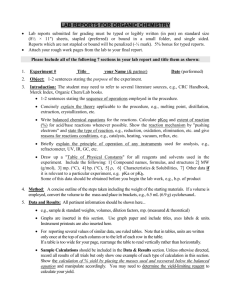

1b. dist post

advertisement

Distillation Experiment 3: Distillation • Common method for the purification of organic liquids • Process involves: 1. vaporization of a compound to separate it from it's less volatile contaminants 2. condensation & collection of the "pure" distillate Part A: Simple Distillation Part B: Fractional Distillation • Various types of distillation; method used will depend on the boiling point of the compound to be isolated & the specifics of the desired separation Reading: Mohrig, Hammond & Schatz Ch. 13 pgs 141-164; 166-173 Ch. 6 pgs 49-53; 55-58 watch the technique video on the course website! Distillation - simple distillation: useful for the separation of liquids with boiling points that differ by 70°C or more - fractional distillation: useful for the separation of compounds that boil at less than 70°C of one another - vacuum distillation: run in a sealed apparatus under vacuum; used for extremely high boiling liquids or those that decompose at high temp Distillation Simple Distillation Apparatus distillation head so, if reduce the applied pressure (e.g. apply vacuum), we effectively lower boiling point! water condenser distilling flask Boiling Point: temperature at which the vapor pressure of a liquid equals the applied pressure note location adapter apply heat reciever cool receiver • heat liquid • vapor pressure increases until equal to applied pressure; liquid begins to boil • vapors rise through the apparatus (condense on thermometer; register temp) • vapors pass through side arm, condense and are collected Temperature vs. Time Behavior Temperature vs. Time Behavior • Pure Liquid - vapor temperature increases to the boiling point - composition of vapor/liquid remain constant (thermal equilibrium) - distillation proceeds at a relatively constant temperature pure liquid • Mixture Mixture 1 bp differ by < 70°C - more complicated! Mixture 2 bp differ by > 70°C - liquid vapor equilibrium changes over the course of the distillation - temperature varies as the distillation proceeds Temperature vs. Time Behavior • These temperature changes described by two principles: Phase Diagram (plot of vapor + liquid composition vs. temp) • Mixture 2: 50:50 Mixture of A + B (BPs differ by > 70°C) Dalton's Law: vapor pressure of a liquid (P) is the same as the partial pressure of the individual components P = PA + PB bp of B Raoult's Law: the partial vapor pressure of a compound in a mixture is equal to the vapor pressure of the pure compound times it's mole fraction PA = PApure • XA both the vapor pressure & the amount of each component is important ! When a mixture begins to boil, the vapor always contains a higher % of the more volatile component than does the liquid ! As the distillation proceeds, the residual liquid is enriched in the higher boiling component, the temperature required to make residue boil increases, & the composition of the vapor changes bp of A Phase Diagram Phase Diagram • Mixture 2: 50:50 Mixture of A + B (BPs differ by > 70°C) • Mixture 2: 50:50 Mixture of A + B (BPs differ by > 70°C) bp of B bp of A bp of B bp of A 50:50 A:B - vapor contains almost exclusively A Temperature vs. Time Behavior 10:90 A:B - vapor still contains almost exclusively A! Phase Diagram • Mixture 1: 50:50 Mixture of A + B (BPs differ by < 70°C) bp of B bp of A Mixture 2 bp differ by > 70°C expect clean separation of A and B by simple distillation Phase Diagram Phase Diagram • Mixture 1: 50:50 Mixture of A + B (BPs differ by < 70°C) • Mixture 1: 50:50 Mixture of A + B (BPs differ by < 70°C) 50:50 A:B - vapor contains ~ 90% A Temperature vs. Time Behavior 20:80 A:B - vapor still only about 80% A How Can We Isolate A? BPs < 70° apart • Successive distillations - isolate partially purified material (say 70:30 A:B) - distill again - and again (etc.) • Fractional distillation!! - basic principles the same Mixture 1 bp differ by < 70°C - now provide surface for repeated vaporization & condensation - the fractionating column! fractionating column can't adequately separate A and B by simple distillation Fractional Distillation Apparatus Fractional Distillation BPs < 70° apart Temperature vs. Time Behavior L3 = 50% A, bp 63° Fractional Distillation bp differ by < 70°C 5:95 mixture of A & B Next Week (September 26-30) Experiment 3: Distillation expect clean separation of A and B as if bps differ by a greater amount Experimental