2014 Northwestern, Low-Pressure Titanium

advertisement

Article

pubs.acs.org/JPCC

Alternative Low-Pressure Surface Chemistry of Titanium

Tetraisopropoxide on Oxidized Molybdenum

Alexis M. Johnson† and Peter C. Stair*,†,‡

†

Department of Chemistry, Northwestern University, Evanston, Illinois 60208, United States

Chemical Sciences and Engineering Division, Argonne National Laboratory, Argonne, Illinois 60439, United States

‡

S Supporting Information

*

ABSTRACT: Titanium tetraisopropoxide (TTIP) is a precursor utilized in atomic layer

depositions (ALDs) for the growth of TiO2. The chemistry of TTIP deposition onto a

slightly oxidized molybdenum substrate was explored under ultrahigh vacuum (UHV)

conditions with X-ray photoelectron spectroscopy. Comparison of the Ti(2p) and C(1s)

peak areas has been used to determine the surface chemistry for increasing substrate

temperatures. TTIP at a gas-phase temperature of 373 K reacts with a MoOx substrate at

373 K but not when the substrate is at 295 K, consistent with a reaction that proceeds via a

Langmuir−Hinshelwood mechanism. Chemical vapor deposition was observed for

depositions at 473 K, below the thermal decomposition temperature of TTIP and within

the ALD temperature window, suggesting an alternative reaction pathway competitive to

ALD. We propose that under conditions of low pressure and moderate substrate

temperatures dehydration of the reacted precursor by nascent TiO2 becomes the dominant

reaction pathway and leads to the CVD growth of TiO2 rather than a self-limiting ALD

reaction. These results highlight the complexity of the chemistry of ALD precursors and demonstrate that changing the pressure

can drastically alter the surface chemistry.

■

kinetics.4,7,8 Many of these experiments are summarized in a

dedicated review by Puurunen.4 Studies of other ALD metal

precursors and corresponding growth processes of metal oxide

films, such as Nb2O5, HfO2, ZrO2, Al2O5, and TiO2, have also

been performed.9−12 Additional experiments have explored the

influence of different oxidizing precursors including H2O,

ozone, and O2 plasma.13−15

While TiCl4 is the common precursor for the growth of

TiO2, titanium tetraisopropoxide (TTIP) is an important

alternative. TTIP is preferable for materials intended for

catalytic applications since residual surface ligands can be

removed by calcination.16 In contrast with TiCl4, residual

surface chlorine induces Brønsted acidity that imparts

potentially undesirable catalytic functionality. While the thermal

decomposition of TTIP for chemical vapor deposition (CVD)

applications is the subject of a number of publications, a smaller

number have looked at the ALD chemistry of TTIP.5,17−19 An

enlightening study by Rahtu and Ritala combines mass

spectrometry, quartz crystal microbalance (QCM), and TPD

experiments to explore the reaction mechanism of TTIP

deposition onto both a predosed Ti(OCH(CH3)2)4−x covered

surface and SiO2 for TPD and QCM experiments, respec-

INTRODUCTION

Atomic layer deposition (ALD) is a technique that relies on

two sequential gas−surface reactions to grow materials in a

layer-by-layer fashion. This method is employed in the

semiconductor industry and is most commonly used to deposit

metal oxides.1 However, ALD has become an emerging

technique for the fabrication of novel and complex catalytic

systems and in the process has been extended to the growth of

metal films and nanoparticles on catalytic supports.2,3

ALD employs multiple cycles that are combined to build

materials with precise thickness control. One ALD cycle is

composed of two half cycles that result in the regeneration of

the initial surface groups, providing new reactive sites for the

following cycle. Given a finite number of surface reaction sites

and steric constraints imposed by the ligands, only a finite

number of precursor molecules can react, resulting in the selflimiting nature of the technique.4 Reactive sites on oxides

include hydroxyl groups, bridging oxygen atoms, and defect

sites.

There has been a significant amount of work directed toward

elucidating ALD chemistry, utilizing techniques such as X-ray

photoelectron spectroscopy (XPS), mass spectrometry, quartz

crystal microbalance (QCM), temperature-programmed desorption (TPD), DFT, and ab initio calculations.5,6 The most

studied system is the deposition of Al2O3 from trimethylaluminum (TMA) and H2O because it is widely used and

considered an “ideal” deposition process. Significant work has

been done to establish a mechanism for the reaction, identify

the source of self-limiting behavior, and understand the reaction

© XXXX American Chemical Society

Special Issue: John C. Hemminger Festschrift

Received: June 6, 2014

Revised: October 13, 2014

A

dx.doi.org/10.1021/jp505653u | J. Phys. Chem. C XXXX, XXX, XXX−XXX

The Journal of Physical Chemistry C

Article

tively.17 The current understanding is that the TTIP reaction

with a metal oxide surface follows eqs 1a and 1b

dosing, transferring into the HPC, and performing analytical

measurements.

The sample was a 1 cm diameter Mo(100) single-crystal disk

that was cut and mechanically polished to within 1° of the 100

plane. It was initially cleaned in a separate UHV chamber by

heating to 1500 K in 5 × 10−7 Torr of oxygen for 48 h to

remove bulk carbon and sulfur. Two 0.25 mm Mo wires were

used to suspend the crystal between two thermally isolated

copper leads at the bottom of the manipulator shaft. The

sample was resistively heated, and the temperature was

measured with a K-type thermocouple spot-welded to the

back of the crystal. Between TiO2 deposition experiments the

crystal was cleaned with argon ion sputtering using 2 keV ions

at normal incidence followed by brief annealing to 1073 K. This

procedure was repeated until the crystal was mostly free of

titanium. The crystal was subsequently annealed at 773 K under

600 L of O2 to remove carbide species that had formed during

the cleaning process. XPS was used to verify the chemical state

and composition of the crystal surface. Peak areas were

calculated with the appropriate sensitivity factor for comparison

between elements, and key elemental ratios are tabulated for

each experiment in the Supporting Information.25

TTIP Deposition. Titanium tetraisopropoxide (TTIP,

Sigma-Aldrich 97 and 99.999%) was purified using several

freeze−pump−thaw cycles before it was deposited onto the

Mo(100) single crystal in the UHV chamber by one of two

experimental methods: (1) dosing lines and (2) the Gemstar-6

ALD system. 97% pure TTIP was used in the dosing lines,

while 99.999% purity was used in the Gemstar-6 system;

however, both systems produced similar deposition chemistry

and are detailed below.26 Once a dose was complete, the

chamber was evacuated for 2−3 h until the pressure reached

10−9 Torr for analysis with XPS. A Mo(3d) satellite peak

overlaps with the C(1s) region and was removed through

subtraction of spectra that were taken of the base substrate

prior to precursor dosing.

Gas Delivery via Dosing Lines. The dosing lines were

used for experiments with the substrate heated to 573 and 473

K. The dosing line is evacuated with a mechanical pump to ∼10

mTorr and is comprised of a precursor vessel, a leak valve, and

a sapphire tube. The precursor vessel is isolated from the

dosing line by a needle valve. A leak valve (Granville-Philips)

separates the low vacuum side of the line from the UHV system

and is used to introduce gaseous precursors into the chamber.

