Robinson Annulation of Chalcone and Ethyl Acetoacetate

advertisement

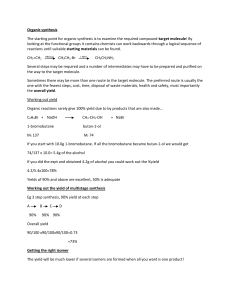

Experiment 1 Report: Robinson Annulation By Randolph J. Student Abstract: In this experiment we performed a Robinson annulation, which can be used to form fused ring structures and has numerous applications in the synthesis of complex organic molecules. The robinson annulation of ethyl acetoacetate and chalcone in the presence of a Ba(OH)2 catalyst produced 2-carboxyethyl-3,5-diphenyl-5-cyclohexen-1-one. My product compound had a melting point 109-111ºC and a yield of 20%. The melting point is the same as the literature value but the lower percent yield1 of 40-60% is due to a large product loss during the recrystallization process. Ethanol, reflux Ba(OH)2·H2O 1 16 h 3 2 4 Figure 1: Synthesis of 2-carboxyethyl-3,5-diphenyl-5-cyclohexen-1-one Introduction: The Robinson annulation can be used to form fused ring structures and has numerous applications in the synthesis of complex organic molecules. Because of its ability to form fussed ring structures, it has been used in the synthesis of natural products such as terpenes and steroids.1 The reaction described here is a three step process (Figure 2). Under the basic conditions of the barium hydroxide catalyst, 1 is deprotonated and converted into the corresponding enolate. The first step involves the addition of enolate 1 to the α,β-unsaturated ketone 2 to form the Michael addition product 5. In the second step 5 undergoes an internal aldol reaction to form ring structure 6. A dehydration reaction converts 6 into the final product, 4. + Ba(OH)2·H2O + 1 2 3 5 6 4 Figure 2: Reaction mechanism of Robinson annulation reaction 1 The Wichterle reaction can also form products similar to those of the Robinson annulation. The only modification the is the replacement of the α,β-unsaturated ketone with 1,3dichloro-cis-2-butene.2 The Robinson annulation was chosen over the Wichterle reaction due to the lower toxicities of the reactants. Experimental: Synthesis of 2-carboxyethyl-3,5-diphenyl-5-cyclohexen-1-one (4): Ethyl acetoacetate (1) (0.62 g), trans-chalcone (2) (1.01 g), and barium hydroxide monohydrate (3) (0.11 g) were added to 12 ml of 99% ethanol in a round bottom flask with a stir bar. The solution was refluxed for 16 h under inert atmostphere. The crude product was recrystallized in 95% ethanol and vacuum filtered in a Buchner funnel to yield a white microcrystalline powder, 4 (0.31 g, 0.96 mmol). m.p. 109-111ºC. The melting point is similar to the literature values but the yield was 20%, a value lower than the 40-60% yield reported in the literature.1 The discrepancy was most likely due to the recrystallization step. The percent yield can be further improved if numerous recrystallizations are performed. Results and Discussion: I successfully synthesized 2-carboxyethyl-3,5-diphenyl-5-cyclohexen-1-one 4 with a yield of 20%, a value lower than the 40-60% yield reported in the literature.1 This is most likely a result of the recrystallization step. It was very difficult to get 4 to dissolve in hot ethanol so a large amount of solvent was needed. It was then difficult to isolate the crystals upon cooling. The percent yield can be further improved if numerous recrystallizations are performed on the 3 rd and 4th crops of the mother liquor. The product 4 was also characterized via melting point. The observed melting range of 109-111ºC is very similar to the reported value of 110ºC. The narrow range indicates that there are very few impurities in the product. The main source of error in this experiment was in the recrystallization. A large amount of solvent was needed to get product 4 to dissolve which made it difficult to isolate the crystals upon cooling. The percent yield can be further improved with more recrystallizations. Conclusions: 2-carboxyethyl-3,5-diphenyl-5-cyclohexen-1-one was successfully synthesized with a 20% yield via Robinson annulation. The melting point was 109-111ºC, which is the same as the reported value of 110ºC, providing further confirmation that the product was pure. The low product yield can be improved if numerous recrystallizations are performed. This is a very useful reaction in which a fused enone ring structure is formed, building on the carbon backbone of the molecule, which has many potential applications in areas such as natural product synthesis. References: (1) Delaude, L.; Grandjean, J.; Noels, A. F. J. Chem. Ed. 2006, 83, 1225. (2) Marshal, J.; Schaeffer, D. J. J. Org. Chem. 1965, 30, 3642. Document prepared by Laura Hoch, LWTA 2013-2014 (Dept. of Chemistry) Document Version 1.0 2