6.3.1 Heavy-liquid bubble chamber for WIMP detection

Low background Screening and Prototyping Facility at the Soudan Underground Mine.

4.1

L. Baudis

1

D. Bauer

2

, J. Beaty

3

, G. Bengtson

4

, J. Collar

5

, P. Cushman

3

,

J. Davis

4

, D. Demuth

6

, L. Duong

3

, R. Gaitskell

7

, D. Hestetune

4

, A. Lu

8

, M. Marshak

3

,

J. Meier 3 , C. Michael 4 , W. Miller 3 , H.Nelson

9 , E. Peterson 3 , J. Reeves 10 , A. Reisetter 3 ,

R. Schnee

11

, T. Shutt

12

, A. Sonnesheim

5

1 University of Florida, 2 Fermilab, 3 University of Minnesota-Twin Cities, 4 Short Elliot

Hendrickson Engineers,

5

University of Chicago,

6

University of Minnesota-Crookston,

7

Brown University,

8

U.C. Berkeley,

9

U.C. Santa Barbara,

10

Reeves & Sons, LLC.,

11

Case Western Reserve University, 13 Princeton University

Table of Contents

1.

Project Summary

2.

NUSEL

3.

Overview of Low Background Counting

3.1 Introduction

3.2 Gamma counting

3.3 Alpha and Beta Counting

3.4 Prototype NUSEL screening

4.

The Soudan Underground Laboratory

5.

The Low Background Counting Facility

5.1 Overview

5.2 Active Veto Shield

5.4 Veto Shield DAQ

5.4 Water Tank

5.5 Purification System

5.6 Shielded Multi-purpose Room

5.7 Radon Reduction

5.8 Copper Electroforming

5.9 High Purity Germanium Detectors

5.10 Beta Cage

5.11 Cloud Chamber

6. Scientific Program

6.1 Gamma Screening

6.2 Beta and Alpha Screening

6.3 Staging new Prototype Experiments

6.3.1 Heavy-liquid bubble chamber for WIMP detection

6.3.2 Liquid Xenon Dark Matter Prototype Experiment: XENON

7. Management

8. Outside Users

9. Timeline

1. Project Summary

By capitalizing on the active veto shield and experimental hall of the Soudan2 detector, screening instruments of unparalleled sensitivity to low level radiation can be established at the Soudan Underground Mine at a modest additional investment. This would serve several purposes:

1) Provide alpha, beta and gamma screening of materials on a rapid timescale for current

users in the underground science community (e.g. Majorana, CDMS, XENON,

ZEPLIN...) as well as the larger community (geomicrobiology, semiconductor

industry, homeland security, public health and environmental monitoring)

2) Test and participate in developing a new counting instrument that advances the current

technology for alpha and beta screening (either a cloud chamber or a wire chamber)

that is immediately useful for the CDMS II detectors and their upgrades.

3) Provide experimental facilities with deep characteristics (via active muon and

passive neutron shielding) for prototype tests of the next generation dark matter,

double beta decay and proton decay experiments using novel technologies such as

liquid noble gas and liquid bubble chamber technology.

4) Advance the techniques of low background screening and shielding for the next

generation NUSEL facility.

The removal of the Soudan2 Proton Decay detector will immediately free up considerable real estate in a detector hall of dimensions 40 ft x 30 ft x 235 ft, located at a depth of

2090 mwe. An active muon shield encloses 100 ft of the hall with muon rejection efficiency of 99.5 % on the ceiling and walls, and 95% from the floor where structural supports interfere, producing a volume that is at effectively twice the Soudan depth with respect to the residual muon rate. The shield is in working order, but requires an upgrade to the readout system.

Additional passive shielding is needed for neutrons and gammas from both cavern radioactivity and muon interactions in the cavern rock. We will build a unique large purified water shield into which detectors are lowered. The background will be limited only by water purity, and thus will provide a lower background environment than standard Pb and plastic shielding. This will provide as much as 4 meters of shielding in the center of the tank, reducing the high energy neutron flux by two orders of magnitude.

It will eliminate the need for expensive lead (including ancient lead) shielding around the instruments. A clean room will be assembled on top of the tank with an adjoining mezzanine for assembly and staging. The beta and new gamma screener will be installed in the tank with access from the tank clean room. There will also be room for cubic meter size experiments to be lowered into the tank.

A clean room will also be built adjacent to the tank on the main floor. Since the water tank already provides excellent shielding from the south wall, a set of shielded bays will be located at its base, inside the clean room coverage. This room will serve as an experimental area for prototypes which require deep underground environments, reducing or eliminating their need for expensive shielding. Since we will tailor the bays to the immediate needs of the incoming experiments, we expect that much of the additional shielding will be provided by the experiments themselves.

Existing 7.5-ton crane coverage will be used to construct the tank, the shielding bays, and mezzanine. In addition to the prefab clean rooms, sample preparation, storage facilities, and radon reduction must be put in place, in order to keep particulate and airborne sources below the newly-established background levels. An existing surface building provides remote computer access to the underground experiments and additional space for offices, storage and preparation for users.

The CDMS II experiment requires immediate use of a beta screening instrument for the solid state dark matter detectors, in order to measure backgrounds in existing detectors and improve the fabrication process for new detectors. Two devices for beta screening are under consideration: a drift chamber referred to as a beta cage, and a cloud chamber. The new beta cage design is a neon drift-chamber with multi-wire proportional readout.

Samples are placed directly in the gas. A set of trigger grids directly above the sample surface tags events that originate at the sample. A drift region beyond this is read out by a set of wire readout grids at the top of the chamber. Crossed grids will be used for x-y position determination, and timing can be used to determine the spatial profile of the track in the z dimension. A cloud chamber technology is also being developed because it is a continuously sensitive volume and provides detailed tracking information. The principal obstacles in the cloud chamber involve long term stability of the device.

A gamma screening facility using two HP Ge detectors is already operating at Soudan. It is being used to screen materials used for the Majorana and CDMS II experiments. There is significant backlog on this program as well as additional demand from other users for gamma spectra counting facilities, and so we propose increasing the facility by 2 additional detectors. In addition, users will be able to install their own screening instruments (e.g. alpha counting or NAA) as desired in the multi-purpose clean room, and utilize the shielding and infrastructure provided.

Ultrapure copper is required for shielding the lowest background counting stations, for building water enclosures, for the Xenon cryostat and for CDMS III shielding needs. Yet the radiopurity of copper is limited by radionuclides produced by cosmic-ray induced interactions above ground. We will therefore house a station for electroforming copper underground in order to produce our own supply of ultrapure copper.

2. NUSEL

Underground science is a multidisciplinary field of scientific and technological studies. It comprises both the study of the underground environment itself which covers geology, rock mechanics, geophysics, geochemistry, geohydrology and geomicrobiology, as well as utilizing the unique properties of the underground environment to probe for extremely rare events: experiments which search for dark matter, nucleon decay, or neutrino-less double beta decays, and experiments which measure neutrino properties.

Although there are opportunities for significant progress in basic and applied underground science, the US now trails the world in the number of facilities where such science can take place, with only Soudan and WIPP (Waste Isolation Pilot Plant) in operation. Since the beginning of 2001, at least five panels and committees have recommended the establishment of a National Underground Science and Engineering

Laboratory (NUSEL) to address this lack, but the timescale for site selection and actual funding continues to slip. Thus it is important to realize that progress in underground science can only be made by utilizing our existing resources in the most efficient manner.

We are therefore proposing to begin work on an identifiable NUSEL component immediately by housing it an existing US underground lab and building a prototype that will advance the state of the facility technology while serving a variety of near-term physics goals, such as improving the sensitivity reach of the ongoing Cryogenic Dark

Matter Search, deep site characterization and first physics run of the XENON prototype, and developing bubble chamber technology for dark matter searches.

