Acta Biomaterialia 3 (2007) 573–585

www.elsevier.com/locate/actabiomat

Surface modifications and cell–materials interactions with anodized Ti

Kakoli Das, Susmita Bose, Amit Bandyopadhyay

*

W.M. Keck Biomedical Materials Research Laboratory, School of Mechanical and Materials Engineering, Washington State

University, Pullman, WA 99164, USA

Received 30 August 2006; received in revised form 21 November 2006; accepted 4 December 2006

Abstract

The objective of this study was to investigate in vitro cell–materials interactions using human osteoblast cells on anodized titanium. Titanium is a bioinert material and therefore becomes encapsulated after implantation into the living body by a fibrous tissue

that isolates it from the surrounding tissues. In this work, a bioactive TiO2 layer was grown on commercially pure titanium substrate

by an anodization process using different electrolyte solutions, namely H3PO4, HF and H2SO4. These electrolytes produced bioactive

TiO2 films with a nonporous structure showing three distinctive surface morphologies. Human osteoblast cell growth behavior was

studied with as-received and anodized surfaces using an osteoprecursor cell line (OPC 1) for 3, 5 and 11 days. When anodized surfaces were compared for cell–materials interaction, it was noticed that each of the surfaces has different surface properties, which led

to variations in cell–materials interactions. Colonization of the cells was noticed with a distinctive cell-to-cell attachment in the HF

anodized surface. Good cellular adherence with extracellular matrix extensions in between the cells was noticed for samples anodized

with H3PO4 electrolyte. The TiO2 layer grown in H2SO4 electrolyte did not show significant cell growth on the surface, and some cell

death was also noticed. Cell adhesions and differentiation were more pronounced with vinculin protein and alkaline phosphatase,

respectively, on anodized surfaces. 3-(4,5-Dimethylthiazol-2-yl)-2,5-diphenyl tetrazolium assays also showed an increase in living cell

density and proliferation with anodized surfaces. It was clear that rough surface morphology, high surface energy and low values of

contact angles were important factors for better cell materials interaction. A mineralization study was done in simulated body fluid

with ion concentrations nearly identical to those of human blood plasma to further understand biomimetic apatite deposition behavior. Similar to cell–materials interaction, variations in mineral deposition behavior were also noticed for films grown with different

electrolytes.

Ó 2007 Acta Materialia Inc. Published by Elsevier Ltd. All rights reserved.

Keywords: Anodization; Cell–material interactions; Oxide film

1. Introduction

Titanium and its alloys are widely used for orthopedic

and dental implants for their superior mechanical properties, low modulus, excellent corrosion resistance and good

biocompatibility. Titanium, being bioinert, cannot directly

bond to bone. After implantation into the living body it

becomes encapsulated by a fibrous tissue that isolates it

from the surrounding bone [1]. Studies have demonstrated

that bone tissue can form on the titanium surface with a

*

Corresponding author. Tel.: +1 509 335 4862.

E-mail address: amitband@wsu.edu (A. Bandyopadhyay).

very thin oxide cementum layer in between [2,3]. This phenomenon is known as osseointegration [4]. It takes several

months for titanium implants and bone tissue to reach integration. Hence, there is a growing interest in shortening the

process toward osseointegration and thereby reducing surgical restrictions. Various surface modifications, including

chemical treatment [5–7], thermal treatment [8], electrochemical method [9] and anodization [10], have been

applied to form a bioactive titanium oxide layer on the

metal surface. Evaluation of the above-processed films in

a simulated body fluid (SBF) demonstrated that apatite

deposition depends on chemical composition, surface properties, concentration of the electrolytes and crystalline

phases present in the film [11].

1742-7061/$ - see front matter Ó 2007 Acta Materialia Inc. Published by Elsevier Ltd. All rights reserved.

doi:10.1016/j.actbio.2006.12.003

574

K. Das et al. / Acta Biomaterialia 3 (2007) 573–585

Several in vitro and in vivo studies have shown that

modified surfaces have a higher early level of cell attachment than the untreated Ti surface. It has been shown that

micro-arc-oxidized and hydrothermally synthesized surfaces showed higher cell adhesion and proliferation rates

than did the untreated Ti surface [12]. Hydrothermal treatment of anodized Ti-substrate with calcium glycerophosphate and calcium acetate as electrolytes also led to

higher protein production than with untreated Ti surface

[13]. It was also shown that a titanium oxide surface had

a greater number of osteoblasts with higher cell activity

than did bare Ti surface [14].

The objective of this study was to understand the bone cell

materials interactions on a commercially pure Ti (cp-Ti) surface that has been modified via anodization in acid electrolytes. A titanium oxide layer on the Ti surface was grown

by an anodization process using H2SO4, HF and H3PO4 electrolytes at an anodizing voltages of 20 V. The biological

properties of these anodized surfaces were evaluated in

SBF for 3, 7, 14 and 21 days, and in vitro with the osteoblast

precursor cell line (OPC1). Apatite precipitation on substrates was observed for all anodized surfaces after incubation in SBF, and each surface gave rise to a different

cellular response due to variations in the surface properties.

2. Materials and methods

spectroscopy (EDS) was performed to qualitatively identify

the composition of the film. Oxide film thicknesses were

measured in SEM from a cross-sectional view of the Tifoils. Three samples were used to give the average thickness

value for each anodized condition.

Glancing angle X-ray diffraction (GAXRD) was conducted using a Bruker/Seimens platform system at University of Wisconsin, Madison. GAXRD studies were carried

out from a sealed Cu tube operating at 40 keV and

20 MPa. Glancing angles of 5° and 10° were used for all

the samples. Each of these samples was scanned in the 2h

range of 20–80°.

2.2. Surface analysis

2.2.1. Surface roughness

The surface roughness of each Ti-control and anodized

sample was measured using a surface profilometer (SPN

Technology, Goleta, CA). The scan was performed on each

sample three times, with a scan distance of 4 mm, at different

places on the sample. For each anodized condition three

samples were used. The stylus radius was 25 lm. The roughness data for 4 mm scan was based on 5000 points on the tip

of the profilometer. From all of these 5000 points, the root

mean square data (r.m.s.) were calculated. The average of

9 r.m.s. values (three from each sample) for each anodized

condition was determined along with the standard deviation.

