dr-01 - Department of Mechanical Engineering

1998 – 99 NCDA

Design Concept Report

Team 1:

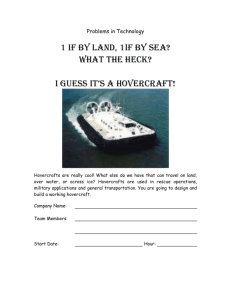

Hovercraft

November 25, 1998

Sponsor: Dr. Stephanie Wright Brandon Fichera

B. Sean Gallagher Delaware Aerospace Academy

Gregory Pease

David Rabeno Advisor:

Dr. Michael Keefe

SUMMARY:

The purpose of this report is to present a summary of the work that was done during the first semester of our senior design project. Presented here in is the final concept including background and its complete history.

In defining the actual project, it was important to determine all the people that could use the hovercraft. Once the customers were established, we had to take into account their role in the project and to determine their specific wants. Once this list of customers and wants was developed, the wants were evaluated with respect to customer importance so that the wants could be easily prioritized.

Next benchmarking was performed to learn more about hovercraft principles and operation. The other purpose of benchmarking was to develop yardsticks for measuring the quality of our design concepts. These yardsticks, called metrics, will be how we compare the different concept ideas. The metrics will not only give measurement scales, but they supply target values to directly compare ideas against each other as they relate to the problem statement.

Before intelligent discussion of ideas could be undertaken, further research was needed. This research consisted of derivation of relevant equations, discussion with experts and trips to libraries. This deepened the understanding of the physics behind the problem.

After benchmarking and further research, concepts were formed as to how the problem could be solved. During these brainstorming sessions, all ideas were considered to be valid. All manner of footprint, educational, fun, lift and thrust possibilities were considered.

Once the ideas were developed, they were compared to wants and constraints via the metrics. After which, some where discarded, some were kept, and some were combined to produce a cohesive design concept that we believe to be the best solution according to the specific problem. The concept selected presents a complete idea for our solution to the problem.

INTRODUCTION:

Dr. Stephanie Wright, president of the Delaware Aerospace Academy (DAA), has sponsored senior design projects for the past few years. The DAA specializes in teaching children about the technology involved in the space program. In teaching, they hope to raise an interest in the United States Space Program by presenting technology that is relatively new and has yet to be widely distributed. This year, Dr.

Wright desires a hovercraft to be used at the DAA technical camps by students of grades 7 – 9. The hovercraft is to simulate exploration of a new planet.

With this as general background information, a mission statement was formed.

It reads as follows:

To design a two person hovercraft for the DAA that will demonstrate the relevant scientific principles involved, simulate planetary exploration, interest children in the space program, and provide a fun, safe and educational environment for everyone involved.

There are plenty of benefits a solution to this mission would yield. The craft will be used as an educational tool to teach scientific principles to children in high school and junior high demonstrations. By utilizing a two-pilot operating system, it will also teach teamwork and cooperation.

CUSTOMERS/WANTS/CONSTRAINTS:

The list of customers consists of anyone that could possibly be affected by the design solution. The list is as follows (in order of importance):

1) Dr. Stephanie Wright – DAA

2) Eric Rabeno – Junior High Student

3) Bethany Fichera - High School Student

4) Martin Rabeno – High School Teacher

5) Selina DiCiccio – Junior High Teacher

6) Ron Perkins – Educational Innovations

7) Dr. Robert Bloom – Aerospace Engineer (DAA)

8) Dr. Mark Elison - Principal of Junior High and High School

Dr. Wright is our most important customer because her company is sponsoring the project, providing the funds and will be the primary user of the hovercraft for demonstrations when it is completed.

Students are our next most important customers because they are the people to benefit the most from the project. To educate them and peak their interest in the space program, while at the same time trying to make it fun are the major wants.

Once we design our concept, we have to make sure that high school and junior high school teachers understand not only what we are trying to accomplish, but also how to teach their students the hovercraft principles.

Educational Innovations supplies lab and science equipment to schools as kits which teach certain scientific principles to children. Mr. Perkins is an important customer because he can provide insight as to what works well and what doesn’t work well as an educational tool. He provides help with the educational aspect of the mission.

The school system superintendents and principals are also concerned with the education of their students. They also know what is and is not allowed in demonstrations as far as safety is concerned.

