MathWorksNews&Notes

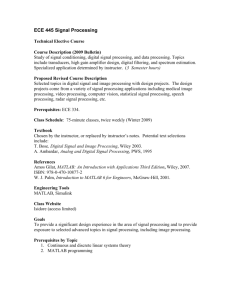

advertisement