The end of the dosing line is a sapphire tube with a 0.25 mm

tantalum wire coiled around it for resistive heating to control

the temperature of the gas entering the system. Prior to

deposition, the head space of the precursor vessels and the

dosing lines were evacuated and purged several times with N2

gas before directed dosing with either TTIP or H2O to a

pressure of 1 × 10−6 Torr. All precursor vessels and dosing lines

were kept at room temperature, ∼295 K, during the duration of

these experiments, while the sapphire tube was heated to 383

K. The vapor pressures of TTIP and water at room temperature

are 0.4 and 21 Torr, respectively.27,28 After each dose, the lines

and the chamber were purged with 1 × 10−5 Torr of N2 for a

minimum of 15 min. The QMS was used to verify the presence

of the intact precursor during the dose and the disappearance of

the precursor during the N2 purge.

Gas Delivery via the Gemstar-6. A commercial ALD

system (Arradiance Gemstar-6) was interfaced to the UHV

chamber through an auxiliary port on the system. One end of a

1/4″ OD stainless steel tube is inserted into the oven of the

2 − OH(s) + Ti(Oi Pr)4(g)

→ ( −O − )2 Ti(Oi Pr)2(s) + 2(CH3)2 CHOH(g)

(1a)

( −O − )2 Ti(Oi Pr)2(s) + 2H 2O(g)

→ ( −O − )2 Ti(− OH)2(s) + 2(CH3)2 CHOH(g)

(1b)

In this mechanism, half of the precursor ligands are removed

upon the initial reaction with surface hydroxyl groups (eq 1a),

and the other half are released with a subsequent water dose

(eq 1b).

Equations 1a and 1b can be generalized for many ALD

processes on metal oxide surfaces for which the majority of the

reactive sites are surface hydroxyl groups. However, as ALD

applications are broadening more nontraditional substrates are

being used, and the chemistry involved is less well understood.

In particular, only a few studies have explored reaction

mechanisms on noble metal surfaces, such as Cu and Pd, and

these studies predominantly involve the TMA/H2O process.20,21

In this study we use a slightly oxidized Mo(100) sample as

our substrate to develop a better understanding of how

deposition proceeds on alternative surfaces compared to

deposition on typical metal oxides such as Al2O3, TiO2, or

SiO2. In addition, it is advantageous to use MoOx as the base

substrate in order to minimize reactions with the alkoxide

ligands on TTIP. While molybdenum oxides can catalyze

alcohol dehydration to alkenes through an alkoxide intermediate, recent studies have shown that an alkoxide on the

surface of MoO3 would be more likely to recombine with a

hydrogen atom to desorb as the alcohol than dehydrate to the

alkene.22,23 As the Mo oxidation state decreases below 6+

dehydration of the alkoxide is even less probable. X-ray

photoelectron spectroscopy (XPS) was used to explore the

nature of the chemistry during TiO2 deposition by TTIP onto

MoOx surfaces at different temperatures. The ratio of Ti(2p)

and C(1s) XPS peak areas was used to determine whether the

TiO2 deposition followed CVD or ALD mechanisms at each

temperature. Surprisingly, we found that CVD can be the

dominant reaction mechanism even at temperatures used in

standard ALD growths that are below where TTIP decomposes.

■

EXPERIMENTAL METHODS

Instrumentation and Sample Mounting. All experiments were performed in a previously described three-level

ultrahigh vacuum (UHV) apparatus with a base pressure that

ranged from 5 × 10−10 to 2 × 10−9 Torr.24 Briefly, the upper

level includes an Extrel quadrupole mass spectrometer, low

energy electron diffraction (LEED), ion sputtering gun, heated

dosing lines, and a dual-anode Thermo/VG Microtech X-ray

photoelectron spectrometer with a hemispherical electron

energy analyzer. The middle level houses a high-resolution

electron energy loss spectrometer, and the bottom level

contains a high-pressure cell (HPC). Recently, an Arradiance

Gemstar-6 ALD system was interfaced to the top level of the

UHV apparatus. A 360° rotating XYZ manipulator with a 1 m

Z-translator was used to position the sample for sputtering, gas

B

dx.doi.org/10.1021/jp505653u | J. Phys. Chem. C XXXX, XXX, XXX−XXX

The Journal of Physical Chemistry C

Article

ALD system, and a fraction of the gas stream is directed into

the UHV system toward the surface of the Mo substrate. A

VCR gasket at the end of the stainless steel tube with a 75 μm

diameter laser-drilled hole reduces the pressure from 1 to 10

Torr to ∼10−7−10−6 Torr. The connecting line could be

evacuated with a turbo pump (Pfeiffer-Balzer 070) and heated

to 383 K. The temperatures of the TTIP and water containers

were 353 and 295 K, respectively. The corresponding vapor

pressure for TTIP is ∼2.2 Torr.28 The head space of the

precursor bottle was evacuated before dosing. Doses were

performed by first closing the isolation valve between the ALD

system and the mechanical pump evacuating it. The precursor

was then dosed into the ALD reaction chamber followed by

minimizing the carrier N2 flow to prevent large changes to the

partial pressures within the reaction chamber over the course of

the dose. After 15 s of equilibration time the gas was introduced

into the UHV chamber. After each dose was complete the

connecting line was purged with N2 for a minimum of 20 min,

and the concentration of precursor remaining in the chamber

was monitored with the QMS. The partial pressure of TTIP

and H2O entering the chamber was less than 3 × 10−7 and 3 ×

10−6 Torr, respectively, based on the changes in the base

pressure read by an ion gauge (Granville-Philips). This

experimental setup was used for the set of deposition

experiments in which the surface of the Mo crystal was heated

to 373 K.

■

RESULTS

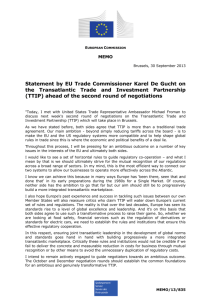

Base MoOx Surface. A clean Mo (100) surface is extremely

reactive and will dissociatively adsorb gases at room temperature until a passivation layer is formed.29 The annealing

temperatures used in the study temporarily removed the

carbon, but were not high enough to completely desorb all of

the oxygen. The base Mo surface in these experiments was

passivated by both carbon and oxygen, as shown in the

representative XPS data in Figure 1 for the base substrate used

in the 573 K experiments. The integrated peaks from panels a,

b and c corresponding to Mo(3d), O(1s) and C(1s) spectra,

respectively, give a Mo:O:C ratio of 11:7:1. The binding

energies for the Mo(3d5/2) peak from the base substrates in this

work ranged between 227.9 and 228.0 eV with a full width halfmaximum (fwhm) of ∼1.1 eV, Figure 1a. The binding energies

for the O(1s) peak range from 530.4 to 530.7 eV with a

corresponding range of fwhm of 1.9−3.3 eV, Figure 1b. All

O(1s) spectra are well fit with two Gaussians, with peaks at

530.5 and 531.4 eV, consistent with O(1s) spectra from

molybdenum oxides found in the literature.30 The C(1s) peak

has a binding energy of 285.2 eV and a fwhm of 2.4 eV,

consistent with adventitious carbon.