Every NUSEL proposal includes a state-of-the-art low background counting facility

1,2

. It is impossible to achieve the full benefit of the large overburden which eliminates cosmic ray-induced backgrounds, without eliminating natural, manmade, and cosmogenic activities which may also contribute to the detector background and interfere with the physics measurement. A screening facility to identify and provide quality control in low activity materials for detector fabrication is essential to the success of the next generation of dark matter searcher, solar neutrino and double beta-decay experiments. An on-site, underground electroforming facility, which is being developed in collaboration with two successful SBIR’s (Reeves & Sons, Inc), will both improve the screening instrumentation itself by providing cost-effective ultra-pure components, as well as producing clean shielding for experimental prototypes.

Such a facility can also serve a multitude of needs outside the nuclear and astro-particle physics community, such as monitoring trace radioactive elements in the environment, serving nuclear nonproliferation needs, and aiding in the manufacture of commercial ultrapure materials. It is expected that once such a facility is in operation, the costs can be recouped by fees from a broad consortium of users. The last section of this proposal contains a first step toward identifying actual users. Their interest is indicated by their letters of support.

3. Overview of Low Background Counting

3.1 Introduction

In the US, Lawrence Berkeley National Laboratory operates an underground counting lab inside the Oroville dam. This facility is now more than 15 years old, and it is not clear how to modernize it in order to reduce the background further. Pacific Northwest

National Laboratory has operated Ge detectors in various underground locations and some university groups and national laboratories perform low background counting either above ground or at very shallow sites

3

. What is lacking is a coordinated program giving access to the broader scientific community. This immediate need would be addressed by the conversion of the old Soudan2 cavern into a multi-user facility, along with developing a web-accessible database with inter-site scheduling functionality. The addition of onsite neutron and gamma shielding, combined with the existing active muon shield, upgrades the moderately deep Soudan site into a facility with deep counting characteristics, unique in the United States. In order to do deep-site counting now, groups must go overseas. Often this is not a viable option for the security-related applications. Although NUSEL will eventually address this issue, the need for additional sites is immediate. A staged approach to the final NUSEL background facility will open up badly needed screening options on a short time scale, as well as give the community experience in setting up such facilities with a view towards improving their design in a final NUSEL proposal.

The new generation of experiments will require material testing which is a factor 100 or even 10000 more sensitive than what can be done with existing Ge detectors. The construction of what may be termed a ``next generation'' counting facility, utilizing large plastic scintillators shielded by a water tank or a large liquid scintillation detector modeled on the Borexino collaboration's Counting Test Facility at Gran Sasso, could serve these needs. The Soudan facility would provide a first step toward understanding how to build the final facility by employing some of the same techniques as an R&D project, while actually serving the counting needs of several immediate users. We therefore propose to dedicate one of the ports in the water tank to a liquid scintillator lined acrylic box read out by low-activity MRS APD’s. It will monitor the neutron background inside the tank as well as samples placed within. The box can move the length of the tank in order to measure the gradient of the neutron flux.

3.2 Gamma counting

Low background gamma ray spectroscopy using Ge semiconductor detectors is a welldeveloped and mature technology which has served as the prime tool for material selection. Sensitivities down to a few hundred ppt of U and Th are routinely achieved using commercially available detectors

4

. The outstanding energy resolution gives these detectors high diagnostic power. This makes them an excellent choice for counting applications where radioisotope identification is important. All current generation solar

neutrino, dark matter and double beta decay experiments have been relying heavily on this detection technique.

5,6

High sample through-put (equivalent to the availability of multiple counting stations) and good diagnostic power are needed to fulfill this task.

Currently we are operating two high purity Ge detectors in a conventional lead shield with nitrogen purge behind the MINOS detector. As is the experience of all who put together these systems, the need far outstrips the capacity. Both CDMS and Majorana screening needs are now seriously backlogged and screening of photodetectors and chamber materials for the XENON prototype are also waiting for slots. We propose to enhance the existing capacity with the addition of two more detectors as well as eventually improving the background capability of the existing set of two Ge detectors by moving them under the muon shield. We expect that the new Ge detectors will be able to probe the few ppt domain and at least one will reside within the water shield.

3.3 Alpha and Beta Counting

Compared to gamma screening, techniques for low background counting of betas are not as well developed. Thus, experiments that require screening for alpha, beta or x-ray emission that is not accompanied by gamma emission are not well served. Low energy x rays are a background for many types of low-background experiments, especially solar neutrino projects. Assaying materials for low-energy x-ray emission in order to eliminate such activities or to quantify the effect is required. Another example is identification of

210

Pb contamination.

210

Pb and its progeny do not have a penetrating radioactivity signature. Since Pb is often used in circuitry and alpha activity within the Pb can create difficulties for the circuit, there is a need to search for samples of Pb that are low in

210

Pb.

210

Po will eventually result from any

210

Pb contamination, and its alpha decay can cause single-site upsets in any circuit that contains the host Pb.

The dominant internal background in CDMS comes from low energy betas from surface contaminants such as potassium or carbon. Inefficient charge collection produces an ionization signature that resembles that of the potential WIMP signal. Screening of the detectors would provide information to improve fabrication of the next generation of cryogenic silicon and germanium detectors, as well as to understand the background of the existing towers. Thus, beta screening is a high priority item for CDMS, and efforts have already produced two possible technologies which we would like to pursue and which would eventually be located at Soudan to serve CDMS and other users. The wire chamber beta cage design has been separately proposed by Tom Shutt (CWRU) and

Steve Elliot (Los Alamos). We will seek other funding for its development in collaboration with the above institutions as well as Caltech. The shielding is provided by the water tank and would not have to be separately procured. It is important to note that the cost of conventional lead/poly shielding appropriate for the beta cage turned out to be comparable to the total water tank cost, yet the water tank will serve more than just one screener or experiment. A second, large-volume multi-wire device for atmospheric samples will be designed using the experience gained from the smaller instruments. This screening device will most likely remain in one of the shielded bays. The cloud chamber technology is being pursued by Harry Nelson (UCSB) and Priscilla Cushman

(Minnesota), possibly as an SBIR with Jeff Radtke of Supersaturated Environments, Inc.

3.4 Prototype NUSEL Screening

The next generation low background experiments (solar neutrino, dark matter and double beta decay) will need to reach background levels that are far below what can be screened for even in the best Ge counters. To achieve these levels a variety of screening techniques will be employed, including specialized use of "chemical" methods such as mass spectrometry and NAA to check for certain radioactive isotopes. These techniques, while powerful, do not provide an ultimate check on the total activity from all isotopes in the material, including short-lived isotopes which are essentially impossible to detect chemically.

An advanced direct counting screening technique with orders of magnitude improvement sensitivity would therefore be extremely important for essentially all next-generation low background experiments. For the case of experiments based largely or purely on advances on material purity, such screening would play an essential enabling role. We propose to begin development work on one of the ideas presented at the Conference on

Underground Science. We propose that one of the detectors which would be available to lower into the tank would be an acrylic sample box lined with liquid scintillator. Light guides, which also are the structural support for the sample box, direct light to external

PMTs. For a sample volume is 0.5 sq meters, the estimated sensitivity, for a plastic, is better than 1 ppt U and Th. This scheme has the advantages of low cost, 1-2 order of magnitude sensitivity improvement over current Ge counters, and large sample volume.

4. The Soudan Underground Laboratory

The University of Minnesota has operated the Soudan Laboratory in northeastern

Minnesota since 1980. At the mine, science is a symbiotic activity with a State Park, which hosts about 40,000 visitors a year for both its historic and science tours.

