Introduction to WHMIS

advertisement

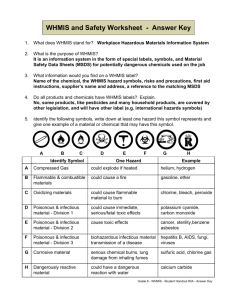

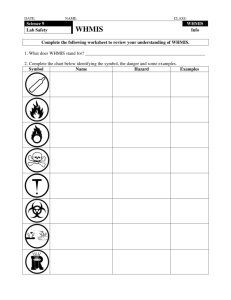

ENVI RONMENTALHEAL TH ANDSAFETYOFFI CE Wo r k p l a c eHa z a r d o u sMa t e r i a l s I n f o r ma t i o nSy s t e m( WHMI S) Ha n d b o o k Ta b l eo f Co n t e n t s nt r oduc t i ont oWHMI S 2 I Wh a t i sWHMI S? Wh a t i st h eo b j e c t i v eo f WHMI S? Co mp o n e n t so f WHMS SLe gi s l a t i on 3 WHMI k e rEduc a t i ona ndTr a i ni ng 4 Wor SCl a s s i f i c a t i ons 5 WHMI Cl a s sA–Co mp r e s s e dGa s Cl a s sB–Fl a mma b l ea n dCo mb u s t i b l eMa t e r i a l Cl a s sBFl a mma b l eGa s e s Cl a s sBFl a mma b l eL i q u i d s Cl a s sBCo mb u s t i b l eL i q u i d s Cl a s sBFl a mma b l eSo l i d s Cl a s sBFl a mma b l eAe r o s o l s Cl a s sBRe a c t i v eFl a mma b l eMa t e r i a l Cl a s sC–Ox i d i z i n gMa t e r i a l Cl a s sD–Po i s o n o u sa n dI n f e c t i o u sMa t e r i a l Cl a s sD–Di v i s i o n1I mme d i a t ea n dSe r i o u sTo x i cEf f e c t s Cl a s sD–Di v i s i o n2–Ot h e r To x i cEf f e c t s Cl a s sD–Di v i s i o n3–Bi o h a z a r d o u sI n f e c t i o u sMa t e r i a l Cl a s sE–Co r r o s i v eMa t e r i a l Cl a s sF–Da n g e r o u s l yRe a c t i v eMa t e r i a l SLa be l s 9 WHMI Su p p l i e r L a b e l s I n n e r L a b e l s mp o r t s Bu l kSh i p me n t s Wo r k p l a c eL a b e l s De c a n t e dPr o d u c t s L a b o r a t o r yL a b e l s L a b o r a t o r ySu p p l yHo u s eCo n t a i n e r L a b o r a t o r yCo n t a i n e r L a b o r a t o r ySa mp l e sf o r An a l y s i s I n Ho u s eAn a l y s i s I n d e p e n d e n t L a bAn a l y s i s Co n s u me r L a b e l s e r i a l Sa f e t yDa t aShe e t s 1 4Mat I n t e r p r e t i n gt h eMSDS Us a g eo f MSDS So u r c e so f MSDS G l o s s a r y o f T e r ms 2 0 Introduction to WHMIS WHAT IS WHMIS? WHMIS stands for Workplace Hazardous Materials Information System. It is a nationwide system to provide information on hazardous materials used in the workplace. WHMIS affects workers, employers, suppliers, and regulators. Nova Scotia’s WHMIS Regulations place duties at any workplace covered by the Occupational Health and Safety Act where hazardous materials are used, stored, or handled. WHAT IS THE OBJECTIVE OF WHMIS? The objective of WHMIS is to reduce the risk of illness or injury to employees, employers, or visitors in the Workplace resulting from the use of controlled products. COMPONENTS OF WHMIS There are three key components to WHMIS: 1. Worker Education and Training Worker education programs provide instruction on the hazards of hazardous materials in the workplace and training inunderstanding and using WHMIS information. 2. Labels Labels must be placed on all containers of hazardous materials to alert employees and workers to the dangers of the product and basic safety precautions. 3. Material Safety Data Sheets Provide detailed health and safety information on a product. 1 WHMIS Legislation WHMIS, Canada’s right-to-know hazard communication standard, came into effect on October 31, 1988. It was developed by the collaborative efforts of government, industry and labor and is supported by both federal and provincial legislation. The federal laws relevant to WHMIS are: • The Hazardous Products Act - this places duties on suppliers, who sell or import a hazardous material for use in a workplace in Canada, to provide supplier labels and material safety data sheets to their customers. • The Controlled Products Regulations made under the Hazardous Products Act. These regulations prescribe the hazardous materials that will be covered by WHMIS and set out, in detail, the information to be put on a supplier label and a material safety data sheet. • The Hazardous Materials Information Review Act and Regulations which sets out how confidential business information will be handled at the federal level. These regulations permit some exemptions from the disclosure of trade secrets that are claimed by suppliers of controlled products. Nova Scotia uses three additional laws to implement WHMIS, they are: • • • The Occupational Health and Safety Act WHMIS Regulations, and Disclosure of Information Regulations To promote consistency across Canada, each provincial and territorial government used the same model to draft its WHMIS regulations. 