After talking with these customers and discussing each of their interests in the project, a list of wants was developed and SSD was used to rank them. The wants are listed below.

1) Demonstrate scientific principles

2) Make it fun

3)

Have it look ‘cool’ (space-like)

4) Maneuverability

5) Transportability

6) Reliability

7) Reproducibility

8) Durability

9) Affordability

There will be some tradeoffs to be made between these wants. All of the wants will be satisfied. However, some wants are more important than others and will be met better. Constraints will partly dictate how well the wants are satisfied. The constraints are listed as follows:

1) Operation (The hovercraft must hover)

2) Allowable Funds ($1600)

3)

Size of door in Room 109 Spencer Lab (4.5’ X 6.3’)

4) Number of pilots (must be able to fit two)

BENCHMARKING (System and Functional):

Benchmarking is an ongoing process and has proven to be very valuable in the design of this project. Initial benchmarking was done on a variety of overall systems as well as components in order to determine competitors best practices. Initial benchmarking determined that there was not a complete system on the market that satisfied the specific problem. The system closest to what is desired is the Triflyer

Hovercraft from Robert Q. Riley Enterprises. The Triflyer was able to handle a max weight of 800 lbs. (3 people), traveled 75 mph and was 12' x 6'. This design satisfied the weight requirement, but was overpowered and not educational. Since this system was very close to the desired goal, plans for the Triflyer were ordered and were used for concept and component design. This allowed for a better look and gave insight as to industry standards for such components as steering, skirt design and mounting points for engines and fans. Other benchmarks are shown in the table below.

Table1: Benchmarking

Robert Q. Riley Enterprises (Triflyer)

Robert Q. Riley Enterprises (Pegasus)

Universal Hovercraft (Kits and components)

Hoverclub of America

Plans for hovercraft. Best practice

Round hovercraft plans, max weight 150 lbs.

Design has no viable propulsion method.

Kits offered are smaller than desired. Cost well above budget.

Offer fans for lift and thrust. Staff very helpful.

Published a variety of articles describing principles of hovercraft such as lift, thrust, and design tips.

Levitation using electromagnets Hovertech

Universal hovercraft, along with supplying hovercraft kits, supplies components such as fans for personal hovercrafts. Universal hovercraft has been contacted for fan information and availability.

Functional Benchmarking was done on a variety of systems and ideas in order to generate concepts and determine components for the design. Six Flags Great

Adventure and the Smithsonian Air and Space Museum were looked at for a concept to satisfy our wants of educational and fun. Six Flags use speed and fast movement in order to make there rides fun for children and adults of all ages. The Air and Space

museum takes a different approach to fun and learning, they use videos, short descriptions and in some cases hands on experiences to facilitate learning and fun. In addition, components, such as engines (Briggs and Stratton, Tecumseh, Honda), were researched and priced form a variety of distributors, such as Grangier and Northern

Tool Supply. Fans and skirt material, electric and wood and building materials were also investigated to get a better idea of what needs to be ordered, costs, lead time associated with each as well as usefulness in fulfilling the design requirements.

METRICS:

During the benchmarking process, notes were taken on some of the important items that are normally used in measuring the quality of a design. Concept ideas can not be compared to best practice ones unless a common yardstick is developed upon which to base the evaluation. By observing what the competitors measured to determine quality, a list of metrics and target values for the wants was generated. The list of metrics is shown below in no particular order.

1) Number of Principles Taught – 3

2) Understanding of video – average score = 80%

3) Performance on a lab experiment (to be explained) - average score = 80%

4) Speed of vehicle – 5 mph min.; 10 mph max.

5) Acceleration of vehicle – 1mph/s

6) Planar Range – unlimited (limited by fuel capacity alone)

7) Directions of Travel – 360 degrees (all horizontal directions)

8) Turning Radius – 5 m

9) Fuel Efficiency/Capacity – 3.5 continuous hours

10) Labor Hours (Construction) - 150

11) Cost - $1600 max.

12) Length – 9’ max.

13) Width – 6’ max.

14) Weight - 1000 lbs.

15) Object Clearance (from bottom of craft to ground) - 6”

16) Skirt to Ground Clearance - 0.5”

17) Number of Colors and Lights – verbal input from students

18) Sound Effects – verbal input from students

19) Maintenance hours per flight hours - 1/10

All target values are from benchmarking or through conversations with our customers.

