MODUL MATA KULIAH SISTEM PEMIPAAN ( 3 SKS ) By Ir. Teguh

advertisement

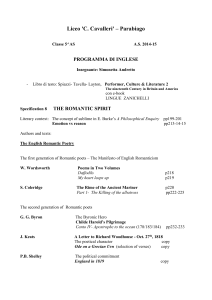

----------------------------------------------------------------------- MODUL MATA KULIAH SISTEM PEMIPAAN ( 3 SKS ) By Ir. Teguh Pudji Hertanto, M.Sc, IPM ‘11 1 Sistem Pemipaan Ir. Teguh Pudji Hertanto, M.Sc, IPM Pusat Pengembangan Bahan Ajar Universitas Mercu Buana ----------------------------------------------------------------------MODUL-13 “PIPING MATERIAL SELECTION” AISI (American Iron and Steel Institute) dan SAE (Society of Automotive Engineers) telah mengelompokkan dan menstandarisasi sistem penomoran untuk berbagai klass baja karbon dan alloy yang dipakai menjadi acuan hingga kini. Untuk baja karbon dan alloy ada 4 (empat) digit, sedangkan stainless steel ada 3 (tiga) digit sebagaimana tabel dibawah. Table 1 Karbon dan alloy grade (AISI, SAE, UNS) ______________________________________________________________________ Numerals and digits UNS SAE/AISI Types of identifying elements ---------------------------------------------------------------------------------------------------------------Carbon steels G10XX0 G11XX0 G12XX0 10XX Nonresulfurized, manganese 1.00% maximum 11XX Resulfurized 12XX Rephosphorized and resulfurized G13XX0 G23XX0 G25XX0 G31XX0 G32XX0 G33XX0 G34XX0 G40XX0 G41XX0 G43XX0 G44XX0 G46XX0 G47XX0 G48XX0 G50XX0 G51XX0 G50XX6 G51XX6 G52XX6 G61XX0 G71XX0 G72XX0 G81XX0 G86XX0 G87XX0 G88XX0 ‘11 13XX 23XX 25XX 31XX 32XX 33XX 34XX 40XX 41XX 43XX 44XX 46XX 47XX 48XX 50XX 51XX 50XXX 51XXX 52XXX 61XX 71XXX 72XX 81XX 86XX 87XX 88XX 2 Alloy steels Manganese steels Nickel steels Nickel steels Nickel-chromium steels Nickel-chromium steels Nickel-chromium steels Nickel-chromium steels Molybdenum steels Chromium-molybdenum steels Nickel-chromium-molybdenum steels Molybdenum steels Nickel-molybdenum steels Nickel-chromium-molybdenum steels Nickel-molybdenum steels Chromium steels Chromium steels Chromium steels Chromium steels Chromium steels Chromium-vanadium steels Tungsten-chromium steels Tungsten-chromium steels Nickel-chromium-molybdenum steels Nickel-chromium-molybdenum steels Nickel-chromium-molybdenum steels Nickel-chromium-molybdenum steels Sistem Pemipaan Ir. Teguh Pudji Hertanto, M.Sc, IPM Pusat Pengembangan Bahan Ajar Universitas Mercu Buana ----------------------------------------------------------------------- G92XX0 G93XX0 G94XX0 G97XX0 G98XX0 92XX 93XX 94XX 97XX 98XX Silicon-manganese steels Nickel-chromium-molybdenum steels Nickel-chromium-molybdenum steels Nickel-chromium-molybdenum steels Nickel-chromium-molybdenum steels Carbon and alloy steels GXXXX1 GXXXX4 XXBXX B denotes boron steels XXLXX L denotes leaded steels S2XXXX S3XXXX S4XXXX S5XXXX 302XX Chromium-nickel steels 303XX Chromium-nickel steels 514XX Chromium steels 515XX Chromium steels Stainless steels Experimental steels None Ex. . . SAE Experimental steels _______________________________________________________________________ Table 2 ASME spec. untuk pemilihan material sistem pemipaan _______________________________________________________________________________ ASME Specification Metal or Alloy Number Grade Other comments MPa Pipe ksi* -----------------------------------------------------------------------------------------------------------------------------------Carbon steel SA-53 A 48,000 UTS/30,000YS (330/205) Carbon steel SA-106 B 60,000 UTS/35,000YS (415/240) Carbon steel SA-106 C 70,000 UTS/40,000YS (485/275) ⁄₂ Cr–1⁄₂ Moly SA-335 P2 55,000 UTS/30,000YS (380/205) 1 Cr–1⁄₂ Moly SA-335 P12 60,000 UTS/32,000YS (415/220) 11⁄₄ Cr–1⁄₂ Mo-Si SA-335 P11 60,000 UTS/30,000YS (415/205) 21⁄₄ Cr–1 Mo SA-335 P22 60,000 UTS/30,000YS (415/205) 5 Cr–1 Mo SA-335 P5 60,000 UTS/30,000YS (415/205) 9 Cr–1 Mo SA-335 P9 60,000 UTS/30,000YS (415/205) 9 Cr–1 Mo-V SA-335 P9 85,000 UTS/60,000YS (585/415) 304H SA-376 TP304H 0.04% Min carbon 304H SA-430 FP304H Forged and bored pipe 316H SA-376 TP316H 75,000 UTS/30,000YS (515/205) Forgings/fittings Carbon steel Carbon steel Carbon steel Carbon-Moly ⁄₂ Cr–1⁄₂ Moly 1 Cr–1⁄₂ Moly ‘11 3 SA-105 SA-181 SA-266 SA-182 SA-182 SA-182 Sistem Pemipaan Ir. Teguh Pudji Hertanto, M.Sc, IPM — C170 C12 F1 F2 F12 Rolled or forged bar 70,000 UTS/36,000YS (485/250) 70,000 UTS/30,000YS (485/205) 0.5% Mo — 70,000 UTS/40,000YS (485/275) Pusat Pengembangan Bahan Ajar Universitas Mercu Buana ----------------------------------------------------------------------- 11⁄₄ Cr–1⁄₂ Mo-Si 11⁄₄ Cr–1⁄₂ Mo-Si 21⁄₄ Cr–1 Mo 5 Cr–1 Mo 9 Cr–1 Mo-V 304H Tubing Carbon steel Carbon steel Carbon-Moly ⁄₂ Cr–1⁄₂ Moly 21⁄₄ Cr–1 Moly 9 Cr–1 Mo-V 304H *UTS and YS in psi. SA-182 SA-182 SA-234 SA-336 SA-234 SA-336 F11a F11b WP12 Fittings F5A WP9 Fittings F304H 75,000 UTS/45,000YS (515/310) 60,000 UTS/30,000YS (415/205) SA-178 SA-210 SA-209 SA-213 SA-213 SA-213 SA-213 A Electric resistance welded A1 60,000 UTS/37,000YS (415/255) T1a Seamless T2 60,000 UTS/30,000YS (415/205) T22 60,000 UTS/30,000YS (415/205) T91 Normalized and tempered TP304H 75,000 UTS/30,000YS (515/205) 80,000 UTS/50,000YS (550/345) 1900_F Min anneal Table 3 Referensi ASME vs UNS ----------------------------------------------------------------------------------ASME specification (and grade) UNS number ----------------------------------------------------------------------------------SA-53 (E-A)(S-A) K02504 SA-53 (E-B)(S-B) K03005 SA-106 (A) K02501 SA-106 (B) K03006 SA-106 (C) K03501 SA-178 (A) K01200 SA-178 (C) K03503 SA-209 (T1) K11522 SA-209 (T1a) K12023 SA-209 (T1b) K11422 SA-210 (A1) K02707 SA-210 (C) K03501 SA-213 (T2) K11547 SA-213 (T3b) K21509 SA-213 (T5) K41545 SA-213 (T7) S50300 SA-213 (T9) S50400 SA-213 (T11) K11597 SA-213 (T12) K11562 SA-213 (T21) K31545 SA-213 (T22) K21590 SA-213/SA-312 (304) S30400 SA-213/SA-312 (304H) S30409 ‘11 4 Sistem Pemipaan Ir. Teguh Pudji Hertanto, M.Sc, IPM Pusat Pengembangan Bahan Ajar Universitas Mercu Buana ----------------------------------------------------------------------- SA-213/SA-312 (304L) S30403 SA-213/SA-312 (304N) S30451 SA-213/SA-312 (310) S31000 SA-213/SA-312 (316) S31600 SA-213/SA-312 (316H) S31609 SA-213/SA-312 (316L) S31603 SA-213/SA-312 (316N) S31651 SA-213/SA-312 (321) S32100 SA-213/SA-312 (321H) S31209 SA-213/SA-312 (347) S34700 SA-213/SA-312 (347H) S34709 SA-213/SA-312 (348) S34800 SA-213/SA-312 (348H) S34809 SA-335 (P1) K11522 SA-335 (P2) K11547 SA-335 (P5) K41545 SA-335 (P7) S50300 SA-335 (P9) S50400 SA-335 (P11) K11597 SA-335 (P12) K11562 SA-335 (P21) K31545 SA-335 (P22) K21590 ---------------------------------------------------------------------------------------------- Table 4 Nominal composition dari Wrought cooper materials -------------------------------------------------------------------------------------------------------------------------- Alloy Composition -------------------------------------------------------------------------------------------------------------------------- Coppers Electrolytic tough pitch (ETP) Phosphorized, high residual phosphorus (DHP) Phosphorized, low residual phosphorus (DLP) Lake Silver bearing (10–15) Silver bearing (25–30) Oxygenfree (OF) (no residual deoxidants) Free cutting Free cutting Free cutting Chromium copper (heat treatable) (b) Cadmium copper (b) 99 Tellurium nickel copper (heat treatable) (b) 98.4 Beryllium copper (heat treatable) ‘11 5 Sistem Pemipaan Ir. Teguh Pudji Hertanto, M.Sc, IPM 99.90 Cu–0.04 O 99.90 Cu–0.02 P 99.90 Cu–0.005 P Cu–8 oz/ton Ag Cu–10 to 15 oz/ton Ag Cu–25 to 30 oz/ton Ag 99.92 Cu (min) 99 Cu–1 Pb 99.5 Cu–0.5 Te 99.4 Cu–0.6 Se Cu _ Cr and Ag or Zn Cu–1 Cd Cu–1.1 Ni–0.5 Te Cu–2 Be–0.25 Co or 0.35 Ni Pusat Pengembangan Bahan Ajar Universitas Mercu Buana ----------------------------------------------------------------------Plain brasses Gilding, 95% 95 Commercial bronze, 90% 90 Red brass, 85% 85 Low brass, 80% 80 Cartridge brass, 70% 70 Yellow brass, 65% 65 Muntz metal 60 Cu–5 Zn Cu–10 Zn Cu–15 Zn Cu–20 Zn Cu–30 Zn Cu–35 