optimal use of waste in biofuel developement

advertisement

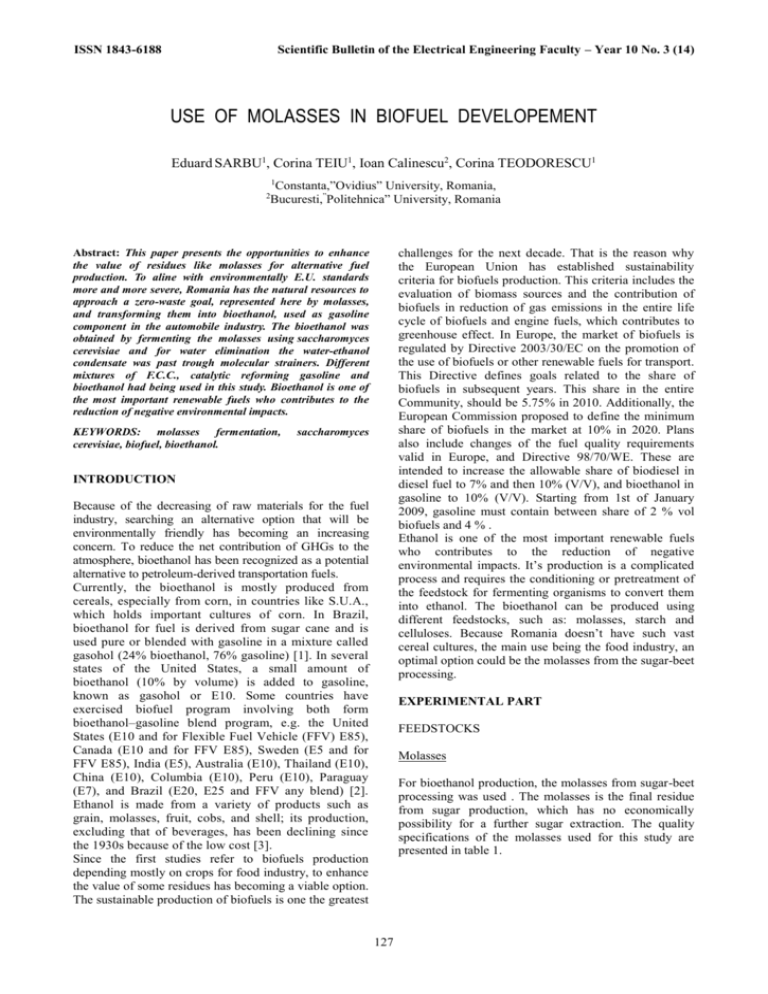

Scientific Bulletin of the Electrical Engineering Faculty – Year 10 No. 3 (14) ISSN 1843-6188 USE OF MOLASSES IN BIOFUEL DEVELOPEMENT Eduard SARBU1, Corina TEIU1, Ioan Calinescu2, Corina TEODORESCU1 1 Constanta,”Ovidius” University, Romania, Bucuresti,”Politehnica” University, Romania 2 challenges for the next decade. That is the reason why the European Union has established sustainability criteria for biofuels production. This criteria includes the evaluation of biomass sources and the contribution of biofuels in reduction of gas emissions in the entire life cycle of biofuels and engine fuels, which contributes to greenhouse effect. In Europe, the market of biofuels is regulated by Directive 2003/30/EC on the promotion of the use of biofuels or other renewable fuels for transport. This Directive defines goals related to the share of biofuels in subsequent years. This share in the entire Community, should be 5.75% in 2010. Additionally, the European Commission proposed to define the minimum share of biofuels in the market at 10% in 2020. Plans also include changes of the fuel quality requirements valid in Europe, and Directive 98/70/WE. These are intended to increase the allowable share of biodiesel in diesel fuel to 7% and then 10% (V/V), and bioethanol in gasoline to 10% (V/V). Starting from 1st of January 2009, gasoline must contain between share of 2 % vol biofuels and 4 % . Ethanol is one of the most important renewable fuels who contributes to the reduction of negative environmental impacts. It’s production is a complicated process and requires the conditioning or pretreatment of the feedstock for fermenting organisms to convert them into ethanol. The bioethanol can be produced using different feedstocks, such as: molasses, starch and celluloses. Because Romania doesn’t have such vast cereal cultures, the main use being the food industry, an optimal option could be the molasses from the sugar-beet processing. Abstract: This paper presents the opportunities to enhance the value of residues like molasses for alternative fuel production. To aline with environmentally E.U. standards more and more severe, Romania has the natural resources to approach a zero-waste goal, represented here by molasses, and transforming them into bioethanol, used as gasoline component in the automobile industry. The bioethanol was obtained by fermenting the molasses using saccharomyces cerevisiae and for water elimination the water-ethanol condensate was past trough molecular strainers. Different mixtures of F.C.C., catalytic reforming gasoline and bioethanol had being used in this study. Bioethanol is one of the most important renewable fuels who contributes to the reduction of negative environmental impacts. KEYWORDS: molasses fermentation, cerevisiae, biofuel, bioethanol. saccharomyces INTRODUCTION Because of the decreasing of raw materials for the fuel industry, searching an alternative option that will be environmentally friendly has becoming an increasing concern. To reduce the net contribution of GHGs to the atmosphere, bioethanol has been recognized as a potential alternative to petroleum-derived transportation fuels. Currently, the bioethanol is mostly produced from cereals, especially from corn, in countries like S.U.A., which holds important cultures of corn. In Brazil, bioethanol for fuel is derived from sugar cane and is used pure or blended with gasoline in a mixture called gasohol (24% bioethanol, 76% gasoline) [1]. In several states of the United States, a small amount of bioethanol (10% by volume) is added to gasoline, known as gasohol or E10. Some countries have exercised biofuel program involving both form bioethanol–gasoline blend program, e.g. the United States (E10 and for Flexible Fuel Vehicle (FFV) E85), Canada (E10 and for FFV E85), Sweden (E5 and for FFV E85), India (E5), Australia (E10), Thailand (E10), China (E10), Columbia (E10), Peru (E10), Paraguay (E7), and Brazil (E20, E25 and FFV any blend) [2]. Ethanol is made from a variety of products such as grain, molasses, fruit, cobs, and shell; its production, excluding that of beverages, has been declining since the 1930s because of the low cost [3]. Since the first studies refer to biofuels production depending mostly on crops for food industry, to enhance the value of some residues has becoming a viable option. The sustainable production of biofuels is one the greatest EXPERIMENTAL PART FEEDSTOCKS Molasses For bioethanol production, the molasses from sugar-beet processing was used . The molasses is the final residue from sugar production, which has no economically possibility for a further sugar extraction. The quality specifications of the molasses used for this study are presented in table 1. 127 Scientific Bulletin of the Electrical Engineering Faculty – Year 10 No. 3 (14) Molasses from sugar-beet Quality Experimental specifications Data 20-25 22 75-80 78 44-52 51 Compound Water, % Dry matter, % Total sugar, % Inverted sugar , % Rafinosses, % Total nitrogen, % Mineral matter, % pH STAS Analyses (% vaporized) 0 10 20 30 40 0.1-0.5 0.3 0.6-1.8 1.2-2.4 1 2.1 7.6-12.3 10.4 6.0-8.6 6.5 ISSN 1843-6188 Table 1. The chemical composition of the molasses from sugar-beet Gasoline components from FCC and CR (platforming) plants In tables 2 4 are presented the properties of the gasoline components used for this study. The CR gasoline has a high initial boiling point, 50 °C (Table 2), which creates problems when starting the engine, specially in the winter. The main properties of the gasoline components are described in table 3. CC Gasoline (0C) CR Gasoline (0C) 34 55 57 65 71 50 100 108 113 119 50 60 70 80 90 95 91 110 130 150 171 - 124 130 138 147 158 168 Table 2. STAS Analyses CC Gasoline CR Gasoline Test Method 0.726 0.806 ASTM D 129899(05) RON MON Benzene Content (%) 93.7 82.6 0 96 85.5 0.9 Sulfur Content (ppm) 15 2 Vapour Pressure (Kpa) Karl- Fischer Water (ppm) Aromatics (%) Copper strip corrosion rating ( 3hrs, 500C) 78.44 67.92 120 160 25 64 SR EN ISO 5164:06 SR EN ISO 5163:06 SR EN 14517-05 SR EN ISO 2084604 SR EN 13016-1:01 SR EN 50081-1 01.92 SR EN 14517-05 1a 1a SR EN ISO 2160-03 Properties Density d1515 Saccharomyces cerevisiae Table 3 Characterization of gasoline components The molasses fermentation process is described in figure 1. THE TECHNOLOGICAL PROCESS OF BIOETHANOL PRODUCTION FROM MOLASSES The process takes place in two steps: Molasses fermentation process The anaerobic fermentation of molasses was made by saccharomyces cerevisiae at laboratory scale, in a 5 dm3 reactor, with a heating device for temperature control. The time for the fermentation process was 72 hrs at a constant temperature of 38 °C. The CO2 effluent generated in reaction was cooled for condensing the bioethanol vapors, preventing the lost by evaporation. The bioethanol quantity has been calculated according to the following reaction: C6H12O6 Figure 1 . The fermentation process using a discontinuous reactor 2 C2H5OH + 2 CO2 128 ISSN 1843-6188 Scientific Bulletin of the Electrical Engineering Faculty – Year 10 No. 3 (14) 1) fermentation reactor;2) heating device;3) cooler;4) thermocouple. The bioethanol recovery by