Section 15010 Mechanical Provisions

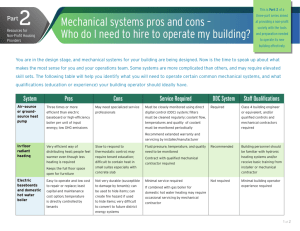

advertisement