Numerical Investigation of Spherical Diffusion Flames at their

advertisement

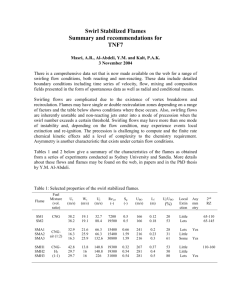

Numerical Investigation of Spherical Diffusion Flames at their Sooting Limits V.R. Lecoustre and P.B. Sunderland Dept. of Fire Protection Engineering, University of Maryland, College Park MD 20742, USA B.H. Chao Dept. of Mechanical Engineering, University of Hawaii, Honolulu HI 96822, USA R.L. Axelbaum Dept. of Energy, Environmental and Chemical Engineering, Washington University, St. Louis MO 63130, USA Submitted to: 33rd Combustion Symposium (Beijing) Submission Date: January 10, 2010 Colloquium: Soot, PAH and other Large Molecules Alternate Colloquium: Laminar Flames Corresponding Author: Peter B. Sunderland Dept. of Fire Protection Engineering University of Maryland College Park MD 20912 USA tel: 301-405-3095 fax: 301-405-9383 pbs@umd.edu Total length: 4840 words equivalent using method 1 (limit 5800) Main text: 2728 Equations: 92 References: 734 Table 1: 152 Figures: 1134 , as follows: Fig. 1, 172; Fig. 2, 159; Fig. 3, 161; Fig. 4, 169; Fig. 5, 160; Fig. 6, 155; Fig. 7, 158. Affirmation to pay color reproduction charges if applicable: Not applicable. 1 Abstract This paper presents detailed numerical simulations of laminar microgravity spherical diffusion flames at their sooting limits. Seventeen normal and inverse flames fueled by ethylene are considered. Observed in a drop tower, these flames were initially sooty but reached their sooting limits 2 s after ignition (or slightly before). The flames span broad ranges of stoichiometric mixture fraction (0.04 – 069), adiabatic flame temperature (1814 – 2670 K), and characteristic flow time (0.12 – 15 s). They were modeled using a one-dimensional, transient diffusion flame code with detailed chemistry (up to pyrene) and transport. Radiative losses from products were modeled using a detailed absorption/emission statistical narrow-band model coupled with a discrete-ordinates method. Flame structure at the sooting limits was examined, emphasizing profiles of temperature, carbon to oxygen atom ratio, and scalar dissipation rate. For sooting limit flames with sufficiently long flow times (i.e., above 0.5 s) a common observation observed for all flames, despite their disparate characteristics, was that soot does not exist unless there is a location in the flame where the C/O ratio exceeds 0.51 and the temperature exceeds 1410 K. Soot inception in flames with local flow times below 0.5 s required increased local temperatures or C/O ratios. Keywords: soot; laminar flames; microgravity. 1. Introduction Owing to its importance in energy production and atmospheric pollution, soot formation in combustion is an active research topic [1-7]. The sooting limit is a fundamental measure of a fuel’s propensity to form soot. Most data on sooting limits come from studies of flat laminar premixed flames [2–4,8–10]. In these flames, temperature and gas species compositions are nearly constant downstream of the flame. This allows identification of sooting limits for various 2 temperatures and equivalence ratios (typically reported as carbon-to-oxygen atom ratios, C/O). Past studies have shown that soot inception in premixed flames arises from a competition between fuel pyrolysis and oxidation of soot precursors [10]. For most fuels the flame remains soot-free regardless of temperature when the C/O ratio is below a critical value [8]. In premixed ethylene flames, the critical C/O ratio is between 0.55 – 0.6 [2–4,8,10]. The local C/O ratio has also been used to explain sooting limits in diffusion flames [11,12]. Du and Axelbaum [12] found that adding CO2 to the fuel side of counterflow and coflow diffusion flames suppresses soot formation chemically. Adding inert to the fuel stream and increasing the oxygen concentration in the