Contextualized Learning Activities (CLAs)

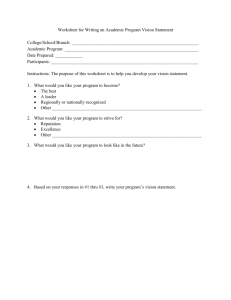

advertisement

Financial Literacy within Technological Education 20011-12 1 Custom Woodworking Since making financial decisions has become an increasingly complex task in the modern world, people need to have knowledge in various areas and a wide range of skills in order to make informed decisions about financial matters. They need to be aware of risks that accompany various financial choices. They also need not only to develop an understanding of world economic forces, but also to become aware of ways in which they themselves can respond to those influences and make informed choices. It is therefore essential that financial literacy be considered an important attribute of a well-educated population so that Ontarians may continue to prosper in the future. Financial literacy may be defined as “having the knowledge and skills needed to make responsible economic and financial decisions with competence and confidence”.1 In addition to acquiring knowledge in such specific areas as saving, spending, borrowing, and investing, students need to develop skills in problem solving, inquiry, decision making, critical thinking, and critical literacy related to financial issues. The goal is to help students acquire the knowledge and skills that will enable them to understand and respond to complex issues regarding their own personal finances and the finances of their families, as well as to develop an understanding of local and global effects of world economic forces and the social, environmental, and ethical implications of their own choices as consumers. This lesson plan along with other BBT lesson plans were developed by members of the Ontario Council for Technology Education (OCTE) in conjunction with the Ministry of Education. The lessons will be posted on the Ontario Education Resource Bank (OERB) https://resources.elearningontario.ca/ Contact Information Board Development date Toronto District School Board July 2011 Contact person Richard Lee Position Secondary Teacher Phone Fax E-mail richard.lee@tdsb.on.ca Course Name Custom Woodworking – Grade 11 and 12 Course code TWJ3/4E 20011-12 Name of lesson plan Brief description of lesson plan Duration Financial Literacy within Technological Education 2 Design a Kitchen within a given budget Students will be given a floor plan of a simple kitchen to look over. After determining the quantity and size of cabinets required, they will determine the cost of building a set of cabinets for the space indicated 2 – 3 hours Overall DESIGN, LAYOUT, AND PLANNING SKILLS expectations TWJ 4E - B1. apply a design process, other problem-solving techniques, and related concepts and principles, as appropriate, to plan construction projects and develop solutions for construction problems and challenges; TWJ3E/4E - B4 apply the mathematical skills required in the design and construction of woodworking projects Specific TWJ3E: expectations B4. Mathematical Skills B4.5 prepare estimates of quantities and costs of materials required to complete woodworking projects, using appropriate metric and/or imperial units (e.g., metres, square metres, litres, board feet, linear feet, square feet) TWJ4E: B1. Design B1.3 demonstrate how the overall design of a project is affected by design concepts and other factors (e.g., structure, ergonomics, aesthetics, cost and availability of materials, customer needs) B1.5 explain the reasons for choosing particular materials for various woodworking projects (e.g., strength, cost, ease of use, availability, environmental considerations) Essential Skills and work habits B4. Mathematical Skills B4.5 prepare detailed, accurate estimates of quantities and costs of materials for woodworking projects (e.g., lumber, hardware, finishes), and of labour costs for these projects Essential Skills Reading Text Writing Document Use Computer Use Oral Communication Numeracy Money Math: Scheduling or Budgeting and Accounting: 20011-12 Financial Literacy within Technological Education Measurement and Calculation: Data Analysis: Numerical Estimation: Thinking Skills Job Task Planning and Organizing Decision Making Problem Solving . Finding Information Work habits Working