After a brief anneal to 573 K the C(1s) signal disappeared

from the base MoOx surface but grew back to the concentration

shown in Figure 1c during the experiment. It is difficult with the

current XPS orientation, θ = 0°, to determine the exact

elemental ratio of the top few layers of the substrate. Previous

work from our laboratory has explored the effects of

chemisorbed oxygen on the structure, oxidation state, and

acidity of Mo(100).29,31−34 These early experiments used CO

dissociation to calibrate the O(1s) signal to establish a metric

for the expected intensity ratio of the Mo(3d5/2) to the O(1s)

peaks for increasing oxygen coverage ranging from 0.3 to 2

monolayers on a Mo(100) surface.35 For this work, the O/Mo

ratios are 0.06, 0.15, and 0.14 for the base substrate in the 573,

473, and 373 K experiments, respectively. These ratios

Figure 1. Representative (a) Mo(3d), (b) O(1s), and (c) C(1s)

spectra from the base Mo substrate.

correspond to oxygen surface coverages of 0.7, 1.7, and 1.5

monolayers. For oxygen coverages above 1.5 monolayers, the

two higher coverages in our case, it has been reported that the

surface has chemical and physical properties similar to MoO2.

Oxygen on surfaces with less than 1.5 monolayers is

chemisorbed.36,37 Because the surface structure and hence the

stoichiometry is not known we refer to the surface as MoOx.

The presence of chemisorbed oxygen implies that the Mo(100)

surface is passivated by a layer of oxygen atoms onto which the

adventitious carbon becomes adsorbed.

TTIP Deposition onto a 573 K MoOx Surface. The

results of TTIP deposition onto a 573 K base MoOx surface in

300 L (1 Langmuir = 1 × 10−6 Torr s) intervals are shown in

Figure 2. 573 K is above the reported TTIP thermal

decomposition temperature and would be expected to produce

chemical vapor deposition, whereby the growth of TiO2 is

dependent only on the integrated precursor exposure. Panels a

and b show the Ti(2p) and C(1s) spectra from the base surface

(black) and after three 300 L doses of TTIP (red). The

Ti(2p3/2) peak from the base Mo surface is insignificant, but

after TTIP exposure there is a large peak with a binding energy

of 459.4 eV and a peak splitting of 5.7 eV which is indicative of

TiO2 formation; however, there is charging in the sample which

leads to slightly higher binding energies.25 There is a persistent

C(1s) peak from adventitious carbon present on the base

surface, but this set of experiments also resulted in a

contribution at lower binding energies from carbidic carbon.

In Figure 2b, the C(1s) spectrum from the base Mo surface and

the total C(1s) spectrum taken after 900 L of TTIP are shown

in black and red. The C(1s) spectrum from the base surface

was subtracted from the total C(1s) spectrum after 900 L of

C

dx.doi.org/10.1021/jp505653u | J. Phys. Chem. C XXXX, XXX, XXX−XXX

The Journal of Physical Chemistry C

Article

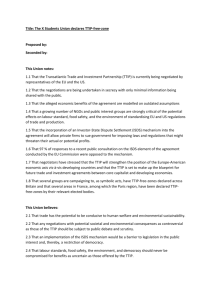

Figure 2. Results for increasing 300 L doses of TTIP onto a 573 K Mo substrate. (a) Ti(2p) spectra taken before (black) and after (red) a total of

900 L of dosing time, (b) C(1s) spectra taken of the base surface (black) and the total C(1s) signal (red) after a total of 900 L of TTIP, (c) the

C(1s) signal added from 900 L of TTIP dosing (red) and the C(1s) spectrum from the isopropoxide in condensed vanadyl triisopropoxide (VOTP),

and (d) Ti (black squares) and C (open blue circles) surface densities as a function of TTIP exposure.

and is commonly used when growing TiO2 inside an ALD

reactor using TTIP as the metal precursor.13 Panels a and b

show the respective Ti(2p) and C(1s) spectra for the base

MoOx (black) and after four sequential 300 L of TTIP (red).

While the peak area is significantly lower at this temperature

than at 573 K, there is still a significant Ti(2p) signal from

deposited TiO2 which has a slightly lower binding energy of

459.0 eV, likely from reduced sample charging on a thinner

deposited metal oxide film. The C(1s) spectrum from the base

surface (black line in Figure 3b) is similar to the base signal in

Figure 2b but is lacking a contribution from carbidic carbon.

The red line represents the increase in C(1s) signal after four

300 L doses. The spectrum is bimodal and resembles the C(1s)

spectrum of condensed isopropoxide ligands, similar to Figure

2c. While the water doses reduced the intensity of the C(1s)

signal, the shape of the peak remained the same, indicating the

loss of exchangeable isopropoxide ligands.

The elemental ratios and surface densities calculated after

each dose are shown in Table S2 of the Supporting

Information. The base substrate had a Ti and C surface

density of 0.4 and 2.0 atoms/nm2. Figure 3c shows the changes

in Ti (black squares) and C (open blue circles) surface

densities above the base substrate value after each dose. The C

surface density grows in a manner similar to the case of the 573

K MoOx surface, in which it remains fairly constant with

increasing TTIP exposure. On the other hand, the Ti surface

density is almost linear with exposure time. These films are

slightly deficient in oxygen, which is consistent with previous

studies of TiO2 ALD with TTIP onto another clean surface,

Si(001), at 373 K.18 The Ti atom surface densities suggest that

40% of a full monolayer of titanium oxide was grown by the

TTIP to isolate the C(1s) signal due to the depositions alone.

The reported C(1s) spectra have been corrected in this

manner. The resultant C(1s) peak shape (Figure 2c) is bimodal

with similar peak ratios to that of the spectrum from an

isopropoxide ligand (blue) obtained in a previous study from

condensed vanadyl triisopropoxide.38

All elemental ratios and surface densities are summarized in

Table S1 (Supporting Information), with an error associated

with the integration and background subtraction process of

∼8%. The Ti and C surface densities for the base substrate

were 0.2 and 1.8 atoms/nm2, respectively. Figure 2d displays

the change in Ti (black squares) and C (open blue circles)

surface density above the base substrate value as a function of

precursor exposure time. As demonstrated by the graph, the Ti

surface density increases linearly with exposure time, while the

C surface density is approximately constant. The ratio of peak

areas, C(1s):Ti(2p), from the spectra after 900 L of TTIP is

∼1:4.9. The Ti(2p):O(1s) ratio indicates that at 573 K the

films are near stoichiometric. The reported density of ALD

grown TiO2 films at 573 K is 4.1 g/cm3, resulting in a Ti surface

density of 9.9 atoms/nm2.39 This is a conservative guide to

determine when a monolayer of TiO2 has been deposited. For a

substrate temperature of 573 K, after the second 300 L TTIP

dose a monolayer of TiO2 has been grown with 11.3 Ti atoms/

nm2.