2.1. Preparation and characterization of anodized Ti

A cp-Ti (99.6 at.%) sheet was used as the starting material. Each of the samples was 12 mm in diameter and

0.5 mm in thickness. Samples were abraded by silicon carbide paper in successive grades from 600 to 1200 grit (Leco

Corporation, MI), then ultrasonically cleaned in distilled

water and dried at room temperature. Final polishing

was performed using a cotton polishing cloth with a 1 lm

alumina suspension. Polished samples were used as controls for the experiments. For the anodization process,

the electrolytic cell consisted of a three-neck round bottomed flask. A cp-Ti anode was suspended from the centre

neck of the cell, a platinum cathode was suspended from

one of the necks by a platinum wire and a thermometer

was placed through the other neck. A DC power supply

(Hewlett Packard 0–60 V/0–50 A, 1000 W) was used to

vary the applied voltage. Three different solutions were

used as electrolyte: 1 (N) sulfuric acid (H2SO4), 1 (N) phosphoric acid (H3PO4) and 0.25 (N) hydrofluoric acid (HF).

All anodization experiments were performed at 20 V. Temperature of the electrolyte was maintained at 30 °C. The

temperature rise due to exothermic anodic reaction was

controlled by using large amount of electrolyte and changing the solution after every 1 h. TiO2 anodized film was

characterized using a scanning electron microscope

(SEM; Hitachi’s-570) and a field emission scanning electron microscope (FESEM; FEI, SIRION, OR) fitted for

energy-dispersive X-ray analysis. The operating voltage

for both SEM and FESEM was 20 kV. Energy-dispersive

2.2.2. Contact angle measurement

Contact angles were measured using the sessile drop

method with a face contact angle set-up equipped with a

microscope and a camera. A 0.5–1.0 ll droplet of distilled

water and McCoys 5A solution at pH 7.4 (cell culture medium) was suspended from the tip of the microliter syringe.

The syringe tip was advanced toward the disk surface until

the droplets made contact with the disk surface. Images

were collected with the camera and the contact angle

between the drop and the substrate was measured from

the magnified image. Three samples for each anodized conditions were used to collect the contact angle data in water

and in cell media. The apolar liquid diiodomethane and

two polar liquids, formamide and glycerol, were used in

the following equation to calculate the surface energy:

LW 1=2

1=2

cL ð1 þ cos hÞ ¼ 2 cLW

þ 2 cþ

S cL

S cL

þ 1=2

þ 2 c

ð1Þ

S cL

In Eq. (1), h is the contact angle of liquid L and solid S,

cLW is the apolar component of the surface energy, c+ is

the Lewis acid component (electron acceptor) and c is

the Lewis base component (electron donor) [15].

2.3. Cell–materials interaction studies

2.3.1. Cell morphology

For the cell–materials interaction studies, human osteoblasts were used. Cells were derived from an osteoblastic

K. Das et al. / Acta Biomaterialia 3 (2007) 573–585

precursor cell line (OPC1) established from human fetal

bone tissue [16]. Cells were plated at a density of

105 cm2 in 100 mm tissue culture plates and were cultured

in McCoy’s 5A medium (with L-glutamine, without phenol

red and sodium bicarbonate). Then 5% fetal calf serum, 5%

bovine calf serum, 2.2 g l1 sodium carbonate, 100 mg l1

streptomycin and 8 lg ml1 Fungizone (GibcoTM Labortories, Grand Island, NY) were added to the medium. Cells

were maintained at 37 °C under an atmosphere of 5%

CO2 and 95% air. Anodized samples were sterilized by

autoclaving (Amerex Instruments Ltd., CA) for 20 min at

121 °C before cell culture. OPC1 cells were seeded onto

the sterilized anodized titania surface. Culture medium

was changed every 2–3 days for the duration of experiment.

Samples were then removed from culture at 3, 7 and

11 days of incubation to study cell–materials interactions

under SEM.

For SEM observation, anodized cell cultured samples

were placed in 0.1 M phosphate-buffered saline (PBS) and

rinsed quickly. Samples were subsequently fixed with 2%

paraformaldehyde/2% glutaraldehyde in 0.1 M cacodylate

overnight at 4 °C. Following three rinses in 0.1 M cacodylate, each sample was post-fixed in 2% osmium tetroxide

(OsO4) for 2 h at room temperature. The fixed sample

was then again rinsed three times in 0.1 M cacodylate

and dehydrated in an ethanol series (30%, 50%, 70%,

95% and 100% three times). Samples were then critical

point dried using acetone and hexamethyldisilazane. Samples were mounted in aluminum stubs, gold coated (Technis Hummer, San Jose, CA) and observed under SEM.

2.3.2. Cell proliferation using MTT assay

3-(4,5-Dimethylthiazol-2-yl)-2,5-diphenyl tetrazolium

bromide (MTT) assay was used to evaluate cell proliferation on anodized samples. Duplicate samples per group

were evaluated. An MTT (Sigma, St. Louis, MO) solution

of 5 mg ml1 was prepared by dissolving MTT in PBS,

then filter sterilized. MTT was diluted with 50 ll of the

solution in 450 ll of serum-free phenol red-free Dulbeco’s

minimum essential medium. A 500 ll quantity of the above

diluted solution was used in each sample in 12-well plates

to form formazan by mitochondrial dehydrogenases. After

2 h incubation at 37 °C, 500 ll of the solubilization solution (10% Triton X-100, 0.1 N HCl and isopropanol) were

added in each well plate to dissolve the formazen crystals.

Then 100 ll of the solution was transferred to a new 96well plate and five data points were obtained from each

sample. The optical density of the solution in each well

was measured at a wavelength of 570 nm using a Microplate reader (Cambridge Tech., Inc., EIA). Experimental

results are presented as the mean of 10 values with standard deviation.