Safely Teamwork Reliability Organization Working Independently Initiative Self-advocacy Customer Service Entrepreneurship Instructional/Assessment Strategies 3 20011-12 Financial Literacy within Technological Education Teacher’s notes The focus of this lesson/activity is financial literacy. It is not meant to be a complete lesson on the design and manufacture of kitchen cabinets. There is enough information included however, that the students can be challenged at various levels depending on the teacher’s goals. By far the most difficult aspect of the lesson will be determining the amount of sheet goods required to build the kitchen. This strongly addresses measurement and layout skills. It is recommended that the students work in pairs to make this task less daunting. To bypass this part of the activity, simply inform the students of the number of sheets required do build the upper cabinets, lower cabinets, and doors. This information is found in Appendix 7 - BILL OF MATERIALS ANSWER KEY The list of materials and hardware provided in this lesson is by no means exhaustive or complete. It has been kept simple to provide a reasonable level of challenge for the students. Items like fasteners, adhesives, edge tape, and finishing supplies are not mentioned. These items can be mentioned for clarity, or brought into play as an extension at the teacher’s discretion. Another aspect that has been omitted for the sake of simplicity is the entrepreneurial side – e.g. labour, overhead, and profit. The teacher who wishes to extend this lesson into a complete unit may address those issues as well. Building on prior knowledge: For the purposes of this activity it is not crucial for the students to have an in depth understanding of how kitchen cabinetry is manufactured, although some experience with shell style cabinet construction might make the first part (estimating the quantity of sheet goods required) easier and more meaningful. Before commencing this exercise, however, the students should have good facility with imperial measurements, and an understanding of how board feet are calculated. Context For cabinetmakers to run a successful business it is essential that they are able to provide accurate estimates of the costs of jobs to their clients. Failure to do so can have serious and potentially disastrous financial consequences for the entrepreneur. Strategies Introduce the lesson, handing out the following sheets: 1. ESTIMATING THE COST OF BUILDING KITCHEN CABINETS (Appendix 1) 2. GALLEY KITCHEN FLOOR PLAN (Appendix 2) 3. CABINET DESIGN (Appendix 3) 4. TYPICAL MATERIAL AND HARDWARE CHOICES FOR BUILDING A KITCHEN (Appendix 4) 5. KITCHEN MATERIALS PRICE LIST (Appendix 5) 6. BILL OF MATERIALS WORKSHEET Appendix 6) Involve students in a discussion about kitchens – what kind of doors does their kitchen have? What kinds of knobs, counter tops etc.? Discuss the various aspects that may determine the budget for a kitchen, and the choices of materials that make up a set of cabinets. Talk about needs versus wants. Have the students go over the handouts in Appendices 2,3, and 4. Help them to identify the various cabinets on the plan, then the various parts of each cabinet on the design sheet, and finally the material choices. 4 20011-12 Financial Literacy within Technological Education 5 Give the students a mandated budget with which to build the kitchen (for more on this see “ADDITIONAL NOTES” below . Be sure to explain that such entrepreneurial concerns such as labour, overhead and profit are not part of this activity. (This may, of course, lead to other fruitful discussions.) Have the students (preferably in pairs) begin by preparing a SHEET GOODS CALCULATOR WORKSHEET. Instructions for doing this are on the back of the first handout (Appendix 1). You may have to start one yourself to serve as an example to get them going. Once the students have completed their SHEET GOODS CALCULATOR WORKSHEET (This may take more than one full class)you can instruct them to start filling out the BILL OF MATERIALS WORKSHEET (Appendix 6). This activity should be accomplished during one class. Have the students write a one half to one page explanation of how they arrived at their quote. What was the reasoning behind their choices? Assessment and Evaluation of Student Achievement Strategies/Tasks Purpose 1.Create and fill out the SHEET GOODS CALCULATOR Formative - Is the student understanding how WORKSHEET (See page two of Appendix 1) various parts are obtained from a sheet? 