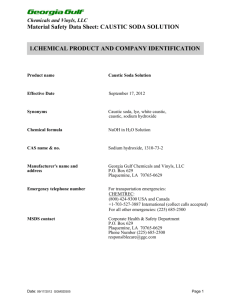

Caustic Soda Handbook - Occidental Petroleum Corporation

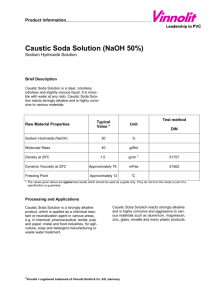

advertisement