Zn Cu–40 Zn Leaded commercial bronze (rod) 89 Leaded brass strip (B121-3) 65 Leaded brass strip (B121-5) 65 Leaded brass tube (B135-3) 66 Leaded brass tube (B135-4) 66 Medium-leaded brass rod 64.5 High-leaded brass rod 62.5 Free-cutting brass rod (B16) 61.5 Forging brass 60 Architectural bronze 57 Cu–9.25 Zn–1.75 Pb Cu–34 Zn–1 Pb Cu–33 Zn–2 Pb Cu–33.5 Zn–0.5 Pb Cu–32.4 Zn–1.6 Pb Cu–34.5 Zn–1 Pb Cu–35.75 Zn–1.75 Pb Cu–35.5 Zn–3 Pb Cu–38 Zn–2 Pb Cu–40 Zn–3 Pb Free-cutting brasses Miscellaneous brasses Admiralty (inhibited) 71 Cu–28 Zn–1 Sn Naval brass 60 Cu–39.25 Zn–0.75 Sn Leaded naval brass 60 Cu–37.5 Zn–1.75 Pb–0.75 Sn Aluminum brass (inhibited) 76 Cu–22 Zn–2 Al Manganese brass 70 Cu–28.7 Zn–1.3 Mn Manganese bronze rod A (B138) 58.5 Cu–39 Zn–1.4 Fe–1 Sn–0.1 Mn Manganese bronze rod B (B138) 65.5 Cu–23.3 Zn–4.5 Al–3.7 Mn–3 Fe ---------------------------------------------------------------------------------------------------------------------------------------- Table 5 Spesifikasi Cooper dan cooper-based pipe ASME specification UNS grade number Characteristics SB-42/SB-68 SB-42/SB-68 SB-42/SB-68 SB-43 SB-75/SB-111 SB-75/SB-111 SB-75/SB-111 SB-75/SB-111 SB-111 C10200 C12000 C12200 C23000 C10200 C12000 C12200 C14200 C23000 99.95 Cu 99.90 plus low Phos 99.9 plus high Phos Red Brass Oxygen Free — — Phosphorized, Arsenical Red Brass ‘11 6 Sistem Pemipaan Ir. Teguh Pudji Hertanto, M.Sc, IPM Pusat Pengembangan Bahan Ajar Universitas Mercu Buana ----------------------------------------------------------------------- SB-111 SB-111 SB-111 SB-111 SB-111 SB-111 SB-111 SB-111 SB-111 SB-111 SB-315 SB-466 SB-466 SB-467 SB-467 SB-161 SB-161 SB-163/SB-407 SB-163/SB-165 SB-163/SB-167 SB-163/SB-167 SB-163/SB-423 01. C28000 C44300 C44400 C44500 C60800 C68700 C70400 C70600 C71000 C71500 C65500 C70600 C71500 C70600 C71500 N02200 N02201 N08800 N04400 N06600 N06690 N08825 Muntz Metal Admiralty Metal Cu-Zn Cu-Zn Aluminum Bronze Aluminum Brass 95-5 Cu-Ni 90-10 Cu-Ni 80-20 Cu-Ni 70-30 Cu-Ni High-Si Bronze 90-10 Cu-Ni 70-30 Cu-Ni Welded 90-10 Welded 70-30 Nickel 200; 99% Ni Low Carbon Alloy 800 Tubing (Ni-Fe70-30 Ni-Cu Monel Alloy 600 (Ni-Cr-Fe) Alloy 690 (60-30-10) Alloy 825 PIPING MATERIAL SPECIFICATION (SECTION 01) - ASTM Section 01. Iron and Steel Products 01.01. Steel—Piping, Tubing, Fittings A53/A53M-02. Standard specification for pipe—steel, black and hotdipped, zinc-coated, welded, and seamless. A105/A105M-02. Standard specification for carbon steel forgings for piping applications. A106-02a. Standard specification for seamless carbon steel pipe for hightemperature service. A134-96(2001). Standard specification for pipe—steel, electric-fusion (arc)-welded (sizes NPS 16 and over). A135-01. Standard specification for electric-resistance-welded steel pipe. A139-00. Standard specification for electric-fusion (arc)-welded steel pipe (NPS 4 and over). A179/A179M-90a(2001). Standard specification for seamless cold-drawn low-carbon steel heat-exchanger and condenser tubes. A181/A181M-01. Standard specification for carbon steel forgings, for general-purpose piping. A182/A182M-02. Standard specification for forged or rolled alloy-steel pipe flanges, forged fittings, and valves and parts for high-temperature service. ‘11 7 Sistem Pemipaan Ir. Teguh Pudji Hertanto, M.Sc, IPM Pusat Pengembangan Bahan Ajar Universitas Mercu Buana ----------------------------------------------------------------------A193/A193M-03. Standard specification for alloy-steel and stainless steel bolting materials for high-temperature service. A194/A194M-03b. Standard specification for carbon and alloy steel nuts for bolts for highpressure or high-temperature service or both. A210/A210M-02. Standard specification for seamless medium-carbon steel boiler and superheater tubes. A234/A234M-03. Standard specification for piping fittings of wrought carbon steel and alloy steel for moderate- and high-temperature service. A268/A268M-03. Standard specification for seamless and welded ferritic and martensitic stainless steel tubing for general service. A269-02a. Standard specification for seamless and welded austenitic stainless steel tubing for general service. A312/A312M-03. Standard specification for seamless and welded austenitic stainless steel pipes. A320/A320M-03. Standard specification for alloy-steel bolting materials for lowtemperature service. A333/A333M-99. Standard specification for seamless and welded steel pipe for lowtemperature service. A334/A334M-99. Standard specification for seamless and welded carbon and alloy-steel tubes for low-temperature service. A335/A335M-03. Standard specification for seamless ferritic alloy-steel pipe for hightemperature service. A350/A350M-02b. Standard specification for carbon and low-alloy steel forgings, requiring notch toughness testing for piping components. A358/A358M-01. Standard specification for electric-fusion-welded austenitic chromiumnickel alloy steel pipe for high-temperature service. A369/A369M-02. Standard specification for carbon and ferritic alloy steel forged and bored pipe for high-temperature service. A376/A376M-02a. Standard specification for seamless austenitic steel pipe for hightemperature central-station service. A381-96(2001). Standard specification for metal-arc-welded steel pipe for use with highpressure transmission systems. A403/A403M-03a. Standard specification for wrought austenitic stainless steel piping fittings. A409/A409M-01. Standard specification for welded large-diameter austenitic steel pipe for corrosive or high-temperature service. A420/A420M-02. Standard specification for piping fittings of wrought carbon steel and alloy steel for low-temperature service. A437/A437M-01a. Standard specification for alloy-steel turbine-type bolting material specially heat treated for high-temperature service. A453/A453M-02. Standard specification for high-temperature bolting materials, with expansion coefficients comparable to austenitic stainless steels. A524-96(2001). Standard specification for seamless carbon steel pipe for atmospheric and lower temperatures. ‘11 8 Sistem Pemipaan Ir. Teguh Pudji Hertanto, M.Sc, IPM Pusat Pengembangan Bahan Ajar Universitas Mercu Buana ----------------------------------------------------------------------A530/A530M-03. Standard specification for general requirements for specialized carbon and alloy steel pipe. A587-96(2001). Standard specification for electric-resistance-welded lowcarbon steel pipe for the chemical industry. A671-96(2001). Standard specification for electric-fusion-welded steel pipe for atmospheric and lower temperatures. A672-96(2001). Standard specification for electric-fusion-welded steel pipe for highpressure service at moderate temperatures. A691-98(2002). Standard specification for carbon and alloy steel pipe, electric-fusionwelded for high-pressure service at high temperatures. A789/A789M-02a. Standard specification for seamless and welded ferritic/austenitic stainless steel tubing for general service. A790/A790M-03. Standard specification for seamless and welded ferritic/ austenitic stainless steel pipe. A815/A815M-01a. Standard specification for wrought ferritic, ferritic/austenitic, and martensitic stainless steel piping fittings. 