TTIP and Water Deposition onto a 473 K MoOx

Surface. TTIP was deposited onto the base MoOx surface

held at 473 K. The results shown in Figure 3 are from four

sequential 300 L doses (1200 total L) of TTIP followed by two

sequential water doses of 300 and 600 L. The temperature of

the substrate is within the ALD window for TTIP deposition

D

dx.doi.org/10.1021/jp505653u | J. Phys. Chem. C XXXX, XXX, XXX−XXX

The Journal of Physical Chemistry C

Article

Reactions on MoOx at 295 and 373 K. TTIP was dosed

into the UHV chamber and onto a 373 K base Mo surface using

the Gemstar-6 system in three 20 L intervals followed by two

70 L intervals. After a total of 200 L of TTIP exposure the

surface was dosed with 360 L of water followed by another 20 L

dose of TTIP. The results are shown in Figure 4. The substrate

Figure 3. Results for increasing 300 L doses of TTIP onto a 473 K Mo

substrate. (a) Ti(2p) spectra taken before (black) and after (red) a

total of 1200 L of TTIP, (b) C(1s) spectra taken before (black) and

after (red) a total of 1200 L of TTIP, and (c) Ti and C surface

densities as a function of TTIP (black squares and blue circles) and

water (red squares and circles) exposure.

Figure 4. Results for increasing three 20 L and two 70 L doses of

TTIP onto a 473 K Mo substrate. (a) Ti(2p) spectra taken before

(black) and after (red) a total of 200 L of TTIP, (b) C(1s) spectra

taken before (black) and after (red) a total of 200 L of TTIP, and (c)

Ti (black squares) and C (open blue circles) surface densities as a

function of precursor exposure. Surface density changes from H2O

doses are shown in red.

end of the final dose. The C surface density is greater than the

Ti surface density for the first two doses with a C(1s):Ti(2p)

ratio of 1.3:1. This ratio implies that an average of 1.3 C atoms

are deposited for every Ti atom. After 1200 L of TTIP exposure

the Ti surface density is larger than that of C with a ratio of

1:2.3.

The red squares and red circles in Figure 3c represent the Ti

and C surface densities, respectively, after 300 L and then 600 L

of H2O. There is a 47% decrease in the C density upon the first

300 L of H2O, but there was no impact on the C density from

the subsequent 600 L H2O dose. As expected, the Ti surface

density increases only slightly due to partial removal of the

carbon overlayer.

temperature is well below reported decomposition temperatures for TTIP. Figure 4a shows the Ti(2p) spectra from a

base Mo surface and after 200 L of TTIP in black and red,

respectively. The binding energy, 458.9 eV, and peak splitting,

5.9 eV, are similar to the results displayed in Figure 3 and

consistent with a Ti−O containing species on the surface.

E

dx.doi.org/10.1021/jp505653u | J. Phys. Chem. C XXXX, XXX, XXX−XXX

The Journal of Physical Chemistry C

Article

control the temperatures of the gaseous precursors and the

substrate and therefore study substrate temperature effects in

more detail. In the current study we have explored the changes

in the chemistry of TTIP with increasing substrate temperatures while keeping the precursor gas temperature at 373 K.

On the time scale of our experiments, there is no evidence of

reaction with either water or TTIP when the substrate is held at

room temperature (295 K). However, deposition was observed

when the substrate temperature was increased to 373 K. Our

results indicate that thermal activation by the substrate is

critical as increasing the gas-phase temperature alone to 373 K

is insufficient for achieving growth. This means that the

precursor first accommodates to the surface temperature prior

to reaction and implies a Langmuir−Hinshelwood rather than

an Eley−Rideal mechanism for the surface chemistry.

Temperature Dependence of TTIP Deposition onto

MoOx. The growth mode and chemistry of TTIP deposition

onto a base MoOx surface was studied with XPS as a function

of substrate temperature. The shapes of the Ti(2p) and C(1s)

spectra, ratio of their peak areas, and Ti and C surface densities

after TTIP or water dosing are used to determine the type of

growth.

Atomic layer deposition and chemical vapor deposition are

related processes for the growth of materials. As mentioned

previously, ALD is a process that is composed of two sequential

self-limiting gas−surface reactions. Alternatively, CVD is the

growth of materials from chemical reactions of gas-phase

precursors. CVD can arise from a variety of mechanisms,

including gas-phase bimolecular reactions, thermal decomposition of the precursor or surface reactions that regenerate

reactive sites. Since CVD and ALD are similar, it can be hard to

distinguish between the two. One critical difference is selflimiting growth in ALD.

Chemical vapor deposition through thermal decomposition

of TTIP has been well studied.17,28,46−52 CVD products can

include TiO2, H2O, propene, H2, isopropanol, acetone, and

diisopropyl ether, depending on the reaction conditions.17,47,48,53,54 A common thermal decomposition mechanism includes propene as a product, as represented in eq 2.

Figure 4b displays the C(1s) peak from the base surface which

has a similar shape to previous adventitious carbon spectra. The

red line in Figure 4b represents the increase in C(1s) signal on

the surface after 200 L of TTIP dosing. While the peak shape

and binding energies are very similar to the spectra in Figures 2

and 3, the signal-to-noise ratio is too low for further peak shape

analysis.

Elemental ratios and Ti atom surface densities are reported

in Table S3 in the Supporting Information. Panel c depicts the

changes in the Ti and C surface densities (black squares and

open blue circles) above the base substrate values as a function

of precursor exposure time. Unlike the previous experiment at

473 K, the C surface density was consistently higher than the

corresponding Ti surface density. The C(1s):Ti(2p) ratio after

the first 20 L TTIP dose was approximately 5.8:1 and dropped

to 2.8:1 after a total of 200 L of TTIP exposure. Following 200

L of TTIP exposure, the surface was dosed with 360 L of water,

and the results are represented by the red markers in Figure 4c.

The Ti surface density remained the same, while the C surface

density decreased by ∼33%. The remaining signal had the same

shape as shown in Figure 4b, consistent with the loss of

isopropoxide from the surface. After the water another 20 L

dose of TTIP was applied which increased both the Ti(2p) and

the C(1s) signals. Films grown at 373 K are significantly oxygen

deficient. The Ti atom surface densities indicate that 17% of a

full monolayer of titanium oxide was grown by the end of the

final dose.

Two experiments with the surface at 295 K were also

performed. In the first experiment, 40 L of 388 K TTIP was

dosed onto a base room temperature MoOx substrate. No

titanium or carbon was deposited. The second experiment

involved dosing a room temperature TTIP-terminated surface

with 720 L of 388 K water. No detectable changes in the C(1s)

spectra were observed.