oxidizer side (with constant adiabatic flame temperature and strain rate), was found to suppress soot formation in diffusion flames [11,13,14]. Past experimental work on spherical diffusion flames in microgravity led to an estimate of 0.59 for the critical local C/O ratio of ethylene [11]. An important difference between premixed and nonpremixed flames is the effect of temperature on soot formation. Increased temperatures suppress soot formation in premixed flames [4,10]. However, in nonpremixed flames increased temperatures enhance the formation of soot in fuel-rich regions. Previous diffusion flames studies have identified a minimum local temperature for soot formation of 1250 – 1650 K [4,5,15,17,18]. While this local temperature applies to disparate flames, an analysis by Chao et al. [13] and experimental observations have found that the adiabatic flame temperature, Tad, of sooting limit flames increases with stoichiometric mixture fraction, Zst, for coflow [14,19] and spherical diffusion flames [11]. In addition to a minimum local temperature and C/O ratio, a sufficiently long flow time is required for soot inception in diffusion flames. Soot induction times of 0.8 – 15 ms were reported by Tesner and Shurupov [20] for acetylene/nitrogen mixtures at 1473 K. A carbonization time of 3 1.8 – 11.9 ms was predicted by Dobbins [15] using a carbonization model. Strain rates of 30 – 200 s−1 were observed to prevent soot formation in counterflow ethylene diffusion flames [2123], depending on the amount of fuel dilution. Strain rates that are too low also can inhibit soot formation via radiative losses. While strain-free flames with long characteristic times can be obtained in microgravity, thus opening up the potential for new insights into soot inception limits, the increase in radiative heat loss at long residence times requires careful consideration [16]. Thus motivated, the objective of this work is to numerically investigate the effects of local temperature, local C/O atom ratio, and local flow time on sooting limits of spherical diffusion flames. The present numerical tools were developed previously for the investigation of spherical diffusion flames [16,25,26]. The flames under consideration are the 17 sooting limit microgravity flames identified experimentally by Sunderland et al. [11]. 2. Experimental Methods The 17 test flames considered here were studied in microgravity using the NASA Glenn 2.2 s drop tower and were initially reported in Sunderland et al. [11]. The burner was a 6.4 mm diameter porous stainless steel sphere. All tests were conducted in a quiescent ambient at 295 K and 0.98 bar. Ignition was performed immediately after release into microgravity. The tests employed three gases: ethylene, nitrogen, and oxygen. A color video camera was used to image the flames. Experimental details can be found in Refs. [11,16,26]. A summary of the 17 sooting limit flames is given in Table 1. A large number of experiments were conducted to identify these sooting limit flames, which initially contained yellow regions, but became all blue at 2 s after ignition (or slightly before). Burner flow rates were selected such that all flames involved a steady-state ethylene consumption rate of 4 1.51 mg/s, generating 71 W for complete combustion. Experiments were conducted with normal or inverse flames correspond to ambients containing either oxidizer or fuel, respectively. The fuel and oxygen mole fractions in the supply gases, XC2H4,0 and XO2,0, were varied widely, which yielded a wide range of Zst as shown. Adiabatic flame temperatures reported in Table 1 were calculated using Chemical Equilibrium with Applications, CEA [27]. 