Kinetic Friction Experiment #13

advertisement

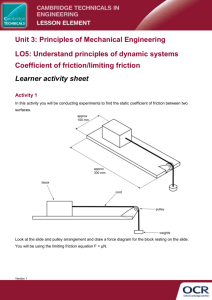

Kinetic Friction Experiment #13 Joe Solution E00123456 Partner - Jane Answers PHY 221 Lab Instructor – Chuck Borener Thursday, 11 AM – 1 PM Lecture Instructor – Dr. Jacobs Abstract In this experiment, we test factors which affect friction. We pulled a wood block across a surface to determine whether the surface area of the block or the type of surface affects friction. We found that the surface area of the block did not change the coefficient of kinetic friction, while the types of materials in contact were directly related to the coefficient of kinetic friction. (66 words) Introduction In this experiment, we examined kinetic friction. We performed two tests to see which physical properties affect kinetic friction. In the first part of the experiment, we determined if the surface area of a block affects the coefficient of kinetic friction between two surfaces. In the second part of the experiment, we determined that varying the materials between two sliding surfaces changes the coefficient of kinetic friction between them. Finally, in both parts, we showed that friction depends on the normal force. To test the coefficient of kinetic friction, we used a small, wooden block, that had one side covered with Teflon tape. The block had a string attached to one face. This string was threaded over a pulley, and was connected to a mass hanger. We added paperclips to the mass hanger to increase its weight, which, in turn, increased the tension in the string. This caused the block to slide across the surface. The set up for the experiment is shown below: Figure 1 – A picture of the experimental set up. We can derive an equation for the coefficient of kinetic friction using the free body diagram from each of the blocks. Using Newton’s Second Law on the hanging mass, we find: " F = T # mh g = mh a (1) Since we want the block to barely move, we set the acceleration to equal zero in this experiment. We can solve equation 1 for the tension in the string (T). Solving for tension, we ! find: T = mh g ! (2) Analyzing the free body diagram for the block, we start by looking at the vertical forces on the block: " Fy = N # (M + m)g = (M + m)ay (3) Since the vertical acceleration of the block is zero, we can find an equation for the normal force (N): ! (4) N = (M + m)g I notice the tension acting on the block will be the same tension acting on the mass hanger. The tension acts in the horizontal direction, so, I can analyze the forces in the horizontal ! direction for the block: " Fx = T # f k = (M + m)a (5) Setting the acceleration equal to zero and solving for tension we find: ! T = fk (6) I also know from lecture that the equation for the frictional force is: ! f k = µk N (7) where fk is the kinetic friction force, and µk is the coefficient of kinetic friction. Substituting equation 6 into equation 7 and solving for the coefficient of kinetic friction, we see ! the equation for the coefficient of kinetic friction will be: µk = T N (8) We will use this equation to find the coefficient of kinetic friction in this lab. We can also see from the equation that the coefficient of kinetic friction has no units. ! Results We started the lab by measuring the mass of the objects. I have listed the masses of the objects in the following table: Data Table 1 - Masses of Objects Mass of the Wood Block = 0.064139 Mass of one small paperclip = 0.003052 Mass of one large paperclip = 0.000422 Mass of the hanger = 0.00500 kg kg kg kg To get the block to move across the surface, we added paperclips to the mass hanger until the block would just start to move. We were able to find the tension in the string using equation 2: This calculation shows the tension for the first trial we did in this lab. It took three paperclips, plus the weight of the hanger (the hanger had a mass of 5 g), to get the block to move. We were able to calculate the normal force on the block using equation 4: This calculation shows the normal force for the second trial. The first mass is the mass of the block, while the 0.050 kg is the mass we added to the block. Once we found the normal force, we were able to calculate the coefficient of kinetic friction for that trial using equation 8. We started with no mass on the wooden block, then we added a 50 g mass to the block for each successive trial. Once the total added mass reached 250 g, we found an average of the coefficient of friction values, as shown below: After we added a total of 250 g to the block, we switched the block from face A to face B. Face B had a smaller area than face A. We repeated the procedures of part A once again to find the coefficients of kinetic friction. Once we found these values, we flipped the block to face C. This face had the same area as face A, but had Teflon tape on it to change the type of surface. Once again, we repeated the experimental procedures to find the coefficient of kinetic friction for the same masses. The table below shows all of the data for the different faces: Data Table 2 - Finding the Coefficient of Kinetic Friction N M + m (kg) (N) T (N) µk A B C A B 0.064 0.629 0.1387 0.1686 0.0821 0.2207 0.2682 0.114 1.119 0.2285 0.2584 0.1088 0.2043 0.2310 0.164 1.609 0.3182 0.3480 0.1553 0.1978 0.2163 0.214 2.099 0.4079 0.4079 0.1893 0.1944 0.1944 0.264 2.589 0.4976 0.4976 0.2192 0.1922 0.1922 0.314 3.079 0.5874 0.5276 0.2491 0.1908 0.1714 Average 0.2000 0.2123 C 0.1306 0.0973 0.0965 0.0902 0.0847 0.0809 0.0967 I notice several trends from this table: • I notice that as the total mass of the block