2.Fill out the BILL OF MATERIALS WORKSHEET Summative - Has the student demonstrated the (Appendix 6) ability ability to interpret the plan and apply the relevant math skills? 3. Write a one half to one page explanation of how you Summative – Has the student demonstrated an arrived at your quote understanding of the financial choices involved in designing and building a kitchen? Assessment tools BILL OF MATERIALS ANSWER KEY (Appendix 7) MARKING RUBRIC (Appendix 8) Additional Notes/Comments/Explanations 20011-12 Financial Literacy within Technological Education ASSIGNING A MANDATED BUDGET: Using the parameters included with this lesson, the cost of materials for this kitchen range from $1152.46 to $3053.55, before taxes. By assigning a budget somewhere in between those two figures, you force the students to make choices. This strongly addresses the financial literacy concepts of working within a budget, and understanding the difference between needs and wants. You may also explain that kitchens are often designed with a “PRICE PER LINEAR FOOT” in mind(in this case, 20 linear feet). Thus, a budget of $100 per linear foot, for example, would limit the overall materials cost for this kitchen at $2000. MAKING IT INTERESTING: With the students working in pairs, you could announce that the first teams to submit a properly completed SHEET GOODS CALCULATOR WORKSHEET will receive higher budgets. This also introduces a certain competitiveness that will be experienced in the real world. SCORING THE SHEET GOODS CALCULATOR WORKSHEET There is more than one way to fit all the parts onto the sheets, so there is no one right answer. Here are a few guidelines, however: The upper and lower cabinets together can be made from 7 sheets with minimal waste. One sheet may have pieces from upper and lower cabinets. The backs can be made from 4 sheets. If melamine or plywood veneer doors are being made, 3 sheets are needed. Encourage the students to start with the largest pieces, and to orient pieces of the same width in one “strip” that can be ripped on the table saw. Remind students that the orientation of the pieces must allow the sheet to be ripped and cross cut easily. The sheet should not look like a jig saw puzzle. If plywood veneer is being used, the orientation of the grain must be consistent. TO FOCUS STRICTLY ON THE FINANCIAL LITERACY COMPONANT OF THIS LESSON: You can skip the SHEET GOODS CALCULATOR WORKSHEET (see page two of Appendix 1) and CABINET DESIGN (Appendix 3) handout and just plug the correct numbers into the BILL OF MATERIALS WORKSHEET (Appendix 6). Students should still submit the explanation page outlining their choices. The total mark in this case would be on 20 rather than 35. Resources 6 20011-12 Financial Literacy within Technological Education Authentic workplace materials Appendix 2 - GALLEY KITCHEN PLAN Websites As an extension to this activity, you may have the students research prices for building materials. The following websites may prove useful: www.leevalley.com (hardware) www.cabinetdoordepot.ca (doors and drawer faces) www.robertbury.com (sheet goods) www.countertop-depot.com (laminated and solid counter tops) Accommodations Students who are struggling may be paired with stronger students. Quantitative numbers can be plugged into BILL OF MATERIALS WORKSHEET (Appendix 6) Choices from KITCHEN MATERIALS PRICE LIST (Appendix 5) may be limited to one per category List of Attachments Appendix 1 - ESTIMATING THE COST OF BUILDING KITCHEN CABINETS Appendix 2 - GALLEY KITCHEN PLAN Appendix 3 - CABINET DESIGN Appendix 4 - TYPICAL MATERIAL AND HARDWARE CHOICES FOR BUILDING A KITCHEN Appendix 5 - KITCHEN MATERIALS PRICE LIST Appendix 6 - BILL OF MATERIALS WORKSHEET Appendix 7 - BILL OF MATERIALS ANSWER KEY Appendix 8 - MARKING RUBRIC 7 20011-12 Financial Literacy within Technological Education 8 Appendix 1 - Estimating the Cost of Building Kitchen Cabinets Imagine that you have been asked to prepare a quote on a