chapter 17 - rope rescue lowering and raising systems

advertisement

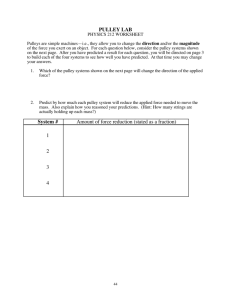

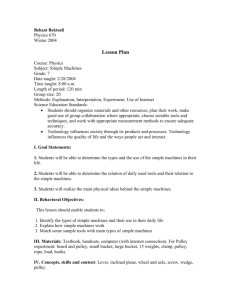

RESCUE SYSTEMS 1 CHAPTER 17 ROPE RESCUE LOWERING AND RAISING SYSTEMS CHAPTER 17 - ROPE RESCUE LOWERING AND RAISING SYSTEMS PULLEY SYSTEMS Many rescue situations require raising a victim from an accident site. To do this requires knowledge of pulley systems so the rescue can be accomplished more safely and easily. By using pulley systems, the rescue team can spread the weight of the load over distance. A 1:1 mechanical advantage means that a 100-pound load that needs to move 10' will take 100 pounds of force and 10' of rope to move 10'. A 2:1 mechanical advantage means it will take 50 pounds of force to move the object, but it will take 20' of rope to move the object 10'. Types of Pulley Systems There are three classes of pulley systems. The Rescue Systems 1 course will work only with simple pulley systems. 1. Simple: A simple system has all its pulleys attached to either the anchor or the load. One end of the rope is tied to the anchor or the load and the rope is reeved through the pulleys. L Figure 17.1 Simple Pulley System 1:1 Odd 2. Compound: A compound system is one simple system pulling on another simple system. L Figure 17.2 Compound Pulley System 4:1 2:1 Pulling on a 2:1 December 2000 - 135 - CHAPTER 17 ROPE RESCUE LOWERING AND RAISING SYSTEMS RESCUE SYSTEMS 1 Complex: A complex system is any system that is a combination of simple and compound systems. Figure 17.3 Complex Pulley System 5:1 RULES FOR DETERMINING MECHANICAL ADVANTAGE There are three basic rules for determining the theoretical mechanical advantage of a simple pulley system. 1. If the rope is tied off to the load, and the first pulley the rope goes through is attached to the anchor, the advantage will be odd (1:1, 3:1, 5:1, etc.). 2. If the rope is tied off to the anchor, and the first pulley is attached to the load, the mechanical advantage will be even (2:1, 4:1, 6:1, etc.). 3. If the last pulley in a system is attached to the anchor, it adds no mechanical advantage. It acts only as a change-of-direction pulley. To determine mechanical advantage, keep rules one through three in mind. Simply count the number of lines between the anchor and the load. Do not count the line if it comes off a change-of-direction pulley. Components Components needed to build a pulley system are: 1. Rescue rope Most pulley systems can be built with 75' or 150' lengths of rope 2. Rescue pulleys 3. Prusiks Hauling prusiks, to grab the rope and pull it into motion Ratchet prusiks, to stop the rope from moving and allow the system to be reset 3. Anchor system - 136 - December 2000 RESCUE SYSTEMS 1 CHAPTER 17 ROPE RESCUE LOWERING AND RAISING SYSTEMS SIMPLE 2:1 PULLEY SYSTEM WITH A CHANGE OF DIRECTION: LADDER RIG This system is used to create lifting capability from anchor points located above the rescue team. It is designed to pull down, toward the load. It is used in conjunction with ladder "A" frames, ladder gins, and other systems where the anchor is above the load. The rope is attached to the anchor, run through a pulley that is attached to the load, and back up to a change of direction pulley attached to the anchor. This rig takes a rescue rope, two carabiners, and two pulleys. It should be operated with a belay line and generally is used for short distance hauling. 2:1 Mechanical Advantage Figure 17.4 Ladder Rig The actual mechanical advantage is less than 2:1 because of friction in the pulleys, rope abrasion, etc. The mechanical advantage referred to in any system is the theoretical mechanical advantage, and you should always assume that the actual mechanical advantage attained is going to be less in field situations. December 2000 - 137 - CHAPTER 17 ROPE RESCUE LOWERING AND RAISING SYSTEMS RESCUE SYSTEMS 1 SIMPLE 3:1 PULLEY SYSTEM: PIG RIG This system is built in the same manner as the ladder rig but is used differently. It is designed to be used horizontally rather than vertically. By attaching the rope to the load, then running it through a pulley that is attached to the anchor, then back to a pulley attached to the load, the mechanical advantage becomes 3:1. The pull will be away from the load. This system lends itself to being attached to another rescue line with a hauling prusik. By hauling on the pig rig, the load attached to the other line is raised with a 3:1 mechanical advantage. Pig Rig Load 3:1 Mechanical Advantage Main Line Figure 17.5 Pig Rig Pig rig is short for piggyback rig. Any system, such as a pulley system, which is attached onto another system, such as a lowering system, creates a piggyback system. The two together are the piggyback system, while the pulley system used to create it is simply called the pig rig. - 138 - December 2000 RESCUE SYSTEMS 1 CHAPTER 17 ROPE RESCUE LOWERING AND RAISING SYSTEMS SIMPLE 3:1 Z-RIG PULLEY SYSTEM A 3:1 Z-Rig takes a rescue rope, two pulleys, and two prusiks to build. The rope is attached to a load and run through a pulley that is attached to an anchor. The rope is then run back toward the load and runs through a pulley that is attached to the rope with a hauling prusik as close to the load as possible. (In most cliff rescue situations, this will be the edge of the cliff where the rope goes over.) The hauling force is away from the load. This system requires a ratchet prusik located on the load side of the pulley that is attached to the anchor. This ratchet grabs the rope and will not let the load drop back down if the haulers should slip, or if any other component should fail. It also allows the forward hauling prusik and pulley to be reset further down the rope (toward the load) as the load is raised. Load 3:1 Mechanical Advantage Main Line Figure 17.6 Z-Rig December 2000 - 139 - CHAPTER 17 ROPE RESCUE LOWERING AND RAISING SYSTEMS Anchor RESCUE SYSTEMS 1 Anchor Attach ratchet prusik and directional change pulley to main line. Load Load (1) (1) Anchor Anchor Four Bars Used For Friction w/Single Person Load Release main line from rack & transfer load to ratchet prusik Single Person Load Load (2) Anchor (2) Anchor Lock Off Rack When Lowering Is Complete Attach haul prusik & mechanical advantage pulley to main line Load Figure 17.7 RPM Lower - 140 - Load (3) Figure 17.8 Change Over (No Change of Direction) (3) December 2000