3. Numerical Methods The spherical diffusion flames of Table 1 were simulated using a one-dimensional diffusion flame solver modified from Sandia’s PREMIX code [28]. This was combined with Sandia’s CHEMKIN and Transport packages [29,30] to obtain detailed chemistry and transport properties. Conservation equations for mass, species, and energy were numerically solved [16,25], assuming ideal gas behavior. These equations were discretized on a non-uniform mesh using a central difference operator for the diffusive terms and an upwind difference operator for the convective terms. Implicit first-order time marching was used. The discretized equations were solved using Sandia’s TWOPNT package [31], which uses a modified damped Newton’s method to solve boundary value problems. Modified transport properties were introduced to improve agreement with experimentally observed flame diameters. Using the same code, Santa et al. [25] found that increasing the species and heat diffusivities by 30% from those provided by the Transport package [30] yielded higher peak temperatures and smaller flames, which compares better with experiments. This increase was also included here. The spherical burner surface was the inner boundary of the computational domain. The imposed conditions at this location were a fixed temperature of 295 K and a steady species mass flux. At the outer boundary, temperature was also specified to be 295 K. Species mass fractions 5 at the outer boundary were specified according to Table 1. Pressure was held constant at 0.98 bar. Emission and reabsorption of radiation was included, considering the participation of CO2, H2O, and CO. Radiative heat losses were obtained by solving the radiative transfer equation using a discrete-ordinates method [32,33] with Gaussian-Legendre quadrature over 20 ordinates. The radiative properties were formulated using a statistical narrow-band model with a spectral bandwidth of 25 cm-1 and wave numbers of 150 – 9300 cm−1. Species radiation parameters were taken from the HITRAN database [34]. Because this work considers flames at their sooting limits, only gas phase chemistry was modeled. The reaction chemistry was simulated with GRI-Mech 3.0 [35] and the Appel, Bockhorn, and Frenklach (ABF) model [36]. The ABF model consists of 101 species and 544 reactions. It includes pyrolysis and oxidation of C1 and C2 species (based on GRI-Mech 1.2), formation and oxidation of linear hydrocarbons up to C6, and formation of aromatics from benzene pyrene (C6H6 to C16H10). GRI-Mech 3.0 contains 53 species and 325 reactions. The two models yielded similar results for the findings presented here. Following the approach adopted by Tse et al. [24] and Santa et al. [25], the initial (ignition) condition for transient calculations was prescribed as the adiabatic steady-state solution of the corresponding flame in a compressed domain with its outer boundary positioned 1.2 cm from the burner center. The grid was adapted to reduce the gradients and curvature and ensure accuracy. For most ignitions 70 – 80 mesh points were used. The steady state solution was then used as the initial condition for the transient computations. The computational domain was extended to a radius of 15 cm, with grid points added between the compressed domain and 15 cm. The transient simulations used 200 – 300 mesh points. Temperature and species gradients 6 at the outer boundary were found to be negligible for the transient cases from 0 – 4 s. At 4 s, the thermal fields extended to less than 10 cm. Thus the location of the outer boundary had no impact on the results presented here. Radiative heat losses were considered for all transient simulations, with fixed temperatures at both boundaries. 