8s-1

The Transportation Model

8s-2

The Transportation Model

CHAPTER

8

Operations Management

Location Planning

and Analysis

William J. Stevenson

8th edition

Operations Management, Eighth Edition, by William J. Stevenson

Copyright © 2005 by The McGraw-Hill Companies, Inc. All rights reserved.

McGraw-Hill/Irwin

8s-3

•

The Transportation Model

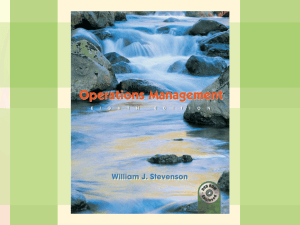

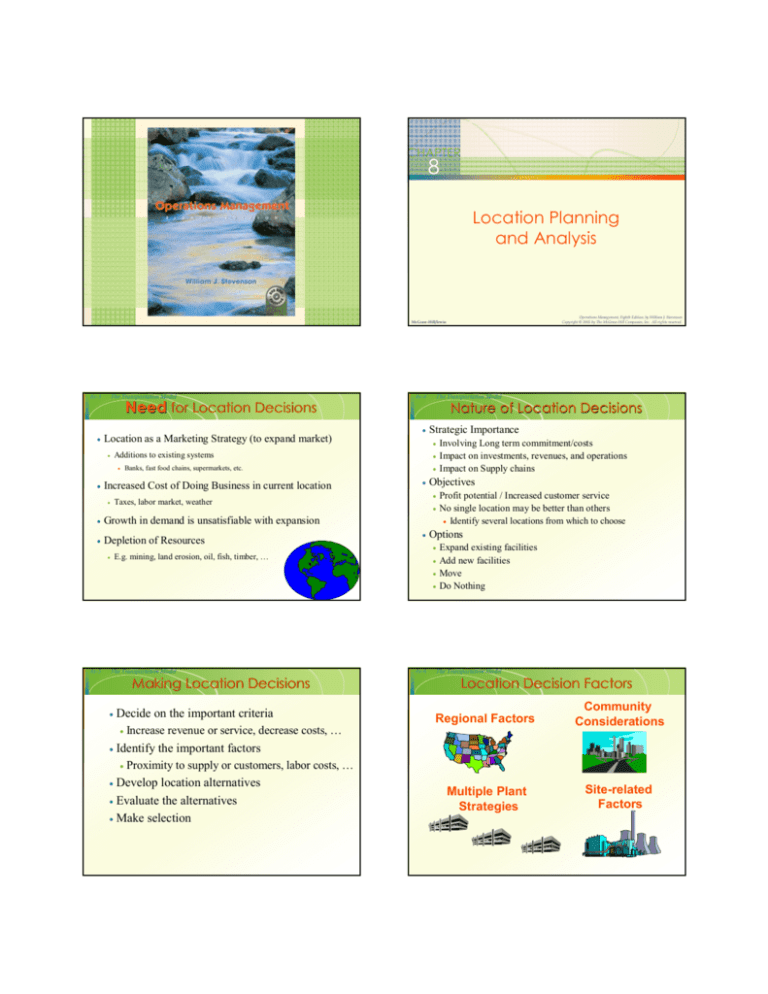

Need for Location Decisions

Location as a Marketing Strategy (to expand market)

•

•

•

Growth in demand is unsatisfiable with expansion

•

Depletion of Resources

•

•

•

•

•

The Transportation Model

Making Location Decisions

•

Decide on the important criteria

• Increase revenue or service, decrease costs, …

• Identify the important factors

• Proximity to supply or customers, labor costs, …

• Develop location alternatives

• Evaluate the alternatives

• Make selection

8s-6

Profit potential / Increased customer service

No single location may be better than others

• Identify several locations from which to choose

Options

•

8s-5

Involving Long term commitment/costs

Impact on investments, revenues, and operations

Impact on Supply chains

Objectives

•

E.g. mining, land erosion, oil, fish, timber, …

•

Strategic Importance

•

•

Taxes, labor market, weather

•

Nature of Location Decisions

•

Banks, fast food chains, supermarkets, etc.

Increased Cost of Doing Business in current location

The Transportation Model

•

Additions to existing systems

•

•

8s-4

Expand existing facilities

Add new facilities

Move

Do Nothing

The Transportation Model

Location Decision Factors

Regional Factors

Community

Considerations

Multiple Plant

Strategies

Site-related

Factors

8s-7

The Transportation Model

Regional Factors

8s-8

Quality of life

Services

• Attitudes

• Taxes

• Environmental regulations

• Utilities

• Developer support

Location of raw materials

• Location of markets

• Labor factors

• Climate and taxes

•

The Transportation Model

Site Related Factors

8s-10

Table 8.2

Comparison of Service and

Manufacturing Considerations

Multiple Plant Strategies

Product plant strategy

• products in different location

• Market area plant strategy

• Close to customer(s)

• Process plant strategy

• Processes in different locations

Land availability/appropriateness

Transportation costs to customer

• Environmental

• Legal

•

The Transportation Model

The Transportation Model

•

•

8s-11

Community Considerations

•

•

8s-9

The Transportation Model

8s-12

The Transportation Model

Trends in Locations

•

Manufacturing/Distribution

Service/Retail

Cost Focus

Revenue focus

Transportation modes/costs

Demographics: age,income,etc

•

•

•

•

Energy availability, costs

Population/drawing area

Labor cost/availability/skills

Competition

Building/leasing costs

Traffic volume/patterns

Customer access/parking

Foreign producers locating in U.S.