01.02 Ferrous Castings, Ferroalloys A47/A47M-99. Standard specification for ferritic malleable iron castings. A48/A48M-00. Standard specification for gray iron castings. A126-95(2001). Standard specification for gray iron castings for valves, flanges, and pipe fittings. A216/A216M-93(2003). Standard specification for steel castings, carbon, suitable for fusion welding, for high-temperature service. A217/A217M-02. Standard specification for steel castings, martensitic stainless and alloy, for pressure-containing parts, suitable for hightemperature service. A278/A278M-01. Standard specification for gray iron castings for pressurecontaining parts for temperatures up to 6508F (3508C). A351/A351M-03. Standard specification for castings, austenitic, austeniticferritic (duplex), for pressure-containing parts. A352/A352M-03. Standard specification for steel castings, ferritic and martensitic, for pressure-containing parts, suitable for low-temperature service. A395/A395M-99. Standard specification for ferritic ductile iron pressureretaining castings for use at elevated temperatures. A426/A426M-02. Standard specification for centrifugally cast ferritic alloy steel pipe for high-temperature service. A451/A451M-02. Standard specification for centrifugally cast austenitic steel pipe for high-temperature service. A487/A487M-93(2003). Standard specification for steel castings suitable for pressure service. A494/A494M-03a. Standard specification for castings, nickel and nickel alloy. A571/A571M-01. Standard specification for austenitic ductile iron castings for pressurecontaining parts suitable for low-temperature service. 01.03 Steel—Plate, Sheet, Strip, Wire; Stainless Steel Bar A167-99. Standard specification for stainless and heat-resisting chromiumnickel steel plate, sheet, and strip. ‘11 9 Sistem Pemipaan Ir. Teguh Pudji Hertanto, M.Sc, IPM Pusat Pengembangan Bahan Ajar Universitas Mercu Buana ----------------------------------------------------------------------A240/A240M-03c. Standard specification for chromium and chromiumnickel stainless steel plate, sheet, and strip for pressure vessels and for general applications. A263-03. Standard specification for stainless chromium steel-clad plate. A264-03. Standard specification for stainless chromium-nickel steel-clad plate, sheet, and strip. A265-03. Standard specification for nickel and nickel-base alloy-clad steel plate. A479/A479M-03. Standard specification for stainless steel bars and shapes for use in boilers and other high-pressure vessels. 01.04 Steel—Structural, Reinforcing, Pressure Vessel, Railway A20/A20M-02. Standard specification for general requirements for steel plates for pressure vessels. A36/A36M-03a. Standard specification for carbon structural steel. A202/A202M-03. Standard specification for pressure vessel plates, alloy steel, chromiummanganese-silicon. A203/A203M-97(2003). Standard specification for pressure vessel plates, alloy steel, nickel. A204/A204M-03. Standard specification for pressure vessel plates, alloy steel, molybdenum. A285/A285M-03. Standard specification for pressure vessel plates, carbon steel, low- and intermediate-tensile strength. A299/A299M-03e1. Standard specification for pressure vessel plates, carbon steel, manganese-silicon. A302/A302M-03. Standard specification for pressure vessel plates, alloysteel, manganese-molybdenum and manganese-molybdenum-nickel. A353/A353M-93(1999). Standard specification for pressure vessel plates, alloy steel, 9% nickel, double-normalized and tempered. A387/A387M-03. Standard specification for pressure vessel plates, alloy steel, chromiummolybdenum. A515/A515M-03. Standard specification for pressure vessel plates, carbon steel, for intermediate- and higher-temperature service. A516/A516M-03. Standard specification for pressure vessel plates, carbon steel, for moderate- and lower-temperature service. A537/A537M-95(2000). Standard specification for pressure vessel plates, heat-treated, carbon-manganese-silicon steel. A553/A553M-95(2000). Standard specification for pressure vessel plates, alloy steel, quenched and tempered 8% and 9% nickel. A645/A645M-99a. Standard specification for pressure vessel plates, 5% nickel alloy steel, specially heat treated. 01.05 Steel—Bars, Forgings, Bearings, Chains, Springs A508/A508M-03. Standard specification for quenched and tempered vacuum-treated carbon and alloy steel forgings for pressure vessels. A675/A675M-90a(2000). Standard specification for steel bars, carbon, hotwrought, special quality, mechanical properties. ‘11 10 Sistem Pemipaan Ir. Teguh Pudji Hertanto, M.Sc, IPM Pusat Pengembangan Bahan Ajar Universitas Mercu Buana ----------------------------------------------------------------------01.06 Coated Steel Products A123/A123M-02. Standard specification for zinc (hot-dip galvanized) coatings on iron and steel products. A153/A153M-03. Standard specification for zinc coating (hot-dip) on iron and steel hardware. 01.07 Ships and Marine Technology. This material is not referenced in ASME B31.3. 01.08 Fasteners; Rolling Element Bearings. A307-03. Standard specification for carbon steel bolts and studs, 60,000 psi tensile strength. A325-02. Standard specification for structural bolts, steel, heat-treated, 120/105 ksi minimum tensile strength. A325M-03. Standard specification for structural bolts, steel heat-treated 830 MPa minimum tensile strength (metric). A354-03a. Standard specification for quenched and tempered alloy steel bolts, studs, and other externally threaded fasteners. A563-00. Standard specification for carbon and alloy steel nuts. 02. PIPING MATERIAL SPECIFICATION (SECTION 02) - ASTM Section 02. Non-Ferrous Metal Products 02.01 Copper and Copper Alloys B21/B21M-01e1. Standard specification for naval brass rod, bar, and shapes. B42-02. Standard specification for seamless copper pipe, standard sizes. B43-98. Standard specification for seamless red brass pipe, standard sizes. B61-02. Standard specification for steam or valve bronze castings. B62-02.Standardspecification forcompositionbronzeorouncemetalcastings. B68-02. Standard specification for seamless copper tube, bright annealed. B68M-99. Standard specification for seamless copper tube, bright annealed (metric). B75M-99. Standard specification for seamless copper tube (metric). B75-02. Standard specification for seamless copper tube. B88-02. Standard specification for seamless copper water tube. B88M-99. Standard specification for seamless copper water tube (metric). B96/B96M-01. Standard specification for copper-silicon alloy plate, sheet, strip, and rolled bar for general purposes and pressure vessels. B98/B98M-03. Standard specification for copper-silicon alloy rod, bar, and shapes. B148-97(2003). Standard specification for aluminum-bronze sand castings. B150/B150M-03. Standard specification for aluminum bronze rod, bar, and shapes. B152/B152M-00. Standard specification for copper sheet, strip, plate, and rolled bar. B169/B169M-01. Standard specification for aluminum bronze sheet, strip, and rolled bar. B171/B171M-99e2. Standard specification for copper-alloy plate and sheet for pressure vessels, condensers, and heat exchangers. B187/B187M-03. Standard specification for copper, bus bar, rod, and shapes and general-purpose rod, bar, and shapes. ‘11 11 Sistem Pemipaan Ir. Teguh Pudji Hertanto, M.Sc, IPM Pusat Pengembangan Bahan Ajar Universitas Mercu Buana ----------------------------------------------------------------------B280-02. Standard specification for seamless copper tube for air conditioning and refrigeration field service. B283-99a. Standard specification for copper and copper-alloy die forgings (hot pressed). B466/B466M-98 Standard specification for seamless copper-nickel pipe and tube. B467-88(2003) Standard specification for welded copper-nickel pipe. B584-00 Standard specification for copper alloy sand castings for general applications. 