 2041 with the supplemental dry-back procedure. Determine maximum specific gravity at the other emulsion contents, corrected for the residue of the emulsion. 3. Determine air voids at each emulsion content. J. Mechanical Measurements 1. Perform resilient modulus testing in accordance with ASTM D 4123 on at least two specimens at each emulsion content after conditioning for at least two hours at 25°C. Test at a frequency of 1 Hz and use a 6 January, 2007 Poisson’s ratio of 0.30 to 0.40 for analysis. This can be performed before the ITS test on the same (dry) specimens. 2. Perform strength testing according to ASTM D 4867. Specimens shall be conditioned at 25°C for two hours before testing. 3. Soak half the specimens at each emulsion content for 24 hours at 25°C before retained strength testing. Thermal Cracking 1. See Appendix 3 K. L. Emulsion Content Selection 1. The mix at the selected emulsion content will conform to requirements in table 1. M. Prepare a final report that summarizes the following mix design information. 1. The name of the road and other pertinent project information 2. Penetration of the emulsion residue used in the mix design 3. A general description of the materials received, their locations, and how samples were obtained 4. Average thickness of bituminous materials. Report density if Proctor testing was not performed. 5. Thickness to be reclaimed 6. Washed gradation of the separate and blended material(s). If RAP was crushed in the laboratory, then the gradation of the RAP shall be reported, and the combined washed gradation of the blend shall be reported. 7. Sand equivalent value of the separate and blended materials 8. Density and OMC from Proctor compaction 9. The moisture content used in mix design 10. Range of emulsion contents 11. Short-term strength at each emulsion content (average values) 12. Density, Gmm, and air voids at each emulsion content (average values) 13. Resilient modulus and indirect tensile strength at each emulsion content (average values) 14. Level of saturation and conditioned indirect tensile strength at each emulsion content (average values) 15. Critical thermal cracking temperature from IDT at the design emulsion content, if performed 16. Design emulsion content as a percent, in gallons per square yard, and in gallons per foot (with assumed width reported) PART 3 3.1. EXECUTION EQUIPMENT – The engineer should approve all the equipment described in this section 7 January, 2007 A. Reclaimer – Use a reclaimer that is/has 1. Self-propelled, With a minimum of 400 horsepower 2. Capable of fully reclaiming the existing road to the required depth 3. Capable of reclaiming the in-place materials into a homogenous mix 4. Capable of reclaiming not less than 8-feet (2.4 m) wide and up to 12inches deep in each pass. 5. Capable of adding asphalt emulsion with a full width spray bar consisting of a positive displacement pump interlocked to the machine speed so that the amount of emulsion being added is automatically adjusted with changes in machine speed. 6. An additive system capable of incorporating up to 7 gallons per square yard of emulsion 7. Individual valves on the spray bar capable of being turned off as necessary to minimize emulsion overlap on subsequent passes. B. Motor Grader 1. Use a motor grader for pre-shaping, aerating, spreading and final shaping of the material. 2. Use a motor grader with a with a cross slope indicator. C. Rollers 1. Use a vibratory padfoot roller with an 84-inch-wide drum and a minimum weight of 10-tons; a blade is recommended for back dragging. 2. Use a pneumatic tire roller of at least 20 tons with water spray system. 3. Use a double drum vibratory steel roller with minimum weight of 10tons with a functioning water spray system. 4. The use of a padfoot roller is optional if the reclamation depth is less than 4 inches. If no padfoot roller is used, then use the pneumatic roller with a minimum weight of 25-tons with a functioning water spray system. Water Truck 1. Use a water truck capable of supplying water to the reclaimer for addition of moisture, as required, during the FDR / GBS operation. 2. Use a truck capable of spraying water onto the road before reclaiming. D. 3.2. PREPARATION A. Pre-Shaping. Shape the road with the reclaimer and / or motor grader to correct for profile, crown, and contour, according to the plans, before the addition of emulsion. Add water and add rock if necessary. B. Compact the material to support equipment and / or traffic and to provide depth control during reclaiming; Use a steel roller unless otherwise requested by the Engineer. 