set of kitchen cabinets for a galley kitchen. A galley kitchen is a narrow kitchen with cabinets, counters and appliances on both sides, and may be found in a small apartment or condo. They are often walk-through (open at both ends). As you will learn in this lesson, the cost of building cabinets for a kitchen can vary greatly, depending on the materials chosen. The owner of an apartment building may be very concerned with the cost (but will still want a certain level of quality), whereas a luxury condo developer may be more concerned with a kitchen that adds value and sales appeal to the unit. As a cabinetmaker, you will be concerned only with the cost of the cabinets and the countertop. The appliances, sink, flooring and backsplash are not part of your quote. The worksheets included in this lesson will help you with the following steps: 1. Determine the amount of material that you need to build the cabinets. 2. Determine how much material you will need to make the doors and drawer faces, or how many of each you will need to order from another company. 3. Determine how many knobs and drawer slides you will need. 4. Determine how many linear feet of countertop you will have to order. 5. Determine the cost of all of the above! 20011-12 Financial Literacy within Technological Education 9 How to calculate how may sheets of material you need: To make your own “Sheet Goods Calculator Worksheet”, take a piece of ¼ inch squared paper, and draw several 8 square by 16 square rectangles on it. Use a pen, and leave at least 2 squares empty between rectangles. Each of these rectangles will represent one 4’ x 8” sheet of melamine or veneer ply. Each line within the rectangle represents 6”, so every two lines is a foot. Using a pencil, start to outline where each piece of each cabinet will fit on a sheet. Be sure to label each piece as you go along. If the width or length of a piece you are marking does not fall on a line, just estimate where the line should be drawn. Some helpful hints: The actual width of the lower gables and bottoms is 23 ¾ inches, allowing two “24” inch pieces to be cut from a 48” wide sheet. The actual width of the top pieces is 11 3/4”, for the same reason. Make sure you orient the parts so that the sheet can be run through on the table saw. Except for the small cabinets above the fridge and stove, all upper and lower cabinet doors are 30” in height. All cabinets with two doors need only two gables. The drawer cabinet is a stand alone cabinet, with two gables. The upper cabinet to the right of the stove has three doors and three gables. If you are using veneered plywood, pay attention to the direction of the grain! To be handed in at the end of this activity: Your completed SHEET GOODS CALCULATOR WORKSHEET Your completed BILL OF MATERIALS WORKSHEET A brief explanation (about a half a page to one page max) of how you arrived at your choice of materials to prepare the quote. Evaluation: SHEET GOODS CALCULATOR WORKSHEET …….... 15 MARKS BILL OF MATERIALS WORKSHEET…………………… 10 MARKS EXPLANATION…………………………………………….. 10 MARKS TOTAL 35 MARKS 20011-12 Financial Literacy within Technological Education APPENDIX 2 - GALLEY KITCHEN PLAN 10 20011-12 Financial Literacy within Technological Education 11 APPENDIX 3 - CABINET DESIGN, SHELL STYLE Modern kitchen cabinets are usually built using a “Shell Style” construction (as opposed to the older “Frame and Panel” style). Lower cabs have two gables, or sides, a bottom, a kick plate, and two top braces. The top braces are used to support the countertop. Upper cabinets have two gables, a top, and a bottom. There are three main options for the back (applies to upper and lower cabs): 1. Full back (usually ½” melamine) – the most expensive and most solid. 2. Two cleats with a masonite back. Masonite is a 1/8” thick hardboard. This solution will hide the wall behind the cabinet but is not a solid or professional looking as a full back. The two cleats (see image of upper cabinet for an example) provide a surface for attaching the cabinet to the wall. This is a mid cost solution. 