02.02 Aluminum and Magnesium Alloys B26/B26M-03. Standard specification for aluminum-alloy sand castings. B209-02a. Standard specification for aluminum and aluminum-alloy sheet and plate. B209M-03. Standard specification for aluminum and aluminum-alloy sheet and plate (metric). B210-02. Standard specification for aluminum and aluminum-alloy drawn seamless tubes. B210M-02. Standard specification for aluminum and aluminum-alloy drawn seamless tubes (metric). B211-02. Standard specification for aluminum and aluminum-alloy bar, rod, and wire. B211M-02. Standard specification for aluminum and aluminum-alloy bar, rod, and wire (metric). B221M-02. Standard specification for aluminum and aluminum-alloy extruded bars, rods, wire, profiles, and tubes (metric). B221-02. Standard specification for aluminum and aluminum-alloy extruded bars, rods, wire, profiles, and tubes. B241/B241M-02. Standard specification for aluminum and aluminum-alloy seamless pipe and seamless extruded tube. B247-02a. Standard specification for aluminum and aluminum-alloy die forgings, hand forgings, and rolled ring forgings. B247M-02a. Standard specification for aluminum and aluminum-alloy die forgings, hand forgings, and rolled ring forgings (metric). B345/B345M-02. Standard specification for aluminum and aluminum-alloyseamless pipe and seamless extruded tube for gas and oil transmission and distribution piping systems. B361-02. Standard specification for factory-made wrought aluminum and aluminum-alloy welding fittings. B491/B491M-00. Standard specification for aluminum and aluminum-alloy extruded round tubes for general-purpose applications. 02.03 Electrical Conductors. This material is not referenced in ASMEB31.3. 02.04 Nonferrous Metals—Nickel, Cobalt, Lead, Tin, Zinc, Cadmium,Precious, Reactive, Refractory Metals and Alloys; Materials forThermostats, Electrical Heating and Resistance Contacts, and Connectors B127-98. Standard specification for nickel-copper alloy (UNS N04400) plate, sheet, and strip. B160-99. Standard specification for nickel rod and bar. B161-03. Standard specification for nickel seamless pipe and tube. ‘11 12 Sistem Pemipaan Ir. Teguh Pudji Hertanto, M.Sc, IPM Pusat Pengembangan Bahan Ajar Universitas Mercu Buana ----------------------------------------------------------------------B162-99. Standard specification for nickel plate, sheet, and strip. B164-03. Standard specification for nickel-copper alloy rod, bar, and wire. B165-93. Standard specification for nickel-copper alloy (UNS N04400)* seamless pipe and tube. B166-01. Standard specification nickel-chromium-iron alloys (UNS N06600, N06601, N06603, N06690, N06693, N06025, and N06045) and nickelchromium-cobaltmolybdenum alloy (UNS N06617) rod, bar, and wire. B167-01. Standard specification for nickel-chromium-iron alloys (UNSN06600, N06601, N06603, N06690, N06693, N06025, and N06045) andnickel-chromium-cobaltmolybdenum alloy (UNS N06617) seamless pipe and tube. B168-01. Standard specification for nickel-chromium-iron alloys (UNS N06600, N06601, N06603, N06690, N06693, N06025, and N06045) and nickel-chromium-cobaltmolybdenum alloy (UNS N06617) plate, sheet,and strip. B265-02. Standard specification for titanium and titanium-alloy strip, sheet, and plate. B333-03. Standard specification for nickel-molybdenum alloy plate, sheet, and strip. B335-03. Standard specification for nickel-molybdenum alloy rod. B338-02. Standard specification for seamless and welded titanium and titanium-alloy tubes for condensers and heat exchangers. B363-03. Standard specification for seamless and welded unalloyed titanium and titanium-alloy welding fittings. B381-02. Standard specification for titanium and titanium-alloy forgings. B407-01. Standard specification for nickel-iron-chromium alloy seamless pipe and tube. B409-01. Standard Specification for nickel-iron-chromium alloy plate, sheet, and strip. B435-03. Standard specification for UNS N06002, UNS N06230, UNS N12160, and UNS R30556 plate, sheet, and strip. B443-00e1. Standard specification for nickel-chromium-molybdenumcolumbium alloy (UNS N06625) and nickel-chromium-molybdenumsilicon alloy (UNS N06219) plate, sheet, and strip. B444-03. Standard specification for nickel-chromium-molybdenum-columbium alloys (UNS N06625) and nickel-chromium-molybdenum-silicon alloy (UNS N06219) pipe and tube. B446-03. Standard specification for nickel-chromium-molybdenum-columbium alloy (UNS N06625), nickel-chromium-molybdenum-silicon alloy (UNS N06219), and nickel-chromium-molybdenum-tungsten alloy (UNS N06650) rod and bar. B462-02. Specification for forged or rolled UNS N06030, UNS N06022, UNS N06200, UNS N08020, UNS N08024, UNS N08026, UNS N08367, UNS N10276, UNS N10665, UNS N10675, and UNS R20033 alloy pipe flanges, forged fittings and valves and parts for corrosive hightemperature service. B463-99. Standard specification for UNS N08020, UNS N08026, and UNS N08024 alloy plate, sheet, and strip. B464-99. Standard specification for welded UNS N08020, UNS N08024, and UNS N08026 alloy pipe. B493-01(2003). Standard specification for zirconium and zirconium alloy forgings. B514-95(2002)e1. Standard specification for welded nickel-iron-chromium alloy pipe. ‘11 13 Sistem Pemipaan Ir. Teguh Pudji Hertanto, M.Sc, IPM Pusat Pengembangan Bahan Ajar Universitas Mercu Buana ----------------------------------------------------------------------B517-03. Standard specification for welded nickel-chromium-ironalloy (UNS N06600, UNS N06603, UNS N06025, and UNS N06045) pipe. B523/B523M-02. Standard specification for seamless and welded zirconium and zirconium alloy tubes. B550/B550M-02. Standard specification for zirconium and zirconium alloy bar and wire. B551/B551M-02. Standard specification for zirconium and zirconium alloy strip, sheet, and plate. B564-00a. Standard specification for nickel alloy forgings. B574-99a. Specification for low-carbon nickel-molybdenum-chromium, low-carbon nickelchromium-molybdenum, low-carbon nickel-molybdenum-chromium-tantalum, low-carbon nickel-chromium-molybdenumcopper,low-carbon nickel-chromiummolybdenum-tungsten alloy rod. B575-99a. Specification for low-carbon nickel-molydbdenum-chromium, low-carbon nickel-chromium-molybdenum, low-carbon nickel-chromium- molybdenumcopper, low-carbon nickel-chromium-molybdenumtantalum, low-carbon nickelchromium-molybdenum-tungsten alloy plate, sheet and strip. B619-00. Standard specification for welded nickel and nickel-cobalt alloy pipe. B620-03. Standard specification for nickel-iron-chromium-molybdenum alloy (UNS N08320) plate, sheet, and strip. B621-02. Standard specification for nickel-iron-chromium-molybdenum alloy (UNS N08320) rod. B622-00. Standard specification for seamless nickel and nickel-cobalt alloy pipe and tube. B625-99. Standard specification for UNS N08904, UNS N08925, UNS N08031, UNS N08932, UNS N08926, and UNS R20033 plate, sheet, and strip. B658/B658M-02. Standard specification for seamless and welded zirconium and zirconium-alloy pipe. B675-02. Standard specification for UNS N08367 welded pipe. B688-96. Standard specification for chromium-nickel-molybdenum-iron (UNS N08366 and UNS N08367) plate, sheet, and strip. B690-02. Standard specification for iron-nickel-chromium-molybdenum alloys (UNS N08366 and UNS N08367) seamless pipe and tube. B705-00. Standard specification for nickel-alloy (UNS N06625, UNS N06219 and UNS N08825) welded pipe. B725-93. Standard specification for welded nickel (UNS N02200/UNS N02201) and nickel-copper alloy (UNS N04400) pipe. B729-00. Standard specification for seamless UNS N08020, UNS N08026, and UNS N08024 nickel-alloy pipe and tube. 03. PIPING MATERIAL SPECIFICATION (SECTION 03) - ASTM Section 03. Metals, Test Methods, and Analytical Procedures 03.01 Metals Mechanical Testing, Elevated and Low-Temperature Tests, Metallography. E112-96e2. Standard test methods for determining average grain size. ‘11 14 Sistem Pemipaan Ir. Teguh Pudji Hertanto, M.Sc, IPM Pusat Pengembangan Bahan Ajar Universitas Mercu Buana ----------------------------------------------------------------------03.02 Wear and Erosion, Metal Corrosion. This situation is not referenced in ASME B31.3. 03.03 Nondestructive Testing. E114-95. (2001) Standard practice for ultrasonic pulse-echo straight-beam examination by the contact method. E125-63(2003). Standard reference photographs for magnetic particle indications on ferrous castings. E155-00. Standard reference radiographs for inspection of aluminum and magnesium castings. E165-02. Standard test method for liquid penetrant examination. E186-98. Standard reference radiographs for heavy-walled (2–41⁄2–12 in.; 51–114 mm) steel castings. E213-02. Standard practice for ultrasonic examination of metal pipe and tubing. E272-99. Standard reference radiographs for high-strength copper-base and nickelcopper alloy castings. E280-98. Standard reference radiographs for heavy-walled (41⁄2 –12 in.; 114–305 mm) steel castings. E310-99. Standard reference radiographs for tin bronze castings. E446-98. Standard reference radiographs for steel castings up to 2 in. (51 mm) thickness. E709-01. Standard guide for magnetic particle examination. 