MANAGEMENT PRACTICE IN SAFETY CULTURE

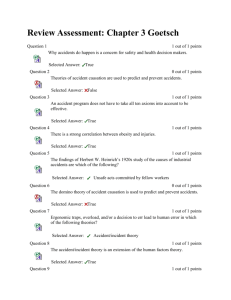

advertisement

MANAGEMENT PRACTICE IN SAFETY CULTURE; INFLUENCE TOWARDS WORKPLACE ACCIDENTS IN MALAYSIA’S BUILDING CONSTRUCTION INDUSTRIES. Abstract This study was conducted to find the relationship between management practice and safety culture implementation. Two degree of management practices were recognized to play the role of motivator in safety working culture towards influencing the workplace accidents occurrences in Malaysia’s building construction industries. Using questionnaire survey method to collect data, this study involved a number of 500 participants of building construction workers from all around the country. Perception surveys were used to effectively identify improvements in and deterioration of safety system elements (Ostrom et al., 1993). Background Construction industry is a sector of national economy engaged in preparation of land and construction, repair of buildings, structures and other properties. Malaysia’s construction industries recorded a GDP growth of 1.6% in the fourth quarter of 2008 in comparison to 3.9% and 1.2% in the second and third quarters of 2008. It turned around to register a small positive growth of 0.6% in the first quarter of 2009. (CIDB, 2009). Although Malaysia had recorded an increase economically, this does not mean Malaysia can settle down comfortably. The major issues in almost all developing construction industries are safety culture involving accidents. The statistics of accidents at construction sites give us proper picture of Malaysia which in need of critical, huge and fast overhaul from the current site safety. From 1995 to 2003, SOCSO received 114134 reports on industrial accidents (SOCSO,2001). In 2007, Department of Occupational Safety and Health recorded 33% cases of occupational accidents in Malaysia came from construction sites which was the highest accidents involving fatal injuries. Di Berardinis (1999) defined accidents as unplanned and unexpected events which invariably preceded by an unsafe act or unsafe condition or the combination of both. Accidents can be in term of damage to equipment and materials and specially those that results in injuries receive the greatest attention (Hinze,1997) . Accidents in workplace can have serious implications to construction industry. Construction accidents may cause many problems such as disruption of site activities; delay of project activities, delay of progress and can heavily affect overall cost of the project and also the reputation of the construction industries (Mohamed, 1999). Considering the adverse effect of accidents towards the project itself, there were many ways of implementing safety culture among workers had been taken into consideration and also already implemented. When human error played role in contributing to accidents, the behavioral causes of failure are often found to be more subtle (Pidgeon , 1991). Expectation then started to build into current safety legislation that specifies the responsibilities of managers and employees with regard to safe working practice. Positive culture attitude towards safety were supposed to be more convenient to exist. The concept of safety culture was developed as a result of the 1986 Chernobyl accident, which focused attention on the human and organizational elements contributing to the unsafe operation (pidgeon, 1991). Turner (1991) defined safety culture as an organization’s norms, beliefs, roles, attitudes and practices concerned with minimizing exposure of employees to workplace hazards. The main objective of a safety culture is to develop a norm which employees are aware of the risks in their workplace and are continually on the lookout for hazards (Ostrom et al, 1993). By focusing on the attitudes and behaviors of the employees, safety culture play a role as the recognizer and motivator for these aspects. Problem Statement In order to nurture and strengthen the safety culture implementation among workers, management practices had been brought forward to assist the implementation process. Expectation then started to build into current safety legislation that specifies the responsibilities of managers and employees with regard to safe working practice. Two degree of management practices; safety training and hiring practices were discussed to study the extent of each one towards safety culture implementation. Other problem is that how effective would management practices towards safety culture implementation as changing current organization’s culture are much more difficult rather than changing the stream or the style of management alongside with issuing a new policy statement. Research Objectives This study intends to find out the relationship between management practice and safety culture. Other than that, this study also tries to find out how effective can management practice influence safety culture implementation towards improving workplace accidents. Besides that, there will also be a study about the role played by both managers and employees themselves towards influencing both management practices and safety culture in workplace environment. Research Questions 1. What is the relationship between management practice and safety culture? 