3. Open back with two cleats. The least expensive solution. Lower cabinets usually have one 16” deep shelf, and upper cabinets typically have two shelves. The shelves and doors are not shown in these images. LOWER CABINET UPPER CABINET NOTE** The top braces on lower cabinets are typically 5” wide, and the back cleats (if used) on both upper and lower cabs are usually 4” wide. 20011-12 Financial Literacy within Technological Education 12 APPENDIX 4 - TYPICAL MATERIAL AND HARDWARE CHOICES FOR BUILDING A KITCHEN The choices of materials and especially hardware that are available for building a kitchen are too numerous to fully cover here. There are dozens of major companies that specialize in hardware for cabinetry, and some of their catalogues are almost the size of a small telephone directory. For the purpose of this activity we will limit the choices to two or three in each category. CABINETS: Standard kitchen cabinets are usually constructed from Melamine. Melamine is an engineered wood product that consists of a sheet of particle board (also called presswood) laminated on both sides with a sheet of paper that is coated with plastic. It is somewhat durable and easily washable, but is prone to scratching and chipping. Melamine comes in a 4’ x 8’ sheet, and a variety of thicknesses. Melamine cabinets are typically made with 5/8” thick material, and the backs of cabinets are often made with 1/2". Custom kitchens are often made with plywood, which is then laminated on both sides with veneer. Veneer is a thin layer of real wood, and gives plywood the appearance of a high quality solid wood. Because of this, and because plywood is much stronger than particle board, this method produces a more durable, higher quality and beautiful cabinet. However, the materials involved and the labour and materials to finish the veneer make these cabinets more expensive. In either case, edges must be covered with melamine tape or wood veneer tape. MELAMINE VENEER PLYWOOD DOORS AND DRAWER FRONTS: The least expensive option here is to cut the doors from a sheet of melamine. Doors that are molded to simulate raised panel doors are available in a variety of sizes and finishes from most big box home improvement stores. The nicest (and most labour intensive and expensive) doors are made from solid woods like pine (for a country look) and oak (for a more classic appearance). Many small cabinet making shops will order these doors from a company that specializes in doors and drawer fronts. MELAMINE DOOR MOLDED DOOR WOOD DOOR 20011-12 Financial Literacy within Technological Education 13 COUNTERTOPS: The two most popular choices for countertops are laminated (particle board with Formica) and granite. Granite is very expensive, but is highly regarded for its beauty and durability. A granite counter top is often a good selling point in the real estate market. There are many other choices, but we will stay with these two. FORMICA GRANITE 20011-12 Financial Literacy within Technological Education 14 HARDWARE: Hardware for a kitchen mainly consists of Hinges, Knobs or Pulls, and Drawer slides. Hinges: Modern cabinets are usually constructed using a “shell design” (see cabinet design sheet), and almost always use European style 35mm hinges. Less expensive hinges open about 95º (a); more expensive models open 135º (b) or even 175º (c). Drawer slides: Standard drawer slides are quite good – full extension slides are even better, but more expensive. Knobs and pulls: There are hundreds of choices on the market, ranging from about $1 each to over $10. The kitchen in the drawing features knobs (attached with one screw), but you may choose pulls (attached with two screws ) if you wish. 20011-12 Financial Literacy within Technological Education APPENDIX 5 - Kitchen Materials Price List SHEET GOODS Melamine, 5/8” x 4 x 8 sheet Melamine, ½” x 4 x 8 sheet Veneer Ply, ¾” x 4 x 8 sheet Masonite, 1/8” x 4 x 8 sheet 40.50 39.00 93.00 13.59 COUNTER TOPS Laminated, per linear foot Granite, per linear foot 17.90 43.75 DOORS Pre-fab wood door Pre-fab wood drawer face Molded door Molded drawer face 22.00 18.00 15.75 13.50 SOLID WOOD Oak, per board foot Maple, per board foot Pine, per board foot 3.95 2.75 2.05 HARDWARE Hinge, 95º 9.90 Hinge, 120º 12.10 Hinge, 170º 18.30 Drawer slides, regular, per pair 7.20 Drawer slides, full extension, per pair 19.60 Simple knob 1.40 Mid-range knob 2.90 High-end