2 Worker Education and Training WHMIS legislation requires that information and instruction be provided to all workers who work with or in proximity to a controlled product, that is any worker who stores, handles, uses or disposes of a controlled product or who immediately supervises another worker performing these duties. In proximity” is the area in which a worker’s health and safety could be at risk during storage, handling, use or disposal of a product, maintenance operation, or emergencies such as an accidental release or spill. It is the supervisor’s responsibility to provide work-site specific WHMIS training. Employees must ensure that they obtain adequate information on a controlled product in order to work with it safely. See your supervisor if you feel you need more information. WHMIS education is performance based and is measured by the ability of workers to demonstrate safe work procedures and the knowledge of why the procedures are required. Regarding frequency of training, WHMIS law does not specify how often WHMIS courses must be provided. Instead, the law provides a standard for effectiveness of the training and requires that the standard be achieved on an ongoing basis. To meet the WHMIS education standard an employee should be able to answer the following four questions: 1. Where can I get hazard information on products that I work with? 2. What are the hazards of the controlled product? 3. How am I protected from those hazards? 4. What do I do in the case of an emergency? 3 WHMIS Classifications WHMIS uses classifications, or classes, to group chemicals with similar properties or hazards. The Controlled Products Regulations specifies the criteria used to place materials within each classification. There are six (6) classes although several classes have divisions or subdivisions. CLASS A - COMPRESSED GASES Cylinders store compressed gases under pressure. Because gas leaking from a cylinder, a value or a regulator can cause injury or damage, WHMIS treats all compressed gases as controlled products. Gases which are also flammable, toxic or have other hazardous properties will also be found in other classes. Typical compressed gases are oxygen which is used in health care and welding, and ammonia which is used in some large scale refrigeration systems. CLASS B - FLAMMABLE AND COMBUSTIBLE MATERIALS WHMIS groups together into a single class all those chemicals which pose a fire hazard. There are 6 subdivisions to the flammable and combustible materials class. Chemicals covered by any of the subdivisions all carry the same stylized flame symbol. Divison 1 - Flammable Gases All gases such as hydrogen and butane which can form ignitable mixtures in air, are classed as flammable gases. Cylinders of these gases carry both the compressed gas and the flammable material symbols. Division 2 - Flammable Liquids All those liquids which present an extreme fire hazard are called flammable liquids. A spark or other ignition source can easily ignite flammable liquids at or below room temperature. Gasoline is a typical flammable liquid. Even at temperature as low as -40 C, gasoline gives off enough vapor to form a vapor/air mixture that will burn. 4 Division 3 - Combustible Liquids Although they are more difficult to ignite, when a combustible liquid is heated, it gives off enough vapor to form a vapor/mixture that will burn. Combustible liquids are those liquids which present a fire risk when the liquid is heated to temperatures between room temperature and about 100o F. Diesel fuel and many other more difficult to ignite liquids are combustible liquids. Many commercial and industrial liquid products that are based upon petroleum or other organic solvents are combustible liquids. Division 4 - Flammable Solids WHMIS regulates all those solids that ignite through friction such as white phosphorus, or that can be readily ignited and burn vigorously such as magnesium and a number of other finely divided metals. Division 5 - Flammable Aerosols Aerosol products containing flammable ingredients or that use a flammable propellant such as propane, butane and dimethyl ether, present a workplace fire hazard. All such products which pass a flame projection or flash back test are included in the flammable aerosol subdivision. Division 6 - Reactive Flammable Materials WHMIS places a few particularly dangerous materials in the subdivision. Included are chemicals that are spontaneously combustible under normal conditions of use or chemicals which, when in contact with water, become flammable or give off a flammable gas. This group includes such chemicals as aluminum alkyls, metallic sodium and lithium aluminum hydride. All of these chemicals are uncommon outside of the laboratory. CLASS C - OXIDIZING MATERIALS Fire is really a chemical reaction involving the fuel and oxygen. Some chemicals called oxidizers, can provide oxygen that can increase the risk that a fire will break out. Once a fire is underway, oxidizers can cause the fire to burn more intensely. Oxidizing materials are not particularly common in the shop or office. However, they are found fairly often in laboratories where researchers commonly use oxidizers generally, and a family of oxidizers are called organic peroxides. The symbol carried by all oxidizing materials resembles the flammable materials symbol in that it also depicts a flame. But the flame rests on an “O” which signifies that oxidizers contribute oxygen. 