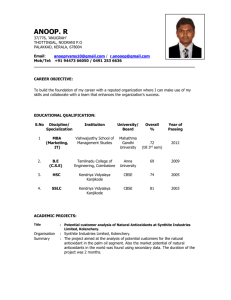

COMPANY INFORMATION

advertisement

COMPANY INFORMATION 1.Company Profile 1. Company 2. Board of Directors 3. Objective of the Company 4. Activities of the Company 5. Unitwise Business Operation 6. Organisational Structure 2.Products and Services 1. Product List 2. Marketing 3.Memorandum of Association 4.Rules and Regulations 1. Standing Orders 2. Delegation of Powers 3. Staff Bye Laws 4. Recruitment and Promotion Policies of Officers 5. Recruitment and Promotion Policies of Workers 6. Leave rules 7. PF Trust Rules 8. Gratuity Rules 9. Welfare Centre Functions 10. Conveyance Advance 11. Medical Reimbursement 12. Group Personal Accident Insurance Scheme 13. Group Personal Leave Encashment Scheme 5. Quality Systems and Certifications 1. Quality Systems 2. ISO 9001 - 2000 Version 3. Quality Policy 4. Quality Objectives 5. ISO Procedures and Manuals 6. Directory of Employee 1. Human Resources 2. Directory of Employees 3. Castwise List of Employees ********* 1. Company Profile 1. Company Kerala Agro Machinery Corporation Ltd. (KAMCO) was established in the year 1973 as a wholly owned subsidiary of Kerala Agro Industries Corporation Ltd. (KAIC), Trivandrum, for manufacture of agricultural machinery specifically Power Tillers and Diesel Engines. Subsequently KAMCO became a separate Govt. of Kerala undertaking in 1986. Paid up capital is Rs. 161 lakh Present Net Worth of the Company is Rs. 6014.14 lakh. Total work force at present is 567 Certified for ISO 9001 - 2000 version from September 2002. At present, KAMCO has four units located at Athani and Kalamassery in Ernakulam District , at Kanjikode in Palakkad District, and at Mala, in Trichur dist. With the present work force KAMCO can produce 8400 Power Tillers & 1200 Power Reapers per annum. 2. Board of Directors Refer Link: Board_of_Directors 3. Objective of the Company The objectives of the Company are to manufacture in India, either in collaboration with or otherwise or import & trade agricultural machinery like Tractors, Power Tillers, Power Reapers, Combine harvester, Transplanter, Diesel Engines, Pump sets, Implements, accessories and spares thereto. The objectives also include establishment of engineering workshops/repair shops to undertake repairs and servicing of agricultural machinery or other machinery, equipment, implements and tools. Assembly Unit was established in 1970 at Athani by M/s. Kerala Agro Industries Corporation for the assembly of Kubota Power Tillers in technical collaboration with M/s.KubotaLtd., Japan, the world's leading manufacturer of Power Tillers and other agricultural machinery. On expiry of the collaboration, KAMCO manufactures power tillers with their own facilities. KAMCO Power Tillers have become the most sought after Power Tillers in India because of their quality and reliability. 4. Activities of the Company KAMCO's manufacturing facilities include Special Purpose Machines, Specially built General Purpose Machines, and Imported machines. The inspection facilities include modern inspection & testing equipment .KAMCO have their own Metrology, Calibration & Engine Test Lab. The following are the main Activities of the Company. Manufacturing and marketing of Agriculture machines like Power Tillers, Tractors, Power Reaper, Diesel Engines etc. Power Tiller produced at Athani & Palakkad units. Major components for Power Tiller are manufactured at Athani and all other components bought out from dedicated Venders in India. There are around 250 vendors now. Kalamassery unit produce Engine for Power Tiller Power Reaper produced at Mala Trading/manufacturing of other farm machines. 5. Unit wise Business Operation The business areas operating in KAMCO are indicated in the matrix given below; Sl. Division / Corporate Location No. Department Set up Athani Palakkad Kalamassery Mala 1.0 Corporate Office * * 1.1 Marketing * * 1.2 Materials * * 2.0 Purchase * * * * 3.0 Production 3.1 Assembly * * * * 3.2 Pretreatment & * * * * Ptg. 3.3 Machine Shop * 4.0 Maintenance * * * * 5.0 Quality Assurance * * * * 6.0 Engineering * 7.0 Store * * * * 8.0 Human Resource * * * * * Management 8.1 Human Resource * * Development 9.0 Finance * * * * * 10.0 Internal Audit * * 11.0 Systems * * * Applicable in the unit location 6. Organisational Structure Organization chart of the Company: Refer Link:Organisational_Structure 2. Products and Services 