■

DISCUSSION

Several studies have demonstrated that ALD can be carried out

under UHV conditions (10−6 Torr) with pressures that are 6−7

orders of magnitude lower than in traditional ALD reactors

(0.1−10 Torr).12,18,40,41 However, it has been suggested that

the pressure difference between UHV conditions and traditional ALD can result in different chemistry.42,43 XPS, mass

spectrometry, secondary ion mass spectrometry (SIMS),

temperature-programmed desorption (TPD), IR spectroscopy,

and electron energy loss spectroscopy (EELS) are some of the

methods that have been used to study and verify self-limiting

growth on flat surfaces at lower pressures.5,8,12,40,44,45 The most

studied process is the growth of Al2O3 by deposition of

trimethylaluminum and water.4 IR and EELS experiments

conducted by Soto et al. and mass spectrometry experiments

performed by Juppo et al. have successfully observed ALD-like

behavior from lower-pressure dosing.8,43 A few other ALD

processes have been explored under UHV conditions, including

XPS studies by Roy et al. on the deposition of ZrO2 and

coupled XPS and SIMS experiments by Lemonds et al. to

investigate the chemistry of TaF5 and Si2H6 half-cycle

reactions.40,41 In both cases self-limiting deposition was

observed with substrate temperatures up to 523 K. Finally,

our own experiments investigating VOx deposition onto metal

oxide surfaces have observed ALD-like growth of vanadia in an

UHV system.38

Room Temperature TTIP Chemistry. Unlike traditional

ALD reactors, our UHV setup allows us to independently

Ti(OCH(CH3)2 )4(g) → TiO2(s) + 4C3H6(g) + 2H 2O(g)

(2)

For ALD of TTIP on a metal oxide surface, the reaction in the

first half-cycle is eq 1a. It is important to note that the reaction

terminates with some number of carbon-containing ligands

remaining on the surface, covering potential reactive sites. This

is responsible for the self-limiting behavior of ALD. Comparing

eq 1a and 2, one critical difference between CVD and ALD is

the lack of carbon expected to remain on the surface after CVD.

In our studies, we use this difference to determine the growth

mode. Not only do we observe surface carbon species but also

the shape of the C(1s) spectra is similar to the C(1s) spectrum

of condensed vanadyl triisopropoxide observed in previous

studies performed in the same apparatus. This indicates that the

carbon signal is predominantly composed of isopropoxide

ligands remaining on the surface after the reaction. Although

the Ti(2p) or Mo(3d) spectra cannot be used to distinguish

whether the isopropoxide ligands are bound to Ti or Mo atoms,

the decreases in C(1s) intensity after water dosing indicate that

exchangeable ligands are present.

The more informative XPS results are the C(1s) to Ti(2p)

peak area ratio and corresponding surface densities which

should indicate the ratio of ligands to titanium atoms remaining

F

dx.doi.org/10.1021/jp505653u | J. Phys. Chem. C XXXX, XXX, XXX−XXX

The Journal of Physical Chemistry C

Article

dose, the total C(1s):Ti(2p) ratio immediately decreases to

2.8:1, indicating that less than one ligand remains on the

surface per reacted TTIP molecule and there was an overall loss

of ligands from the first dose to the second. The ratio remains

relatively constant through 200 L of TTIP exposure. These

ratios are more suggestive of CVD-like growth of TiO2

compared to the first dose. These results suggest that ALD

chemistry takes place during the first dose because TiO2 is not

yet present on the surface, but following doses approach CVD

behavior as the TiO2 concentration builds up and the

dehydration reaction pathway becomes possible.

We have considered the possible role of the MoOx surface in

this alternative reaction pathway. MoO3 and to a lesser degree

MoO2 are also alcohol dehydration catalysts; however, recent

studies have shown that the surface alkoxides preferentially

desorb as the alcohol rather than dehydrate to the alkene.22,23

The presence of MoO3 was undetectable by XPS, and its

presence is not expected on Mo surfaces treated as described.

Therefore, substrate-catalyzed dehydration is not expected to

contribute to the overall dehydration reaction. To further

address the possibility of molybdenum oxide catalyzed

dehydration TTIP was deposited onto a 473 K MoOx substrate

with an oxygen coverage of 0.5 monolayer, a significantly lower

oxygen concentration than in the previous experiment.

Vibrational spectroscopy and surface polarizability studies

have shown that oxygen overlayers with this concentration do

not have the structure or electronic properties of molybdenum

oxide but rather behave as chemisorbed oxygen.34−36 This

surface will have even less activity than MoO2 for dehydration

of the alkoxide ligand. The elemental ratios, Ti atom surface

densities, and a description of the experiment are detailed in

Table S4 of the Supporting Information. Due to the low

reactivity of TTIP only 45% of a complete TiO2 monolayer is

deposited after a total of 2040 L of TTIP exposure. However,

we observe low C(1s):Ti(2p) ratios, indicating CVD-like

growth which is consistent with the results from the more

oxidized substrate. This suggests that the base MoOx substrate

does not play a significant role in the alternative reaction

pathway.

Implications for Atomic Layer Deposition Processes.

This alternative reaction pathway to ALD chemistry for TTIP

deposition is not restricted to MoOx substrates because the

active dehydration site is predominantly TiO2. However, it is

improbable that the dehydration reaction pathway plays a major

role during ALD processes in traditional reactors because the

precursor flux on the surface is 106−107 higher. Because of the

higher flux, all active dehydration sites are covered by deposited

TTIP molecules, and dehydration is quenched. This flux

dependence has possible implications for substrate architectures

with mass transport limitations, such as long nanoscale pores.

Our results suggest that CVD, instead of ALD, occurs at the

bottom of these pores because the flux of TTIP molecules may

be insufficient to inhibit the dehydration pathway. The CVD

reactions would then lead to a filling of the pores rather than a

thin conformal coating.

after each dose. For ALD-like reactions, we expect that there

should be, on average, 1−2 isopropoxide ligands per Ti atom

remaining on the surface if there is less than one monolayer

coverage. This would be reflected in the XPS spectra as a

C(1s):Ti(2p) ratio that is greater than or equal to 3:1. Instead,

for all doses of TTIP onto a 573 K MoOx surface the Ti(2p)

signal is greater than the C(1s) signal (Figure 2d), and the Ti

surface density increases linearly with TTIP exposure, therefore

indicating that TiO2 is being formed by CVD. This observation

is consistent with previous thermal decomposition studies.17,19,46,47,49,51

Chemical Vapor Deposition of TTIP at 473 K. At 473 K

all doses of TTIP also resulted in low C(1s):Ti(2p) atomic

ratios which decreased from 1.3:1 to 1:2.3 as the TTIP

exposure increased. This indicates that CVD also occurs at 473

K even though this is within the observed ALD temperature

window.13,55 Moreover, while thermal decomposition is a

common mechanism of CVD, 473 K is below the reported

TTIP thermal decomposition temperatures. We have considered the possibility of gas-phase reactions from residual water in

the chamber regenerating reactive sites from ligand exchange

causing uncontrolled growth, especially during the long

evacuation and data collection periods. However, this can be

ruled out by our experiment showing the absence of reaction

between dosed water and the 295 K TTIP-covered surface.