5 CLASS D - POISONOUS AND INFECTIOUS MATERIALS WHMIS considers all the toxic effects of chemicals in this class. Because there are a variety health hazards that need to be considered, WHMIS deals with the health hazards in 3 subdivisions: Division 1 - Materials Causing Immediate and Serious Toxic Effects Materials included in this subdivision are generally those highly toxic chemicals which cause death within a short period following exposure. At high enough doses, almost any chemical can have serious and even fatal consequences. But the massive doses of weakly toxic chemicals that would be needed to produce death are unlikely in the workplace. But those chemicals, such as many cyanides, which are sufficiently toxic to cause death following a workplace exposure are placed in subdivision A. Other chemicals for which higher doses are needed to produce lethality, are placed in subdivision B. All the chemicals that meet the criteria for inclusion in the Materials Causing Immediate and Serious Toxic Effects, regardless of whether they fall into the Very Toxic or Toxic subdivisions, carry the skull and crossbones symbol. Division 2 - Materials Causing Immediate and Serious Toxic Effects As well as short term poisoning, chemicals can cause other effects. Prolonged exposure to chemicals at exposure levels that are below those which cause short term symptoms can also be harmful to health. WHMIS places chemicals which irritate the skin and eyes and chemicals which present a long term health risk, in a separate class. Containers of these chemicals are marked with the WHMIS “T” symbol. Some people refer to the symbol as “a T over a period” to reinforce the idea that many of the criteria that place chemicals in this division, deal with long term hazards. Contact with many chemicals, including some chemicals as familiar as vinegar, cause skin and eye irritation. As a consequence, when they are sold for industrial or commercial use, these chemicals carry the WHMIS T symbol. People working with these chemicals need to consult the MSDS to find out whether a product is classed as causing “other toxic effects” because it causes irritation or because it poses a long term health risk. Toxic effects included under “other toxic effects” include skin and eye irritation and chronic toxic effects such as: 6 Mutagenicity causing genetic damage Sensitization causing skin or respiratory allergies Carcinogenicitycausing cancer Teratogenicity causing birth deformities Embryotoxicity causing fetal death reproductive toxicity Division 3 - Biohazardous Infectious Materials Few people outside a research or clinic laboratory of a hospital are likely to encounter a material classed as a Biohazardous infectious agent. Materials which fall into this class include viruses and bacteria which can cause infection in people. Also included are the toxins that some of these viruses and bacteria produce. Containers of biohazardous infectious materials carry the internationally recognized three broken rings symbol. CLASS E - CORROSIVE MATERIALS WHMIS groups together chemicals which can corrode metal or destroy skin into a corrosive materials class. Included in the class are many of the common acids such as sulfuric acid, (used in automotive batteries) hydrochloric (muriatic) acid and others. Lye (also called caustic soda or sodium hydroxide) is another corrosive chemical that is present in many commonly used products such as household oven cleaner. The symbol demonstrates the corrosivity of these chemicals in attacking metal and human skin. CLASS F - DANGEROUSLY REACTIVE MATERIALS The last WHMIS class brings together all those chemicals which present a hazard as a result of their tendency to undergo violent reaction. The chemical reaction can sometimes lead to a fire or an explosion. This class also includes a few chemicals such as sodium cyanide which can react with water to produce a toxic gas. Dangerously reactive chemicals are not common outside of the laboratory. 