knob 6.50 Simple pull 2.30 Mid-range pull 4.90 High-end pull 7.50 15 20011-12 16 Financial Literacy within Technological Education APPENDIX 6 - BILL OF MATERIALS WORKSHEET This worksheet will help you calculate the cost of materials that you would need to order to build the kitchen. Description Lower Cabs: Include gables, bottoms, braces, kick plates, shelves, (and cleats if not using a full back) Upper cabs: Include gables, bottoms, tops, shelves,( and cleats if not using a full back) Backs for upper and lower cabs Counter tops Doors & Drawer faces: If melamine determine # of sheets. If wood, determine # of board feet if you are making them. Hinges (2 per door) Knobs or pulls Drawer slides Other items SUBTOTAL 13% HST GRAND TOTAL FOR MATERIALS ONLY: Material (circle choice) Melamine 5/8” Qty Unit 4’ x 8’ sheets Veneer Ply ¾” Melamine 5/8” 4’ x 8’ sheets Veneer Ply ¾” Masonite 1/8” Melamine ½” 4’ x 8’ sheets Laminated Granite Melamine Molded Doors Drawer Faces Prefab wood doors Drawer Faces Solid wood * *(add15% waste) 95º, 135º, 175º See price list Regular Full extension Linear foot 4x8 sheets, doors, or board feet each each pairs Cost Total 20011-12 17 Financial Literacy within Technological Education APPENDIX 7 - ANSWER KEY TO: BILL OF MATERIALS WORKSHEET Description Lower Cabs: Include gables, bottoms, braces, kick plates, shelves, (and cleats if not using a full back) Upper cabs: Include gables, bottoms, tops, shelves,( and cleats if not using a full back) Backs for upper and lower cabs Material (circle choices) Qty Unit Cost Total (Circle choices) Melamine 5/8” OR 3.5 4’ x 8’ sheets (must buy full sheets) 40.50 162.00 472.00 Veneer Ply ¾” 118.00 4’ x 8’ sheets Melamine 5/8” OR Veneer Ply ¾” 3 40.50 121.50 3 118.00 354.00 4 13.59 54.36 39.00 17.90 43.75 40.50 15.75 13.50 22.00 18.00 2.053.95 156.00 268.50 656.25 121.5 283.50 67.50 396.00 90.00 153.75296.25 Hinges (2 per door) Masonite 1/8” OR Melamine ½” Laminated Granite Melamine Molded Doors Drawer Faces Prefab wood doors Drawer Faces Solid wood * *(add15% waste) 95º, 135º, 175º 36 each Knobs or pulls See price list 23 each Drawer slides Regular Full extension 5 pairs Counter tops Doors & Drawer faces: If melamine determine # of sheets. If wood, determine # of board feet if you are making them. SUBTOTAL 13% HST GRAND TOTAL FOR MATERIALS ONLY 4 15 15 3 18 5 18 5 75 4’ x 8’ sheets Linear foot 5/8x4 x 8 sheets, doors, or board feet 9.90356.40 18.30 658.80 1.4032.20 7.50 172.50 7.20 36.00 19.60 98.00 from 1152.46 to 3053.55 149.82 396.96 from 1302.28 to 3450.51 20011-12 18 Financial Literacy within Technological Education APPENDIX 8 - RUBRIC FOR GALLEY KITCHEN ESTIMATE Name_____________________ Course Name: Unit Title: Criteria : Create and fill out a ”sheet goods calculator worksheet” Complete the “bill of materials” worksheet Create a report explaining material choices. The student: TOTAL: Custom Woodworking Course Code: TWJ Financial Literacy Task: Estimate the cost of building kitchen cabinets Level 1 50 – 59% Level 2 60 – 69% Level 3 70 – 79% Level 4 80 % + Worksheet is partially complete. Most major parts are present. Worksheet is complete with more than one extra sheet and /or several parts missing. Worksheet is filled out with several errors. Total estimate is inconsistent with budget. Worksheet is complete with up to one extra sheet used and few or no parts missing. Worksheet is complete with correct number of sheets and all parts. /15 Worksheet is filled out with minor errors in calculation. Total estimate is within 20% of budget Worksheet is correctly filled out. Total estimate is within budget. /10 explains their material choices and demonstrates an understanding of the estimation process with a moderate degree of success explains the material choices and demonstrates an understanding of the estimation process with considerable success explains the material choices and demonstrates an understanding of the estimation process with a high degree of success /10 Quantities listed on worksheet do not correspond with the plan. There are several errors in calculation. Total estimate not accurate. explains their material choices and demonstrates an understanding of the estimation process with limited success Mark. /35