CONCEPT GENERATION:

There are three main goals of this project: education, fun and functionality.

These three requirements lead to a very unique process of concept generation.

Through brainstorming, several ideas were obtained to satisfy the needs individually. Once we had a few concepts for each requirement, the next stage was to try and combine these best or most feasible ideas into a global concept that would satisfy our mission statement best according to our metrics.

The two proven leaders in education and fun are museums and amusement parks. For best practices, the Smithsonian and Six Flags Great Adventure Parks were chosen. The Smithsonian approach is great for learning. In addition, they incorporate as much fun as possible through hands on experiences. The amusement park dealt strictly with fun by making rides bigger, faster, and scarier. Using these techniques, amusement parks are able to keep people entertained, but do not provide them with much educational value.

Next, concepts were generated from the functional point of view. Both fans and magnets were looked at for way of lifting the hovercraft. One concept was to have magnets on the ground along with opposing ones on the craft. The magnets would repel each other and lift the craft. Traditionally, hovercrafts have been lifted with fans, which force air under the craft. This could be done with a gas or an electric motor as long as enough power is supplied to the fan.

The shape is also important in lifting the hovercraft. The amount of force underneath the craft is directly proportional to the footprint (i.e. surface area) of the craft. A number of shapes were looked at when considering the design of the footprint, these are included in Appendix A along with a sample pressure calculation.

Maneuverability and thrust is another area where concepts were generated.

Benchmarking showed that a fan system used for thrust seemed to be the best practice. Other possible thrust methods would be to have the craft pulled/pushed by another person, or using some sort of jet propulsion. Maneuverability could be done with a rudder system, or by having multiple fans which rotate changing the direction of airflow.

Two concepts were generated for the skirt design. A bag skirt, which is a lot like an inflated innertube under the craft, or a C skirt, which is a piece of material draped along the craft much like a table cloth.

Pilot positioning was also a concern. The pilots could be positioned one behind the other or side by side. Their position determines the stability of the craft. If the craft is not stable air will escape through the skirt and lower the efficiency of the lift system.

CONCEPT SELECTION:

Arriving at a harmonious union of education and fun, proved to be accomplished easily. The solution combines both the methods of the Smithsonian and

Six Flags. Included in this approach are a video that students will watch (script is located in Appendix B), a lab to be preformed on the concept of lift (located in

Appendix C), and then a ride on the actual hovercraft.

It is felt that students will learn the most by watching the video and performing the lab before operating the hovercraft. In the video students will see the hovercraft operating, and the governing principles such as lift and thrust will be explained. Next student will built a simple hovercraft themselves in a short lab. The lab is designed to show how lifting force and footprint sizes are related. After completing these steps, students will be allowed to ride the hovercraft with a better understanding of its working principles.

To determine the final result of the lab and video, several iterations of each will be done. These iterations will increase the understanding of how students learn, allowing the presentation to educate more effectively. The methods for evaluating effectiveness are multiple surveys with feedback from students and quizzes following the lab and video. Based on the results of these, the presentation of important concepts will be altered until optimal understanding is obtained.

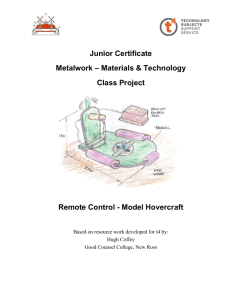

The actual hovercraft is a 9 ft long and 6 ft wide rectangle. Drawings are shown in Appendix D. This shape was picked as it was the easiest shape to manufacture (labor hours) as well as meeting the metrics for length and width best.

The lifting is done with a single fan located in the front of hovercraft. A fan system was chosen over a magnetic system due to the cost restriction on the project. In addition, the magnetic system did not allow unlimited planar range. An 8 HP vertical shaft gas engine mounted directly above powers the fan. Gas power was chosen due to the cost and power output per pound of a gas engine compared to electric. An 8 HP gas engine costs about $400 and weighs about 60 lbs.; the batteries to operate an equivalent engine weigh twice as much. . The lift fan diameter was determined, after talking with Universal Hovercraft, according to their calculations the fan needed is

26" in diameter and has four blades. Information on how this was determined is currently being sent to the group for evaluation. Unless it is determined otherwise this is the fan that will be used.