2.3.3. Immunochemistry and confocal microscopy

Cells cultured on anodized samples for pre-specified

number of days were fixed in 4% paraformaldehyde in

0.1 M phosphate buffer and were kept for 24 h at 4 °C

575

for future use. Those samples were rinsed in Triton for

10 min and blocked with TBST/BSA (Tris-hydroxymethyl

aminomethane (Tris)-buffered saline with 1% bovine serum

albumin, 250 mM NaCl, pH 8.3) for 1 h. Primary antibody

alkaline phosphatase (ALP) (Sigma, St. Louis, MO) or

Vinculin (Sigma–Aldrich, MO) was added at a 1:100 dilution and incubated at room temperature overnight. ALP

was used for cell differentiation, while vinculin was used

for cell attachment. The following day, samples were rinsed

with TBST/BSA three times for 10 min each. The secondary antibody, Oregon green goat anti-mouse antibody

(Molecular Probes, Eugene, OR), was added at a 1:100

dilution and incubated at room temperature for 1 h. Samples were then mounted on coverslips with Vectashield

mounting medium (Vector Labs, Burlingame, CA) with

propidium iodide (PI) and observed in confocal scanning

laser microscopy (BioRad 1024 RMC).

2.4. Mineralization study in simulated body fluids

Bioactivity of anodized titanium samples were evaluated

by immersion in simulated body fluids (SBF), which has a

similar ionic composition to human blood plasma. The

solution was prepared by dissolving NaCl, KCl, NaHCO3,

MgCl2 Æ 6H2O, CaCl2 Æ 2H2O, Na2SO4 Æ 10H2O and

K2HPO4 into distilled water and buffered at pH 7.35 with

tris-hydroxymethyl aminomethane (Tris) and 1 N HCl at

37 °C [17]. Samples were immersed in the glass vial containing 10 ml of SBF solutions and were kept under static conditions inside a biological thermostat at 37 °C for 3, 7, 14

and 21 days. All experiments were performed in duplicate

by running two independent glass vials simultaneously.

After exposure, samples were washed with distilled water

and then dried at 150 °C for 24 h.

3. Results

3.1. Anodization and surface characterization

Three different electrolytes. (a) 1 N H2SO4, (b) 1 N

H3PO4 and (c) 0.25 N HF were used for anodization of

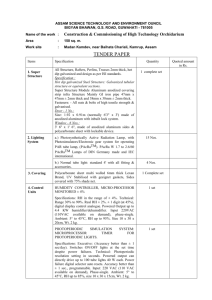

the Ti-substrates that led to three different surface morphologies. Fig. 1 shows representative scanning electron

micrographs of anodized and Ti-control surfaces. The Ticontrol, being metal, shows a smooth surface, as shown

in Fig. 1(a). All the anodic surfaces were nonporous, with

patterned micrographs. The H2SO4 anodized surface was

nonporous but a few bigger pores were noticed in some

regions of the undulated topography, as shown in

Fig. 1(b). The H3PO4 anodized surface was rough with a

flowery pattern, as shown in Fig. 1(c), while the HF anodized surface shows rough granulated debris pattern, and is

shown in Fig. 1(d). The average coating thickness of the

film was between 200 and 400 nm. Samples anodized for

60 min showed complete coverage of TiO2 on Ti for all

electrolytes, whereas samples anodized for <60 min were

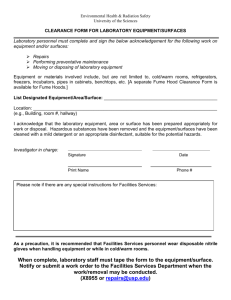

partially covered with the oxide film. Fig. 2 shows the

576

K. Das et al. / Acta Biomaterialia 3 (2007) 573–585

Fig. 1. FESEM micrographs showing morphology of (a) Ti surface, anodized oxides surfaces prepared by anodization in (b) H2SO4, (c) H3PO4 and

(d) HF electrolytes.

200

Table 1

GAXRD results analysis for different phases in the anodized and heattreated sample

T

160

Intensity

T

120

T

80

A

A

A

(c)

40

T

T

(b)

Sample condition

Phases

H2SO4

H2SO4 – 400 °C

H2SO4 – 600 °C

H3PO4

H3PO4 – 400 °C

H3PO4 – 600 °C

HF

Amorphous/anatase

Anatase

Antase + rutile

Amorphous/anatase

Anatase

Anatase + rutile

Anatase + rutile

(a)

0

30

40

50

60

70

80

2-Theta

Fig. 2. GAXRD results on oxide film anodized in (a) H2SO4, (b) H3PO4

and (c) HF electrolytes. A – denotes anatase, T – titanium phases.

GAXRD results on the anodized films. Most of the oxide

films show some anatase phase in an amorphous background, which is also given in Table 1. The oxide films were

uniform and adherent.

3.2. Cell–materials interactions

3.2.1. Cell morphology

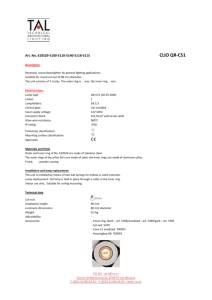

OPC1 cell attachments on sample surfaces were analyzed for cell–materials interactions using a scanning electron microscope. Fig. 3 shows the SEM of cell

morphologies on Ti-control and anodized surfaces after

3 days of cell culture. Cells on Ti-control in Fig. 3(a) show

an elongated, flattened morphology. Cells on the H2SO4

anodized surface show a rounded morphology, along with

some cell death, as shown in Fig. 3(b). The H3PO4 surface

shows good cell attachment in Fig. 3(c), but cells are confined to one region and do not extend like the TiO2 surface

from the HF electrolyte. The HF anodized surface is

entirely covered with OPC1 cell layers, and filopodia extensions were observed coming out from the cell to grasp the

granulated pattern rough surface for anchorage, as shown

in Fig. 3(d). To further understand the osteoconductivity of

the anodized surfaces, cells were cultured for 11 days and

are shown in Fig. 4. Fig. 4(a) shows cells in the Ti-control

surface, in which a flattened, elongated cell morphology

with many filopodia extensions from the cell to the substrate and small calcified nodules after 11 days of cell culture can be seen. It can be seen in Fig. 4(b) that cells

minimized the surface area of attachment in the H2SO4

anodized surface. However, cell spreading and prolifera-

K. Das et al. / Acta Biomaterialia 3 (2007) 573–585

577

Fig. 3. SEM micrograph illustrating OPC1 cell adhesion after 3 days of culture on (a) control-Ti and oxide surfaces anodized in (b) H2SO4, (c) H3PO4 and