1. Product List KAMCO manufacture & market mainly two products KAMCO POWER TILLER Model KMB 200 KAMCO Super DI POWER TILLER KAMCO Power Reaper Model KR 120 KAMCO Stone Cutter KSC 625 KAMCO AGRIA 602 DE Power Tiller For More Details Refer Link:Product List 2. Marketing The Company has 45 dealers all over India. New Dealers appointed to cover selected districts in Tamil Nadu, Karnataka, Maharashtra, Orissa and Andra Pradesh. Close interaction with the Govt. of India in the formulation of new schemes & policies for farm mechanization. Regular demonstrations and service camps are being organized in various States. Kamco Power Reaper has been exported to Iran and Sri Lanka recently. These Machines has been well accepted by the customers. 3. Memorandum of Association Refer Link:MEMORANDUM_OF_ASSOCIATION(MOA) 4. Rules and Regulations 1. Standing Orders Refer Link:Standing_Order 2. Delegation of Powers Refer Link:Delegation_of_powers 3. Staff Bye Laws Refer Link:Staff_Bye_Laws 4. Recruitment and Promotion Policies of Officers Refer Link:Recruitement_and_Promotion_Policy-Officers 5. Recruitment and Promotion Policies of Workers Refer Link:Recruitement_and_Promotion_Policy-Workers 6. Leave rules Leave Rules for Officers Leave rules for Workers : Refer Link:Leave_rule-Officers : Refer Link:Leave_rule-Workers 7. PF Trust Rules PF rules : Refer Link:PF Rules 8. Gratuity Rules Gratuity : Refer Link:GRATUITY 9. Welfare Centre Functions Welfare Centre : Refer Link:KAMCO WELFARE CENTRE 10. Conveyance Advance Conveyance Advance rules : Refer Link:Conveyance 11. Medical Reimbursement Medical Reimbursement rule : Refer Link:Medical_Reimbursement 12. Group Personal Accident Insurance Scheme Group Personal Accident Insurance Scheme Rules : Refer Link:GPAIRULES 13. Group Personal Leave Encashment Scheme Refer Link:Group Leave Encashement Scheme Rules 5. Quality Systems and Certifications 1. Quality Systems Well defined quality system procedures adopted covering all activities to ensure quality of products & customer satisfaction Improvements are made on regular basis based on the feedback from the customers & dealers Regular interactions with all Venders including site visits to maintain and improve the acceptance level of components KAMCO Power Tiller certified for compliance with Minimum Performance Standards of Govt. of India KAMCO Power Reaper has been tested by SRFMT&TI, Ananthapur of Govt. of India 2. ISO 9001 - 2000 Version Improvement in the systems and improved Customer/Dealer satisfaction Comply with the requirement of Customers and applicable statutory/regulatory requirements Improvement in the effectiveness of the established quality systems Addresses Customer, Dealer, Vendor, Society, Employees & Share holders - for their requirement & satisfaction 3. Quality Policy Total customer satisfaction through quality products and services with improved technology and employee participation. Comply with the requirements of customers and the applicable statutory / regulatory requirements. The effectiveness of the established quality management system is continually improved to enable achievement of the policy. 4. Quality Objectives To ensure that the quality requirements of the products and services offered are maintained at all stages. To create a culture among all employees towards total quality concepts and productivity through total involvement and commitment of all employees To create healthy working environment for attainment of quality goals with excellence and to make quality a way of life To detect and prevent nonconformance and defects as early as possible and to eliminate them through appropriate changes to the Quality Management System To achieve and maintain Quality Leadership through continuous technology upgradation, improvements in techniques, systems and procedures 5. ISO Procedures and Manuals Quality System Manual : Refer Link:ISO_QUALITY_MANUAL Quality System Procedures : Refer Link:QUALITY SYSTEM PROCEDURE 6. Directory of Employee 1. Human Resources Total employee strength 567 persons Periodical training is being conducted to improve the performance levels of workmen Mainly management development programmes conducted for officers Training programmes designed to specific requirements based on individual needs Periodical assessment of employees performance carried out after training 2. Directory of Employees Refer Link:Directory_of_Employees