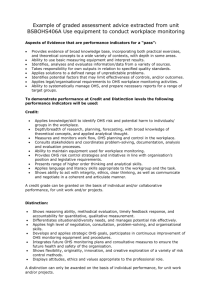

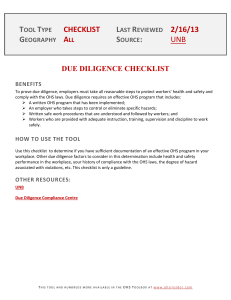

OHS Management System Framework for the

advertisement