(d) HF electrolytes.

tion are excellent for the H3PO4 anodized surface shown in

Fig. 4(c). An abundant amount of extracellular matrix

(ECM) can be seen between the neighboring cells on the

anodized H3PO4 surface, forming a three-dimensional fibril

network. Colonization of the cells was noticed, with cells

developing a double net-like layer structure in the HF

anodized surface after 11 days of cell culture; these are

shown in Fig. 4(d). Distinctive cell-to-cell attachment was

noticed, with small calcified nodules as an early sign of cell

differentiation after 11 days in both the HF and H3PO4

anodized surfaces.

anodized surfaces there was no difference (p* < 0.001) in

cell spreading but there was a significant difference between

cells on the H2SO4 (p** < 0.01) and Ti-control at 11 days of

culture.

0.25

Day-5

Day-11

Day-16

P*

Optical density

0.2

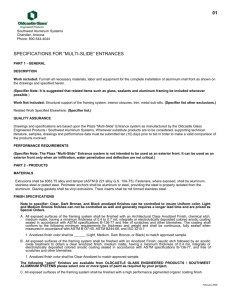

3.2.2. Cell proliferation using the MTT assay

The MTT assay was used to determine the OPC1 cell

proliferation on control-Ti and different anodized surfaces.

Fig. 5 shows a comparison of cell densities on the different

anodized surfaces for 5, 11 and 16 days. For 5 days of culture, a slightly higher value in optical density was noticed

in the H3PO4 and HF anodized surfaces in comparison

with the Ti-control and H2SO4 anodized surfaces. After

11 days of culture a significant difference in optical density

was noticed. Cell density for the anodic oxide increased in

the order H3PO4 < HF < H2SO4 < Ti- control. A slight

increase in density was noticed with increasing culture time

to 16 days for each anodic condition when compared with

11 days. However, the number of cells on the H3PO4 and

HF anodic surfaces was always higher than those of the

H2SO4 and Ti-control surfaces. For the H3PO4 and HF

P*

P**

0.15

0.1

0.05

0

H3PO4

HF

H2SO4

Ti-Control

Sample conditions

Fig. 5. Optical density measured after culture for 5, 11 and 16 days at a

wavelength of 570 nm by reader. There were significant difference in

optical density after 11 days in the different anodized conditions samples.

P* < 0.001 for H3PO4, HF and P** < 0.01 for H2SO4 compared with Ticontrol at 11 days of culture.

Fig. 4. SEM micrographs showing the cellular adhesion and proliferation on (a) control Ti, oxide surfaces anodized in (b) H2SO4, (c) H3PO4 and (d) HF

electrolytes after 11 days of incubation.

578

K. Das et al. / Acta Biomaterialia 3 (2007) 573–585

3.2.3. Immunochemistry and confocal microscopy

Vinculin aids in the assembly of focal contacts by crosslinking and recruiting other proteins to form adhesive plagues. Vinculin also acts as an adhesion molecule between

the cells and the substratum. Antibody bound to vinculin

expressed green fluorescence and nuclei stained with PI in

the mounting medium expressed red fluorescence. Fig. 6

shows the vinculin study for 5 days at two different magnifications. Vinculin expression shows that a lower number

of cells attach to one another and to the substratum in

the Ti-control and H2SO4 anodized samples, as shown in

Fig. 6(a) and (b), than in the H3PO4 and HF surfaces,

shown in Fig. 6(c) and (d), respectively. However, based

on our data, there was no difference in the distribution of

focal adhesion sites in these samples.

Alkaline phosphatase is an early marker for osteoblast

differentiation and is thought to play a major role in bone

formation [18]. Fig. 7(a)–(d) show ALP activity for samples

after 5 days in culture. Little difference was found in the Ticontrol and H2SO4 anodized surfaces shown in Fig. 7(a)

and (b), respectively. Fig. 7(c) and (d) shows that the

ALP enzymatic activity was higher in the H3PO4 and HF

anodized surfaces. With the increase in cell culture time

from 5 to 11 days, the ALP activity increased progressively

in all the anodized oxide surfaces, as shown in Fig. 7(f)–(h)

for 11 days of culture. At day 11, all the anodized surfaces

show better cell differentiation activity compared with the

Ti-control (Fig. 7(e)).

3.3. Apatite-forming ability of the anodized film

To compare their biocompatibility, the anodized samples and the control Ti were immersed in SBF for 3, 7,

14 and 21 days. Fig. 8(a)–(d) shows surface micrographs

of the samples after immersion in SBF for 21 days. It can

be seen that anodized surfaces have a low level of ability

for Ca-apatite deposition in SBF. No apparent changes

appeared on the polished surface of Ti-control even after

21 days. It has been reported that heat treating anodized

samples at a higher temperature results in more apatite

deposition [19]. Therefore, in the present study the influence of temperature on the surface TiO2 layer for apatite

deposition was investigated by heat treating the anodized

samples at 400 and 600 °C for 2 h. It was found that heat

treatment resulted in anatase and rutile titanium oxide

phases with different surface morphologies compared with

Fig. 6. Immunolocalization of adhesive molecule vinculin in OPC1 cells for 5 days culture on (a) Ti-control, (b) H2SO4, (c) H3PO4, (d) HF surfaces; green

fluorescence indicating antibody bound to vinculin, red fluorescence indicating antibody bound to DNA (nucleus). (For interpretation of the references in

color in this figure legend, the reader is referred to the web version of this article.)

K. Das et al. / Acta Biomaterialia 3 (2007) 573–585

579

Fig. 7(a–d). Confocal micrographs of ALP expression for 5 days in OPC1 cells cultured on (a) Ti-control, (b) H2SO4, (c) H3PO4 and (d) HF for 5 days.