8 January, 2007 C. 3.3. Proceed to reclaiming with emulsion unless moisture content is not within 1 percent from the mix design recommendation and as measured in Section 5.4; aerate if too wet and add water if too dry. RECLAMATION A. Use the amount of asphalt emulsion recommended in the mix design. B. Check the gradation requirement of section 3.3.D before spreading and compacting. C. Mix Homogeneity 1. If the reclaimed mixture looks uniform with one pass with emulsion, water and add rock then no extra passes are necessary. 2. If the entire operation cannot be completed in one pass, an extra pass will be necessary. a. Reclaim the existing road to the depth described on the plans only adding water and add rock if necessary; pre-shaping can also be accomplished at this time. After completing the first pass, shape the road with a motor grader and compact it with a steel roller to provide better depth control. In the second pass, add the required amount of emulsion. D. Initial Compaction. 1. Ensure the breakdown roller (padfoot or pneumatic) is not behind the reclaimer by more than 500 feet. 2. Use the padfoot roller, applying high amplitude and low frequency, or the pneumatic roller to perform initial compaction. Provide enough passes until the roller walks out of the material. a. Walking out for the padfoot roller is defined as light being evident between all of the pads at the material–padfoot drum interface. b. Walking out for the pneumatic roller is defined as no significant wheel impressions being left on the surface. E. Remove any pad foot marks after the completion of padfoot rolling and spread the material using a motor grader cut no deeper than necessary to remove the padfoot marks. Achieve the desired slope and shape at this point. Compaction will be aided if the steel roller (high frequency / low amplitude) and / or pneumatic roller follow the motor grader; Use this if there are no compaction measurement requirements. After the first day of emulsion addition, the reclaimed base shall not be shaped or significant chunking will result. 9 January, 2007 F. Intermediate and Final Compaction 1. The vibratory double-drum steel roller and pneumatic roller shall compact the bladed material. 2. The best combination of number of passes and order of rollers shall be used to meet compaction requirements. 3. Do not finish roll in vibratory mode. A light spray of water may aid in final compaction density and appearance. G. Proof Rolling 1. Proof roll the compacted material according to the Engineer’s approval. 2. Proof rolling pattern to represent the type of traffic expected on the road. a. If deformation does not occur, moving truck traffic can be allowed on the reclaimed base. b. If deformation does occur, truck traffic should be kept off until the reclaimed material is firm enough. 3. It is expected that the reclaimed base can support moving car traffic after finish rolling has occurred. H. Curing 1. Confirm that moisture content is less than 2.5 percent before surfacing the reclaimed material. 2. Surface material before winter 3.4. A. B. C. 3.5. A. LIMITATIONS Cease reclaiming operations when weather is rainy. Confirm the weather forecast does not call for freezing temperatures for seven days. Confirm the historical weather database does not call for freezing temperatures within 7 days of the end of the project; based on 50 percent reliability. QUALITY CONTROL The Contractor is responsible for quality control (QC) of the FDR / GBS process and the completed reclaimed base. Quality control includes the following activities, and the results of the QC reported daily in writing to the Engineer. See Appendix 1 for data sheets. Pre-Construction Meeting 1. Supervisory personnel of the contractor and crew and the testing laboratory will meet a representative(s) of the Agency at a mutually agreed time prior to the start of the project to discuss methods of accomplishing all phases of the project. A representative of the asphalt 10 January, 2007 emulsion supplier will be available to discuss handling of emulsions and delivery issues. B. Asphalt Emulsion 1. The asphalt emulsion will meet the requirements listed in Table 2. 2. A representative from the asphalt emulsion supplier will check the mixing and setting properties for at least the first three days of construction. The asphalt emulsion representative will adjust the asphalt emulsion formulation if necessary. Changes will comply with Table 2. Table 2 Test Minimum Maximum Residue from distillation, % ASTM D2441 63 Oil distillate by distillation, % ASTM D2441 0.5 Sieve Test, % ASTM D2441 0.1 Penetration (TBD2), 25°C, dmm ASTM D5 -25% +25% 1 Modified ASTM D244 procedure – distillation temperature of 177°C with a 20 minute hold. The ASTM D244 vacuum distillation procedure may be substituted once the maximum oil distillate is satisfied. 2 TBD – To be determined from the mix design prior to emulsion manufacture for project. Penetration range will be reported on the submitted mix design. 