Minnesota State Parks has maintained access to the mine for historic tours since 1962 and added the science tours in 2001. The underground complex of the Soudan Laboratory currently consists of two fully-equipped laboratories at a depth of 710 m. One laboratory

(15m x 15m x 70m ) houses the Cryogenic Dark Matter Search (CDMS II) and the decommissioned Soudan 2 Proton Decay Detector. The adjacent laboratory (15m x 16 m x 90m ) contains the 5,500 tonne MINOS Far Detector for the Neutrinos at the Main

Injector (NUMI) Oscillation Search and a small gamma screening facility for Majorana and CDMS. In addition to the experimental offices and counting rooms, there is a 2-story office complex at one end of the CDMS II hall which houses the lunch room, conference facilities and the computer networking infrastructure. A second-floor visitors’ gallery lines the edge of the MINOS hall, with MINOS and lab management offices off the gallery. There is a machine shop, welding facilities, detector assembly and storage areas.

Both halls have 7.5 ton crane coverage

Figure 1. The Cavern Layout of the Soudan Underground Science Laboratory.

There is an existing 640 m

2

Soudan Surface Building, which has been serving as a receiving facility and warehouse for MINOS. On the mezzanine level it now also houses the remote counting room and computing farm for the CDMS II experiment, with a direct fiber link to the underground laboratory. This under-utilized space can easily be converted into sample storage and preparation areas or to provide remote access to underground experiments for new users of the counting facility.

5. Low Background Counting Facility

5.1 Overview

The southernmost 35 m of the Soudan2 cavern are encased in a 1700 m

2

working muon veto shield. The kiloton Soudan2 proton decay experiment is a modular steel/drift tube array which presently occupies the central space. Catwalks to the east and west, and a northern mezzanine provide access to the muon shield electronics. The removal of this detector would take several months at the cost of up to $100k. Due to the soaring steel prices, this cost will be recovered or exceeded by selling it for scrap. This would leave a

4300 m 3 room at 2080 mwe with full muon veto coverage. A modest investment in infrastructure would provide a new venue for a host of experiments and screening instruments which service existing and future experiments as well as ongoing research programs in other disciplines.

A cross section of the existing cavern is shown in figure 2. Steel I-beams support the proton decay experiment a meter above the muon shield with a crawl space below for repair and replacement. Since the floor muon shield is less efficient due to penetrations by the structure, prone to damage by any new construction, and hard to repair, the decision was taken to remove tubes from the floor to free up another 5’ of vertical space for the tank and prototyping space. These tubes are in good condition and could be placed near the roof as the second coincidence plane. All proposed clean rooms and structures will fit within the existing cavern structure with 4 ft clearance on all sides to maintain access to the muon shield and to satisfy safety requirements. The height is constrained by access to the shield and air handling systems. The 7.5 ton crane adds another meter to the required clearance. Removing the last set of overhead air ducts will not affect air ciculation. This, plus restricting crane access to certain parts of the cavern, can give us a maximum of 30 ft of vertical extension.

Figure 2. Cross section of the Soudan2 Cavern with intact proton decay calorimeter

Figure 3. The proposed plan and elevation of the Low Background Facility

A 28 ft diameter, 19 ft deep stainless steel water tank will be constructed underground by a commercial water storage tank manufacturer. This tank will be located at the southern end of the cavern. It will provide the best shielding for low background screening applications as well as a proving ground for the next generation facility at NUSEL. A purification system will recirculate water originally brought down from the surface in specially-designed containers. The water collected at the 23 rd

and 27 th

level has percolated through rock. Although it appears clean and sediment could easily be removed, it is most likely contaminated with trace radioactive elements from the surrounding rock. Tests at SNOLab will be conducted, but it is likely that we will need to transport surface water. The containers will travel down by hoist and be emptied to a holding tank during the fill procedure. A clean room plus anteroom will be constructed over the tank. Three slots with movable covers and a portable 1.5 ton internal lowering crane will be installed inside the clean room. In order to maximize the height of tank and accompanying clean room, outside crane coverage will not be extended over the top of the clean room.

Next to the tank is an experimental hall which consists of a clean room surrounded by a passive neutron shield. The shield material will be determined by the members of this collaboration after proper evaluation and sample counting. Since the clean room is installed first, the sample evaluation might take place in the room itself using one of the screening instruments described below. Candidates are plastic extrusions with recirculated purified water, sealed water-filled plastic tanks, and commercial plastic composite lumber. – electroformed copper only if we get a company involved who also wants to install electroforming underground - . This multipurpose room will be used to

test prototype dark matter experiments/technology. It will also house additional HPGe detectors for gamma screening. Testing of the prototype beta cage will take place here, as well as its final installation as a user-oriented beta and alpha screener.

5.2 Active Veto Shield

Most of the veto shield is made of extruded aluminum proportional tube modules

7

filled with 95-5 Ar-CO

2 at 1.12 bar. The module cross section is a honeycomb pattern of hexagonal cells arranged in two 4-cell interlocking layers. The overall thickness of the module is 9.5 cm with thin (2.2 mm) tube walls. The modules range in length from 6.6 to

7.9 m. Each tube has one 60 um sense wire running down the middle, operated at 2.4 kV with a maximum drift length of 2.5 cm. Each set of 4 cells is ganged together in readout to form an element 0.18 m wide and approximately 7 m long.

The wall modules are hung from a steel framework supported by bolts inserted into the rock walls and lie within 0.5 m of the rock. The 9.5 x 31 m 2 east and west walls are each constructed from four panels of modules mounted horizontally. The gaps between the panels, required for electrical and gas connections, are covered by curtains of modules mounted vertically. These curtains can be slid to the side for access to the horizontal module panels. The 9.5 x 13.4 m

2

south wall consists of two panels of horizontal modules, with the center gap covered by movable vertical curtains. The north wall is similar, except that its west panel has been broken into two subpanels with one set back to allow general access to the veto-lined room. It has also been modified over the years for ease of access into the mezzanine area and will have to be supplemented.

The ceiling modules rest on a steel framework built to support the central proton decay calorimeter, lying 2 m below the roof at the central highest point, but adjacent to the roof at the east and west edges. The array consists of two 7.0 x 31 m

2

sections which overlap, yet allow the ventilation ductwork to pass through. The floor array is mounted on a platform welded to the support structure, lying only 0.1 m above the cavern floor. The shield floor consists of two 6.6 x 31 m 2 sections, oriented with wires running east-west in the east half and north-south in the west half. The center gap is covered by a 0.7 m wide strip oriented north-south. There are 63 gaps in the shield floor corresponding to the 0.2 x

0.2 m 2 posts which hold up the steel floor framework.

The tubes mentioned above were built by Tufts University and form the principle veto shield system. Additional veto modules were obtained from Harvard (the HPW tubes) and Oxford (the TASSO tubes). The HPW tubes are 2” x 6” in cross section and run from 6 feet to 21 feet. They have a single channel consisting of two parallel sense wires and a pair of field shaping wires. They were arranged perpendicular to the Tuft’s tubes on the ceiling and floor with approximately 60% coverage. The TASSO tubes are 12” x

1.5” in cross section. Each module consists of 8 cells with a sense wire read out for each channel. There are three steel pallets of these tubes resting on top of the proton decay calorimeter. Each pallet is a double layer with twenty-four 4-meter modules above fourteen 8-meter modules. Each pallet covers ~32 square meters. These pallets would have to be removed before disassembling the calorimeter. It is unlikely that we would bother to restore the TASSO tubes to working order.

The veto shield is operated in threshold mode. The current pulse from each set of 4 sense wires is amplified and converted to a voltage pulse with gain of 190 mV/uA (determined by the resistor values). A comparator returns a +5 volt pulse whenever the input pulse rises above 100 mV. A multivibrator stretches the pulse to 1.1 us, followed by a differential line driver to a 100

twisted pair. The components for the two channels are mounted on a 6.0 x 14 cm 2 printed circuit board mounted inside the exterior well of the module endcap. A metal coverplate shields the card from electromagnetic interference.