The engine will be mounted in the front of the craft. This was determined by looking at competitors best practices. Due to the fact that the mounting points of the motor are unknown, a drawing of the mounting bracket for the lift engine has yet to be determined. Specifications from the vendor are on order.

A bag skirt was chosen for the design for two reasons. Bag skirts allow for a more complex shape of a craft. The C skirt is a very unstable system because it has the tendency to flap out, releasing air and lowering the craft.

Bag Skirt

‘C’ Skirt

In the design the pilots are positioned side by side. The pilot compartment if pilots were positioned front to back would have to be longer than currently designed, therefore forcing the hovercraft to be longer. With the pilots positioned side by side,

neither the width nor the length need to be increased and the stability is still preserved. Balancing the difference with weights under the seat can compensate for any mismatch in weight.

Thrust will be accomplished by a large fan enclosed by a small duct on the back of the hovercraft. Maneuvering will be done with a rudder system attached to the fan at the rear. The thrust fan will be powered by a horizontal shaft engine attached to the fan by a belt. At the current time, it is unknown how much power is required, but the system described will be effective based on the best practices of the industry.

Currently, a more detailed look at this system is in progress and will be completed in due time.

DRAWING PACKAGE:

The completed drawing package to date is located in Appendix D

BUDGET

Appendix E contains the budget for this project. All major costs have been included, however some are estimates based on an average price. Items, such as engines, contain different options. These options are in the process of being determined. For ease of construction of the ribs shown in the drawing package, two templates will be made for each of the rib sections. These templates will act as a female mold for the rib section allowing for each one to be manufactured with ease and repeatability. That is, the rib will be assembled inside of the templates.

Appendix A: Shapes of Footprint and Sample Calculation

Sample Calculation for rectangle:

Area = length x width = 9 x 6 = 48 ft

2

= 6912 in

2

Weight = 2000 lbs. (Weight from metrics with a factor of safety of 2)

Cushion Pressure = Weight/Area = 2000 lbs./6912 in

2

= .289 lbs./in

2

Appendix B: Script for Video

The portion of the video script shown here demonstrates the relevant physic equations. The part of the script not shown is to include information on propulsion. At the time of this draft, the propulsion systems are under evaluation. The final script will include the propulsion information.

This script is presented for preliminary comments.

Dave:

Hello, this video has been created so that you will have a better understanding of the physical principles behind a hovercraft.

We will review some of the basic terms that we will use in describing these principles and then step by step go through the more sophisticated topics of lift and thrust.

First, let’s discuss the difference between mass and weight. Weight is a force, which is defined as a mass multiplied by acceleration. (Show equation W=m*a)

A good example is that everything has a mass but something only has a weight when it’s acted on by the acceleration of gravity.

Your mass stays the same if you were on Earth, the moon, or in space. You weight changes because the acceleration of gravity changes. Gravity on the moon is only one-sixth it is on Earth and there is no gravity in space, so your weight on the moon is only one-sixth it is on Earth and you would have no weight in space

This is important for NASA scientists to remember when designing things to be used in places other than Earth.

Greg:

A friction force is a force that opposes the motion of an object because of the contact of two surfaces.

If I push this block, it doesn’t keep going forever in that direction because a friction force slows it down until it stops.

On level ground, the friction force is a friction coefficient times the weight of the object (show

F friction

=

*W), where

depends on the two materials that are in contact.

The reason we want our hovercraft to hover is so there is no contact with the ground and

becomes very small. Because

is small, the friction force will be small and it will be much easier to move the hovercraft. (Demonstrate the model with and without the fans on)

Sean:

Moments are something else to be aware of. A moment is a force times a distance. (Show equation M=F*d)

If you were trying to loosen a nut with a wrench, the force you push on the handle doesn’t loosen the nut, the moment you create by the force you push times the length of the handle does. (Take out bolt on a board, fastened with a nut, and a wrench)

Just think, if you push on the nut like this it wouldn’t turn. (push directly on the nut with your hand or the wrench)

It’s the length of the handle that matters. (Turn the nut with the wrench illustrating the length of the handle and where the force is applied)

Brandon:

Something really important to a hovercraft is pressure. Pressure is a force, which is applied to a surface.