One possible CVD mechanism which explains our

observations is that, under UHV conditions at 473 K, we are

observing TiO2-catalyzed dehydration of TTIP molecules. As

far as we know, this reaction mechanism has not been proposed

before; however, it is well known that TiO2 is a dehydration

catalyst that is active for alcohol dehydration above 500 K.56−60

Recent TPD experiments of isopropanol on TiO2(110)

reported a low-temperature dehydration pathway around 300

K.58,59 It has also been established that the intermediate for the

reaction is the alkoxide which then undergoes β-hydride

elimination to form the alkene.56−58,60 While the adsorbed

species from TTIP deposition onto TiO2 is not exactly

equivalent to the reaction intermediate for isopropanol

dehydration on TiO2, the same mechanism and products,

H2O and C3H6, have been reported for TTIP decomposition.17,46,47,53,54 It is reasonable that the alkoxide ligand

chemistry of a deposited TTIP is similar to the chemistry of

the intermediate alkoxide formed during alcohol dehydration.

Thus, during low-pressure deposition, initially formed TiO2

species catalyze dehydration of subsequent TTIP molecules, to

form more TiO2 and regenerate reactive sites rather than

terminating the deposition reaction by saturating the surface

with isopropoxide ligands. This alternative dehydration pathway is always possible during TTIP deposition onto/or near

TiO2 but is likely suppressed under the higher-pressure ALD

conditions because the increased flux of TTIP molecules hitting

the surface leads to a more rapid surface saturation covering the

TiO2 sites active for dehydration. We propose that under the

experimental conditions of low flux and moderate temperatures

the ALD reaction kinetics are slow enough that dehydration

becomes the dominant pathway.

Lowering the MoOx substrate temperature to 373 K causes a

significant change in the growth mode. The integrated C(1s)

signal is larger than for the Ti(2p) signal for all TTIP and water

doses. After the first TTIP dose the calculated C(1s):Ti(2p)

ratio is 5.3:1 which means that on average 1−2 ligands are

remaining on the surface per reacted TTIP molecule, consistent

with ALD chemistry for the first dose. After the second TTIP

■

CONCLUSION

The chemistry of TTIP deposition on to a MoOx surface was

explored at a series of substrate temperatures in UHV

conditions. Compared to successful depositions onto a 373 K

MoOx surface, the lack of reactivity of 373 K TTIP with a 295

K surface indicates that the surface temperature is a critical

parameter. TTIP molecules must accommodate to the surface

G

dx.doi.org/10.1021/jp505653u | J. Phys. Chem. C XXXX, XXX, XXX−XXX

The Journal of Physical Chemistry C

Article

Reaction between Trimethyl Aluminum and Water. J. Vac. Sci.

Technol., A 1991, 9, 2686−2695.

(9) Aarik, J.; Aidla, A.; Sammelselg, V.; Uustare, T.; Ritala, M.;

Leskela, M. Characterization of Titanium Dioxide Atomic Layer

Growth from Titanium Ethoxide and Water. Thin Solid Films 2000,

370, 163−172.

(10) Kukli, K.; Forsgren, K.; Aarik, J.; Uustare, T.; Aidla, A.;

Niskanen, A.; Ritala, M.; Leskela, M.; Harsta, A. Atomic Layer

Deposition of Zirconium Oxide from Zirconium Tetraiodide, Water

and Hydrogen Peroxide. J. Cryst. Growth 2001, 231, 262−272.

(11) Kukli, K.; Ritala, M.; Sundqvist, J.; Aarik, J.; Lu, J.; Sajavaara, T.;

Leskela, M.; Harsta, A. Properties of Hafnium Oxide Films Grown by

Atomic Layer Deposition from Hafnium Tetraiodide and Oxygen. J.

Appl. Phys. 2002, 92, 5698−5703.

(12) Rahtu, A.; Kukli, K.; Ritala, M. In Situ Mass Spectrometry Study

on Atomic Layer Deposition from Metal (Ti, Ta, and Nb) Ethoxides

and Water. Chem. Mater. 2001, 13, 817−823.

(13) Ritala, M.; Leskela, M.; Niinisto, L.; Haussalo, P. Titanium

Isopropoxide as a Precursor in Atomic Layer Epitaxy of Titanium

Dioxide Thin Films. Chem. Mater. 1993, 5, 1174−1181.

(14) Rai, V. R.; Vandalon, V.; Agarwal, S. Influence of Surface

Temperature on the Mechanism of Atomic Layer Deposition of

Aluminum Oxide Using an Oxygen Plasma and Ozone. Langmuir

2012, 28, 350−357.

(15) Rai, V. R.; Agarwal, S. Surface Reaction Mechanisms during

Ozone-Based Atomic Layer Deposition of Titanium Dioxide. J. Phys.

Chem. C 2008, 112, 9552−9554.

(16) Lu, J. L.; Kosuda, K. M.; Van Duyne, R. P.; Stair, P. C. Surface

Acidity and Properties of TiO2/SiO2 Catalysts Prepared by Atomic

Layer Deposition: UV-visible Diffuse Reflectance, DRIFTS, and

Visible Raman Spectroscopy Studies. J. Phys. Chem. C 2009, 113,

12412−12418.

(17) Rahtu, A.; Ritala, M. Reaction mechanism studies on titanium

isopropoxide-water atomic layer deposition process. Chem. Vap.

Deposition 2002, 8, 21−28.

(18) Lee, S. Y.; Jeon, C.; Kim, S. H.; Kim, Y.; Jung, W.; An, K.-S.;

Park, C.-Y. In-Situ X-ray Photoemission Spectroscopy Study of Atomic

Layer Deposition of TiO2 on Silicon Substrate. Jpn. J. Appl. Phys.

2012, 51, 031102/1−031102/3.

(19) Cho, S.-I.; Chung, C.-H.; Moon, S. H. TemperatureProgrammed Desorption Study on the Decomposition Mechanism

of Ti(OC3H7)4 on Si(100). J. Electrochem. Soc. 2001, 148, C599−

C603.

(20) O’Neill, B. J.; Jackson, D. H. K.; Crisci, A. J.; Farberow, C. A.;

Shi, F. Y.; Alba-Rubio, A. C.; Lu, J. L.; Dietrich, P. J.; Gu, X. K.;

Marshall, C. L.; et al. Stabilization of Copper Catalysts for LiquidPhase Reactions by Atomic Layer Deposition. Angew. Chem., Int. Ed.

2013, 52, 13808−13812.

(21) Lu, J.; Liu, B.; Greeley, J. P.; Feng, Z.; Libera, J. A.; Lei, Y.;

Bedzyk, M. J.; Stair, P. C.; Elam, J. W. Porous Alumina Protective

Coatings on Palladium Nanoparticles by Self-Poisoned Atomic Layer

Deposition. Chem. Mater. 2012, 24, 2047−2055.

(22) Seman, M.; Kondo, J. N.; Domen, K.; Reed, C.; Oyama, S. T.

Direct Observation of Surface Intermediates Formed by Selective

Oxidation of Alcohols on Silica-Supported Molybdenum Oxide. J.

Phys. Chem. B 2004, 108, 3231−3239.