The two interleaved 4-channel layers can be used in coincidence mode, if so desired.

Differential signals from the digital output cards are transmitted to single-width 64channel CAMAC modules via twisted pair. The input signals are sampled at 1 MHz.

The results are twofold multiplexed in time and then written to a random access memory.

The address is incremented at 2 MHz with the address cycling continuously through 256 locations. Thus each input/output port of the memory serves as a pair of 128-element delay lines for the hits recorded within the previous 128 us interval. Upon receiving an external trigger, the modules scan through the delay lines for hits recorded within the previous 128 us interval. The information for each hit (channel and time) is coded and stored in another memory. Following completion of the data scan in 1 ms, the readout module sets a flag to indicate data-ready.

The rate in a 7 m long element is about 270 Hz near the ceiling and 320 Hz near the floor.

The rate of coincidences between two four-cell elements in a module is roughly 3 Hz.

Due to local radioactivity, this coincidence rate is far in excess of the 3 x 10 -3 Hz rate expected from the cosmic ray muon flux in the mine. The efficiency is measured to be

99.5% on walls and ceiling and 80-90% on the floor due to the gaps caused by the floor supports.

Since the shield was turned off in July 2001, nothing has been disassembled. In order to confirm its health, a pressure test was performed this March (2004) on one of the oldest

Veto panels (Panel 5: the southernmost panel on the east wall). It is constructed of fifty

7-m long Tufts tubes covering some 70 square meters. The panel was pumped up to 5 psig with an old bottle of C-10 mixture, sealed off and left over the weekend. The absolute pressure gauge showed a drop of 128 mbar in the course of 95.5 hours or

1.3mbar/hr. The original standard for acceptability was .3mbar/hr. From experience we know that 1.3mbar/hr for an entire panel corresponds to a single small leak that should not be hard to find or fix. There is no evidence of catastrophic failures of the epoxy sealing on the chamber ends (16/tube) or joint failures in the gas manifold piping. The panel was then brought up to bias voltage and signals observed.

Since that time, all the panels have been pressure tested and a database maintained under the direction of University of Minnesota (Crookston) as part of student work-study grants. Although the electronics is generally in working order, the removal of the proton decay calorimeter may disturb the thousands of feet of 32-twisted pair signal cables running from the individual tubes to the CAMAC crates. While easy to repair once the break is found, we have budgeted considerable time to thoroughly checking all channels.

We anticipate minor repairs. There is an existing test/repair stand for the preamps and there are boxes of spare components. There are also a number of pre-assembled spare preamp cards and spare CAMAC cards.

5.3 Veto Shield DAQ

Although the data acquisition VAX cluster is still working, we plan to replace the VAX and CAMAC with a modern DAQ to improve throughput and speed, as well as to avoid parts obsolescence. We will maintain the VAX cluster only for the initial shield checkout, since it will speed up this process to have an existing software interface. The final

DAQ must be developed as an integrated system with flexible extension to multiple users and their screening instruments. Thus we are designing a system which assigns a geographical location and a time-stamp to every muon event. Any experiment or screener can then use this data via ethernet to provide their own veto or test trigger. The finalization of the DAQ design and implementation is covered by supplementary funds already acquired in 2004.

Each readout module will be able to handle incoming data from 96 tube modules.

Signals from each channel first pass through a Coincident Logic Network (CLN), which is a simple on-board network of AND and OR gates which select coincidences between the back and front 4-wire planes of the same and adjacent tube modules, thus determining muon candidates and rejecting singles noise. The 3 microsecond variation in proportional tube drift times require one-shots on each input. The output of the CLN will be latched until the Serialization Module (see diagram above) can read it and reset the latch. We are in the process of modifying this design to use off-the-shelf components and

FPGA’s, but the original schematic is useful in demonstrating the overall concept of the new DAQ. In either case, a 1 MHz oscillator will provide the 1 microsecond timestamp precision. It will be reset every second using the TTL signal provided by the MINOS

GPS receiver. A chain of 4-bit counters (4029’s) create a 32-bit clock which provides the timestamp. Epoch information for each pulse (second, minute, day, year) will be provided from the MINOS timing PC which is decoding the same receiver. All computer clocks will thus be synchronized using NTP protocol.

A 50 MHz Ubicom SX processor will read and store the data and the corresponding timestamp from the multiplexer arrays. A coincidence occurring in the veto shield will interrupt the processor and tell it to begin reading. The 74150 multiplexers have a 36 ns propagation time, so that 16 channels can be read out in just over ½ microsec. All of the multiplexers will be cycled simultaneously to allow a parallel data read, starting from the least significant bit, resulting in 16 cycles for 128 bits of data (32 bits from the clock and

96 bits from the CLN). Since the SX processor has 8 banks of 16-byte RAM, a complete read from the clock and the CLN fits exactly in one RAM bank, allowing the banks to act as an 8-event FIFO. While the processor is not collecting data from a triggered event, it will dump the contents of its event buffer to the host computer system via an RS-485 serial network. Since each event will require 30.5 microsec to transmit, and any single

CLN will be generating hit events at a rate less than 1 Hz, the processor’s idle time is sufficient.

Should more than 8 events occur in less than 30.5 microseconds, the FIFO will flood and the incoming event will be dropped. A flood situation will only occur for a “hot” tube.

In this case, the processor will poll for the tube and ignore further events from that tube until such time as the tube is fixed. The decision time is less than one second.

Once sent to the host computer, the data will be made available through an API that will be designed to allow the projects under the shield to access the data from the shield. It will also have the ability to determine the detected particle’s path (panel region coincidences) in order to check whether that particle passed through any of the experiments under the shield or not.

5.4 Water tank

Two commercial storage tank companies have bid on this item. One company has visited the mine, but both have explored the detailed plans required to transport materials and weld the tank underground. Both a carbon steel with liner or epoxy paint and stainless steel options have been evaluated. The stainless steel option is about 1/3 higher in price, but is the safest bet for maintaining the highest standards of purity in the water. The tank can be assembled in place using commercial techniques relatively cheaply, since most commercial tanks are built on location. The size of the unassembled steel sheets needs to be slightly narrower and shorter than usual due to the cage constraints, but this is not a large perturbation. The height of the tank plus clean room is constrained by the size of the cavern itself. With only 1 upward-going muon a week, we have decided to remove the shield from under the tank and construct it directly on the floor. The shield can be reinstalled above the clean room to provide additional coincidence information if desired.

The expected neutron flux inside the water tank was estimated using a GEANT4.5 Monte

Carlo. Neutrons with energies of 20 MeV, 100 MeV and 1 GeV were tracked from the cavern walls through the water tank geometry. The number of muons making it to a central 1 m detector volume is shown below. 87 % of the 20 Me neutrons are removed when water, rather than air, fills the tank. Another simulation was run to estimate the expected neutron spectrum due to cosmogenic muons at the Soudan depth, propagating the estimated muon spectrum starting at a depth well above the cavern through 30m of rock surrounding the cavern, using the QGSC physics list and the additional

G4MuNuclearInteraction process. We have not finished this study, but the Boulby Mine cosmogenic neutron spectrum is displayed below for a rough idea of how many low and high energy neutrons will impinge on the tank. Once we have finished generating our own muon and neutron spectrum, we will run the entire spectrum in order to determine the expected neutron flux at the immersed detector space. Neutrons due to natural radioactivity in the rock surrounding the cavern do not have to be simulated, as they will thermalize in the outer meter of tank volume.

At present, we plan to purchase a pre-fab class 10,000 clean room from Clean Air

Products or Gateway Air Filter, Inc. Installation on site is included in the bids. This is the price included in the budget. Another option is to extend the steel supports around the tank and basically build a taller tank, the top piece of which will be the clean room.