4. Results and Discussion Measurements and computations indicate that these flames do not reach steady state within 2 s. Flame diameters may briefly decrease after ignition, but then increase with time [25,26]. This decreases peak temperatures owing to radiative losses, which are proportional to flame diameter squared [16]. At 2 s, the model predicts peak temperatures for the 17 flames to vary from 1479 – 2262 K and to be 300 – 700 K below the adiabatic flame temperatures of Table 1. These peak temperatures are well above the 1100 K identified for radiative extinction of spherical ethylene diffusion flames [16]. The radiative heat loss fractions are around 0.42 for all flames except flames 10 – 12, which have radiative heat loss fractions of about 0.28. Flow times are important to this study owing to the slow chemical kinetics of soot formation/oxidation reactions. The simplest such time is the residence time for a fluid parcel to be convected from the burner to the location of peak temperature [11]. However, in inverse flames this residence time may not properly indicate the residence times of fuel species. Moreover, it includes periods when temperatures are too low for soot to form. A flow time based only on local conditions is thus sought, and in this work 1 / χ is used, where χ is the local scalar dissipation rate defined as χ = 2 α ( dZ / dr )2 , where α is the local thermal diffusivity and Z is the mixture fraction. 7 (1) Mixture fraction is commonly defined as the local mass fraction of the elements that originated in the fuel supply. For the present flames this is ZCHN = YC + YH + YN* , (2) where Y is the local mass fraction, the subscripts denote the element(s) considered, and N* denotes nitrogen atoms that originated from the fuel supply. In this paper, an alternative definition that follows past work [38,39], was also considered: Z CHO YO ,ox YO Y YH C 4M H 2M C 3M O , YH , f YC , f YO ,ox 4M H 2M C 3M O (3) where M is element mass and subscripts f and ox denote the fuel and oxidizer supplies. In flames with fuel dilution, ZCHO is simpler to evaluate than ZCHN because YN* is not readily available. To compare these two definitions, the predicted temperature profiles are plotted versus Z for flame 10 in Fig. 1 as in Zhou and Mahalingam [37]. For Zst = 0.041 the ZCHN definition predicts the peak temperature to fall on the rich side of Zst (Table 1). In contrast, the ZCHO definition predicts the peak temperature to occur at Zst. The ZCHO definition of Eq. (3) is thus adopted here for computing χ as was done in Refs. [37,39]. Distributions of T, C/O ratio, and χ were computed for the 17 flames at 2 s. Figure 2 plots these profiles for flame 10 using the ABF model. The highest C/O ratios are in a region of low temperature on the fuel (ambient) side of the flame. Fuel diffuses inward from the ambient toward the reaction zone. It eventually reaches regions hot enough for soot formation, but here the C/O ratio is lower. The peak temperature is located near C/O = 0.33, which is too low for soot to form. Where C/O ratio is low, oxygen containing species are abundant, and therefore hydrocarbon oxidation reactions are favored over soot inception reactions. As will be shown 8 later, Fig. 2 depicts conditions where temperature increases above the soot formation threshold just where C/O ratio falls below the critical value required for soot formation. The 17 flames are observed to reach sooting limits at 2 s. Therefore, the hypothesis that soot formation requires a region where both T and C/O are above certain critical values (values which are yet to be determined) is supported if a single pair of critical values applies for all 17 flames. For very short residence times, the critical temperature for soot formation may increase, but otherwise the competition between C/O ratio and temperature is expected to be unaffected by residence time. To identify the critical C/O ratio for soot formation in these flames, various C/O ratios between 0.4 – 0.8 were considered and the associated local temperatures for the 17 flames were found. For each