USLI2011Proposal 1 - Laulima

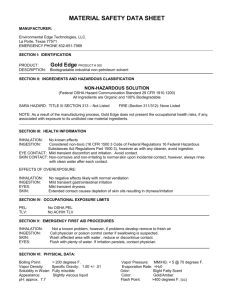

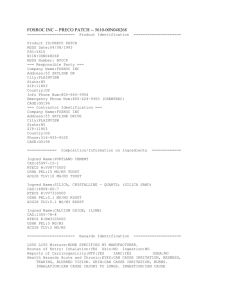

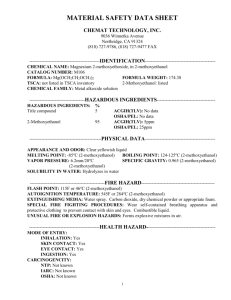

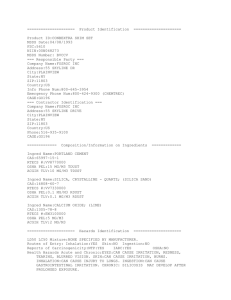

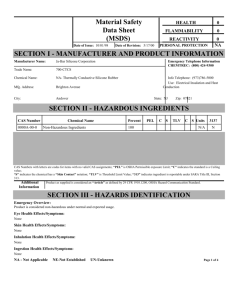

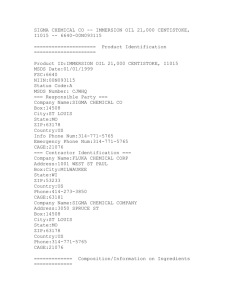

advertisement