We will explore both alternatives to find the most cost efficient plan.

5.5 Purification System

The goal of the Soudan purification is to provide low radioactivity water. A necessary condition is that the water must be very pure. Absolutely pure water has a resistivity of

18 megohm-cm. If a solute is present at the 1ppm level, the resistivity plummets to 0.5 megohm-cm; i.e., resistivity is a good indicator of dissolved material. Since the final purity will be determined by the nature of the solutes and the mass and type of shielding immersed in the water, it is best to plan for a high quality purification system with the flexibility for upgrades built in. The tank itself will be made of a material able to withstand very pure water, either stainless steel or a lining of Teflon (C and F chain) or

Kynar (C and F and H chain). If the tank is an unlined stainless steel, the welds must be covered with Teflon tape.

A high purity water system is installed for the DIRC at the BaBar detector at SLAC. This system has about 5 tons of water and is capable of recirculating 6 times a day. The purpose of this system is to maintain light transmission at better than 1 meter at 280nm.

The input water is 18 megohm-cm and the returning water is typically 12-14 megohmcm. Another system is installed at Milagro in New Mexico. This system holds approximately 20 ktons of water, capable of recirculating once a month. The goal is again light transmission but only down to 320nm. At Soudan, a system capable of recirculating once or twice a week is adequate.

The purification plant would have a series of components. A rough screen filter would remove large particulates. This would be followed by some charcoal filters leading to a reverse osmosis unit. Next would come a series of ion-exchange units followed by a degasser. An ultra-violet lamp will be required to kill bacteria, followed by a filter for the dead bacteria. Since this is a recirculating system, the return water would come in after the reverse osmosis unit, which is not needed after the initial pass. Any new makeup water would go through the whole loop. Since units can fail, and even in normal operation, filters need to be cleaned or changed and resin beds need replacement, there should be two parallel lines for everything in the system except the reverse osmosis unit and the de-gasser. Most of these units are standard in the industry with the exception of the de-gasser which would be a Teflon microtube system in which the air in the water diffuses out into a vacuum surrounding the microtubes. The main purpose of the degasser is to eliminate oxygen which promotes bacterial growth and to cut down on radon in the water. The footprint of such a purification system would be roughly 6 ft by 12 ft for the steel box tubing base plus additional space for the return reservoir and pumbing.

5.6 Shielded Multi-purpose Room

The water tank provides an excellent passive shield for neutrons and gammas from the south wall of the cavern. A set of shielded bays can be built against the side of the water tank to provide a low background staging area for prototype dark matter and double beta decay experiments. Experiments that will eventually opt for the ultra-low background of the water shield can refine their material selection (using the on-site screening facilities) while taking data in a deep site environment and preparing for the next step. Other experiments may find that their needs are already met by additional shielding in the bays.

High density plastic extrusion material or HPDE (like the plastic lumber for decks) can be used for the outer shielding since it is available in quantity, cheap ($1,400/cubic meter) and easily rearranged and stacked for various geometries. A good shield would be enough plastic to thermalize the neutrons, then a thin cadmium layer to capture the thermals, then lead for the 2614 keV gamma (thorium chain), ending with ultra-pure copper from the electroforming facility to get rid of the Pb210. This is a fairly conventional low background shield. The question is how much we will provide through the facility, recouped by lease fees, versus how much we expect experimenters to bring themselves. One option is to surround the outside of the bay area with a 0.5 meter thickness of the inexpensive plastic and then let the experimenters provide their own shielding, which might include purchasing electroformed copper produced locally.

The entire shielded bay complex and adjoining assembly area will be contained in a class

10,000 clean room with HEPA filter modules, sealed light fixtures, anti-static vinyl floor and a class 100 laminar flow workstation. Additional radon–free storage space for samples and shielding materials will be available. An anteroom provides a place to suit up and to clean items to be brought into the clean room.

5.7 Radon Reduction

One challenge underground is the high ambient Rn levels. If not reduced, these will lead to the Rn daughters 210 Pb, 210 Bi, and 210 Po being deposited on any samples or detector surfaces that are exposed to air. Local reduction techniques, such as glove boxes, can be effective, but obviously have limited applicability. Instead we plan to provide two clean room areas with Rn-reduced air.

Figure 5. The Borexino radon-scrubbing unit at Princeton

While readily-available liquid nitrogen boil-off is low in Rn, there is no simple means to have a large volume of low-Rn breathable air. Air synthesized from liquid nitrogen and oxygen, is conceptually simple, but very expensive, and the liquid oxygen would present serious safety issues underground. Storage of air long enough for Rn to decay away

(with 5.5 day half life) is also impractical. We will instead use a copy of the system developed by the Princeton Borexino group 8 . This is a room temperature process that uses two large (250 Kg) charcoal columns that strongly retard the flow of Rn relative to air. A cyclic process in employed in which one column cleans the air, while a small fraction of the cleaned air is used to regenerate the other column using a “vacuum swing” technique.

This system supplied ~ 100 m

3

/hr of air with the Rn reduced from an ambient level of 30

Bq/m

3

to ~ 0.3 Bq/m

3

. Since this value is likely to have been limited by the measurement technique, it is believed that overall Rn reduction factor is more like 10

4

, Thus a Rn value this low should be achieved even starting with the much higher Rn-content air in

Soudan. At Princeton, this air provided the make-up flow which creates the necessary overpressure in a 770 m

3

clean room. The final Rn level of 1.5 Bq/m

3

is believed to be the result of Rn emanation in the room, and thus depends on the air turnover rate (room volume / make-up flow). Thus, with a similar size Rn scrubber, we will expect at least comparable performance for the proposed rooms with 300 m

3

volume each. We estimate a cost of $120 K for this system when commercially fabricated, of which ~ $50K is for equipment (dominated by a gas throughput pumping system).

Typical clean rooms of size we are considering have make-up air flows much larger than

100 m 3 /hr. To achieve a low make-up flow, the seams in walls must be better sealed than is typical, and the air handling system should be situated in an interior plenum space.

Based on the Princeton experience, we expect these to be done for a modest additional cost.

5.8 Copper Electroforming

It is also important to further reduce the level of radioactive contamination in at least one of the major materials (copper) used in low background experiments. As experiments go to larger mass in order to increase sensitivity to the signal of interest, the larger mass of support materials and internal electronics will increase the background as well, unless purer materials are found. Radionuclides are produced in copper from cosmic ray induced interactions when copper is above ground

9

. Therefore, electroforming will be performed underground in order to reduce this source of radioactivity. Under research funded by an

SBIR, Reeves & Sons, LLC. expects to produce copper containing only one microBecquerel (or less) per kilogram. This would already be a great advantage. A second objective is to enhance the electroplating technique to produce material thicker than the approximately 1 to 3 millimeters currently attainable before the copper must be removed from the bath and machined.

Copper sulfate will be purified by repeated dissolution/precipitation steps and ultra pure sulfuric acid can be purchased from suppliers. Then, beginning with a relatively pure form of copper (OFHC) as anodes and using the purified materials for the plating bath, new anodes will be electroformed, and these will contain significantly less radioactive contamination. These anodes will be used in the bath producing the final copper product.

It would take about 30 days to purify the copper sulfate and prepare anodes. With 4 baths running, approximately 500 pounds/week could be electroformed.

The proposed design for the electroforming facility includes a modular system that will have each electroforming bath individually enclosed and with a cover gas exhausted through a filter designed to trap any corrosive fumes that might otherwise escape. The low-background counting facility specified in the SBIR for testing the material is itself a proprietary design that should rival the MEGA detector. It will be used primarily for the copper testing, but after the procedure is perfected, it will be available for use as a general screening device. The enclosure for each bath would be made from plastic such as PVC or acrylic or a combination of metal and plastic if required. It is important to be able to see inside each enclosure from at least one location since manipulations inside each enclosure would be accomplished through glove ports. The footprint for a single typical bath is about two feet square. A larger bath with a footprint of three feet square may also be needed. A room height of about eight feet is desirable.