Green fluorescence indicating antibody bound to ALP, red fluorescence indicating antibody bound to DNA (nucleus). (For interpretation of the references

in color in this figure legend, the reader is referred to the web version of this article.)

the anodized surface, as shown in Fig. 9(a)–(f). Heat-treated samples showed significant Ca-apatite deposition in

SBF after 7 days, as shown in Fig. 10(a)–(f). From EDS

analysis in Fig. 11(a), it was observed that the precipitated

particles on the surface of anodic film were Ca, P and Mg

compounds, and these are reported in Table 2. Infrared

results in Fig. 11(b) show the presence of OH, PO2

4

and CO2

3 groups.

4. Discussions

The different kinetic steps of growth of an anodic film

reported by Vermileya [20] are as follows: nucleation of

the anodic film; growth of crystals; possible formation of

a continuous film; thickening of the film; limitation of the

film thickness. Deplancke et al. described that there is

always presence of natural continuous oxide film before

anodization [21]. Therefore, the last two steps were changed as: thickening of the natural oxide film; oxygen evolution and dissolution of the film in sulfuric acid. In general,

oxide film begins inhibiting the active dissolution of titanium according to the following reaction:

Ti þ 2H2 O ! TiO2 þ 4Hþ þ 4e

It is generally known that titanium oxide growth involves

field-assisted migration of ions through the oxide films

[22,23]. A slower dissolution rate also creates a saturation

effect on the film thickness.

Surface properties of implant material have a crucial

role for cell adhesion and cell proliferation. The different

morphology for the three different anodized surfaces

leads to different cell–materials interactions. When a biomaterial is implanted into a body, its surface is immediately covered with blood and serum proteins [24]. Cell

adhesive proteins such as fibronectin and vitronectin,

found in high concentrations in the blood, can provide

attachment sites for cells. Materials that adsorb more

attachment proteins can provide more sites for osteoblast

precursor bonding to the implant, which then lead to faster bone in-growth and implant stabilization. Surface

topography plays an important role as it gives focal

adhesion points for the proteins to get attached and thus

help in the cell adhesion process [25,26]. The ‘‘flowery

effect’’ in the H3PO4 and rough patterned HF anodized

surfaces give more focal points than the smooth metallic

580

K. Das et al. / Acta Biomaterialia 3 (2007) 573–585

Fig. 7(e–h). Confocal micrographs of ALP expression for 11 days in OPC1 cells cultured on (a) Ti-control, (b) H2SO4, (c) H3PO4 and (d) HF for 11 days.

Green fluorescence indicating antibody bound to ALP, red fluorescence indicating antibody bound to DNA (nucleus). (For interpretation of the references

in color in this figure legend, the reader is referred to the web version of this article.)

Ti-control surface. The three anodized surfaces are nonporous, but only two of them gave better cellular attachment, the exception being the H2SO4 surface. This led us

to investigate other factors that control cell–materials

interactions.

Factors which also play a crucial role in the cell attachment process are surface roughness, contact angles or wettability and surface energy. It is generally accepted that

high roughness led to better cell attachment. Table 3 shows

the average r.m.s. roughness values for different surfaces.

There is almost an order of magnitude difference in roughness for the Ti-control and anodized surfaces. As-received

and polished titanium samples show a smooth surface with

an r.m.s roughness value of 0.0074 lm. In the literature it

has also been noted that cellular adhesion, proliferation

and detachment strength are sensitive to surface roughness.

A roughness of 4.68 lm on the surface of HA disc-shaped

pellets showed a higher cellular adhesion than a roughness

of 0.73 lm [27]. Lampin et al. also showed that the degree

of roughness affects the surface energy and hence the cell

adhesion process [28].

The contact angle on the anodized and Ti-control surfaces was measured using cell media and distilled water,

as shown in Fig. 12. It was seen that the contact angle

decreased significantly in the H3PO4 surface, improving

the wettability of the surface. A contact angle higher than

20° shows the hydrophobic nature of the surface. Since the

cell media is water based, the cellular attachment is poor in

any hydrophobic surface. The H3PO4 surface with

improved wettability enhanced the cell attachment process.

Webb et al. also noted the highest level of cell attachment

on moderately hydrophilic surfaces [29]. A high contact

angle with a hydrophobic nature led to poor cell attachment in the H2SO4 surface. A low contact angle also led

to high surface energy, which is another factor that contributes to better cell attachment.

To better understand the cell–materials interaction, the

effect on surface energies of the anodized surfaces was calculated using three different well-characterized liquids. The

contact angles for each of the liquids on the samples are

listed in Table 4. The contact angles in diiodomethane

and formamide were 1° and 5° for the H3PO4 anodized

K. Das et al. / Acta Biomaterialia 3 (2007) 573–585

581

Fig. 8. FESEM photographs demonstrating the deposition of precipitates in SBF for 21 days on (a) Ti-control, oxidized titanium surface anodized in

(b) H2SO4, (c) H3PO4 and (d) HF electrolytes.

Fig. 9. FESEM micrograph showing the surface morphology of TiO2 layer prepared by heat treatment at (a) 400 °C, (b) 600 °C anodized H2SO4 surface,

(c) 400 °C, (d) 600 °C anodized in H3PO4 and (e) 400 °C, (f) 600 °C of the anodized HF surface.

surface, and a very high surface energy value, 101.27 mJ

m2, was obtained in comparison with the Ti-control. A

very low surface energy value of 55.60 mJ m2 leads to

poor cellular attachment in the H2SO4 surface. Cell attachment and proliferation were inferior in the Ti-control surface than in the anodized surfaces, indicating that surface

582

K. Das et al. / Acta Biomaterialia 3 (2007) 573–585

Fig. 10. Mineralization study for 7 days on the anodized surface H2SO4 followed by heat treatment at (a) 400 °C, (b) 600 °C, anodized in H3PO4 and heat

treated at (c) 400 °C, (d) 600 °C for anodized HF surface.