3. The sampling frequency will be in accordance with the Engineer’s requirements and will be established prior to the start of the project. The testing will meet the requirements in Table 2. C. Add Rock. Check the spread rate and type of the add-rock and conform to the quantity required by the mix design. The Engineer will decide the frequency at which rates will be checked by yield. D. Maximum Material Size. Obtain samples (40 pounds) of the reclaimed material before beginning compaction. Sieve to determine compliance with the requirements in table 3. Frequency is determined by the Engineer. Table 3 Sieve Size 2.0 in. (50 mm) 1.75 in. (44 mm) E. Percent Passing 100 97-100 Moisture Content. Check moisture content before adding emulsion 1. Use a microwave oven to confirm moisture content according to ASTM D 4643. Use a minimum sample size of 700 grams for the microwave procedure after screening through a ¾-inch sieve. Other methods such as the nuclear gauge, direct heating or infrared are acceptable. 11 January, 2007 2. 3. 4. 5. 6. 7. 8. Check the moisture content on the same day that emulsion will be added. Re-check the moisture content if it rains after testing and before emulsion addition or if it has been manipulated. Adjust moisture content of the materials if the average moisture content is not within 1 percent of the mix design recommendation. Take a representative sample. Ensure the sides of the sample hole are perpendicular to the road surface. Keep samples sealed until they are ready for testing. Check the moisture content on at least each of three reclaimer passes on the first day of FDR / GBS. After the first day, the Engineer will decide sampling frequency. F. Emulsion Content. Use the amount of asphalt emulsion recommended on the mix design. 1. The Engineer must approve any changes in asphalt emulsion content. 2. The Engineer will determine sampling frequency. 3. Determine the percentage of emulsion by determining the amount used by meter readings or truck weight tickets and by estimating the quantity of road reclaimed – depth, width, length, and estimated inplace density by Proctor density (mix design or field check) or nuclear density. 4. On the first day of FDR / GBS determine the emulsion content on the first emulsion transport. Make adjustments in equipment if necessary. After adjustments check the emulsion content. G. Depth Control 1. Monitor reclaiming depth at least twice a day. 2. Confirm the depth on each side of the reclaimer pass and adjust immediately as necessary. H. Compaction 1. There are two options for reference density – a test strip or Modified Proctor density. It is recommended that moisture and emulsion contents be checked and established before determination of reference density. a. Test Strip Option. If the sand cone method is used for test strip reference density, then it shall be used for acceptance testing. If the nuclear density gauge is for test strip reference density, then it shall be used for acceptance testing. The test strip shall be at least 1000 feet long. The final roller pattern shall result in the maximum achievable density with the rollers specified. This roller pattern shall be used throughout the rest of the project. However, any significant changes with the road, such 12 January, 2007 as materials, moisture content, or emulsion content, shall require a new test strip for roller pattern determination and new reference density determination. A reference density shall be determined on the test strip at a recommended three to five locations after finish rolling and measured by sand cone (ASTM D 1556) or nuclear gauge (ASTM D 2950, direct transmission). If measured, all subsequent material shall be compacted to a minimum of 97 percent reference density of the test strip average reference density at a sampling frequency to be determined by the Engineer. If accurate dry (nuclear) density results cannot be obtained, then wet density shall be the reference. Correction to dry density shall be by direct moisture measurement, as described in Section 3.3.E. b. I. Modified Proctor Density Option. Refer to ASTM D 1557, Method C or equivalent; the 6 inch diameter mold is required. Only the nuclear gauge shall be used for acceptance testing when Modified Proctor is used as the reference density, and it shall be measured at the same location as the nuclear gauge reading. Samples shall be obtained to the full depth of reclamation before rolling and stored in a sealed container for no longer than one hour before Proctor compaction. Material shall be compacted to a minimum of 97 percent reference density of the Modified Proctor average reference density. Moisture contents on the material shall be obtained in accordance with Section 3.3.E for reference. The mold shall be placed on a firm surface during compaction. If accurate dry (nuclear) density results cannot be obtained, then wet density shall be the reference. Correction to dry density shall be by direct moisture measurement, as described in Section 3.3.E. Reclaimed Base Contour and Profile. 