You can calculate the pressure by dividing the applied force by the surface area that it is acting on. (show equation P=F/A)

The whole reason that a hovercraft is able to hover is because the force of its weight acting down (show on diagram of the hovercraft, W) is opposed by another force acting up. (show on diagram as F

L

)

This opposing force is the lift force. The lift force is created by the air pressure underneath the hovercraft, between the bottom of the craft, and the ground. (illustrate on diagram)

If you reverse the pressure equation we showed you, you can see how the lift force depends on the air pressure. (show first equation, then F

L

=P air

/A)

The surface area you see in the equation is the area of the bottom of the hovercraft.

Dave:

Now you know why the hovercraft hovers, but where does that air pressure come from?

The answer is: from a big, powerful fan. As you know, a fan takes air from one side and forces it out the other. Our fan takes the outside air and shoves it underneath the hovercraft (show on diagram)

By putting all that air in a small space, we create the air pressure needed to create the lift force to make the craft hover.

Because its hovering, though, air escaped from underneath. (show on diagram)

This is why we need the keep the fan running constantly, to keep plenty of air squeezed under the hovercraft.

Greg:

Once the hovercraft is hovering it is important to keep the moments balanced. (Show M=F*d)

Just like a seesaw, if the moments are not balanced, one side will tip over. (Show seesaw with different weights at different distances from the fulcrum)

As you can see, we can balance the moments by placing objects of certain weights at certain distances from the center.

Sean:

Only when the moments are balanced, is the hovercraft stable.

Now we have a craft with a weight acting down and a lift force acting up but it isn’t moving.

To move along the ground , another force must be applied in the direction you want to go.

There are many ways to generate this force. You could have a friend push you or attach a rocket to the craft and light it. The way we have designed is by using fans.

By pushing the air out the back of the fan, the fan creates a force called thrust. Isaac

Newton’s laws state that for every force you apply on an object, that object pushes back with the same force.

A fan pushes air out the back and the air effectively pushes the fan forward with the same force. This force forward is the thrust force.

Appendix C: Lab

Demonstration of Lift System for

Anti-Gravity Vehicles

Purpose:

It is important to understand the scientific principle of lift in any vehicle that is free-floating or built specifically to defy gravity. The purpose of this experiment is to learn about how a free floating vehicle actually “defies” gravity. It will be important to understand the relationship between surface area of the vehicle, weight of the vehicle and the air pressure developed between the vehicle and the ground. This experiment will provide the information necessary to understand the concept of lift.

Theory and Background:

Anti-gravity vehicles have become an area of great interest recently. Some people build them at home as a hobby much like go-carts. There are also important scientific uses for hovercrafts and other free-floating vehicles. The present level of scientific technology is so advanced that NASA and separate state space programs and space camps would have very important uses for an anti-gravity hovercraft. One of the uses is to use a hovercraft to explore unknown places on a planet. Astronauts that land on a planet for the first time would not be able to completely know what the terrain is like before they land. Because of this fact, a vehicle that hovers off of the ground is the best way to explore that planet in case it is not easy to drive a vehicle with wheels. The Delaware Aerospace Academy will demonstrate a life size hovercraft that was designed for the purpose of showing how planetary exploration would take place. By performing this experiment before viewing the demonstration, you will better understand how the hovercraft actually lifts off the ground and how it works. The equation that is important in figuring out if a hovercraft will actually hover is F = (P) X (A). In this equation, F = weight of the hovercraft plus passengers (the force needed to lift the hovercraft). A = the surface area on the bottom of the hovercraft (in this experiment the hovercraft is a rectangle and its A = length X width. And the P = air pressure between the hovercraft and the ground. Its units are pounds per square inch. You will construct hovercrafts of different weight (F) and area (A) and find the air pressure needed to cause lift.

Necessary Equipment:

Two standard 3” computer cooling fans (12VDC, .13Amps, 1.60Watts)

One 12 Volt DC battery

-

Two pieces of styrofoam posterboard 9” X 16”

Eight strips of pre-cut plastic (trash bag material)

-

Four 16” strips, two 9” strips, and two 18” strips

Tape

A set of small weights totaling about 4 lbs.