Fig. 11. (a) EDS analysis for the apatite deposition on anodized surface in SBF. Presence of calcium to phosphorous ratio: Ca/P = 1.36. (b) IR data for

H3PO4 oxide surface immersed in SBF for 21 days.

Table 2

EDS results presents in the table shows the amount of different element

present in wt.% and at.%

Element

wt.%

at.%

CK

OK

Mg K

PK

Ca K

Ti K

10.04

20.16

0.52

1.60

2.10

65.58

23.21

34.88

0.65

1.43

1.94

37.89

energy plays an important role on cell–materials interaction. Other studies also showed that a better cell attachment takes place on surfaces with higher energy [12].

Redey et al. showed that the low-energy strata in carbon-

Table 3

Surface roughness on the anodized and control Ti-surface

Surfaces

Average r.m.s. values (lm)

Standard deviation (lm)

Ti-control

H2SO4

HF

H3PO4

0.007414

0.025

0.0830

0.0157

0.000101

0.00145

0.00415

0.00075

ate apatite led to poorer human trabecular osteoblastic cell

attachment and spreading than the high-energy strata

hydroxyapatite surface [30]. Ti-materials interaction with

osteoblast cells depend not only on the oxide surface but

also on the surface properties of the film. A patterned

microstructural topography, improved wettability, high

K. Das et al. / Acta Biomaterialia 3 (2007) 573–585

Contact Angle (deg.)

80

water

60

cell media

40

20

0

Ti-Control

H2SO4

H3PO4

HF

Sample

Fig. 12. Contact angle of liquid droplets measured on the anodized and

Ti-control samples.

surface energy and surface roughness lead to more cell

attachment and proliferation than with the control Ti

surface.

Osteoblasts are attachment-dependent cells, i.e. they

must attach first to the surface then spread and mineralize

their extracellular matrix [31]. The attachment phase is an

initial stage involving physicochemical linkage between

cells and the attaching surface. Adhesion of cells is affected

by the attaching surface morphology, surface roughness,

surface wettability and surface energy [31–33]. With

increasing roughness, the cell attachment also increases,

as shown in the 5 day cell culture results with vinculin protein expression in Fig. 6. A higher intensity of adhesion plague was noticed in Ti6Al4V surfaces with degrees of

roughness of grade 4000, 1200, 80 shows higher intensity

of adhesion plague than the mirror-finish smooth surfaces

as reported by Linez-Bataillon et al. [34]. The surface

roughness affected the surface morphology, which in turn

affected the surface wettability. In the present case, cells

were attached more to the hydrophilic H3PO4 anodized

surface (Fig. 6(c)) than in the hydrophobic Ti-control surface (Fig. 6(a)).

From the MTT assay study, we observed that cell proliferation increased significantly when osteoblasts were cultured for 11 and 16 days. The proliferation of cells

usually follows a standard pattern: (1) the initial lag phase:

a period of adaptation during which cells replace elements

of the cell surface; (2) the log phase: a phase of exponential

increase in cell number; and (3) the plateau phase: cell division is balanced by cell loss and bone cell phenotypic markers are expressed [35,36]. Cell cultures were consistent and

started to follow a log phase after 5 days of culture, and

there was a high yield of proliferative activity in osteoblast

583

cells after 11 days. It was also noticed that cell proliferation

was affected by surface topography and roughness. A significant difference in cell density was noticed on anodized

surfaces and the flat-polished Ti-control surface. The difference in cell density was statistically significant after 11 days

in the H3PO4 and HF anodized surfaces compared with the

Ti-control.

ALP is an early marker for osteoblast differentiation

and it is generally accepted that differentiation increases

with surface roughness [37–39]. Boyan and co-workers

found that, with increase in surface roughness of the Ti

substrate, the ALP activity of MG 63 cells was higher after

7 days [37]. Similar results were observed in our 5 day

results, which showed higher ALP expressions in rougher

H3PO4 and HF anodized surfaces than the smoothpolished Ti-control and H2SO4 anodized surfaces in

Fig. 7(a–d). ALP also plays a role in mineralization. With

an increase in culture time to 11 days there is an enhancement in ALP expression in all the anodized surfaces, indicating the beneficial effect of the anodization of the surface

on ECM mineralization.

A mineralization study of anodized samples showed the

presence of a Ca-compound on the surface. It has been suggested that apatite, once nucleated, will grow spontaneously in the body environment [40]. There have been

several reported models for apatite deposition on the

TiO2-surface [5,42,43]. A TiO2 layer forms Ti–OH groups

in an aqueous solution and these groups serve as nucleation

sites for apatite crystals and favor deposition. Reaction of

the Ti–OH groups with aqueous solution changes the surface charge of the Ti surface. The negatively charged OH

interacts with positively charged Ca2+ ions and thus reveals

a positive charge on the surface. The surface then interacts

with phosphate groups and forms amorphous calcium

phosphate [41]. These calcium phosphates eventually crystallize to bone-like apatite. The high ability for apatite

deposition on heat-treated samples led us to study the influence of the surface properties on the kinetics of nucleation

of calcium-apatite. Surface properties were characterized

by contact angle measurement on two different surfaces –

one with anatase phase heat treated at 400 °C and other

with anatase/rutile phase heat treated at 600 °C. The

observed contact angles of various liquids are much larger

on rutile/anatase surfaces than on the just anatase surface

(Table 5). In nucleation, the tendency for a crystal to form

depends on two thermodynamic factors: (a) Gibbs free

energy and (b) the activation energy barrier to diffusion

Table 4

Surface energy of the samples

Surfaces

Formamide

Glycerol

Diiodomethane

Surface energy (mJ m2)