7 WHMIS Labels Labelling of controlled products is a requirement of the WHMIS system. A label identifies the product within and provides quick information on the hazards and safe handling of the product. Labelling requirements differ depending on whether the containers are supplier or workplace containers; whether the containers contain laboratory products, laboratory samples for analysis or non-laboratory products; and the size of the containers. All hazardous materials in the workplace must be properly labeled. SUPPLIER LABEL A supplier label is applied to the container of a controlled product by the manufacturer. Materials packaged in 100 mL or less containers can have labels without risk phrases, precautionary measures and/or first aid measures Containers of controlled product that are sold for use in Canadian workplaces must carry a supplier label that contains 9 required elements. 1) Hatched Border 6) MSDS Reference 2) Written in English and French 7) Risk Phrases 3) Product Identifier 8) Precautionary Measures 4) Supplier Identifier 9) First-Aid Measures 5) Hazard Symbol(s) 8 Inner Containers If the employer receives a controlled product in a multi-container shipment, and the inner containers have not been labelled by the supplier, then the employer must put labels on all inner containers when the outer container is opened. The labels must meet all the requirements of supplier labels. Inner containers also include a hatched border, English and French translation, product identifiers, supplier identifier, hazard symbols, MSDS reference, risk phrases, precautionary measures and first-aid measures. Imports If the employer receives a controlled product that has been imported into Canada that has no supplier label and that has been shipped directly to the employer’s workplace from the off-shore source, then the employer must label the controlled product with a label that meets the requirements of a supplier label. Bulk Shipments A shipment of a controlled product that is contained without intermediate packaging in one of the following: A vessel with a capacity of more than 454 liters A freight container, road vehicle, railway vehicle, portable tank freight container (carried on a road vehicle, railway vehicle, ship, or aircraft), or a portable tank (carried on a road vehicle, railway vehicle, ship, or aircraft) The hold of a ship A pipeline If a controlled product is received at the workplace as a bulk shipment, then the employer must attach a label to the container of the controlled product or to the controlled product. The employer can use either a supplier label or a workplace label depending on the circumstances. WORKPLACE LABEL 1) Product Identifier 2) Safe Handling Procedures 3) MSDS Statement 9 If the supplier label is destroyed or chemicals are transferred from the supplier container to another, a workplace label is required. Because it assumes that people in the workplace are familiar with the chemicals they are using, WHMIS sets less stringent requirements for an acceptable workplace label. Decanted Products Decanted products are materials that have been taken from one container and put in another container for short term use. This new container does not need a label if: the container is portable and has been filled from a container to which a supplier or workplace label has been affixed; AND the material is under the control of and is used exclusively by the employee who filled the portable container; AND the container is used only during the shift in which the container was filled; AND the contents of the portable container are clearly identified; OR if all of the product is for immediate use LABORATORY LABELS Under WHMIS, the labeling requirements for some controlled products present in a laboratory differ from the labeling requirements for controlled products present in non-laboratory workplaces. In addition, in some cases within the laboratory environment, the WHMIS laws further distinguish between a controlled product this is used in the laboratory and a controlled product that is being tested in a laboratory. Supply House Container 1) Product Identifier 2) Reference to MSDS 3) Risk Phrases 4) Precautionary Measures 5) First-Aid Measures 10 Laboratory Container If a product is transferred from a lab supply house container into another container, this container only requires a product identifier if the product is intended only for use, analysis or testing in the lab. Product identifier: includes any means of identification (chemical name, brand name, generic name, code name, code no., etc.) and must be combined with worker education to ensure workers can identify product and know where to obtain further info related to