(23) Li, Z.; Fang, Z.; Kelley, M. S.; Kay, B. D.; Rousseau, R.;

Dohnalek, Z.; Dixon, D. A. Ethanol Conversion on Cyclic (MO3)3

(M = Mo, W) Clusters. J. Phys. Chem. C 2014, 118, 4869−4877.

(24) Parker, B. R.; Jenkins, J. F.; Stair, P. C. The Adsorption of

Methyl Radicals on Oxygen-Modified Mo(100) Studied by HREELS.

Surf. Sci. 1997, 372, 185−192.

(25) Briggs, D.; Seah, M. P.; Eds., Practical Surface Analysis by Auger

and X-ray Photoelectron Spectroscopy; John Wiley and Sons: New York,

1983; p 533.

(26) The dosing lines and the Gemstar-6 system were both used to

deposit TTIP onto a MoOx substrate at 473 K. It was challenging to

quantitatively compare the total flux from each system as the dosing

methods are significantly different. In the Gemstar-6 the TTIP had to

prior to reaction and follow a Langmuir−Hinshelwood

mechanism.

CVD of TiO2 from TTIP was observed for substrate

temperatures of 573 and 473 K, which are, respectively, within

and below the reported thermal decomposition range for TTIP.

It is believed that, under the conditions of low pressure (10−6

Torr) and moderate temperatures (473 K), dehydration of

TTIP molecules by nascent TiO 2 not only becomes

competitive with the ALD reaction but actually becomes the

dominant reaction. At lower temperature, 373 K, ALD-like

chemistry is observed during the first TTIP dose, but XPS

results suggest that for subsequent doses the growth mode

transitions into CVD. In all cases, the influence of the MoOx

substrate appears to be negligible. While these results may not

directly impact traditional ALD processes, this type of

alternative chemistry may be relevant to high surface area

substrates with long nanopores, where mass transport to the

bottom of the pore is limited and CVD occurs in preference to

typical ALD reactions.

■

ASSOCIATED CONTENT

* Supporting Information

S

Details on elemental ratios and surface densities and effects of

the oxygen coverage on the base substrate on TTIP deposition.

This material is available free of charge via the Internet at

http://pubs.acs.org.

■

AUTHOR INFORMATION

Corresponding Author

*E-mail: pstair@northwestern.edu.

Notes

The authors declare no competing financial interest.

■

ACKNOWLEDGMENTS

This material is based upon work supported by the National

Science Foundation under Grant No. CHE-1058835. The

authors would also like to thank Kunlun Ding, Miles Tan,

Charlie Campbell, and Bruce Rosen for helpful discussions.

■

REFERENCES

(1) George, S. M. Atomic Layer Deposition: An Overview. Chem.

Rev. 2010, 110, 111−131.

(2) Lu, J. L.; Elam, J. W.; Stair, P. C. Synthesis and Stabilization of

Supported Metal Catalysts by Atomic Layer Deposition. Acc. Chem.

Res. 2013, 46, 1806−1815.

(3) Stair, P. C. Synthesis of Supported Catalysts by Atomic Layer

Deposition. Top. Catal. 2012, 55, 93−98.

(4) Puurunen, R. L. Surface Chemistry of Atomic Layer Deposition:

A case study for the Trimethylaluminum/Water Process. J. Appl. Phys.

2005, 97, 52.

(5) Knapas, K.; Ritala, M. In Situ Studies on Reaction Mechanisms in

Atomic Layer Deposition. Crit. Rev. Solid State Mater. Sci. 2013, 38,

167−202.

(6) Lei, Y.; Lu, J.; Zhao, H.; Liu, B.; Low, K.-B.; Wu, T.; Libera, J. A.;

Greeley, J. P.; Chupas, P. J.; Miller, J. T.; et al. Resolving Precursor

Deligation, Surface Species Evolution, and Nanoparticle Nucleation

during Palladium Atomic Layer Deposition. J. Phys. Chem. C 2013,

117, 11141−11148.

(7) Rahtu, A.; Alaranta, T.; Ritala, M. In Situ Quartz Crystal

Microbalance and Quadrupole Mass Spectrometry Studies of Atomic

Layer Deposition of Aluminum Oxide from Trimethylaluminum and

Water. Langmuir 2001, 17, 6506−6509.

(8) Soto, C.; Tysoe, W. T. The Reaction Pathway for the Growth of

Alumina on High Surface Area Alumina and in Ultrahigh Vacuum by a

H

dx.doi.org/10.1021/jp505653u | J. Phys. Chem. C XXXX, XXX, XXX−XXX

The Journal of Physical Chemistry C

Article

be heated to 353 K; there is a carrier gas (N2); and the aperture

restricts the pressure of TTIP into the chamber to 3 × 10−7 Torr.

Most importantly, both methods resulted in TiO2 deposition where

the ratio of the Ti(2p) peak area was greater than the C(1s) peak area

indicating CVD. In addition, both methods did not result in TiO2

deposition with the substrate at 295 K, verifying that the chemistry is

taking place on the MoOx surface and is independent of which dosing

technique was used.

(27) Wagner, W.; Pruss, A. The IAPWS Formulation 1995 for the

Thermodynamic Properties of Ordinary Water Substance for General

and Scientific Use. J. Phys. Chem. Ref. Data 2002, 31, 387−535.

(28) Siefering, K. L.; Griffin, G. L. Growth Kinetics of CVD TiO2Influence of Carrier Gas. J. Electrochem. Soc. 1990, 137, 1206−1208.

(29) Henry, R. M.; Walker, B. W.; Stair, P. C. Adsorption Selectivity

of Lewis-Acids and Bases on an Oxidized Mo(100) Surface Studied by

LEED, Auger, and XPS. Surf. Sci. 1985, 155, 732−750.

(30) Bianchi, C. L.; Cattania, M. G.; Villa, P. XPS Characterization of

Ni and Mo Oxides Before and After “In Situ” Treatments. Appl. Surf.

Sci. 1993, 70−71 (Part 1), 211−216.

(31) Grant, J. L.; Fryberger, T. B.; Stair, P. C. ESCA Measurement of

Surface Atom Oxidation-states on Chemically Modified Mo(100)

Surfaces. Appl. Surf. Sci. 1986, 26, 472−487.

(32) Overbury, S. H.; Stair, P. C. The Structure of Atomic Oxygen

and Carbon Overlayers on the Mo(001) Surface Studied by LowEnergy Ion-Scattering. J. Vac. Sci. Technol., A 1983, 1, 1055−1058.

(33) Walker, B. W.; Stair, P. C. Chemical Evidence for the Formation

of an Acidic Mo(100) Surface by Adsorbed Oxygen. Surf. Sci. 1980, 91,

L40−L44.

(34) Kim, S. H.; Stair, P. C. The Structure of Oxygen Adsorbed on

Mo(100) Studied by High-Resolution Electron Eenergy-Loss Spectroscopy. Surf. Sci. 2000, 457, L347−L353.