distillation and water elimination When the fermentation was complete the mixture has been distillated for the bioethanol recovery. It was used a distillation column with glass rings filling and a height of 110 cm, heated all along its height. The heating was realized to maintain the vapour temperature, to avoid the precocious condensation of the vapors, before leaving the column. Product Density d1515 Water Content (%) Acidity (acetic acid % m/m) pH Test Method ASTM D4052 ASTM E203 ASTM D1613 pH paper Bioethanol 0.795 0.5 0.0015 6.5 RON SR EN ISO 5164:06 108 Table 4. Properties of the bioethanol obtained ACHIEVING OPTIMAL MOTOR GASOLINE BLEND Bioethanol is appropriate for the mixed fuel in the gasoline engine because of its high octane number [4]. Before making the blends, it was studied mathematically, based on properties of different components, witch are the optimal proportions of each component in the blends. Thus, it was decided to study 3 of those mixtures, the proportions of each compound are presented in table 5. 5 Blend 2 (10% bioethanol) 10 Blend (15% bioethanol) 15 40 37.5 35 45 42.5 40 3 7 3 7 3 7 Blend 1 (5% bioethanol) Compound Bioethanol (%) CR Gasoline (%) CC Gasoline (%) Iso C5 (%) Figure 2. The distillation and water elimination ETBE (%) process Table 5. The making of the three types of auto gasoline 1) boiling vessel;2) heating device;3) distillation column with glass rings filling and heating system;4) thermal insulation;5) thermometer;6) coolers;7) collecting vessel;8) molecular strains;9) CaCl2; ICW = input cooling water; OCW = output cooling water. The mixture’s distillation was made with a strictly temperature control to restrict water vaporization together with bioethanol. The water-ethanol condensate was past trough a molecular strainer layer and collected in a container in the presence of CaCl2 for water adsorption as air humidity. For a better efficiency in water adsorption, the bioethanol was past trough a second step for obtaining an anhydrous product, using a new layer of molecular strainer. The distillation and water removing are described in figure 2. RESULTS AND DISCUSSIONS The fermentation process needs the following the quantities of the input compounds witch are presented in table 6. Compounds Molasses C6H12O6 (glucose+fructose) C2H5OH Water Thus, the bioethanol was produced and used for the studied mixtures. Molecular weight (g/mol) 180 Quantity (g) 1000 510 46 18 3000 Table 6. Quantities of the input compounds The properties are described in table 4. The theoretical amount of bioethanol that can be gained through the fermentation process is given by relation (1): Tq 129 mC6 H 12O6 g MC 2 H 5 OH g / mol (1) MC 6 H 12O6 g / mol 3 Scientific Bulletin of the Electrical Engineering Faculty – Year 10 No. 3 (14) Tq The analyses made according to European standards for fuel quality (SR EN 228:2008) are presented in the next tables. 510 2 46 260.66 g 180 Compound Bioethanol (theoretical- Tq) Bioethanol (experimental- Eq) In the process of fermentation, followed by the distillation and the water elimination, 159 g bioethanol had resulted; of witch 0.5% represents the amount of water remaining in bioethanol. In conclusion, the pure bioethanol quantity is Eq =158.21 g. The yield of the process (fermentation plus distillation) is given by the relation (2). ISSN 1843-6188 Eq 158.21 100 100 60.70% Tq 260.66 Quantity (g) 260.66 158.21 Yield 60.70 % Table 7. The fermentation process yield Once the bioethanol, ETBE and i-C5 were added, the final blends had improved their behavior at reference temperature distillation. From the analyses of the 3 final