Procedure:

1) Using the piece of posterboard with the computer fans attached (holes will be precut in the posterboard with computer fans taped into them), tape one

9” piece of plastic to each shorter edge of the posterboard. Then, use the two 16” strips of plastic and tape those to the longer edges of the posterboard. Turn the posterboard over and use one piece of tape at each corner to attach the plastic strips as shown in figure 1 on the next page.

2) Before you turn the fans on, you must make sure the hovercraft is rightside up and all the loose ends of plastic are tucked under the craft. Then, hook the red wires on the fans to the positive (+) terminal of the battery. Then hook the black wires to the negative (-) terminal. Observe what happens.

Does the hovercraft lift off the table? If it lifts, try putting some small weights on the posterboard away from the fans. If it lifts, write down the largest amount of weight it can hold up (and add this value to the weight of the hovercraft which is 1 lb.). The area A = 16” X 9” = 144 inches squared. With this weight (F) and area (A), use the equation F = P X A to calculate the air pressure. If it does not lift at all, move on to the next part.

3) Take the pieces of plastic off and tape the other piece of poster board onto the first one. Now use the two 18” pieces of plastic on the edges you used the 9” pieces on before and put the two 16” pieces on the other two edges as in figure 2.

Then tape the corners as before and use the fans to try and lift the new set up. Again, add different weights to the hovercraft away from the fans. Does this one lift? Does this hovercraft lift better than the first one? Write down the largest amount of weight it can lift this time

(remember to add the weight of this craft which is 1.25 lbs.). The area for this craft is A = 288 inches squared. Calculate the value of air pressure for this hovercraft.

4) Based on what you saw for the two hovercrafts, which one seemed to work better? Which one had a lower value of air pressure (P)? What can you say about the relationship between the value of P and how well the hovercraft works?

FIGURE 1

Top View

FIGURE 2

Bottom View

Top View

Appendix D: Drawings

Appendix E: Budget

Esimated Price for Skeleton

Size

1x2x10

1x2x12

2x4x10

1/2 plywood

1/8 plywood

Quantity Price Per Piece Total

39 $2.50

$97.50

22 $2.50

$55.00

3

3

11

$3.00

$10.22

$11.00

$9.00

$30.66

$121.00

Total: $313.16

Price of 1/8 plywood is an estimate

Size

1x2x10

1x2x12

1/2 plywood

Tooling Price

Quantity Price Per Piece Total

6

4

2

$2.50

$2.50

$10.22

$15.00

$10.00

$20.44

Total: $45.44

Total Price: $358.60

Hovercraft Budget

Total Allowance $ 1,600.00

Status

Received

Received xxx xxx xxx xxx xxx

Description

Plans for Tryflyer Hovercraft

Computer Fan and Battery

Wood For Frame

Tooling

Fan (lift)

Engine (Lift)

Engine (Thrust)

Fan (Thrust)

*** On order xxx Estimated

Quantity

1

Price

$45.00

Total

$45.00

1 $23.87

$23.87

see sheet $313.16

$313.16

see sheet $45.44

1 $227.00

$45.44

$227.00

1

1

1

$400.00

$244.99

$200.00

$400.00

$244.99

$200.00

Total $1,499.46

Appendix F: Theoretical Work and Graphs

Equations Used And Derivation of Power Equation:

V = velocity

P = pressure

= desity

W s

= Work done by shaft

A = area l= lenth w = width h =height of skirt to ground

Conservation of Energy and Conservation of Mass from the fluid mechanics perspective is used throughout.

P

1

V

2

1

2

gz

1

P

2

V

2

2

2

gz

2

W s m

0

0

0

w

A

W s

W s

w

A

w lw

; A

lw

P

2

V

2

2

2

gz

2

P

3

V

2

2

3

gz

3

W m s

P

2

0

0

0

V

2

3

2

0

V

3

Q

A p

A p

2 l

2 w

h

V

3

(

2 P

2

)

1 / 2

2 w

( lwp

)

1 / 2

W

w s

m

w ( Q

) lw

w ( 2 l

2 w ) h ( 2 w )

1 / 2 lw ( lw

)

1 / 2

Figure 1 : Gap Height = 1.0cm Figure 2 : Gap Height = 1.5cm

Figure 3 : HP = 8

Figure 5 : HP = 7

Figure 4 : HP = 6

Appendix G: Schedule