value of C/O, the standard deviation of these temperatures, T, was obtained as shown in Fig. 3. Flames 7 – 9 were not included in Fig. 3 because they had significantly higher values of χ over this range of C/O ratios, as will be discussed below. The standard deviation in Fig. 3 has a minimum at C/O = 0.51. Thus the critical (i.e., minimum) C/O ratio for soot formation in these flames is established as C/Ocrit = 0.51. This is close to previous reports of 0.55 – 0.6 in ethylene premixed flames [2–4,8,10], 0.59 using a simpler analysis of these flames [11], and 0.53 for gas-jet diffusion flames [14]. The local temperature and χ-1 where C/O = 0.51 are denoted T0.51 and χ0.51-1 and are plotted in Fig. 4. Parameter χ0.51-1, also shown in Table 1, covers a broad range, from 0.13 – 15.6 s. The values of T0.51 in Fig. 4 are close to each other for most of these flames. Excluding flames 7 – 9, the mean T0.51 is 1410 K. Flames 7 – 9 have the highest local scalar dissipation rates (shortest flow times), i.e., χ0.51-1 < 0.5 s, and thus reach their sooting limits at higher local temperatures. This means that these flames require higher temperatures for the soot formation 9 reactions to be activated. For these three flames T0.51 increases as χ0.51-1 decreases. Figure 4 reveals no statistically significant effect of convection direction (i.e., flow from oxidizer to fuel or fuel to oxidizer) on the critical temperature for soot formation, T0.51. Figure 5 shows the relationship between T0.51 and Zst for the 17 flames. The critical temperature that characterizes soot inception is independent of the flame structure (represented by Zst) when flames 7 – 9 are excluded. It is remarkable to find such uniformity of the critical temperature for soot formation for such disparate fuel and oxidizer supply mole fractions, Zst, Tad, scalar dissipation rates, and convection directions. Insight is available from plots of T and C/O versus Z for sooting limit flames. This is shown in Fig. 6 for flames 1 and 17, which are normal and inverse flames, respectively. These flames have relatively high χ0.51-1 times. The y axes of Fig. 6 (and Fig. 7) are such that T = 1410 K aligns with C/O = 0.51. For both flames, when moving from the fuel supply toward the peak temperature, the C/O ratio falls below its critical value (0.51) at the same location as the temperature increases above its critical value (1410 K). As shown in Figs. 2 – 5, similar behavior was also observed for flames 1 – 6 and 10 – 17. In Fig. 7, the temperature and C/O profiles in Z space for flame 5 at three times are considered to see if these findings can explain why the flames first appear yellow after ignition (i.e., are producing soot) and then become blue at 2 s. At times of 0.1 and 1.0 s, the experiments revealed abundant yellow emission from soot in the video record. This is supported by the computations, as Fig. 5 reveals regions where T > 1410 K and C/O > 0.51 at early times. In contrast, at 2 s the experiments reveal a sooting limit (i.e., they have transitioned to blue) and the computations predict the absence of any region with T > 1410 K and C/O > 0.51. 5. Conclusions 10 Computational simulations of 17 spherical diffusion flames at their sooting limits were performed using detailed chemistry, transport, and radiation. These flames were previously observed to reach their sooting limits at (or slightly before) 2 s in microgravity. Experiments and numerical predictions were used to evaluate the hypothesis that soot formation in diffusion flames requires a region with sufficient temperature, C/O atom ratio, and flow time. This hypothesis is supported by these 17 flames, which represent a broad variation of reactant dilution, peak temperature, and convection direction. A region with a temperature above 1410 K and a C/O ratio above 0.51 is