2. How does safety culture influenced by management practices? 3. How do managers and employees involved in the safety culture implementation? 4. What role does managers and employees play in safety culture implementation? Significance of study This study will provide information about the relationship between management practice safety culture. Furthermore, this study would also provide the information of the effectiveness of management practice towards safety culture implementation. This study would be beneficial to any building construction contractor in Malaysia such as CIDB, Syarikat Perumahan Negara and other small organization. Besides contractors, this study will also be beneficial to the Department of Occupational Safety and Health Human Resource Department Malaysia whereby the result of this study can be used as a guideline in implementing a more efficient safety culture in building construction industries in Malaysia. Literature Review Management Practices Safety training For employees to be active in a safety program, they must first receive a safety training. A well designed and administered training program will emphasize safe work practices. Training should be followed with a program based on goal setting and performance feedback (Cohen and Jensen, 1984). Training program assessment should verify that the safe work practices could be demonstrated to be effective and to endure beyond cessation of performance feedback. There should be a redefinition of group norms sustained through informal influences such as peer modeling of desired behaviors, continued management support of the program, and a behavior sampling procedure specifying performance-based criteria (Cohen and Jensen, 1984). Safety training provides the means for making accidents more predictable. The basic difference between safe employees and those who frequently get hurt is that safe employees can recognize hazards and hazardous actions and understand the consequences. To improve the quality of safety and health for all employees, organizations should institute a systematic, comprehensive safety and health training program for new employees, provide a mentor for these employees, and use a buddy system to help orient new employees in the safety and health and quality systems. According to Roughton (1993) they should also institute a system of continual reeducation and retraining of employees in current safety and health issues. Several issues affecting the perception of risk levels and should be understood when training employees in occupational safety. People tend not to use the likelihood of injury in their judgments of product safety; rather, the severity of injury plays the foremost role in decisions to read warnings and act cautiously (Young et al, 1990). The level of perceived danger increased compliance to warnings and instructions; therefore, it is critical that all employees are trained to identify the hazards associated with their workplace (Vredenburgh and Cohen, 1995) Reward System People are motivated to behave in ways that lead to desired consequences; they will modify their behavior to conform to a cultural norm if it is perceived that compliance will lead to a desirable outcome. Culture is learned through a connection that is made between behaviors and consequences. Thompson and Luthans (1990) state that since organizational culture occurs in an environment where there are multiple reinforcements and reinforcing agents, changing an organization involves identifying the various reinforcing agents in order to determine their effects on the change process. A correctly designed safety-incentive program reinforces the reporting of a hazard or an unsafe act that leads to an injury while giving bonuses for fewer lost-time accidents. A safety incentive program must be part of a campaign that runs parallel to safety education and training. It must be directed at the prevention of accidents, not punishment after an accident occurs (Peavey, 1995). Informational (feedback, self-recording), social (praise, recognition), and tangible reinforcers (trading stamps, cash bonuses) have been used as well as nonmonetary privileges (Komaki, Barwick, & Scott, 1978). As with any policy, the effort to develop a strong safety culture is unlikely to be effective if the organization is not reinforcing the desired behaviors (or is rewarding inconsistent behaviors such as speed or production rates). A well-designed incentive program offers recognition, which can help modify behavior. A key characteristic of a successful incentive program is that it receives a high level of visibility within the organization. Participants must be able to comprehend what the incentive program is designed to accomplish and how their performance will be measured (Halloran, 1996). Simply distributing prizes and money without pairing them with a clear, consistent set of contingencies reduces the potential to achieve the desired outcome. It may