Ti-control

H2SO4

HF

H3PO4

18 ± 1.15

21 ± 1

11 ± 3.05

5 ± 0.57

40 ± 2.04

41 ± 1.15

39 ± 4.61

31 ± 1.73

37 ± 0.57

35 ± 0.57

23 ± 2.08

1 ± 0.577

73.68 ± 0.20

55.60 ± 0.53

77.25 ± 1.09

101.27 ± 1.08

584

K. Das et al. / Acta Biomaterialia 3 (2007) 573–585

Table 5

Contact angles (deg) of various liquids on anatase and rutile surfaces

Liquid

Anatase

Anatase/rutile

Diiodomethane

Glycerol

Formamide

Water

13 ± 0.82

24 ± 1.70

10 ± 1.63

58 ± 2.08

30 ± 1.64

28 ± 3.11

12 ± 1.71

60 ± 2

Table 6

Surface energy components and parameters of anatase and anatase/rutile

Sample

cLW

c+

c

DG

Anatase

Anatase/rutile

49.5

44.22

57.57

4.57

51.97

2.53

705.6

151.42

from bulk solution to substrate. The energy barrier, caused

by Lewis acid–base interactions across the interface, is

reduced due to the high value of the Lewis base (c+) parameter in the anatase surface (Table 6) [44]. According to a

physical model, it is reported that an increase in adhesion

energy promotes nucleation on solid substrates [45]. The

calculated free energy of adhesion of water on the anatase

surface is DG = 705.6 mJ m2. The low free energy on the

anatase surface facilitates faster nucleation of apatite than

the high free energy (DG = 151.42 mJ m2) of the anatase/rutile surface.

5. Conclusions

Titanium oxide nonporous films were grown on Ti surfaces via anodization for biomedical applications in three

different acidic solutions. A difference in microstructure

changes the cellular behavior from a rounded cell morphology with minimized surface attachment in the H2SO4 anodized surface to cell spreading and abundant extracellular

matrix in the H3PO4 and HF anodized surfaces. Cell adhesion using the vinculin adhesive molecule and cell proliferation using MTT assays showed that the best adherence

and proliferation were in the HF and H3PO4 anodized

oxide surfaces compared with the H2SO4 and Ti-control

surfaces. ALP expression on anodized surfaces shows pronounced cell differentiation. It was seen that higher surface

roughness, low contact angle, improved wettability and

high surface energy led to better cell attachment and proliferation in two of the anodized surfaces. It was also

observed that with the emergence of the rutile phase the

free energy of the surface increases, leading to a decrease

in apatite deposition on the oxide surfaces.

Acknowledgements

The authors would like to thanks Ms. Jessica Moore

and Professor Howard L. Hosick of the School of Biological Sciences and Molecular Biosciences, WSU. We would

also like to acknowledge Dr. Weichang Xue, a postdoctorate fellow in our laboratory, for his helpful assistance. We

acknowledge the financial support from the Office of Naval

Research (N00014-01-04-0644 and N00014-01-05-0583).

References

[1] Nishiguchi S, Nakamura T, Kobayashi M, Kim HM, Miyaji F,

Kokubo T. The effect of heat treatment on bone-bonding ability of

alkali-treated titanium. 20, 1999. p. 491–500.

[2] Sennerby L, Thomsen P, Ericson LE. Ultrastructure of the bone–

titanium interface in rabbits. Mater Med 1992;3:262–71.

[3] Branemark P-I, Hansson BO, Adell R, Breine U, Lindström U,

Hallen O, Ohman A. Osseointegrated implants in the treatment of the

edentulous jaw. Experience from a 10 year period. Scand J Plast

Reconstruct Surg 1977;11:1–132.

[4] Branemark P-I. Osseointegration and its experimental background. J

Prosthet Dent 1983;50:399–410.

[5] Jonášová I, Müller FA, Helebrant A, Strnad J, Greil P. Biomimetic

apatite formation on chemically treated titanium. Biomaterial

2004;25:1187–94.

[6] Xiao F, Tsuru K, Hayakawa S, Osaka A. In vitro apatite deposition

on titania film derived from chemical treatment of Ti substrates with

an oxysulfate solution containing hydrogen peroxide at low temperature. Thin Solid Films 2003;441:271–6.

[7] Wu J-M, Hayakawa S, Tsuru K, Osaka A. Porous titania films

prepared from interactions of titanium with hydrogen peroxide

solution. Scripta Mater 2002;46:101–6.

[8] Fujibayashi S, Neo M, Kim H-M, Kokubo T, Nakamura T.

Osteoinduction of porous bioactive titanium metal. Biomaterials

2004;25:443–50.

[9] Sul Y-T, Johansson CB, Jeong Y, Albrektsson T. The electrochemical

oxide growth behavior on titanium in acid and alkaline electrolytes.

Med Eng Phys 2001;23:329–46.

[10] Yang B, Uchida M, Kim H-M, Zhang X, Kokubo T. Preparation of

bioactive titanium metal via anodic oxidation treatment. Biomaterials

2004;25:1003–10.

[11] Rohanizadeh R, Al-Sadeq M, LeGeros RZ. Preparation of different

forms of titanium oxide on titanium surface: effects on apatite

deposition. J Biomed Mater Res 2004;71A:343–52.

[12] Zhang YM, Bataillon-Linez P, Huang P, Zhao YM, Han Y, Traisnel

M, Xu KM, Hilderbrand HF. Surface analyses of micro-arc oxidized

and hydrothermally treated titanium and effect on osteoblast behavior. J Biomed Mater Res 2004;68A:383–91.

[13] Rodriguez R, Kim K, Joo Ong L. In vitro osteoblast response to

anodized titanium and anodized titanium followed by hydrothermal

treatment. J Biomed Mater Res 2003;65A:352–8.

[14] Feng B, Weng J, Yang BC, Qu SX, Zhang XD. Characterization of

surface oxide films on titanium and adhesion of osteoblast. Biomaterials 2003;24:4663–70.

[15] van Oss CJ, Giese Jr RF, Giese RJ. Reevaluation of the surface

tension components and parameters of polyacetylene from contact

angles of liquids. Langmuir 1990;6:1711–3.

[16] Winn SR, Randolph G, Uludag H, Wong SC, Hair GA, Hollinger

JO. Establishing an immortalized human osteoprecursor cell line:

OPC1. J Bone Miner Res 1999;14:1721–33.