hazards or safe handling if needed Laboratory Samples for Analysis In-House Analysis Samples analyzed in-house require only the product identifier if: 1) produced in the lab solely for use, analysis or testing the lab and 2) remain under the control of the researcher producing the chemical in Independent Lab Analysis Applies to lab samples sent to an independent lab for testing. If you submit a sample to an outside lab for analysis, you are in effect the supplier 11 1) WHMIS Border 6) Supplier’s Name 2) Product Identifier 7) Supplier’s Emergency Phone Number 3) Hazardous Ingredients 8) Statement: “Hazardous lab sample; for hazard information or in an emergency call ____” Consumer Labels Consumer products, which are available to the public in retail stores, are exempt from the labeling and MSDS requirements of WHMIS. However, they can be purchased and brought into the workplace and, if they would otherwise meet the criteria of a controlled product they are not exempt from the training requirements of WHMIS. Consumer products have their own labeling system which is defined in the Consumer Chemicals and Containers Regulation under the federal Hazardous Products Act. Since these products can be brought into and used in the workplace, it is important to understand these labels. The labels generally display a border or shape that indicates the degree of risk - caution (triangle), warning (diamond), or danger (octagon) and a symbol or pictogram inside the border that indicates the type of hazard: toxic or poisonous products, flammable products, corrosive products, and pressurized or explosive. 12 Material Safety Data Sheets The Material Safety Data Sheet, or MSDS for short, is an important source of information for the worker at the worksite. The purpose of the MSDS is to provide detailed information on the ingredients, hazards and properties of a hazardous material (controlled product) in order that it may be used safely. Since the MSDS contains detailed health and safety information specific to each controlled product, it should be used as a key source of information for developing training programs and safe work procedures. In Canada, every material that is controlled by WHMIS must have an accompanying MSDS that is specific to each individual product or material. That is, both the product name and supplier on the MSDS must match the material in use. Suppliers and employers have a number of responsibilities for MSDSs. Suppliers must provide their customers with a current MSDS, but are also responsible for reviewing and updating the information contained in their MSDS every three years. If new, significant information becomes available before the three years has elapsed, the supplier is required to update the product label and the MSDS. Employers must make sure that all controlled products have an up-to-date (less than three years old) MSDS when it enters the workplace. The MSDS must be readily available to the workers who are exposed to the controlled product during work hours. In the case of controlled products being made in the workplace, the employer has a duty to prepare an MSDS for any of these products. Finally, employers must ensure that all expired MSDSs are updated. Employers may establish an MSDS database on a computer as long as all employees have access to and are trained on how to use the computer, the computers are kept in working order, and that the employer makes a hard copy of the MSDS available to the employee or safety and health committee/representative upon request. Employees should ensure that they obtain adequate information on a controlled product before using it. Read the MSDS and question your immediate supervisor if you feel you need more information. INTERPRETING THE MSDS Chemical manufacturers are required by law to supply Material Safety Data Sheets upon request by their customers. The information provided is required to be complete and must include what can be expected to be known about the material and the hazards it may present. MSDS’s from different companies may not look the same but they should contain the same basic information. The WHMIS regulations specify requirements for a 9 section MSDS. (However, several agencies have made recommendations for the format and content of 16-section MSDSs). 