The maximum power required will be typical 60 cycle ~117 volts AC. A total of eight 20 amp circuits would be needed to provide lights, air conditioning, vacuum system, plating power, and power for a small combination lathe/milling machine. For large tasks such as

providing large quantities of ultra-pure copper for gamma-ray shielding, continuous power at near 20 amps per circuit would be required for up to four circuits for several days at a time. However, for smaller tasks, the power requirements would be less since a typical DC power supply providing both voltage and current control requires less AC current when operated at low DC current.

Very little water is required and could be brought to (and removed from) the lab in plastic carboys. However, if water is available, it would be used as input to a small water treatment unit that would produce the 18 megohm water needed. Alternatively, some amount of the purified water used in the large tank could be diverted to this use.

Fresh air requirements are minimal since the plating itself will happen within closed modules and the vapor pressure of the copper sulfate plating bath is low. However, air suitable for breathing and sufficient to sink the heat from the power supplies and a small air conditioner will be necessary. If a water supply sufficient to handle the heat load is available, then only sufficient breathing air for two people would normally be required.

The primary waste is plastic and paper. Plastic gloves are used extensively as are plastic bags and paper products. Otherwise, there is very little waste material. Machining produces copper turnings and shavings but it is believed that a large part of this material can be used as anodes in the plating baths, especially since it will be the cleanest copper available if not contaminated during machining. Each plating bath is composed of ~ 8% high purity sulfuric acid and ~ 150 grams per liter high purity copper sulfate (somewhat similar to a lead-acid battery but lower acid concentration and copper rather than lead) and high purity water. Very small quantities of cobalt and barium (a few milligrams per liter) are the only other chemicals being used in the bath at this time. A typical plating bath would be about 10 to 100 liters and be contained in a plastic vessel, generally a right circular cylinder. A second plastic vessel provides secondary containment and the floor section of the main room will be assembled in such a manner to provide backup containment. The main room will be maintained at a slightly positive pressure and the exhaust can be directed in the most suitable direction and pass through appropriate filters to remove any trace amounts of sulfates, if any. A monitor with alarm capabilities will continually monitor the air and sound the alarm if a corrosive or dangerous level is reached.

5.9 High Purity Germanium Detectors

Currently there is gamma screening facility named SOLO, operating in the Soudan Lab behind the MINOS detector. A 10 ton, 14” thick Pb castle with a 2” thick liner of 50 mBq/kg German lead houses two HP Ge detectors borrowed from a previous double beta decay experiment. The “TWIN 2124” is 1.05 kg and “Diode M” is 0.5 kg, each with its own (8”) 3

sample chamber. A double layer of 100 um mylar and boil-off from the liquid nitrogen dewar provides a radon shield. The spectra shown below provide a brief history of the shielding improvements, starting with the cavern background at the top, followed by the first run without radon elimination and with a few “radioactive” lead bricks from

FNAL, followed by the radon purged,final shield configuration over 40 kg-days.

Figure 6. Background spectra from the SOLO-TWIN HP Ge detector at Soudan.

To extend the existing SOLO facility, Laura Baudis will purchase a large volume p-type

HP coaxial Ge detector using University of Florida startup funds. The detector is being constructed by Canberra Semiconductors (USA) with selected low background materials provided by the company. However, the background of this detector will most likely be dominated by the cryostat made of high-conductivity, oxygen-free copper. To increase its sensitivity after an initial period of operation below ground, the cryostat and the internal fittings would have to be replaced with new components made of electroformed copper produced in the underground electroforming facility.

The new cryostat will be constructed at Florida in close cooperation with Canberra.

To establish a competitive Ge spectroscopy facility, we propose to construct a second

100% efficency HPGe detector, in parallel to constructing the new cryostat system of the first one. We also propose to build new sample chambers for these detectors. The sample chambers will have inner dimensions of 25 cm x 25 cm x 35 cm, allowing one to place more than 10 l of sample material around the cryostat housing. The chambers would be formed by 5 cm thick plates of electropolished copper surrounded by several layers of low radioactivity lead (a total of 20 cm). The innermost Pb layer with a 210-Pb contamination of 5Bq/kg. The chambers would be closed on top with large Cu plates carrying the Pb. The entire shield would be surrounded by an airtight steel box containing

also an operating box and an airlock for accessing the samples. The entire system would be flushed permanently with gaseous nitrogen. The samples would be first stored above the closed sample chamber in nitrogen, allowing the trapped radon and the plate-out radon progenies to decay before the chamber is opened and the sample measured.

The operating box would contain 2 windows and a glove system. A crane would be mounted on top of this box to handle heavy loads and lower them into the chamber.

5.10 Beta Cage

There are two types of technology which we plan to develop in order to screen for alpha and beta particles. The first technology is a large area gaseous detector for measuring surface contamination of low-energy beta emitters. The principles which guide its design are as follows:

1. Use the minimum amount of gas needed to stop electrons of interest in order to minimize background from ambient penetrating gammas.

2. The detector should have the minimum possible surface area which itself can be a source of betas.

3. There must be sufficient spatial information about events to distinguish those coming from the sample surface. drift grids trigger grids sample bottom guard grids

Figure 7. Side view of the Beta Cage. Each grid set consists of an anode plane where charge multiplication occurs, plus two field shaping grids. One field grid plane and the anode plane will be read out for the trigger grids to determine x-y position.

These goals are met by using a gas drift-chamber with multi-wire proportional readout.

A sketch of the detector is shown in Figure 7. Samples are placed directly in the gas. A set of trigger grids directly above the sample surface tags events that originate at the

sample. A drift region beyond this is read out by a set of wire readout grids at the top of the chamber. The depth of the drift region sets the energy of betas whose full energy is contained in the detector. Crossed grids will be used for x-y position determination, and timing can be used to determine the z-profile of the track. The region below the sample is also an active veto region. The gas of choice (neon gas at STP), and detector thickness are determined by electron stopping based on Monte Carlo studies. The trigger region will be as small as is practical, roughly 0.5 cm, and the drift region will be 15 cm, which should contain ~ 90% of 150 keV betas. The region below the sample is also an active veto region. Initially we plan to segment the x-y readout with only a few channels in order to set a guard region at the edges of the detector. The wire pitch on the trigger grid will be roughly 2.5 mm, so much more fine-grained readout could be used if it proves beneficial.

The layout of the grids is based on distinguishing events from the sample surface from all others. Until the level of surface contamination of beta-emitters is systematically reduced, we can expect betas coming from the surfaces of the detector itself. However those from the outer walls of the chamber are readily distinguished by use of the bottom veto, the drift region, and the x-y position. Good events are located above the sample in x-y , deposit energy in the trigger region, and an have a small enough (or zero) energy in the drift region that they could not have penetrated the drift region from above. (A veto region above the drift region could also readily be employed). By design, the only surface of the detector near the sample is that of the wires, which are a few % of the sample surface.

Each grid structure consists of a center anode grid, surrounded by two sense grids. The anode and one sense grid will be read out, to provide x-y information. The grid structures will have a grid spacing and wire pitch of 5 mm, though for the trigger grid structure this distance may be reduced to 2.5 mm. Anode wires will be 20 µm Ø.

The dominant background is expected to come from penetrating gamma rays that interact

(primarily Compton scattering) in the trigger region, or in the sample or drift region such that a recoil electron or X-ray interacts in the trigger regions. These photons come from contamination in the shield, and are present in all low-background environments.