03.04 Magnetic Properties. Such properties are not referenced in ASME 04. PLASTIC LINED (KETAHANAN KOROSI) Dalam perkembangan selanjutnya, untuk mendapatkan kemampuan kombinasi antara kekuatan yang tinggi dengan ketahanan yang tinggi pula tetapi berharga lebih murah, maka muncullah kombinasi antara baja karbon dengan lining plastik misalnya. Berikut sedikit di paparkan permasalahan dari plastic lining pada sistem pemipaan. Plastik lining material dibagi dalam 2 (dua) kategori, yaitu : (1) Fluorinated Plastic dan (2) non-fluorinated plastics. Fluorinated plastic adalah fully fluorinated, seperti polytetrafluoroethylene (PTFE), perfluoroalkoxy, dan perfluoroethylenepropylene dalam kasus ethyleneetetrafluoroethylene (ETFE) dan polyvinylidenefluoride. Non-fluorinated plastic seperti polypropylene (PP) dan polyvinylidene chloride (PVDC) yang banyak dipakai dengan ketahanan kimiawi yang tinggi. JENIS-JENIS LINER ‘11 PTFE (POLYTETRAFLUOROETHYLENE). Ini jenis lapisan dikembangkan oleh DuPont tahun 1938, dan mulai dikembangkan untuk pelapis pada sistem pemipaan tahun 1950an. DuPont dikenal pada market sebagai Teflon untuk 15 Sistem Pemipaan Ir. Teguh Pudji Hertanto, M.Sc, IPM Pusat Pengembangan Bahan Ajar Universitas Mercu Buana ---------------------------------------------------------------------- produk ini, tapi manufacture lain menggunakan nama seperti Fluon, Hustaflon, Algoflon dal Polyflon. FEP (FLUORINATED ETHYLENE PROPYLENE). FEP di kenalkjan ke pasaran tahun 1960an dalam bentuk cairan resin yang memiliki ketahanan kimiawi. Produk ini juga dikembangkan oleh DuPont dan dikenal dengan Teflon FEP. Kemampuan pemakaiannya dibawah temperatur PTFE, cakupan pemakaiannya berkisar antara -20oF (-29 oC) ~ 300oF (149 oC). PVDF (POLYVINYLIDINE FLUORIDE). Diperkenalkan di pasaran oleh Elf Atochem North America dan Ausimont dibawah bendera KYNAR. Pelapis jenis ini memiliki ketahanan kimiawi yang sangat baik dengan cakupan kerja temperatur -20oF (-29 oC) ~ 275oF (135 oC). PP (POLYPROPYLENE). Secara umum dikenal juga memiliki ketahanan kimiawai yang bagus dengan cakupan temperatur kerja 0 oF (-18C) ~ 225oF (107 oC). PP banyak dan umum dipakain sebagai media hantar inorganic acid seperti hydrochloric dan sulfuric sebaik caustic seperti halnya sodium hydroxide. PVDC (POLYVINYLIDENE CHLORIDE). PVDC ini memiliki ketahanan terendah dalam temperetur kerja berkisar 0oF (-18 oC) ~ 175oF (79 oC), di pasaran dikenal dengan nama SARAN. PE (POLYETHYLENE). PE memiliki ketahanan kimiawi yang cukup baik dan temperatur kerjanya dibawah 180oF (82 oC). Dibawah di sajikan list dari pelapis terhadap service yang ditanganinya. Table 6 Bahan pelapis pada temperatur maksimumnya (oF) Chemical Acetic acid (glacial) Acetone (10%) Ammonia (dry gas) Ammonia aqua (30%) Amyl acetate Benzene Bromine liquid Chlorine liquid Chlorine gas Chlorine dioxide (15%) Chlorosulfonic acid Cyclohexane Diethylamine Ethyl acrylate Formaldehyde (37%) Formic acid Hydrochloric acid (10%) Hydrochloric acid (20%) Hydrochloric acid (36%) ‘11 16 Sistem Pemipaan Ir. Teguh Pudji Hertanto, M.Sc, IPM ETFE 230 150 300 230 250 212 150 212 212 250 75 300 230 212 230 275 300 300 300 PVDF NR 75 NR 175 125 170 150 200 175 150 NR 275 70 70 120 250 275 275 275 PP 70 120 140 150 NR NR NR NR NR NR NR NR 120 NR 140 140 185 175 150 Pusat Pengembangan Bahan Ajar Universitas Mercu Buana PVDC 125 75 — — 125 75 NR NR 75 125 NR 125 NR — 125 150 175 175 — ----------------------------------------------------------------------Hydrofluoric acid (35%) Hydrofluoric acid (100%) Hydrogen peroxide (30%) Hydrogen peroxide (90%) Methyl ethyl ketone Methylene chloride Nitric acid (10%) Nitric acid (50%) Nitric acid (90%) Phenol Phosgene (gas or liquid) Phosphoric acid Propyl alcohol Sodium hydroxide (10%) Sodium hydroxide (50%) Sodium hypochlorite Sulfuric acid (30%) Sulfuric acid (50%) Sulfuric acid (93%) Sulfuric acid (98%) Sulfuric acid—fuming Toluene Trisodium phosphate 275 230 250 150 230 212 212 150 NR 212 212 275 212 230 230 300 300 300 300 200 120 250 275 250 212 212 75 NR 70 225 120 NR 120 120 250 120 NR NR 125 230 230 200 120 NR 170 275 200 70 70 70 70 70 150 70 NR 140 NR 225 140 225 225 150 200 125 NR NR NR NR 150 Table 7 Standar Spesifikasi dari Polymer ‘11 17 Sistem Pemipaan Ir. Teguh Pudji Hertanto, M.Sc, IPM Pusat Pengembangan Bahan Ajar Universitas Mercu Buana 175 NR 125 125 NR NR 150 125 NR 75 — 125 150 150 75 125 75 NR NR NR NR 75 150 ----------------------------------------------------------------------Table 8 Biaya rasio pemasangan (ref baja karbon = 1.0) PVC (sch 80) CPVC (sch 80) PIPING MATERIAL COST RATIO Carbon steel (Sch. 40) 304L S.S. (Sch. 10) Rubber-lined steel (Sch 40) 316L S.S. (Sch. 10) 304L S.S. (Sch. 40) 316L S.S. (Sch. 40) Hastelloy C-276 (Sch 40) FRP/vinyl ester FRP/epoxy FRP/polyester Polypropylene lined steel (Sch 40) Saran lined steel (Sch 40) PVDF-lined steel (Sch 40) Alloy 20 (Sch. 10) Monel (Sch 10) Glass-lined steel (Sch 40) PVDF (Sch 80) PTFE-lined steel (Sch 40) Titanium (Sch 10) FEP-lined steel (Sch 40) 2.99 0.56 0.63 1.00 1.13 1.16 1.20 1.31 1.45 4.46 1.78 1.86 1.86 1.90 1.91 2.47 2.60 2.61 2.69 2.71 2.94 2.99 PTFE-lined FRP Monel (Sch 40) Alloy 20 (Sch 40) Nickel (Sch 10) Hastelloy C-276 (Sch 10) 3.20 3.24 3.32 3.34 3.52 PTFE-lined 304L SS (Sch 10) Nickel (Sch 40) Titanium (Sch 10) 4.12 4.27 4.46 Hastelloy B (Sch 40) Zirconium (Sch 10) 5.71 5.95 Zirconium (Sch 40) 7.04 Figure 1. CRE, ELBOW DAN TEE yang di liner ‘11 18 Sistem Pemipaan Ir. Teguh Pudji Hertanto, M.Sc, IPM Pusat Pengembangan Bahan Ajar Universitas Mercu Buana ----------------------------------------------------------------------- Figure 2. Working pressure ASME class 150, 300 yang di lapis plastik 05. CEMENT LINED (KETAHANAN KOROSI) Sudah lebuh dari 100 tahun, semen mortar ini digunakan sebagai bahan anti koorosi pada logam besi untuk service air, juga pada kondisi di pendam dalam tanah. Refference AWWA standard untuk cement mortar lining di berikan pada tabel dibawajh ini. Table 9 AWWA Standard untuk cement mortar lined NUMBER Standard for Cement-Mortar Lining for Ductile Iron Pipe and Fittings for Water ANSI/AWWA C2052 Standard for Cement-Mortar Protective Lining and Coating for Steel Water PipeNPS 4 (DN 100) and Larger-Shop Applied ANSI/AWWA C3003 ANSI/AWWA C3014 ‘11 19 TITLE American National Standards Institute (ANSI)/American Water Works Association (AWWA) C104/A21.41 Sistem Pemipaan Ir. Teguh Pudji Hertanto, M.Sc, IPM Standard for Reinforced Concrete Pressure Pipe,Steel-Cylinder Type Pusat Pengembangan Bahan Ajar Universitas Mercu Buana REMARKS For factory-applied mortar linings in ductile iron pipe For factory-applied mortar linings in steel pipe For concrete and mortar linings in concrete pressure pipe For concrete and mortar linings in concrete pressure pipe ----------------------------------------------------------------------ANSI/AWWA C3025 ANSI/AWWA C3036 ANSI/AWWA C6027 Standard for Prestressed Concrete Pressure Pipe, Steel-Cylinder Type Standard for Reinforced Concrete Pressure Pipe,Non-Cylinder Type For concrete and mortar linings in concrete pressure pipe For mortar linings in concrete pressure pipe For Standard for Concrete Pressure Pipe, field-applied mortar Bar Wrapped, Steel-CylinderType linings in steel pipe, cast iron pipe, and ductile iron Standard for Cement-Mortar Lining of pipe Water Pipe lines in Place-NPS 4 (DN 100) and Larger Fluida yang bisa menggunakan cement mortar lining ini adalah : Raw fresh