GT-Jet Manual - Cross

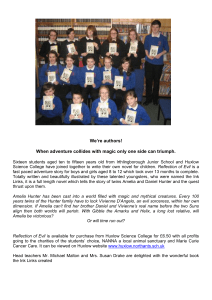

advertisement