required for soot formation in these flames. This was shown for flames with χ0.51-1 > 0.5 s, but flames with shorter times required higher local temperatures because soot formation was suppressed. Acknowledgments This work was supported by NASA. Helpful discussions with David L. Urban and Dennis P. Stocker are appreciated. References [1] H. Bockhorn, Soot formation in combustion: mechanisms and models, Springer, Berlin, 1994. [2] I. Glassman, F.L. Dryer, R.F. Sawyer, Physical and Chemical Aspects of Combustion: A Tribute to Irvin Glassman, Taylor and Francis, 1997. [3] B.S. Haynes, H.G. Wagner, Prog. Energy Combust. Sci. 7 (1981) 229–273. [4] I. Glassman, Proc. Combust. Inst. 22 (1988) 295–311. [5] I. Glassman, Proc. Combust. Inst. 27 (1998) 1589–1596. [6] M. Frenklach, Phys. Chem. Chem. Phys. 4 (2002) 2028–2037. [7] Z.A. Mansurov, Combustion, Explosion, and Shock Waves 41 (2005) 727–744. [8] M.M. Harris, G.B. King, N.M. Laurendeau, Combust. Flame 64 (1986) 99–112. [9] P. Markatou, H. Wang, M. Frenklach, Combust. Flame 93 (1993) 467–482. 11 [10] F. Takahashi, I. Glassman, Combust. Sci. Tech. 37 (1984) 1–19. [11] P.B. Sunderland, D.L. Urban, D.P. Stocker, B.H. Chao, R.L. Axelbaum, Combust. Sci. Tech. 176 (2004) 2143–2164. [12] J. Du, R.L. Axelbaum, Combust. Flame 100 (1995) 367–375. [13] B.H. Chao, S. Liu, R.L. Axelbaum, Combust. Sci. Tech. 138 (1998) 105–135. [14] B.M. Kumfer, S.A. Skeen, R.L. Axelbaum, Combust. Flame 154 (2008) 546 – 556. [15] R.A. Dobbins, Combust. Flame 130 (2002) 204–214. [16] K.J. Santa, B.H. Chao, P.B. Sunderland, D.L. Urban, D.P. Stocker, R.L. Axelbaum, Combust. Flame 151 (2007) 665–675. [17] R.J. Santoro, T.T. Yeh, J.J. Horvath, H.G. Semerjian, Combust. Sci. Tech. 53 (1987) 89– 115. [18] P.B. Sunderland, G.M. Faeth, Combust. Flame 105 (1996) 132–146. [19] B.M. Kumfer, S.A. Skeen, R. Chen, R. Axelbaum, Combust. Flame 147 (2006) 233–242. [20] R.A. Tesner, S.V. Shurupov, Combust. Sci. Tech. 92 (1993) 61–67. [21] D.X. Du, R.L. Axelbaum, C.K. Law, Combust. Inst. 22 (1988) 387–394. [22] K.C. Lin, G.M. Faeth, J. Prop. Power 12 (1996) 691–698. [23] D.X. Du, R.L. Axelbaum, C.K. Law, Proc. Combust. Inst. 23 (1990) 1501–1507. [24] S. Tse, D. Zhu, C. Sung, Y. Ju, C. Law, Combust. Flame 125 (2001) 1265–1278. [25] K.J. Santa, Z. Sun, B.H. Chao, P.B. Sunderland, R.L. Axelbaum, D.L. Urban, D.P. Stocker, Combust. Theo. Model. 11 (2007) 639–652. [26] P. Sunderland, R. Axelbaum, D. Urban, B. Chao, S. Liu, Combust. Flame 132 (2003) 25– 33. [27] S. Gordon, B.J. McBride, Computer program for calculation of complex chemical equilibrium compositions and applications, National Aeronautics and Space Administration, Office of Management, Scientific and Technical Information Program, 1996. [28] R.J. Kee, J.F. Grcar, M.D. Smooke, J.A. Miller, E. Meeks, Premix: A FORTRAN Program for Modeling Steady Laminar One-Dimensional Premixed Flames, Report No. SAND858240, Sandia National Laboratories, 1987. 12 [29] R.J. Kee, F.M. Rupley, E. Meeks, J.A. Miller, Chemkin-III: a Fortran chemical kinetics package for the analysis of gas-phase chemical and plasma kinetics, Report No. SAND968216, Sandia National Laboratories, 1996. [30] R.J. Kee, G. Dixon-Lewis, J. Warnatz, M.E. Coltrin, J.A. Miller, H.K. Moffat, A Fortran Computer Code Package for the Evaluation of Gas-Phase Multicomponent Transport Properties, Report No. SAND86-8246, Sandia National Laboratories, 1988. [31] J.F. Grcar, The Twopnt program for boundary value problems, Report No. SAND91-8230, Sandia National Laboratories, 1991. [32] B.G. Carlson, K.D. Lathrop, in H. Greenspan, C. Kelber, D. Okrent (Eds.), Computing Methods in Reactor Physics, Gordon and Breach, New York, 1968, pp. 165–266. [33] P. Riviere, D. Scutaru, A. Soufiani, J. Taine, in: Proceedings of the 10th International Heat Transfer Conference, Taylor & Francis, 1994. [34] L.S. Rothman, A. Barbe, D. Chris Benner, L.R. Brown, C. Camy-Peyret, M.R. Carleer, K. Chance, C. Clerbaux, V. Dana, V.M. Devi, et al., J. Quant. Spectrosc. Radiat. Transf. 