water Potable water Raw sewage Treated sewage Seawater Power plant cooling water (both seawater and fresh water) JOINT PROTECTION. Pada gambar dibawah , ada sedikit celah/gap antara lining dan joinan pipanya dari hasil penggabungan menggunakan concrete nyang pake spigot joint dilapangan. Figure 3 Joining dengan mortar lining di inside 06. CRYOGENIC MATERIALS Pertimbangan yang cukup penting dalam pemilihan material untuk sistem pemipaan kriogenik meliputi kecocokan propertis baik mekanis maupun fisik, sehingga kompatibel dengan serficenya, mudah difabrikasi, murah dan cocok dengan regulasi standardnya. Stainless steel (Ferritic maupun austenitic), adalah material Ferrous yang bisa dipergunakan pada service cryogenik ini, lihat pada tabel di bawah ya…. ‘11 20 Sistem Pemipaan Ir. Teguh Pudji Hertanto, M.Sc, IPM Pusat Pengembangan Bahan Ajar Universitas Mercu Buana ----------------------------------------------------------------------Table 10 Jenis Paduan Besi nyang dipake pada Cryogenic Piping PADUAN MIN. TEMP * C-Mn steel1 21⁄₄% Ni steel1 31⁄₂% Ni steel1 9% Ni steel1 304 Stainless steel2 304L Stainless steel2 316 Stainless steel2 316L Stainless steel2 347 Stainless steel2 -46oC (-50oF) -73oC (-100oF) -101oC (-150oF) -196oC (-320oF) -254oC (-425oF) -254oC (-425oF) -196oC (-320oF) -196oC (-320oF) -254oC (-425oF) ASME Spec. KOMEN SA-3333 Grade 1 SA-3333 Grade 7 SA-3333 Grade 3 SA-3333 Grade 8 SA-3123 SA-3123 SA-3123 SA-3123 SA-3123 Aluminum killed, fine grain practice Aluminum killed, fine grain practice Aluminum killed, fine grain practice Aluminum killed, fine grain practice Catatan : * Design minimum temperature for which material is normally suited without impact testing other than that required by material specification. 1 Ferritic steels. 2 Austenitic steel. 3 Corresponding ASTM specifications are A333 and A312. Table 11 Jenis Paduan Besi nyang dipake pada Cryogenic Piping (Mekanik & Physical propertis nya) Alloy C-Mn steel1 21⁄₄% Ni steel2 31⁄₂% Ni steel2 9% Ni steel2 304 stainless steel 304L stainless steel 316 stainless steel 316L stainless steel 347 stainless steel ASME3 spec. Temper ature4 (oF) SA 333 Grade 1 SA 333 Grade 7 SA 333 Grade 3 SA 333 Grade 8 SA 312 TP 304 SA 312 TP 304L SA 312 TP 316 SA 312 TP 316L SA 312 TP 347 RT -50 RT -100 RT -150 RT -320 RT -425 RT -425 RT -325 RT -325 RT -425 Ultimate tensile strength (ksi) 0.2% Offset Yield strength (ksi) Elongation in 2 in. (%) 55 30 21(1) 65 75 100 120 115 170 85 250 80 225 87 197 85 35 40 75 87 90 135 38 70 37 65 38 65 38 18(1) 90 230 65 70 Charpy impact strength (ft-lb.) Thermal expansion (in/in oF x 10-6) Thermal conductivity (BTU(hr · ft.oF) 25 27 45 3 45 31 45 56 45 70 50 58 20 96 22 47 25 115 75 60 60 — — — 50 38 60 45 6.5 3.0 — — 5.8 4.8 5.8 4.8 9.0 1.2 EQ. 304 EQ. 304 9.0 7.8 EQ. 316 EQ. 316 8.7 7.2 30 — — — 21 — 15.7 7.6 9 0 EQ. 304 EQ. 304 9 0 EQ. 316 EQ. 316 8.5 0 18(1) * Minimum value as stated in ASME Specification SA-333. 1 Normalized, aluminum killed, fine grain practice. 2 Quenched and tempered. 3 Corresponding ASTM specifications are A333 and A312. 4 RT is room temperature. ‘11 21 Sistem Pemipaan Ir. Teguh Pudji Hertanto, M.Sc, IPM Pusat Pengembangan Bahan Ajar Universitas Mercu Buana ----------------------------------------------------------------------Material non besi yang bisa digunakan untuk service nyang dingin banget ini adalah Alumunium, Cooper ataupun kelompok nickel. Nah, tabel dibawah adalah material besi nyang diperguanakan untuk service kriogenik… Table 12 Jenis Paduan NON-Besi nyang dipake pada Cryogenic Piping Alloy Tempers 1100 Aluminum 3003 Aluminum 5052 Aluminum 5083 Aluminum 5086 Aluminum 6061 Aluminum Copper (C10200, C12200) Copper-nickel (70600) Copper-nickel (C71500) Monel 400, Al-Cu alloy Minimum temperature O, H11 O, H112 O, H32 O, H112 O, H112 T6 Annealed Annealed Annealed Annealed _254_C (_452_F) _254_C (_452_F) _254_C (_452_F) _254_C (_452_F) _254_C (_452_F) _254_C (_452_F) _198_C (_325_F) _198_C (_325_F) _198_C (_325_F) _198_C (_325_F) ASME1 spec. SB 210 SB 210 SB 210 SB 210 SB 210 SB 210 SB 75 SB 467 SB 467 SB 165 * Design minimum temperature for which material is normally suitable without impact testing other than that required by material specification. 1 Corresponding ASTM specifications are B75, B165, B210 and B467. Table 13 Jenis Paduan non-Besi nyang dipake pada Cryogenic Piping (Mekanik & Physical propertis nya) Alloy 1100 Aluminum 0, H112 3003 Aluminum 0, H112 5052 Aluminum O, H32 5083 Aluminum 0, H1112 5086 Aluminum 0, H112 6061 Aluminum T6 Copper (C10200, C1200) 90/10 Cu-Ni CDA 706 70/30 Cu-Ni CDA 715 Monel 400 ‘11 22 ASME1 spec. SB-210 SB-210 SB-210 SB-210 SB-210 SB-210 SB-75 SB-467 SB-467 SB-165 Temper ature (oF) RT -452 RT -452 RT -452 RT -452 RT -452 RT -452 RT -452 RT -325 RT -325 RT Sistem Pemipaan Ir. Teguh Pudji Hertanto, M.Sc, IPM Ultimate tensile strength (ksi) 0.2% Offset Yield strength (ksi) Elongation in 2 in. (%) 13S 24H 24S 16S 29H 32S 43S 46H 76S 86H 42S 44H 63S 38S 42H 78S 96H 45 70 33 52 44 5S 152H 8S 6S 186H 9S 37S 290H 47S 379H 21S 193H 23S 17S 117H 20S 179H 40 58 10 14 16 44 85 80 20 31 25 Charpy impact strength (ft-lb.) Thermal expansion (in/in oF x 10-6) Thermal conductivity (BTU(hr · ft.oF) 40S 10H 56S 35S 7H 48S 12S 8H 42S 30H 22S 16H 32S 22S 12H 38S 30H 12 25 45 69 42 16S 70H 16S 70H 13 5 12 5 13.2 125 160 92 85 75 7 68 4 73 10 12 56 75 10 2 9.5 5.0 9.5 150 75 26 40 60 42 79 87 56 9 17 7.5 15 Pusat Pengembangan Bahan Ajar Universitas Mercu Buana 13 5 13.2 99 -----------------------------------------------------------------------325 115 50 64 50 2.5 5 * The letters S and H designate soft and hardened conditions respectively. 1 Corresponding ASTM specifications are B75, B165, B210 and B467. 07. SISTEM PEMIPAAN FIBER GLASS Fiberglass Reinfoced Plastic (FRP) telah banyak dan sukses di pakai lebih dari lima puluh tahunan sebagai material pemipaan, karena menjadi kombinasi antara plastik material yang resistant corrosion dengan kekuatan (karena ada reinforced-nya…). Penggunaan FRP ini pada temperatur -40o s/d 300 o F (-40o s/d 149 o C) Resin pada FRP di memiliki ketahanan korosi untuk acid, caustic ataupun solvent. Nah, kalau medianya abrasif misalnye aja slurry… maka bisa ditambahkan abrasion resistat material pada inside pipenye. Nah berikut aplikasi FRP di dindustri secara umum… INDUSTRY Chemical process Aeration lines Brine slurry lines Chemical feed lines Column piping Condensate return Conduit Cooling water lines Disposal well systems Downhole tubing and casing Effluent drain lines Fire mains Guttering and downspouts Oily water Scrubber headers Seawater lines Slurry lines Vent lines Water lines Waste treatment Buried gasoline piping1 1. At gasoline service stations. Food proces sing Marine & Offshor e Mining Petroc hem & Petrole um Pharm aceutic al Power Plants Pulps & paper WW TP X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X Table 14 Metode Test nya FRP for P (Pipes) and F (Fittings) PROPERTY TESTED ‘11 23 Sistem Pemipaan Ir. Teguh Pudji Hertanto, M.Sc, IPM ASTM Standard DIN Standard Pusat Pengembangan Bahan Ajar Universitas Mercu Buana ISO Standard ----------------------------------------------------------------------Beam bending stress & modulus Beam deflection, full bore flow Chemical resistance Laminates Molding compounds Pipe, deflected Circumferential flexural modulus Short-term Long-term creep Circumferential tensile strength Compressive stress & modulus Constituents; % resin, glass, aggregate, filler Dimensions Density Dielectric strength Electrical resistance, DC Indentation hardness, barchol impressor Impact resistance Joints, pressure & bending as applicable Cemented socket & spigot Bolted flanges Socket & spigot with elastomeric seals Pipe stiffness Short-term Long-term creep Pressure, external Pressure, internal Cyclic Hydrostatic design basis Short-time hydraulic failure Time to failure, constant pressure Regression analysis Ring-bending