increases, the tension required to move the block increases. • The coefficient of kinetic friction does not significantly change no matter how much mass is added to the block. • The average value in column A and column B are very close to one another. • The average coefficient of kinetic friction value is significantly different in column C compared to columns A and B. We can also graph the data to find the value for the coefficient of kinetic friction. If I plot the Tension vs. the Normal Force, the slope of a best-fit line will give me another average value of the coefficient of kinetic friction. Figure 2 – Graph of T vs N to find µk. We can see that the best-fit lines for data set A and B are very close to one another. I would expect these lines to be very close, since the average values for each column are so close to one another in the data table. The graph shows that surface area does not have a large impact for wood. Since the slope is smaller for the line representing data set C, we can see the coefficient of friction in part C is smaller than it is in parts A and B. This indicates that changing the materials between the surfaces changes the coefficient of friction. We can find a percent difference between the average value from the chart and the slopes of the best-fit lines. The percent difference for data set A is shown below: The percent difference for data set B is 11.1%, while the percent difference for data set C is 11.7% Error Analysis There were two main sources of error in this experiment. The biggest error is the sensitivity of the apparatus to accidental bumps. Anytime we bumped the table, even slightly, the horizontal surface on the apparatus would shift. It was very difficult to avoid this error, as even the slightest bump would make it move. This bump could change the incline of the surface by as much as 10 degrees. If it were tilted 10 degrees upwards, this would make it so there were weight and tension components in two dimensions. Using Newton’s Laws, I was able to derive the following equation: By my calculations, this would change the first µ value in column A to 0.043, a difference of 130%. The second error in this experiment is the non-uniformity of the block surface from one end to the other. Since the surface is not uniform, the value of µk is not constant. This means we are only finding an average value of µ. This leads to inconsistencies of µ, since the block will not always follow the exact same path on the surface. Another source of inconsistency was a “stuttering” affect of the block as it moved across the surface. When we analyze side C of the block, the range of values for µk is 0.0809 to 0.1306. Using the average value from the slope of the best fit line, the percent difference between the high and average values is 41.1%, while the percent difference between the low and average values is 6.2%. This trend continues for the other faces of the block. From these percents, it shows that the values for µk are more accurate as the mass increases. A more massive block/hanger would have greater inertia, and be less prone to the affects of the “stuttering” motion of the block down the surface. Conclusion In this experiment, we tested two factors that may affect the coefficient of static friction. First, we tested whether the surface area affects the coefficient of kinetic friction. My data from columns A and B are very close to one another. Since these values are close, I can conclude that surface area does not affect the amount of friction on an object. We also tested whether the type of surface affects the coefficient of kinetic friction. The data from column C shows the coefficient of kinetic friction is about half of the coefficients of kinetic friction from columns A and B. From this set of data, I can conclude the material of the surface does affect the coefficient of kinetic friction. It can also be seen from the graphs that friction increases linearly with the normal force. The value of sliding friction does depend on the normal force between the two objects. This is shown by the equation, and is also shown in Table 2. Whenever the normal force increased, the frictional force increased. The value of sliding friction between two objects does not depend on the area of contact between the two objects. This is shown by my data in columns A and B. The value of sliding friction between two objects does depend on the materials that are in contact. This was shown by my data when I compared column C with columns A and B. The percent differences are close to one another. My percent difference for the data in column A is 3.56%. My percent difference for the data in column B is 11.1%. My percent difference for the data in column C is 11.7%. These are reasonable percent differences when comparing an average value with a best-fit line. I believe the slope of the best-fit line gives a more accurate value for µk. When Excel creates a best-fit line, it uses the method of least-squares for the line. The least-squares fit accounts for the uncertainty in the experiment. An average does not account for uncertainty. I would use rubber on one side of the block to reduce the error in measuring µ. I believe by using a material of higher µ, any small changes in the value of the coefficient of friction will be hard to detect as the actual value is so much larger. In general, whenever the measured value is much greater than the uncertainty, error is decreased. A material that is easy to find with a low µ value is aluminum. We could attach aluminum foil to one of the surfaces to test yet another case for µ.