1. Ensure the contour, profile, methods and tolerances are as indicated on the plans or as required by the Engineer. 13 January, 2007 APPENDIX 1 QC Data Sheet (Use one or more data sheets per day) Information Date: QC personnel: Temperature at start of day: Climate conditions: Other notes: Project / location: Phone: Temperature at end of day: Results of mix design Optimum moisture content (OMC) from Modified Proctor Density at OMC Recommended field moisture range Recommended emulsion content Add Rock Station / location Type and source Length, ft Width, ft Weight, lb Rate, lb/SY Test strip for sand cone or nuclear density Location Station Wet density, pcf Average (Reference density) Operator Gauge model Moisture, % Gauge serial # Final roller pattern: Density measurements not required. Final roller pattern: Material Tests Station / location Max. size (Sec. 5.3) – 2” 14 Dry density, pcf Notes January, 2007 Size (Sec. 5.3) – 1.75” Moisture content, % (Sec.3.3.E.) Emulsion content, % (Sec. 3.3.F) Wet Density, pcf (Sec. 3.3.H) Dry density, pcf (Sec. 3.3.H) Proctor dry density, pcf (Sec. 3.3.H) Percent of reference density Reported by:___________________________ APPENDIX 4 Procedures for performing AASHTO T-322 for FDR and GBS Design Specimens NOTE: Procedure for critical cold temperature selection Specification temperature shall be chosen using FHWA LTPPBind software (Version 2.1) using the weather station closest to the project. The required temperature for the specification is the coldest temperature at the top of the FDR / GBS layer in the pavement structure. Use 98 percent reliability. Perform the indirect tensile testing (IDT) according to AASHTO T-322 with the following exceptions: 1. 2. 3. 4. 5. 6. Specimens shall be 150 mm in diameter and at least 115 mm in height and cured and compacted as described in the testing procedures. After curing, two specimens shall be cut from each compacted specimen to 50 mm in height. Perform bulk specific gravity after cutting. Two to three specimens are required at each of three temperatures. Select two temperatures at 10ºC intervals that bracket the required specification. For example, if the required specification temperature is –25ºC, then select testing temperatures of –20ºC and –30ºC. A temperature of –10ºC or –40ºC should then be selected to complete the third required temperature. The tensile strength test shall be carried out on each specimen directly after the tensile creep test at the same temperature as the creep test. The environmental chamber must be capable of temperatures down to –40ºC. The critical cracking temperature is defined as the intersection of the calculated pavement thermal stress curve (derived from the creep data) and the tensile strength line (the line connecting the results of the average tensile strength at the two temperatures). 15 January, 2007 16 January, 2007 APPENDIX 2 Additional Instructions for the Short-Term Strength Test Ensure that the following calibrations are made: 1. The counter balance should be positioned exactly so that the hinged plate just barely remains horizontal when the top brackets and empty bucket are in place. This ensures that there is no force on the sample until shot begins to flow into the bucket. 2. The gap between the bars of the switch that turns off the flow of shot should have a gap of ¾ inch when there is 3000 g of shot in the bucket. During this adjustment the locking bolt that prevents the plate from moving is in place. To test cohesion 1. Tare the balance with the empty bucket weight. 2. Center the specimen on the unit. 3. Place plates on top of sample and press down while adjusting the outer lower nuts up until they just contact the bottom of the plate. 4. Use a torque wrench or torque-meter to tighten the nuts on the specimen to 20 inchpounds (maximum). 5. Gently support the bar so the unit does not move when the pin is pulled releasing the hinged plate. 6. Pull pin and push open valve to start the flow of shot. 7. After the unit shuts off the flow of shot, immediately put the locking pin in place and then record the weight of shot. 8. Loosen top nuts to remove plates and rotate specimen 90°. 9. Repeat procedure on the other axis of the specimen. 10. Calculate short-term strength as follows: shot weight / (15 * (0.031*height + 0.0027*height2)) where shot weight is in grams and height is in cm. 11. A total of two results will be obtained for each specimen at each emulsion content, and a total of four results will be obtained at each emulsion content. 17