strain Shear strength Specific gravity Stiffness factor Short-term Long-term creep Tensile elongation ultimate Tensile stress & modulus Hoop Laminate Longitudinal Thermal conductivity Thermal expansion, linear coefficient Between _30_ and 30_C Other temperatures ‘11 24 Sistem Pemipaan Ir. Teguh Pudji Hertanto, M.Sc, IPM # P F D 790 modified D 2925 Yes No Yes No C 581 D 3615 D 3681 Yes No Yes Yes Yes No 53 393 Yes Yes D 2412 Yes No D 2290 D 695 D 2584 D 3567 D 792 D 149 D 257 D 2583 D 2444 Yes Yes Yes Yes Yes Yes Yes Yes Yes No No No Yes Yes Yes Yes Yes Yes 53 769-3 EN 761 EN 1393 Yes Yes Yes EN 637 53 479 D 2412 Yes No D 2924 Yes No D 2143 D 2992 D 1599 D 1598 Yes Yes Yes Yes No Yes Yes No D 2992 D 5365 Yes Yes Yes No D 792 Yes Yes D 2412 Yes No D 2105 Yes No D 1599 D 638 D 2105 C 177 Yes Yes Yes Yes Yes Yes No Yes D 696 E 228 Yes Yes No No # P F # P F ISO 178 Yes No No No No 10466 7684 Yes Yes No No Yes Yes 7510 Yes Yes Yes Yes EN 1449 EN 1450 EN 1448 Yes Yes Yes Yes Yes Yes 53 769EN 761 Yes Yes No No 10466 7684 Yes Yes No No 10928 Yes Yes 10466 7684 Yes Yes No No 527-4 Yes Yes EN 59 53 769-3 53 758 EN 1447 53 768 EN 705 Yes Yes Yes No Yes Yes 53 769-1 No Yes 53 769-3 EN 761 EN 1393 Yes Yes Yes No No No Pusat Pengembangan Bahan Ajar Universitas Mercu Buana ----------------------------------------------------------------------Table 15 Standard Produk FRP pipe & Fitting Product Description Fittings Contact molded Dimensions, nominal Flanges, contact molded Flanges other than contact molded Gravity flow Line pipe, low pressure Pressure Jet fuel lines, belowground Joints Bell & spigot gasket joints Marine pipe & fittings Laminates, contact molded Pipe Casing and tubing Centrifugally cast Contact molded Dimensions, nominal Filament wound Line pipe, high pressure Line pipe, low pressure Machine made classification Sewer Water Industrial wastes & corrosive fluids Process plant piping Water supply or sewerage piping Water systems Standard Pipe Fittings Size nps (DN) Pressure psig (bar) ASTM D 6041 ISO 7370 ASTM D 5421 ASTM D 4024 ASTM D 3840 API 15LR ASTM D 5685 ASTM D 5677 No Yes No No No Yes No Yes Yes Yes Yes Yes Yes Yes Yes Yes All 1–144 (25–3600) 1–96 (25–2400) All 8–144 (200–3600) 1–16 (25–400) 1–16 (25–400) All 0–150 (0–10) NA 25–150 (2–10) 50–500 (3–34) Gravity up to 1000 (68) 25–1000 (2–68) up to 150 (10) ASTM D 4161 ASTM F 1173 ASTM C 582 Yes Yes Yes Yes Yes Yes 8–144 (200–3600) 1–48 (25–1200) All up to 250 (17) All All API 15AR ASTM D 2997 ASTM C 582 ISO 7370 ASTM D 2996 API 15HR API 15LR ASTM D 2310 ASTM D 3262 ASTM D 3517 ASTM D 3754 BS 6464 BS 5480 AWWA C-950 M45 design manual Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes Yes No No Yes Yes No No Yes No No No No Yes Yes Yes 1–10 (25–250) All All 1–144 (10–3600) 1–16 (25–400) 1–8 (25–200) 1–16 (25–400) NA 8–144 (200–3600) 8–144 (200–3600) 8–144 (200–3600) 1–36 (25–1000) 1–144 (25–3600) All All NA All 500–1000 (34–68) up to 1000 (68) NA Gravity up to 250 (17) up to 250 (17) up to 940 (64) 50–250 (3–17) RESIN yang banyak digunakan adalah : Epoxy Resins limit temp 250oF (121oC) Polyester Resins Vinyl Ester Resins. limit temp 225oF (107oC); special aplication limit temp 350oF (177oC) Bisphenol-A Fumarate Polyester Resins. limit temp 250oF (121oC) Chlorendic Polyester Resins. limit temp 350oF (177oC) Isophthalic Polyester Resins. . limit temp 180oF (82oC) Phenolic Resins limit temp 300oF (149oC) SISTEM JOIN Dalam sistem join di FRP ini dikenal dengan berbagai cara, yaitu : ‘11 25 Sistem Pemipaan Ir. Teguh Pudji Hertanto, M.Sc, IPM Pusat Pengembangan Bahan Ajar Universitas Mercu Buana ----------------------------------------------------------------------- 08. TEKANAN DAN UJI KEBOCORAN Table 16 Uji dan pengujian tekanan CODE JENIS UJI TEKANAN UJI MINIMUM ASME B31.1 Hydrostatic1 1.5 times design ASME B31.1 Pneumatic 1.2 times design ASME B31.1 Initial service Normal operating pressure ASME B31.3 Hydrostatic ‘11 26 1.5 times design2 Sistem Pemipaan Ir. Teguh Pudji Hertanto, M.Sc, IPM TEKANAN UJI MAKSIMUM Max allowable test pressure any component or 90 percent of yield 1.5 times design or max allowable test pressure any component Normal operating pressure TEKANAN UJI (HOLD TIME) TEKANAN PENGUJIAN 10 minutes Design Pressure 10 minutes Lower of 100 psig or design pressure 10 minutes or time to complete leak examination Normal operating pressure Pusat Pengembangan Bahan Ajar Universitas Mercu Buana 1.5 times design ----------------------------------------------------------------------ASME B31.3 Pneumatic ASME B31.3 Initial service3 ASME I Hydrostatic ASME III Division 1 Subsection NB Hydrostatic Pneumatic ASME III Division 1 Subsection NB ASME III Division 1 Subsec tion NC 1.1 times design Design pressure 1.5 times max allowallowable Workworking pressure4 1.25 times system design pressure5 1.2 times system design pressure6 Hydrostatic 1.5 times system design pressure Pneumatic ASME III Division 1 Subsection NC ASME III Division 1 Subsection ND ASME III Division 1 Subsection ND ‘11 27 1.25 times system design pressure Hydrostatic Pneumatic 1.5 times system design pressure for completed components, 1.25 times system maxidesign pressure for piping systems 1.25 times system design pressure Sistem Pemipaan Ir. Teguh Pudji Hertanto, M.Sc, IPM Not to exceed yield stress 1.1 times design plus the lesser of 50 psi or 10 percent of test Pressure Design pressure Time to complete leak exAmination but at least 10 minutes 10 minutes Time to complete leak examination Not specified, typically 1 hr Not to exceed 90 percent yield stress 10 minutes Not to exceed stress limits of design section NB-3226 or maximum test pressure of any system component5 Not to exceed stress limits of design section NB-3226 or maximum test pressure of any system component If minimum test pressure exceeded by 6 percent establish limit by the lower of analysis of all test loadings or maximum test pressure of any component If minimum test pressure exceeded by 6 percent establish limit by the lower of analysis of all test loadings or maximum test pressure of any component If minimum test pressure exceeded by 6 percent establish limit by the lower of analysis of all test loadings or maxidesign mum test pressure of any component 10 minutes 10 minutes or 15 minutes per inch of design minimum wall thickness for pumps and valves 10 minutes 10 minutes Design pressure Design pressure Max allowable working pressure4 Greater of design pressure or .75 times test pressure Greater of design pressure or .75times test pressure Greater of design pressure or .75 times test pressure Greater of design pressure or .75 times test pressure Greater of design pressure or .75 times test pressure 10 minutes Pusat Pengembangan Bahan Ajar Universitas Mercu Buana Greater of design pressure or .75 times test pressure ----------------------------------------------------------------------If minimum test pressure exceeded by 6 percent establish limit by the lower of analysis of all test loadings or maximum test pressure of any component 09. HAZARDOUS PIPING SYSTEM ASME CODE B31.3 “PROCESS PIPING” mendefinisikan hazardous fluid service sbb : ‘‘a fluid service in which the potential for personnel exposure is judged to be significant and in which a single exposure to a very small quantity of a toxic fluid, caused by leakage, can produce serious irreversible harm to persons on breathing or bodily contact, even when prompt restorative measures are taken [emphases added].’’ Code dan standard yang dipergunakan untuk membantu dalam identifikasi proses terutama uang berkaitan dengan hal ini khususnya bagi owner maupun designer adalah : ‘11 28 API 570, ‘‘Piping Inspection Code: Inspection, Repair, Alteration, and Rerating of In-service Piping Systems’’ API RP 574, ‘‘Inspection of Piping, Tubing, Valves, and Fittings’’ API RP 750, ‘‘Management of Process Hazards’’ ASME B31 ‘‘Code for Pressure Piping.’’ The ASME B31 Code for Pressure Piping consists of several sections: B31.1 Power Piping, B31.3 Process Piping,etc. (see Chap. A4). All the sections, published as separate books, may have useful information relevant to the design and construction of hazardous piping systems for their particular application. B31.3, however, is the only section that includes a chapter on hazardous piping systems. ASME B31G, ‘‘Remaining Strength of Corroded Pipe’’ ASME Boiler and Pressure Vessel Code, Section VIII, Divisions 1 and 2, ‘‘Rules for Construction of Pressure Vessels’’ NBBPVI, ‘‘National Board Inspection Code’’ NIOSH, ‘‘Registry of Toxic Effects of Chemical Substances’’ NFPA 30, ‘‘Flammable and Combustible Liquids Code’’ NFPA 49, ‘‘Hazardous Chemical Data’’ NFPA 325M, ‘‘Fire Hazard Properties of Flammable Liquids, Gases, and Volatile Solids’’ NFPA 491M, ‘‘Manual of Hazardous Chemical Reactions’’ Sistem Pemipaan Ir. Teguh Pudji Hertanto, M.Sc, IPM Pusat Pengembangan Bahan Ajar Universitas Mercu Buana ----------------------------------------------------------------------Table 17 Material yang sangat beracun dan reaktif Acetaldehyde Acrolein (2-Propenal) Acrytyl chloride Allyl chloride Allytamine Alkylaluminums Ammonia, Anhydrous Ammonia solutions Ammonium perchlorate Ammonium permanganate Arsenic hydride (also called Arsine) Arsine (also called Arsenic hydride) Bis(chloromethyl) ether Boron trichloride Boron trifluoride Bromine Bromine chloride Bromine pentafluoride Bromine trifluoride 3-Bromopropyne (also called Propargylbromide) Butyl hydroperoxide (tertiary) Butyl perbenzoate (tertiary) Carbonyl chloride (also called Phosgene) Carbonyl nitrate Chlorine Chlorine dioxide Chlorine pentrafluoride Chlorine trifluoride Chlorodiethylaluminum (also called Dieth- Bromoylaluminum chloride) 1-chloro-2, 4-dinitrobenzene Chloromethyl methyl ether Chloropicrin Chloropicrin and Methyl bromide mixture Chloropicrin and Methyl chloride mixture Cumene hydroperoxide Cyanogen Cyanogen chloride Cyanuric fluoride Diacetyl peroxide Diazomethane Dibenzoyl peroxide Diborane Dibutyl peroxide (tertiary) ‘11 29 Sistem Pemipaan Ir. Teguh Pudji Hertanto, M.Sc, IPM Dimethylhydrazine, 1,1Dimethylamine, anhydrous 2, 4-Dinitroaniline Ethyl methyl ketone peroxide (also called Methyl ethyl ketone peroxide) Ethyl nitrite Ethylamine Ethylene fluorohydrin Ethylene oxide Ethyleneimine Fluorine Formaldehyde (Formalin) Fuming sulfuric acid (also called Oleum) Furan Hexafluoroacetone Hydrochloric acid, anhydrous Hydrofluoric acid, anhydrous Hydrogen bromide Hydrogen chloride Hydrogen cyanide, anhydrous Hydrogen fluoride Hydrogen peroxide Hydrogen selenide Hydrogen sulfide Hydroxylamine Iron, pentacarbonyl Isopropylamine Ketene Methacrylaldehyde Methacryloyl chloride Methacryloyloxyethel isocyanate Methyl acrylonitrile Methylamine, anhydrous Methyl bromide Methyl chloride Methyl chloroformate Methyl ethyl ketone peroxide (also called Ethyl methyl ketone peroxide) Methyl fluoroacetate Methyl fluorosulfate Methyl hydrazine Methyl iodide Methyl isocyanate Methyl mercaptan Pusat Pengembangan Bahan Ajar Universitas Mercu Buana Nitromethane Nitrogen dioxide Nitrogen oxides (NO; NO2; N2O4; N2O3) Nitrogen peroxide (also called Nitrogen tetroxide) Nitrogen tetroxide (also called Nitrogen peroxide) Nitrogen trifluoride Nitrogen trioxide Oleum (also called Fuming sulfuric acid) Osmium tetroxide Oxygen difluoride (Fluorine monoxide) Ozone Pentaborane Peracetic acid (also called Peroxyacetic acid) Perchloric acid Perchloromethyl mercaptan Perchloryl fluoride Peroxyacetic acid (also called Peracetic acid) Phophoryl chloride (also called Phosphorusoxychloride) Phosgene (also called Carbonyl chloride) Phosphine (Hydrogen phosphide) Phosphorus oxychloride (also called Phosphoryl chloride) Phosphorus trichloride Propargyl bromide (also called 3Bromoylaluminumpropyne) Propyl nitrate Sarin Selenium hexafluoride Stibine (Antimony hydride) Sulfur dioxide (liquid) Sulfur pentafluoride Sulfur tetrafluoride Sulfur trioxide (also called Sulfuric anhydride) Sulfuric anhydride (also called Sulfur trioxide) Tellurium hexafluoride Tetrafluoroethylene Tetrafluorohydrazine ----------------------------------------------------------------------Dicloro acetylene Diclorosilane Diethylaluminum chloride (also called Chlorodiethylaluminum) Diethylzinc Diisopropyl peroxydicarbonate Dilaluroyl peroxide Dimethyldiclorosilane Methyl vinyl ketone Methyltrichlorosilane Tetramethyl lead Thionyl chloride Trichloro (Chloromethyl) silane Trichloro (Dichlorophenyl) silane Trichlorosilane Trifluorochloroethylene Nickel carbonyl (Nickel tetracarbonyl) Nitric acid Nitric oxide Nitroaniline Trimethyloxysilane EXAMINATION, INSPECTION DAN TESTING. Umumnya pada piping kode dibedakan antara examination dan testing; dimana examination adalah tanggung jawab manufacturer, fabricator atau erector sedangkan inspection adalah tanggung jawabnya owner. Table 18 Rekomendasi design dan opration untuk Hazardous Piping “DO” “DON’T” Identify and give hazardous piping systems special consideration. Evaluate consequence of piping failure (forexample, quantities released, personnelexposure, harm to the environment). Understand operating modes of the system,including variations in normal and abnormal operating conditions. Consider dynamic effects, such as fluid hammering, vibrations, earthquake. Perform stress analysis incorporating all the loadings expected. Select materials that will not deteriorate in service. Use ductile materials. Eliminate or minimize the use of mechanical joints. Provide smooth transitions at welded joints. Choose valves to be consistent with hazardous service. Provide designs to minimize fugitive emissions. Use appropriate NDE methods to assure quality fabrication and erection. Try to provide advice to plant designers regarding piping layout needs. Use piping geometry to compensate for thermal ‘11 30 Sistem Pemipaan Ir. Teguh Pudji Hertanto, M.Sc, IPM View hazardous piping systems as conventional systems. Assume piping system cannot fail. Expect operating conditions to be without variation. Overlook potential dynamic effects. Disregard short-term loadings combined with sustained loads or the fatigue effects of short-term loadings. Choose materials sensitive to corrosion or erosion. Use low-ductility materials, such as castiron or glass. Use mechanical joints without considering means to safeguard them. Have abrupt changes in joint geometry. Use stem packing designs that can leak. Forget to perform a sensitive leak test with an appropriate sensitivity. Limit NDE methods to those in codes and standards if newer methods will give reliable results. Believe that plant designers will understand hazardous piping layout needs. Use expansion joints. Pusat Pengembangan Bahan Ajar Universitas Mercu Buana ----------------------------------------------------------------------expansion and contraction. Provide a collection and disposal system for pressure relief of hazardous systems. Segregate hazardous piping systems during fabrication, erection, and testing to facilitate all requirements being met. Design and maintain supports as part of the piping system. Provide design details of critical elements to construction. Provide mechanism for positive identification of piping materials of construction. Provide an in-service monitoring program for early detection of problems. Maintain service records throughout life of system. Periodically examine critical elements. ‘11 31 Sistem Pemipaan Ir. Teguh Pudji Hertanto, M.Sc, IPM Vent directly to atmosphere without proper treatment. Treat hazardous piping like other systems. Treat piping supports as independent components. Leave critical fabrication and assembly details to be provided by field. Rely on specifying materials with no follow-up. Wait for a catastrophic event. Repair piping without documenting it. Install system and forget about it. Pusat Pengembangan Bahan Ajar Universitas Mercu Buana