82 (2003) 5–44. [35] G.P. Smith, D.M. Golden, M. Frenklach, N.W. Moriarty, B. Eiteneer, M. Goldenberg, C.T. Bowman, R.K. Hanson, S. Song, W.C. Gardiner, V. Lissianski, Z. Qin, available at http://www.me.berkeley.edu/gri_mech/. [36] J. Appel, H. Bockhorn, M. Frenklach, Combust. Flame 121 (2000) 122–136. [37] X. Zhou, S. Mahalingam, Combust. Flame 133 (2003) 197–199. [38] R.W. Bilger, Proc. Combust. Inst. 22 (1988) 475–488. [39] S.A. Skeen, G. Yablonsky, R.L. Axelbaum, Combust. Flame 156 (2009) 2145-2152. 13 Table 1 Summary of the 17 experimentally identified sooting limit flames, reproduced in part from [11] Flame Environment XC2H4,0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 Oxidizer Oxidizer Oxidizer Oxidizer Oxidizer Oxidizer Oxidizer Oxidizer Oxidizer Fuel Fuel Fuel Fuel Fuel Fuel Fuel Fuel 1 0.6 0.31 0.25 0.18 0.17 0.11 0.11 0.15 1 0.8 0.6 0.21 0.19 0.15 0.12 0.13 XO2,0 Zst Tad (K) χ0.51-1 (s) 0.22 0.21 0.21 0.23 0.28 0.29 0.5 0.8 1 0.13 0.13 0.13 0.25 0.3 0.5 0.8 1 0.065 0.102 0.18 0.225 0.333 0.353 0.586 0.685 0.661 0.041 0.051 0.066 0.277 0.336 0.509 0.666 0.692 2390 2326 2226 2238 2306 2308 2381 2528 2740 1847 1835 1814 2274 2370 2539 2578 2670 14.56 7.09 2.74 1.72 0.86 0.78 0.37 0.23 0.12 10.16 8.08 6.14 1.95 1.88 2.34 4.55 5.09 14 1600 1400 1200 T (K) 1000 800 ZCHN ZCHO 600 400 Zst = 0.041 200 0 0 0.02 0.04 0.06 0.08 0.1 Mixture fraction Fig. 1. Predicted temperatures of flame 10 at 2 s after ignition plotted with respect to two definitions of mixture fraction. 2500 10 1 C/O 2000 T (K) -1 T 1500 ZCHO, C/O, (s ) 100 ZCHO 10-1 1000 10-2 500 0 0 0.5 1 1.5 2 2.5 10-3 3 r (cm) Fig. 2. Predicted T, C/O, Z, and χ profiles for flame 10 at 2 s after ignition. 15 100 80 T (K) 60 40 20 0 0.4 0.5 0.6 0.7 0.8 C/O Fig. 3. Predicted standard deviation of local temperature plotted with respect to local C/O ratio for flames 1 – 6 and 10 – 17 at 2 s after ignition. 2000 Normal Inverse 1500 T0.51 (K) 1410 K 1000 500 0 0 5 10 -10.51 (s) 15 20 Fig. 4. Predicted relationship between T0.51 and χ0.51-1 for flames 1 – 17 at 2 s after ignition. 16 2000 -10.51 < 0.5 s 1500 T0.51 (K) 1410 K Normal Inverse 1000 500 0 0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 ZST Fig. 5. Predicted relationship between local temperature at C/O = 0.51 and stoichiometric mixture fraction for flames 1 – 17 at 2 s after ignition. 2500 0.8 Flame 17 2000 0.6 C/O = 0.51 T (K) T = 1410 K 0.4 1000 C/O 1500 Flame 1 0.2 500 0 0 0.2 0.4 0.6 0.8 0 1 ZCHO Fig. 6. Temperature (solid curves) and C/O profiles (dash-dot curves) in Z space for flames 1 and 17 at 2 s after ignition. 17 2500 0.8 2000 t = 0.5 s T (K) C/O = 0.51 T = 1410 K 0.4 t = 2.0 s C/O 0.6 t = 1.0 s 1500 1000 0.2 500 0 0 0.2 0.4 0.6 0.8 1 0 ZCHO Fig. 7. Temporal evolution of T (solid curves) and C/O (dash-dot curves) in Z space for flame 5. Figure Captions Fig. 1. Predicted temperatures of flame 10 at 2 s after ignition plotted with respect to two definitions of mixture fraction. Fig. 2. Predicted T, C/O, Z, and χ profiles for flame 10 at 2 s after ignition. Fig. 3. Predicted standard deviation of local temperature plotted with respect to local C/O ratio for flames 1 – 6 and 10 – 17 at 2 s after ignition. Fig. 4. Predicted relationship between T0.51 and χ0.51-1 for flames 1 – 17 at 2 s after ignition. Fig. 5. Predicted relationship between local temperature at C/O = 0.51 and stoichiometric mixture fraction for flames 1 – 17 at 2 s after ignition. Fig. 6. Temperature (solid curves) and C/O profiles (dash-dot curves) in Z space for flames 1 and 17 at 2 s after ignition. Fig. 7. Temporal evolution of T (solid curves) and C/O (dash-dot curves) in Z space for flame 5. 18