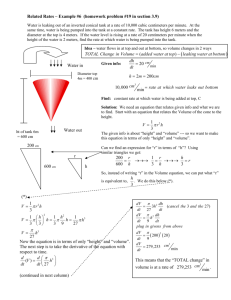

Recommended Practice on Light Product Quality

advertisement