blends, presented in table 8, the density, RON and MON are directly related to the increasing content of bioethanol. The content of the aromatics and olefins are in inverse ratio to bioethanol. (2) In the following table are presented the results of the fermentation process, the theoretical and experimental ethanol in order to present the reaction yield. Blend 1 Blend 2 (10% Properties (5% bioethanol) bioethanol) Blend 3 (15% bioethanol) Test method 0.7622 0.7648 0.7665 ASTM D 129899(05) RON 98.4 99.5 100.7 SR EN ISO 5164:06 MON 86.1 86.6 87.2 SR EN ISO 5163:06 Benzene content (%) 0.77 0.65 0.67 SR EN 14517-05 Sulfur content (ppm) 8.3 8.5 8.5 Water content (ppm) 180 220 275 Aromatics (%) 34.2 33.3 32.9 Olefins (%) 4 1.5 1.3 Copper strip corrosion rating ( 3hrs, 500C) 1a 1a 1a Density d1515 Table 8. Characterization of the blends: 130 SR EN ISO 20846-04 SR EN 50081-1 01.92 SR EN 14517-05 SR EN ISO 216003 Scientific Bulletin of the Electrical Engineering Faculty – Year 10 No. 3 (14) ISSN 1843-6188 The evolution of research octanic number with the increasing bioethanol content is represented in figure3. R ON 102 100.7 99.5 100 98.4 98 96 96 94 93.7 92 90 CC g a s oline 5 % bioetha nol 15 % bioetha nol Figure 3. Research octanic number related to bioethanol content [2] Kadiman OK. Crops: beyond foods. In: Proceedings of the 1st international conference of crop security, Malang, Indonesia, September 20–23, 2005. [3] Akpan UG, Kovo AS, Abdullahi M, Ijah JJ. The production of ethanol from maize cobs and groundnut shells. AU J Technol 2005;9:106–10. [4] Kim H, Choi B, Park S, Kim YK. Engine performance and emission characteristics of CRDI diesel engine equipped with the WCC and the DOC. Using ethanol blended diesel fuel. [5] Rothman H, Greenshields R, Calle FR. The alcohol economy: fuel ethanol and the Brazilian experience. London: Francis Printer; 1983. [6] Balat M. Current alternative engine fuels. Energy Sources 2005;27:569–77. [7] Hansen AC, Zhang Q, Lyne PWL. Ethanol–diesel fuel blends—a review. Bioresource Technol 2005;96:277–85. [8] Pimentel D. Ethanol fuels: energy balance, economics, and environmental impacts are negative. Natural Resources Res 2003;12:127–34. [9] Balat M. Global bio-fuel processing and production trends. Energy Explor Exploit 2007;25:195–218. [10] MacLean HL, Lave LB. Evaluating automobile fuel/propulsion system technologies. Prog Ener Combust Sci 2003;29:1–69. In: Proceedings of the 15th international symposia on alcohol fuels (ISAF XV), San Diego, September 26–28, 2005. CONCLUSIONS The bioethanol can be produced using molasses as a raw material, the process having two advantages: 1) the processing of waste, which has a positive environmental impact;2) the production of bioethanol, an important fuel component of the future. According to 614/2009 Ordin published in The Official Gazette, Romania has 104688.8 tons of sugar as a total production for 2009-2010. Because the molasses represents~1/3 of the sugar, this means that 34896.3 tons of molasses will be produced every year. In accordance of a study of Petro World taken by Energy Business Review, in 2008 Romania had a 1.6 mil tons of gasoline consumption. If we can introduce a maximum 5 % bioethanol (SR EN 228:2008) we will be needing ~ 80000 tons of bioethanol and so, a fourth of this quantity may be supplied by using molasses as raw material. The blends using bioethanol have good qualities and can be used as commercial fuels for the automobile industry. REFERENCES [1] Oliveria MED, Vaughan BE, Rykiel Jr EJ. Ethanol as fuel: energy, carbon dioxide balances, and ecological footprint. BioScience 2005;55:593–602. 131