[17] Kokubo T, Kushitani H, Sakka S, Kitsugi T, Yamamuro T. Solutions

able to reproduce in vivo surface-structure changes in bioactive glassceramics A-W. J Biomed Mater Res 1990;24:721–34.

[18] Laintinen M, Halttunen T, Jortikka L, Teronen O, Sorsa T,

Lindholm TS. The role of transforming growth factor-beta on

retarded osteoblastic differentiation in vitro. Life Sci 1999;64:847–58.

[19] Wang X-X, Yan W, Hayakawa S, Tsuru K, Osaka A. Apatite

deposition on thermally and anodically oxidized titanium surfaces in

a simulated body fluid. Biomaterials 2003;24:4631–7.

[20] Vermileya DA. Anodic films. Adv Electrochem Electrochem Eng

1963;3:211–86.

[21] Delplancke J-L, Degrez M, Fontana A, Winand R. Self-colour

anodizing of titanium. Surf Technol 1982;16:153–62.

K. Das et al. / Acta Biomaterialia 3 (2007) 573–585

[22] Yahalom J, Zahavi J. Electrolytic breakdown crystallization of

anodic oxide films on A1, Ta and Ti. Electrochim Acta

1970;15:1429–35.

[23] Ammar IA, Kamal I. Kinetics of anodic oxide-film growth on

titanium-I. Electrochim Acta 1971;16:1539–53.

[24] Puleo DA, Nanci A. Understanding and controlling the bone–

implant interface. Biomaterials 1999;20:2311–21.

[25] Hormia M, Kononen M. Immunolocalization of fibronectin and

vitronectin receptors in human gingival fibroblasts spreading on

titanium surfaces. J Periodontal Res 1994;29:146–52.

[26] Degasne I, Basle MF, Demais V, Hure G, Lesourd M, Grolleau B,

et al. Effects of roughness, fibronectin and vitronectin on attachment,

spreading and proliferation of human osteoblast-like cells (Saos-2) on

titanium surface. Calcified Tissue Int 1999;64:499–507.

[27] Deligianni DD, Katsala ND, Koutsoukos PG, Missirlis YF. Effect of

surface roughness of hydroxyapatite on human bone marrow cell

adhesion, proliferation, differentiation and detachment strength.

Biomaterials 2001;22:87–96.

[28] Lampin M, Warocquier-Clerout R, Degrange M, Sigot-Luizard

MF. Correlation between substratum roughness and wettability,

cell adhesion, and cell migration. J Biomed Mater Res

1997;36:99–108.

[29] Webb K, Hlady V, Tresco PA. Relative importance of surface

wettability and charged functional groups on NIH3T3 fibroblast

attachment, spreading and cytoskeletal organization. J Biomed Mater

Res 1998;41:422–30.

[30] Redey SA, Nardin M, Bernache-Assolant D, Rey C, Delannoy P,

Sedel L, Marie PJ. Behavior of human osteoblastic cells on

stoichiometric hydroxyapatite and type A carbonate apatite: role of

surface energy. J Biomed Mater Res 2000;50:353–64.

[31] Anselme K. Osteoblast adhesion on biomaterials. Biomaterials

2000;21:667–81.

[32] Boyan BD, Lohmann Ch, Dean DD, Sylvia VL, Cochran DL,

Schwartz Z. Mechanism involved in osteoblast response to implant

surface morphology. Annu Rev Mater Res 2001;31:357–71.

[33] Zhu X, Chen J, Scheideler L, Reichl R, Geis-Gerstorfer J. Effects of

topography and composition of titanium surface oxides on osteoblast

responses. Biomaterial 2004;25:4087–103.

585

[34] Linez-Bataillon P, Monchau F, Bigerelle M, Hildebrand

HF. In vitro MC3T3 osteoblast adhesion with respect to

surface roughness of Ti6Al4V substrates. Biomol Eng

2002;19:133–41.

[35] Stein GS, Lian JB. Molecular mechanism mediating proliferation/

differentiation interrelationships during progressive development of

the osteoblast phenotype. Endocr Rev 1993;1:424–42.

[36] Stein GS, Lian JB, Owen TA. Relationship of cell growth to the

regulation of tissue-specific gene expression during osteoblast differentiation. FASEB J 1990;4:3111–23.

[37] Martin JY, Schwartz Z, Hummart TW, Schraub DM, Simpson J,

Lankford J, et al. Effect of titanium surface-roughness on proliferation, differentiation, and protein-synthesis of human osteoblast-like

cells (MG63). J Biomed Mater Res 1995;29:389–401.

[38] Kieswetter K, Schwartz Z, Hummert TW, Cochran DL, Simpson J,

Dean DD, et al. Surface roughness modulates the local production of

growth factors and cytokines by osteoblast-like MG-63 cells. J

Biomed Mater Res 1996;32:55–63.

[39] Boyan BD, Batzer R, Kieswetter K, Liu Y, Cochran DL, SzmucklerMoncler S, et al. Titanium surface roughness alters responsiveness of

MG63 osteoblast-like cells to 1alpha, 25-(OH)2D3. J Biomed Mater

Res 1998;39:77–85.

[40] Li P, Ohtsuki C, Kokube K, Nakanishi N, Soga N, Yamamuro T,

et al. A role of hydrated silica, titania and alumina in forming

biologically active bone-like apatite on implant. J Biomed Mater Res

1994;7:28–30.

[41] Brunette DM, Tengvall P, Textor M, Thomsen P. Titanium in

medicine: material science, surface science, engineering, biological

responses, and medical applications. New York: Springer; 2001.

[42] Li PJ, Ohtsuki C, Kokubo T, Nakanishi K, Soga N, Degroot K. The

role of hydrated silica, titania and alumina in inducing apatite on

implants. J Biomed Mater Res 1994;28:7–15.

[43] Kim H-M, Miyaji F, Kokubo T, Nakamura T. Preparation of

bioactive Ti and its alloys via simple chemical surface treatment. J

Biomed Mater Res 1996;32:409–17.

[44] Oss van CJ. Interfacial forces in aqueous media. New York: Dekker;

1994.

[45] Walton AG. Nucleation. New York: Dekker; 1969, p. 225.