(35) Fryberger, T. B. Studies of Chemically Modified Mo(100) Surfaces

using Photoelectron Spectroscopies and Physisorbed Xenon as a Probe;

Northwestern: Illinois, 1986.

(36) Smudde, G. H.; Stair, P. C. The Oxidation of Mo(100) Studied

by XPS and Surface Raman-Spectroscopy - The Onset of MoO2

Formation and The Formation of Surface Polymolybdate. Surf. Sci.

1994, 317, 65−72.

(37) Zhang, C.; Vanhove, M. A.; Somorjai, G. A. The Interaction of

Oxygen with the Mo(100) and Mo(111) Single-Crystal Surfaces Chemisorption and Oxidation at High-Temperatures. Surf. Sci. 1985,

149, 326−340.

(38) Johnson, A. M.; Quezada, B. R.; Marks, L. D.; Stair, P. C.

Influence of the Metal Oxide Substrate Structure on Vanadium Oxide

Monomer Formation. Top. Catal. 2014, 57, 177−187.

(39) Rausch, N.; Burte, E. P. Thin TiO2 Films Prepared by LowPressure Chemical Vapor-Deposition. J. Electrochem. Soc. 1993, 140,

145−149.

(40) Lemonds, A. M.; White, J. M.; Ekerdt, J. G. Surface Science

Investigations of Atomic Layer Deposition Half-Reactions using TaF5

and Si2H6. Surf. Sci. 2003, 538, 191−203.

(41) Roy, P. C.; Jeong, H. S.; Doh, W. H.; Kim, C. M. Atomic Layer

Deposition (ALD) of ZrO2 in Ultrahigh Vacuum (UHV). Bull. Korean

Chem. Soc. 2013, 34, 1221−1224.

(42) Ritala, M.; Leskela, M. In Atomic Layer Deposition; Academic

Press: New York, 2002; pp 103−159.

(43) Juppo, M.; Rahtu, A.; Ritala, M.; Leskelae, M. In Situ Mass

Spectrometry Study on Surface Reactions in Atomic Layer Deposition

of Al2O3 Thin Films from Trimethylaluminum and Water. Langmuir

2000, 16, 4034−4039.

(44) Matero, R.; Rahtu, A.; Ritala, M. In Situ Quadrupole Mass

Spectrometry and Quartz Crystal Microbalance Studies on the Atomic

Layer Deposition of Titanium Dioxide from Titanium Tetrachloride

and Water. Chem. Mater. 2001, 13, 4506−4511.

(45) Zaera, F. Mechanisms of Surface Reactions in Thin Solid Film

Chemical Deposition Processes. Coord. Chem. Rev. 2013, 257, 3177−

3191.

(46) Siefering, K. L.; Griffin, G. L. Kinetics of Low-Pressure Chemical

Vapor Deposition of TiO2 from Titanium Tetraisopropoxide. J.

Electrochem. Soc. 1990, 137, 814−818.

(47) Wu, Y. M.; Bradley, D. C.; Nix, R. M. Studies of Titanium

Dioxide Film Growth from Titanium Tetraisopropoxide. Appl. Surf.

Sci. 1993, 64, 21−28.

(48) Komiyama, H.; Kanai, T.; Inoue, H. Preparation of Porous,

Amorphous, and Ultrafine Titanium Dioxide Particles by Chemical

Vapor Deposition. Chem. Lett. 1984, 1283−6.

(49) Karlsson, P. G.; Richter, J. H.; Andersson, M. P.; Johansson, M.

K. J.; Blomquist, J.; Uvdal, P.; Sandell, A. TiO2 Chemical Vapor

Deposition on Si(111) in Ultrahigh Vacuum: Transition from

Interfacial Phase to Crystalline Phase in the Reaction Limited Regime.

Surf. Sci. 2011, 605, 1147−1156.

(50) Taylor, C. J.; Gilmer, D. C.; Colombo, D. G.; Wilk, G. D.;

Campbell, S. A.; Roberts, J.; Gladfelter, W. L. Does Chemistry Really

Matter in the Chemical Vapor Deposition of Titanium Dioxide?

Precursor and Kinetic Effects on the Microstructure of Polycrystalline

Films. J. Am. Chem. Soc. 1999, 121, 5220−5229.

(51) Chen, Z. X.; Derking, A. TiO2 Thin Films by Chemical Vapor

Deposition: Control of the Deposition Process and Film Characterization. J. Mater. Chem. 1993, 3, 1137−40.

(52) Battiston, G. A.; Gerbasi, R.; Porchia, M.; Marigo, A. Influence

of Substrate on Structural Properties of TiO2 Thin Films Obtained via

MOCVD. Thin Solid Films 1994, 239, 186−91.

(53) Fictorie, C. P.; Evans, J. F.; Gladfelter, W. L. Kinetic and

Mechanistic Study of the Chemical Vapor Deposition of Titanium

Dioxide Thin Films using Tetrakis(isopropoxo)titanium(IV). J. Vac.

Sci. Technol., A 1994, 12, 1108−13.

(54) Chen, S.; Mason, M. G.; Gysling, H. J.; Paz-Pujalt, G. R.;

Blanton, T. N.; Castro, T.; Chen, K. M.; Fictorie, C. P.; Gladfelter, W.

L.; Franciosi, A.; et al. Ultrahigh Vacuum Metalorganic Chemical

Vapor Deposition Growth and In Situ Characterization of Epitaxial

Titania Films. J. Vac. Sci. Technol., A 1993, 11, 2419−29.

(55) Ritala, M.; Leskela, M.; Nykanen, E.; Soininen, P.; Niinisto, L.

Growth of Titanium Dioxide Thin Films by Atomic Layer Epitaxy.

Thin Solid Films 1993, 225, 288−295.

(56) Kim, K. S.; Barteau, M. A. Reactions of Aliphatic Alcohols on

the {011}-Facetted Titanium Dioxide (001) Surface. J. Mol. Catal.

1990, 63, 103−17.

(57) Gamble, L.; Jung, L. S.; Campbell, C. T. Decomposition and

Protonation of Surface Ethoxys on TiO2(110). Surf. Sci. 1996, 348, 1−

16.

(58) Bondarchuk, O.; Kim, Y. K.; White, J. M.; Kim, J.; Kay, B. D.;

Dohnalek, Z. Surface Chemistry of 2-Propanol on TiO2(110): Lowand High-Temperature Dehydration, Isotope Effects, and Influence of

Local Surface Structure. J. Phys. Chem. C 2007, 111, 11059−11067.

(59) Kim, Y. K.; Kay, B. D.; White, J. M.; Dohnalek, Z. Alcohol

Chemistry on Rutile TiO2(110): The Influence of Alkyl Substituents

on Reactivity and Selectivity. J. Phys. Chem. C 2007, 111, 18236−

18242.

(60) Farfan-Arribas, E.; Madix, R. J. Role of Defects in the

Adsorption of Aliphatic Alcohols on the TiO2(110) Surface. J. Phys.

Chem. B 2002, 106, 10680−10692.

I

dx.doi.org/10.1021/jp505653u | J. Phys. Chem. C XXXX, XXX, XXX−XXX