Having as small a gas mass in the trigger region as possible minimizes these backgrounds, except for the case of electrons emerging from the sample (ejectrons) which are indistinguishable from surface beta decays. Further reduction of these backgrounds will be achieved by use of a passive water shield and an active muon veto provided by the refurbished Soudan2 veto shield in the new Low Background Counting

Facility at Soudan.

The gas choice, and detector thickness are determined by electron stopping. Based on

Monte Carlo studies described below, we intend to use Ne gas at STP. The trigger region will be as small as is practical, roughly 0.5 cm, and the drift region will be 15 cm, which should contain ~ 90% of 150 keV betas. Higher energy betas can be studied in the same chamber by use of Xe gas.

The demand for a low radioactive background environment requires that the basic construction materials of the chamber be copper or plastic. Gas handling is simplified, and non-atmospheric pressures can be utilized if a vacuum tight, and, possibly pressurecapable copper box is constructed. This will be expensive and technically difficult, especially for large detector sizes. If a plastic chamber at STP is used, initial purging of the box will be needed. With Ne, this is probably practical. With Xe, a more complicated, sealed gas system will be needed.

Monte Carlo studies for the beta cage option

Two main issues have addressed with Monte Carlo study using Geant4. The first is the size of the electron tracks. We find that tracks < 100 keV have completely curled up on themselves. For Ne, 150 keV events are contained within 10 cm. The second issue is the background expected inside a shielded environment. We simulated the event rate in the counter under an ambient background of gamma rays typically of shielded environments, and scaled to give 1 count/kg/keV/day in Ge at low energy. This is a typical, if somewhat high background in such setups. The results are shown in figure 8.

Figure 8. Simulated event rate for a beta cage at Soudan. The surface area was

700 cm 2 , so 2x10 -2 cnts/keV/day corresponds to 3x10 -5 cnts/cm

The curve labeled “all events” represents the final background.

2 /keV/day.

Other sources of internal background are expected to be small compared to the photonrelated backgrounds. Several are summarized below:

Source

Photon, nominal 1 dru (in Ge) environment

Kr rate in full volume. Assume 20 ppb.

5% methane quench gas (assume 10

-18

C

14

/C

12

).

Rate in full volume.

Rate

(cnts/keV/cm 2 /day)

3x10

-5

4x10 -6

5x10 -8

~ 10

-8

Wires: Internal beta rate < 100 keV. U, Th contamination is typical for dirty metals, e.g. SS.

Wires: Rate from gammas in full volume.

30 resistors: Rate from gammas in full volume.

Assume ~ ppm U, Th, typical of ceramics

~ 10

-13

~ 10

-6

The Kr and methane backgrounds will become important if the photon background is reduced to 0.1 dru equivalent in Ge. The Kr value is near the limit of commercial measurement techniques, but should be readily reduced by use of a charcoal trap operated at 77 K. The

14

C/

12

C ratio assumed for methane is typical of petrochemical values.

Reduced concentrations or non-organic quench gasses such as SF

6 can be explored. The rate from bulk contamination of the wires based on Ge-counter based screening of metals, does not appear important. We may learn, however, that wire surfaces are contaminated with beta emitters that we must remove. The radioactivity of resistors should dominate the rest of the electronics, and could become an important background. If lower activity components cannot not be found, it is possible to place the resistors outside the shield.

Sensitivity of the beta cage.

The sensitivity of the detector depends on the sample area and final background. In figure 9 we show the 3

(99.8 % CL) sensitivity for 30 days counting time. Gaussian statistics are assumed. For large enough exposures, there is non-zero background due to photons, especially at low energy. It is standard in low-background counting to subtract the background after having measured the blank background with no sample present. We will do this here, but more care must be taken as photon interactions in the sample leading to escaping electrons (and X-rays) are not measured in a blank run. Instead, gamma calibration sources or samples that have already been found to have low surface contamination could be used.

Figure 9. Sensitivity of the beta cage as a function of linear dimension of the sample area, and for several photon backgrounds. Our target background is at least 1 dru, and ultimately 0.1 dru. The heavy lines indicates < 1 background count in each energy bin, so that no background subtraction is applied.

In order to reach the sensitivity goal of 0.1 cnts/m

2

/keV/day with a rather long 30 days of counting, a sample area of at least roughly 30 cm on a side is indicated. At this scale, background subtraction (in 30 keV bins) is just becoming necessary for a gamma background in the range of 0.1 and 1 dru equivalent in Ge.. A smaller detector will require very long counting times. A larger detector will allow faster counting, and would be desirable. As our understanding of background subtraction improves, and especially if the photon background is low, a detector of 1 m

2

in area can lead to 0.01 cnts/m

2

/keV/day sensitivity. A sample area 31 cm in diameter can hold 12 x 8 cm Ø samples, for 550 cm 2

= (23.4 cm)

2

. Significantly larger areas will require a large number of samples.

5.11 Cloud Chamber

The second technology is a triggerable cloud chamber. This device will be developed by

UCSB using other funding. It will be installed in one of the shielded bays for evaluation of its efficiency and operation at low background.

The concept of the chamber is shown in Figure 10. The chamber would be of the diffusion type (15), and thus be continuously sensitive. Digital images from two cameras with stereoscopic views would be continuously read out, and a software trigger based on the number of hits above threshold would trigger the retention of interesting candidates.

Since the rate of events is extremely low, this strategy should be effective. Subsequent offline analysis would select the beta candidates.

A prototype device has already been built; an image of a roughly 100 keV electron from this device is shown in Figure 11. Electrons at this energy multiple scatter quite a bit, and the sense of their motion can be determined by dE/dx. Backgrounds would be rejected principally through exploitation of the exquisite information on the track provided by the images. Electrons from beta decay in the sample would have a track that emanated from the sample, and that multiple-scattered like a low energy beta. The energy of the beta would be reconstructed from the total length of the track.

The chamber and the alcohol would be maintained at the highest degree of cleanliness, for the good operation of the device, and so as not to contaminate the sample. The inert gas would be nitrogen. Alcohols are used in the final cleaning of the CDMS detectors.

Cloud chambers built for low backround applications have achieved good sensitivities in the past, for example, to measure the naturally occurring tritium concentration in water.

We anticipate that the dominant background will come from conversion of ambient gammas near the surface of the sample. The rate of this background depends primarily on the ambient flux of gammas; the canonical flux in a good lead shield gives one

Compton electron recoil per keV per kilogram in standard materials. The portion of those that can escape the surface indicates about one false beta every 10 days for one of the

CDMS ZIP detectors, or equivalently, about 1

10

-5

events per cm

2

per keV per day. This sensitivity is of interest to future incarnations of CDMS, although another order of magnitude would be optimum. The main obstacle to greater sensitivities is likely to be gamma flux from radioactivity in the shield and components.

Figure 10. Concept of the cloud chamber for beta screening. The material to be screened

(in this case, a ZIP detector, one of the CDMS dark matter detectors) is placed above the sensitive region. The cooling (or heating) coils would maintain stable and necessary temperature conditions for operation of the device. Alcohol from the tray evaporates, and diffuses throughout the volume. A cooler temperature and the temperature gradient in the lower portion of the chamber allows the vapor to become supersaturated, and becomes the area where tracks can be imaged by the droplets they induce. For scale, the ZIP detector is approximately 8 cm in diameter.

The second prototye chamber would be rather small, a cube of 30 cm dimension. The main purpose would be to develop the temperature control and digital imaging readout, and understand stability issues, and the efficiency of the device near the surface of the material to be screened. The target for operation of this chamber would be September,

2004. We would then move the device to Soudan, and operate it in such space as is available until a bay in the new lab was ready. Based on the performance of that prototype, we would plan the third chamber, which we envision to be capable of handling a significantly larger area.

Figure 11. Image of a recoil electron from a Compton scatter in the UCSB prototype cloud chamber. The energy of the electron is of order 100 keV. The bright horizontal line is a reflection from one edge of the chamber.