even increase the undesired behavior, more accidents (Swearington, 1996). ACCIDENT An accident can be defined as an unplanned, undesirable, unexpected, and uncontrolled event. An accident does not necessarily result in an injury. It can be in term of damage to equipment and materials and especially those that result in injuries receive the greatest attention (Hinze, 1997). All accidents, regardless of the nature of the damage or loss, should be of concern. Accidents that do not cause damage to materials or equipment or injury to personnel may foretell future accidents with less desirable results. CAUSE OF ACCIDENT Accident don’t just happen, they are caused. According to Ridley 99 per cent of the accident are caused by either unsafe acts or unsafe conditions or both (Ridley, 1986). As such, accidents could be prevented. The unsafe act is a violation of an accepted safe procedure which could permit the occurrence of an accident. The unsafe condition is a hazardous physical condition or circumstances which could directly permit the occurrence of an accident. Most accident results from a combination of contributing causes and one or more unsafe acts and unsafe condition. Accident theories and models discussed in the previous section have evolved from merely blaming workers, conditions, machineries into management roles and responsibilities. Nowadays, accident models are being used to better explain the causes of accident so that appropriate actions could be taken to make improvement. However, in order to effect permanent improvement, we must deal with the root causes of accident. A review of the literature indicates that finding the factors and causes that influence construction accidents has been the passion of many researchers. Kartam and Bouz (1998) did a study in Kuwaiti construction and noted that the causes of accidents were due to worker turnover and false acts; inadequate safety performance; improper cleaning and unusable materials; destiny; low tool maintenance; supervisory fault; and misplacing objects. Abdelhamid and Everett (2000) conducted a more comprehensive study in the USA and classified the causes into human and physical factors. Human factors were due failed to secure and warn; Failed to wear personal protective equipment (PPE); horseplay; operating equipment without authority; operating at unsafe speed; personal factor; remove safety device; serviced moving and energized equipment; took unsafe position or posture; used defective tool or equipment; and other unsafe action. While, physical factors were due to; unsafe act of another person(s); disregard known prescribed procedures; defects of accident source; dress or apparel hazard; environmental hazard; fire hazard; hazardous arrangement; hazardous method; housekeeping hazard; improper assignment of personnel; inadequately guarded; public hazard; and other unsafe conditions. Lubega et al (2000) did a study in Uganda and concluded the causes of accidents were mainly due to lack of awareness of safety regulations; lack of enforcement of safety regulations; poor regard for safety by people involved in construction projects; engaging incompetent personnel; non-vibrant professionalism; mechanical failure of construction machinery/equipment; physical and emotional stress; and chemical impairment. Pipitsupaphol and Watanabe (2000) did a study in Thailand construction sites and classified the causes into the most influential factors i.e. unique nature of the industry; job site conditions; unsafe equipment; unsafe methods; human elements; and management factors. They further concluded that major immediate causes were due to failure to use personal protective equipment; improper loading or placement of equipment or supplies; failure to warn co-workers or to secure equipment; and improper use of equipment. Toole (2002) also did a study in the USA and suggested that the causes of accidents were due to lack of proper training; deficient enforcement of safety; safety equipment not provided; unsafe methods or sequencing; unsafe site conditions; not using provided safety equipment; poor attitude toward safety; and isolated and sudden deviation from prescribed behavior. Tam et al (2004) did a study in China and noticed that the causes of accidents were due poor safety awareness from top leaders; lack of training Theoretical Framework Safety Training Workplace accident Hiring Practices Hypothesis 1 : There is a positive relationship between safety training and workplace announcement Hypothesis 2 : There is a positive relationship between Hiring practices and workplace accident. METHODOLOGY This study adopted the perception survey proposed by Ostrom et al (1993) to effectively identify improvement or deterioration in safety programs and performances. This study covers 500 workers from building construction industries all around Malaysia with minimal 30 persons for each state. Questionnaire will be provided to each participant to answer and collect data. All workers coming from building construction industries are eligible to be a participant regardless of their position in the industries.