13 Section 1: Product and Company Information The first category is Product Information. This includes the product identifier (name), manufacturer and suppliers names, addresses, and emergency phone numbers. Section 2: Hazardous Ingredients All potentially hazardous ingredients of the material and the approximate percent of each ingredient of the material must be listed in this section. When a material contains ingredients that are registered as a trade secret, a registration number assigned by the Hazardous Materials Information Review Commission will appear in place of the ingredients. In the event of a medical emergency the company must disclose the identity of the ingredients to a medical professional. Section 3: Physical Data The physical state, appearance and odour of acetone may aid in its identification. 14 Section 4: Fire and Explosion Data Describes how to fight a fire that involves the material, and fire properties of the material, such as flash point, and explosive limits. Section 5: Reactivity Data Describes information on the chemical instability of a product and the substances it may react with. 15 Section 6: Toxicological Properties Describes information on the health effects and exposure limits of the material Section 7: Preventive Measures Describes methods and steps to be taken to avoid exposure and safely work with the material. 16 Section 8: First Aid Measures Highlights the specific first aid measure to follow if an individual was exposed to the material. Section 9: Preparation Date Presents the individual(s) responsible for preparation and date of preparation of MSDS. For more detail on what information must be present you can refer to the Controlled Products Regulations. With many supplies of controlled products serving users in North America, a 16-category MSDS is commonly distributed. The 16heading format is acceptable in Canada provided that the information provided is compliant with the Controlled Product Regulations. 17 USAGE OF MSDS Traditionally the intended readers of MSDSs were occupational hygienists and safety professionals. Now the audience also includes employers, workers, supervisors, researchers, and emergency responders. For most people who work with controlled products, there are some sections that are more important than others. Always be familiar with the hazards of a product before you start using it. You should review the MSDS, match the name of the chemical on your container to the one on the MSDS, know the hazards, understand safe handling and storage instructions, as well as understand what to do in an emergency. The information provided is expected to be comprehensive and must include what can reasonably be expected to be known about the material and the hazards it may present. At times the hazards in a MSDS may seem to be overstated, but the same MSDS is used to convey the hazards of the chemical in micro scale quantities in research laboratories to large volumes used in industrial processes. MSDSs look different because only certain content of the MSDS is specified by law. MSDS’s from different companies may not look the same but they should contain the same basic information. Some suppliers put more details in than what is required. However, the information for the nine basic categories must always be in a Canadian MSDS for a controlled product. Keep in mind that a lot of health hazard information, for example, is written in general terms. The staff of the Environmental Health and Safety Office will be able to help you find more information if needed. SOURCES OF MSDS You can obtain MSDSs from various sources. They are as follows: 18 • Supplier When ordering new chemicals. Please note that MSDS’s expire three years from preparation date, so make sure you have a current one. • Workplace Location See your supervisor for more details. • Databases A USB stick, for example. • Internet Websites such as Canadian Centre for Occupational Health and Safety, Fisher Scientific, and Sigma-Aldrich. • Other Download MSDS apps for your smartphone Gl o s s a r yo f Te r ms Bi oha z a r dousI nf e c t i onsMa t e r i a l –ama t e r i a l t h a t c o n t a i n so r g a n i s msa n dt h et o x i n sp r o d u c e db yt h e s eo r g a n i s mst h a t h a v eb e e ns h o wnt oc a u s ed i s e a s eo r a r eb e l i e v e dt o c a u s ed i s e a s ei ne i t h e r h u ma n so r a n i ma l s . Boi l i ngPoi nt –t h et e mp e r a t u r ea t wh i c hal i q u i dc h a n g e sf r o mal i q u i dt oag a s , a t n o r ma l a t mo s p h e r i cp r e s s u r e . Ca r c i noge n–a g e n t st h a t ma yi n d u c ec a n c e r i nh u ma n s . Compr e s s e dGa s–ama t e r i a l wh i c hi sag a sa t n o r ma l r o o mt e mp e r a t u r e( 2 0C) a n dp r e s s u r eb u t i sp a c k a g e da sap r e s s u r i z e dg a s , d i s s o l v e dg a s , o r g a sl i q u e f i e db y c o mp r e s s i o no r r e f r i g e r a t i o n . Cont r ol l e dPr oduc t –d e f i n