•

“Made in USA”

Currency fluctuations

Just-in-time manufacturing techniques

Microfactories

Information Technology

8s-13

•

The Transportation Model

8s-14

Evaluating Locations

Cost-Profit-Volume Analysis

•

The Transportation Model

Location CostCost-Volume Analysis

•

For each location:

•

Determine fixed and variable costs

• Plot

•

total costs

Remember TC = F + Q(R – v)

• Determine lowest

Assumptions

• Fixed costs are constant

• Variable costs are linear

• Output can be closely estimated

• Only one product involved

total costs for variable

outputs

8s-15

The Transportation Model

8s-16

Example 1: CostCost-Volume Analysis

The Transportation Model

Example 1: Solution

Fixed and variable costs for

four potential locations

L o c a t io n

F ix e d

C o st

$ 2 5 0 ,0 0

1 0 0 ,0 0

1 5 0 ,0 0

2 0 0 ,0 0

A

B

C

D

8s-17

Fixed

Costs

V a r ia b le

C ost

$11

30

20

35

0

0

0

0

A

B

C

D

The Transportation Model

8s-18

Example 1: Solution

$(000)

800

700

600

500

400

300

200

100

0

0

D

Remember we are minimizing costs

(not maximizing profit).

B

C

A

A Superior

C Superior

B Superior

2

4

6

8

10

12

14

Annual Output (000)

Pick 2 easy, reasonable production quantities, Q, e.g. 0 and 20,000,

then plug these two values into each location alternative and graph.

16

$250,000

100,000

150,000

200,000

Variable

Costs

$11(10,000)

30(10,000)

20(10,000)

35(10,000)

Total

Costs

$360,000

400,000

350,000

550,000

The Transportation Model

Evaluating Locations

•

Transportation Model

• Decision based on movement costs of raw

materials or finished goods (linear

programming approach)

• Factor Rating

• Decision based on quantitative and qualitative

inputs (weighted averages) (pg. 366 in text)

• Center of Gravity Method

• Location of Supply node is based on minimum

distribution costs

8s-19

The Transportation Model

8s-20

The Transportation Model

Requirements for Transportation Model

CHAPTER

Costs from origin to

destination listed here

8s

The Transportation Model:

Used to Evaluate Locations of

Supply Nodes & to Minimize Total

Distribution Costs

100

$6

200

450

300

150

75

350

75

Origins

The Transportation Model

8s-22

The Transportation Problem

D

(demand)

D

(demand)

S

(supply)

D

(demand)

•

•

•

D

(demand)

D

(demand)

Factory

4

7

7

1

100

3

8

16

Figure 8S.2

5

150

3

450

Demand

The Transportation Model

Costs

200

10

E.g. x1_3 = 100 units (at $2.50/unit) Î $250 in costs

Factory 1

can supply 100

units per period

8

2

8

E.g. $2.50/unit shipped from S1 to D3

D

1

12

Amount of demand at demand node

Excel Template for up to 5x5 Transportation Problem

Cost from Factory to Warehouse

Warehouse

C

Supply capacity at the node

Variables are the number of units shipped from origin to a

destination

8s-24

A Transportation Table

B

•

•

The Transportation Model

A

80

90

120

160

450

Warehouse B

demands 90

units per

period

cost of shipping

from a Supply (origin)

node to a Demand

(destination) node

Unit cost of shipping from a supply to a demand node

•

Table 8S.1

• Unit

Demand or destination nodes (e.g. warehouse, customer,

distribution center)

D

(demand)

D

(demand)

of Demand

destinations and each

one’s demand

Supply or origin nodes (e.g. factories, storage areas)

S

(supply)

S

(supply)

• List

The Transportation Model

•

•

D

(demand)

of Supply origins

and each one’s capacity

Typical Elements of Transportation Problem

What is lowest

cost distribution

of supply to

demand?

Figure 8S.1

8s-23

Destinations

Operations Management, Eighth Edition, by William J. Stevenson

Copyright © 2005 by The McGraw-Hill Companies, Inc. All rights reserved.

McGraw-Hill/Irwin

8s-21

• List

Total supply

capacity per

period

Total demand

per period

Changing Cells