Details - Parts A & B Work in pairs (each student does one distillation): 1. Obtain cyclohexane:toluene mixture - add to clamped distilling flask A. Simple Distillation B. Fractional Distillation DUE: 2. Add a boiling chip provides surface for nucleation - promotes vaporization helps to disperse heat; prevents hot spots & "bumping" separation of cyclohexane & toluene by these methods 3. Assemble microscale apparatus (simple or fractional - record which) will work in pairs (one distillation each; exchange data) lab reports are done individually 4. Before you begin check to be sure all joints are sealed & apparatus is secure check thermometer position!! Recrystallization Lab Report (exp 2) Lab Reports are due at the beginning of your regular lab session 5. Proceed with distillation carefully control temperature; optimal rate - 2 drops per minute record temperature with increasing distillate volume (every 2 drops) e.g. at 2 drops, at 4 drops, at 6 drops. etc. record total volume collected and "hold-up" 6. Exchange data with your lab partner (record their name) Simple Distillation: Microscale Apparatus note thermometer position: bulb is below the elbow wrap loosely with foil to help maintain temperature thermometer adapter distillation head connector with support rod long-neck roundbottom flask boiling chip collection flask Fractional Distillation: Microscale Apparatus thermometer adapter bulb location distillation head air condenser packed with stainless sponge connector with support rod collection flask ice bath ice bath short-neck roundbottom flask wrap loosely with foil to help maintain temperature boiling chip stir sand around to control temp (HOT! use a spatula) sand bath Some Pointers: • Control the temperature carefully - don't overheat - collect distillate at a rate no faster than 2 drops per minute (be sure collection flask is arranged so can see individual drops!) - if faster, separation (results) will be poor • Watch for leaks - check connectors before you begin - be sure joints are tight (avoid evaporation of distillate along the way) • Do not stop the distillation too soon - continue until only about 0.4mL solution remains in the roundbottom - temperatures may fluctuate a bit " a sudden drop in temperature may signify your distillation is over " alternatively, may mean you have exhausted the first component, with the second yet to distill " commonly seen in fractional distillation (sometimes the simple) " check the volume in the "still pot" (= roundbottom flask) sand bath Some Pointers: • Don't distill to dryness - flask may overheat and break • Data Collection - make a table in your notebook before you begin to collect data " volume of distillate (# drops, e.g. 2, 4, 6, 8 …) " versus temperature (°C) - measure the total volume of distillate collected (recovery) " transfer to graduated test tube to get an accurate measurement - measure the volume of distillate that remains in the roundbottom " again, transfer to graduated test tube " this is your "hold-up" - the amount of liquid not recovered " the amount of liquid retained by the apparatus Writing the Lab Report: Exp #2 Recrystallization See pgs 9-12 and pg 44 in your lab manual for more detailed instructions # Purpose - technique experiment: what will you learn? - what conclusions will you reach? Writing the Lab Report: Exp #2 Recrystallization # Results & Discussion (continued) - Part B: recrystallization of phenacetin evaluate success of your purification present your data specifically identify solvent you would use to recrystallize compound Is the compound pure? what data do you have at your disposal? physical appearance? TLC and melting point what do you expect to see if the compound is pure? what do you expect to see if the compound is impure? only after you answer these questions can you address clearly explain why you made this choice (refer to your observations) (a clear decision!) whether or not the purification was a success! comment of the efficiency of your recrystallization # Results & Discussion - Part A: solubility experiments how much did you get back? % recovery Writing the Lab Report: Exp #2 Recrystallization # Appendix A: Calculations - Rf values (just one!) yes, even though you've done it before - Percent Recovery amount of compound you got back versus "percent yield" # amount of compound that you made % recovery = amount pure product recovered (g) amount of crude material used (g) x 100