belt and wrap friction - Statics for Engineering Technology

advertisement

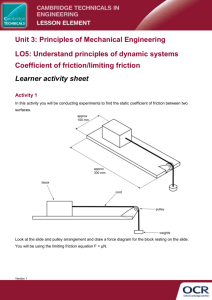

BELT AND WRAP FRICTION Rob Wendland, driving Mike Troxel's Federal-Mogul Dragster In-N-Out Burger A Capstan-Style Winch Belt and Wrap Friction When flat belts, V-belts, band brakes, and line-wrap around capstans are used in any form of product, the frictional forces developed must be determined. All forms of wrap friction are analyzed similarly. Let's first look at flat belts θ r T2 T1 2 A flat belt has a wrap angle around a pulley of θ radians. Normal forces develop at each finite point of contact with a resulting frictional force acting tangent to the pulley and opposite the direction of rotation. This reduces belt tension around the pully such that tension T1<T2 Furthermore, since belt tension changes continuously, so do the incremental normal and frictional forces Belt and Wrap Friction To help determine how frictional forces affect belt tension, consider a finite element over angle ∆θ. Acting on this element is slackside tension T and tightside tension T + ∆T y T T 2 F=⋅ N 2 T N Incremental forces ∆N and ∆F develop as a result of the applied incremental tensions. By performing an equilibrium analysis: x Fx = 0 = T cos ⋅ N − T T ⋅cos 2 2 Fy= 0 = N − T T ⋅sin 3 − T⋅sin 2 2 Belt and Wrap Friction y T T 2 F=⋅ N 2 T N x Substituting N => T = ⋅T⋅ Since this expression is developed over a very small angle, this would have to be summed around the wrap angle T i = ⋅T⋅ i i 4 = and cos =1 2 2 2 Substituting: F x => T = ⋅ N F y => N = T⋅ For small , sin i Belt and Wrap Friction y T T 2 F=⋅ N 2 T N x Since this expression is developed over a very small angle, applying such a summation would be impractical However, if we replaced the finite quantities of ∆T and ∆θ with infinitely small values of dT and dθ, we could integrate over θ as follows: T2 ∫ dTT T1 5 = ∫ d 0 T 2 = T 1 e This evaluates to: It's important to remember T2 is always larger than T1 and θ is in radians V-Belt Friction α The friction developed by a V-belt can be developed in a similar fashion. The relationship between tightside and slackside tension for a V-belt is: T 2 = T 1 e /sin / 2 6 Angle α must be expressed in radians Example 18 The accessory package for the engine shown below requires a torque of 30 ft-lbf. The pulley in contact with the belt has a diameter of 8” and a coefficient of static friction of 0.30. Determine the tension in each part of the belt if the belt is not to slip and: 40o 60o 7 the system uses a flat belt the system uses a V-belt with a 38o V and the same coefficient of friction Example 18 First determine angle of wrap. Draw a construction line at the base of T vector TB and parallel to vector TA. Angle α is the difference between angles of the two vectors and is equal θ α α to 20o. This results in a wrap angle of 200o or 1.11π radians Since there are two unknowns, we must develop two mathematical relationships to solve for the unknown tensions. These are the moment about the center of the pulley and the friction equation for a flat belt. Since moment is applied clockwise, tension TB is tightside tension; we will let T2 = TB and T1 = TA TA 40o B 60o 8 Example 18 M o = T B⋅4 in − T A⋅4 in − 30 ft⋅lb f ⋅12 in / ft . . . T B = T A 90 (Moments) -and0.3⋅1.11 T B = T A⋅e (Friction) TA 40o TB 60o θ Substituting: 0.3⋅1.11 T A 90 = T A⋅e = 2.85⋅T A . . . T A = 48.6 lb f and T B = 139 lb f α α o The application of a V-belt changes only the friction equation. The 38 V is 0.211 radians. Modifying the friction equation changes the solution to: 0.3⋅1.11 /sin 0.106 T A 90 = T A⋅e . . . T A = 3.82 lb f and = 24.5⋅T A T B = 98.4 lb f Notice the efficiency increase of a V-belt over that of a flat belt. The reduced tensions help increase bearing life 9 Frictional Forces Real Life Mechanisms T1 45o 90o T1 A 135o T1 T2 B µ = 0.40 C (A) T2 (A) o = 45 45⋅ = 180 = 0.25 rad 0.40⋅0.25 T 2 = T 1⋅e = 1.37⋅T 1 10 Since area does not affect the developed friction for a belt, the formula for flat belts is applicable to round line. Only angle of wrap and coefficient of friction govern developed tension T2 (B) o = 90 90⋅ = 180 = 0.50 rad 0.40⋅0.50 T 2 = T 1⋅e = 1.87⋅T 1 (C) o = 135 135⋅ = 180 = 0.75 rad 0.40⋅0.75 T 2 = T 1⋅e = 2.56⋅T 1 Example 19 300 lbf 11 F You are lifting an engine out of your friends car. In your front yard is a sturdy oak tree. You wrap a rope around a tree branch to lift the engine. The engine weighs 300 lbf, the rope has a 180o wrap, and µ = 0.1 How much force does it take to lift the engine from the vehicle? How much force must you apply to lower the engine back into place? Example 19 Line wrap is 180o or π radians. When lifting, force F is the tightside of the line (T2). To solve for T2: T 2 = T 1e T 2 = 300⋅e 0.1⋅ = 411 lb f 300 lbf 12 F To lower the engine, force F becomes the slack side of the line (T1). To solve for T1: T 1 = T 2 e− −0.1⋅ T 1 = 300⋅e = 219 lb f Frictional Forces Real Life Mechanisms Mechanisms using wrap friction are often critical life-safety devices. Such devices are used in rappelling, rock climbing, sailing, and rigging of equipment From left to right are: RescueTECH rappell rack; PMI brake tube for lowering long distances; and the Wichard gyb`easy to control the boom of a sailboat during a gybe. All devices must meet stringent NFPA, OSHA, ABYC, or Coast Guard requirements depending upon their application Some devices, such as the rack, have adjustable bars. Others, like the brake tube, rely on the number of wraps around the tube, while the anti-gybe device relies on how many passes of line through the non-adjustable bars 13 Example 20 (A) (A) (B) o = 800 = 4.44 rad T 2 = T 1⋅e 0.25⋅4.44 = 32.8⋅T 1 14 (C) (B) Consider the adjustable rack shown. The leftmost configuration has closely spaced bars resulting in 120o of contact on each turn. The other two are spaced to provide contact arcs as shown. Determine the tension ratio for each configuration if µ = 0.25 o = 560 = 3.11 rad T 2 = T 1⋅e 0.25⋅3.11 = 11.5⋅T 1 (C) o = 315 = 1.75 rad T 2 = T 1⋅e 0.25⋅1.75 = 3.95⋅T 1 Building the Great Pyramids... Friction Was a Factor µ=0.5 roll-rope µ=0.04 bearings µ=0.04 sledge-tracks µ=0.2 static friction The Egyptions and Mayans responsible for building the pyramids on their respective continents were able to reduce friction where it wasn't wanted and maximize friction where it was useful and desired. We still do this today in equipment design 15