e du n d e r t h eCo n t r o l l e dPr o d u c t sRe g u l a t i o na sama t e r i a l , p r o d u c t o r s u b s t a n c ewh i c hi si mp o r t e do r s o l di nCa n a d aa n dme e t st h ec r i t e r i a f o r o n eo r mo r eo f t h ef o l l o wi n gc l a s s e s : Cl a s sA–Co mp r e s s e dGa s Cl a s sB–Fl a mma b l ea n dCo mb u s t i b l eMa t e r i a l Cl a s sC–Ox i d i z i n gMa t e r i a l Cl a s sD–Po i s o n o u sa n dI n f e c t i o u sMa t e r i a l Cl a s sE–Co r r o s i v eMa t e r i a l Cl a s sF–Da n g e r o u s l yRe a c t i v eMa t e r i a l Cor r os i v eMa t e r i a l –ama t e r i a l t h a t c a na t t a c k( c o r r o d e ) me t a l so r c a u s ep e r ma n e n t d a ma g et oh u ma nt i s s u e ss u c ha st h es k i na n de y e so nc o n t a c t . Cr y oge ni c s–ma t e r i a l swh i c he x i s t a t e x t r e me l yl o wt e mp e r a t u r e ss u c ha sl i q u i dn i t r o g e n . Da nge r ous l yRe a c t i v eMa t e r i a l s–ma t e r i a l st h a t ma yu n d e r g ov i g o r o u sc o n d e n s a t i o n , d e c o mp o s i t i o no r p o l y me r i z a t i o n . Th e yma yr e a c t v i o l e n t l yu n d e r c o n d i t i o n so f s h o c k o r i n c r e a s ei np r e s s u r eo r t e mp e r a t u r e . Th e yma ya l s or e a c t v i g o r o u s l ywi t hwa t e r o r wa t e r v a p o u r t or e l e a s eat o x i cg a s . Fl a s hPoi nt –t h el o we s t t e mp e r a t u r eo f al i q u i da t wh i c hi t g i v e so f f e n o u g hv a p o u r t of o r ma ni g n i t a b l emi x t u r eo f v a p o u r a n da i r i mme d i a t e l ya b o v et h el i q u i ds u r f a c e . Th e l o we r t h ef l a s hp o i n t , t h eg r e a t e r t h er i s ko f f i r e . Fr e e z i ngPoi nt –t h et e mp e r a t u r ea t wh i c hal i q u i db e c o me sas o l i da t n o r ma l a t mo s p h e r i cp r e s s u r e . Ha z a r d–t h ep o t e n t i a l f o r h a r mf u l e f f e c t s Ha z a r dousPol y me r i z a t i on–p o l y me r i z a t i o ni sap r o c e s so f f o r mi n gap o l y me r b yc o mb i n i n gl a r g en u mb e r so f c h e mi c a l u n i t so r mo n o me r si n t ol o n gc h a i n s ( p o l y e t h y l e n ef r o me t h y l e n e , o r p o l y s t y r e n ef r o ms t y r e n e ) . Un c o n t r o l l e dp o l y me r i z a t i o nc a nb ee x t r e me l yh a z a r d o u sa ss o mep o l y me r i z a t i o np r o c e s s e sc a n r e l e a s ec o n s i d e r a b l eh e a t o r c a nb es or a p i da st ob ee x p l o s i v e . I nge s t i on–t a k i n gama t e r i a l i n t ot h eb o d yb ymo u t h( s wa l l o wi n g ) . I nha l a t i on–t a k i n gama t e r i a l i n t ot h eb o d yb yb r e a t h i n gi t i n . I r r i t a nt –ama t e r i a l t h a t c a u s e si r r i t a t i o n , i n f l a mma t i o no r a g g r a v a t i o no f wh a t e v e r t i s s u ewi t hwh i c ht h ema t e r i a l c o me si n t oc o n t a c t . LC5 0–t h ec o n c e n t r a t i o no f ama t e r i a l wh i c hc a u s e sd e a t hi n5 0 %o f ag r o u po f t e s t a n i ma l s . L Cs t a n d sf o r l e t h a l c o n c e n t r a t i o n . I t i su s u a l l yd e f i n e di nt e r mso f a i r c o n c e n t r a t i o n . LD5 0t h ewe i g h t o f ma t e r i a l wh i c hc a u s e dt h ed e a t ho f 5 0 %o f ag r o u po f t e s t a n i ma l s . I t i su s u a l l ye x p r e s s e da st h ewe i g h t o f ma t e r i a l p e r we i g h t o f t e s t a n i ma l . L Ds t a n d sf o r l e t h a l d o s e . Ox i di z i ngMa t e r i a l –ama t e r i a l t h a t g i v e su po x y g e ne a s i l yo r c a nr e a d i l yo x i d i z eo t h e r ma t e r i a l . Pol y me r i z a t i on–t h ep r o c e s so f f o r mi n gap o l y me r b yc o mb i n i n gl a r g eu n i t so f c h e mi c a l u n i t so r mo n o me r si n t ol o n gc h a i n s . Pr oduc t I de nt i f i c a t i onNumbe r( PI N) : an u mb e r , s p e c i f i e di nt h eTr a n s p o r t a t i o no f Da n g e r o u sGo o d sRe g u l a t i o nt h a t i d e n t i f i e st h ec h e mi c a l . Th i sn u mb e r i su s e d b yf i r ef i g h t e r sa n do t h e r e me r g e n c yr e s p o n s ep e r s o n n e l f o r i d e n t i f i c a t i o no f ma t e r i a l d u r i n gt r a n s p o r t a t i o n . Te r a t oge n–a g e n t so r c o mp o u n d st h a t c a nc a u s ed e f e c t si naf o e t u s . Tox i c i t y–t h ea b i l i t yo f as u b s t a n c et oc a u s eh a r mf u l e f f e c t s . Tr a deNa me–t h en a meu n d e r wh i c hap r o d u c t i sc o mme r c i a l l yk n o wn . Va pour–ag a s e o u sf o r mo f ama t e r i a l wh i c hi sn o r ma l l ys o l i do r l i q u i da t r o o mt e mp e r a t u r ea n dp r e s s u r e .