6. Scientific Program

This proposal is designed to meet near term needs of the astroparticle, nuclear, and high energy physics communities whose underground experiments are either now running or in the R&D stage. As such, it has definite physics goals which will be met by its timely construction, as well as creating an economy of scale that should actually reduce the overall costs of the experimental program which needs the facility. It is an attempt to bring together a set of known users under one umbrella, such that shielding requirements

(both active and passive), screening needs, data acquisition, off-site infrastructure and personnel can be shared. The scientific program outlined below is structured to bring experiments from our community online quickly in the 8 year hiatus before NUSEL is available, and maintain a general capacity that will be available to the larger community on a fee basis.

6.1 Gamma Screening

Immediate screening needs are Majorana and CDMS, as well as XENON. Majorana contributed to the development of the SOLO HPGe facility and has been using it to screen – SPECIFICS PLEASE. CDMS also needs to screen samples of the plastic and copper from its shield to determine whether their higher gamma flux is due to radon plate-out or not. The XENON collaboration requires immediate screening for phototube selection and design, as well as other photodetectors such as APD’s or HPD’s which may be preferable due to their lower intrinsic radioactivity. They also need to count the various commercial components such as HV resistors and feedthroughs, and finally characterize their shielding. At the sensitivity required, such tests can take approximately 30 days. We are backlogged on the current facility and need to extend it by at least a factor of 2. Eventually, the older HPGe detectors will be moved under the muon shield and the lead reconfigured to accommodate users from outside the nuclear/astro-particle physics community on a per-fee basis when the ports are not in use.

At least one of the most sensitive HP Ge detectors will reside inside the water tank.

6.2 Beta and Alpha Screening

The CDMS experiment running at the Soudan Mine is currently among the world leaders in the direct search for Weakly Interacting Massive Particles (WIMPs), which may comprise the dark matter in the Universe. CDMS II has already produced the best limit worldwide from only a short run at Soudan with one out of the five towers. Over the next couple years, the number of towers will be increased to 5 and eventually to 7 under the

CDMS III experiment. However, there is significant competition from advances being made elsewhere in the community, including the Edelweiss and Zeplin programs, which are now operating experiments with sensitivities similar to our best CDMS-I results.

To maintain a leading role, we must begin to explore ways to improve the sensitivity of our dark matter search. This must occur immediately if the results are to influence the processing of towers 4 and 5, which will be fabricated and tested soon. The work proposed here is aimed at reducing the dominant internal background in CDMS: lowenergy betas from detectors or nearby surfaces. These low-energy betas come from surface contaminants in the tens of keV energy range. Since their charge is inefficiently collected compared to that of beta’s which interact in the bulk, their ionization yield

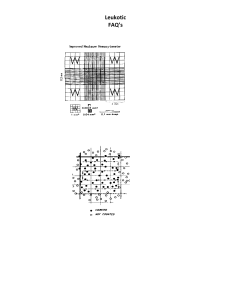

(ionization/recoil energy) is lower. On a plot of yield vs recoil energy (see figure above), they produce a continuum of events (small green dots) which leak out of the band where we expect electron recoil events (yield = 0.8 – 1.2) and into the band where WIMP-like nuclear recoils are to be found (yield = 0.2-0.4) , thus compromising our beta rejection.

Figure 12. Data from the CDMS run at the Stanford shallow site.

Significant progress toward a no-background dark matter experiment can be made by reducing the level of beta-emitting contaminants on the detectors and nearby surfaces. In

CDMS-II, time limitations in the fabrication and testing cycle have precluded fast feedback on the presence and sources of these contaminants. Diagnosis of the contamination has relied on operating the detectors themselves at the CDMS-I setup in the Stanford Underground Facility. In order to develop handling and processing methods that minimize the introduction of beta-emitting contaminants, or to test cleaning methods, we need to use faster-turnaround techniques for screening and probing for contaminants.

Screening methods have been used by a variety of low-background experiments.

However, nearly all such screening depends on detecting bulk contamination using counters sensitive to gamma rays, but not to beta particles. Available surface-analysis techniques using in materials science are useful for detecting some possible beta contaminants. However, no low-background screening technology exists with good sensitivity for surface contamination of low-energy beta emitters. Since such direct counting is the only way to measure the final background of interest, such screening is critical. Thus we propose to build a novel dedicated detector for this activity, based on multi-wire proportional counting.

Screening would be used not only on fully instrumented detectors but also on test wafers subjected to only some of the processing steps or fabricated under different conditions. If the results indicate contamination introduced during detector processing, we would evaluate how to refine handling and processing methods for the next batch of test wafers and detectors. If the results indicate contamination from handling, methods to clean identified contaminants would be attempted, or handling most likely to introduce the contaminant would be altered or removed. Possible cleaning steps range from chemical methods to light sputtering with argon beams, with possible post-cleaning introduction of clean buffer layers to reduce the reintroduction of beta-emitting contaminants.

In order to determine how to remove a contaminant, it must first be identified. The screening must therefore be sensitive enough to detect contaminants at the level that

would cause the raw background goal of 8 x 10

-3

events/ (keV kg day) in the 15-45 keV region. Beta contamination on the surfaces of the detectors themselves is the most critical to limit. Since the detectors have a mass of 250 g and a surface area of about 100 cm

2

, the beta screening needs to be sensitive to 2 x 10

-5

counts/ (keV cm

2

day). Most surface analysis techniques cannot reach this sensitivity goal and are limited to radioactive isotopes such as 40 K and 14 C, which can be tagged by their more common isotopes. A direct measurement of the ejected beta’s themselves using beta screening is superior, since it is not limited in this way.

6.3 Staging new Prototype Experiments

The following experiments have either committed or are seriously considering occupying the multi-purpose room as soon as possible. For most of them, the radon scrubber can be a later addition. They will take advantage of the local screening facilities for their material selection prior to installation and for shield characterization during commissioning. This list is by no means exhaustive and simply represents those who have already contacted us.

6.3.1 Heavy-liquid bubble chamber for WIMP detection

Recent progress in the application of superheated liquids to WIMP detection at the

University of Chicago indicates that it may be possible to keep bulk volumes in a radiation-sensitive metastable state for long enough to perform rare event searches. For certain pressure and temperature operating conditions the vaporization of the liquid can only be produced by particles having a large stopping power (e.g., nuclear recoils,

Figure 13), making the detector insensitive to most minimum ionizing backgrounds. The devices are operated at near room temperature and the industrial refrigerants used are non-flammable, non-toxic and inexpensive, with a chemical composition (e.g., CF

3

I) that is optimal to maximize sensitivity to neutralino interactions through both the spindependent and –independent channels. For these reasons the technique seems to be ideally fitted for the goal of building tonne or even multi-tonne WIMP detectors, able to prove most of the supersymmetric phase space where the neutralino may abide.

First tests using a ~20 g active mass prototype bubble chamber show an event rate compatible with the fast neutron background in a shallow (6 m.w.e) underground laboratory. Calibrations using monochromatic neutron sources have shown good agreement with theoretical predictions for the response of the detector and a sensitivity to recoils down to ~7 keV (tests with a Sb-124/Be photonuclear source able to demonstrate sensitivity to ~1 keV recoils are underway). The construction of a second prototype chamber, able to house an active 2 kg target mass of CF

3

I is well advanced. Installation in the Soudan laboratory is expected during summer of 2004.

Fig. 13. Left: Calibrations using Am/Be and monochromatic Y-88/Be neutron sources show good agreement with theoretical predictions of recoil energy threshold, while demonstrating insensitivity to a strong (3 mCi) gamma source. Right: multiple scattering events can produce more than one simultaneous bubble in the chamber, providing a strong rejection mechanism against neutron-induced events like that in the image.