obeya operations - Lean Leadership Academy

advertisement

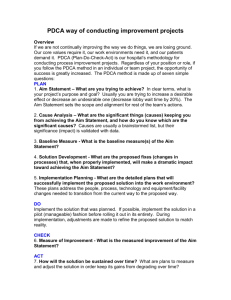

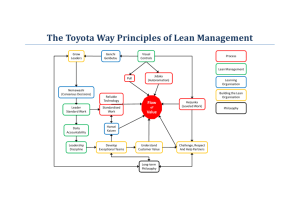

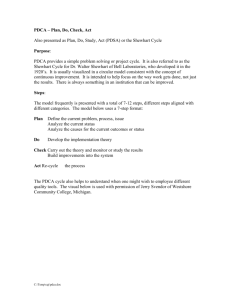

OBEYA OPERATIONS Tearing Down the Walls to Achieve Breakthrough Performance Sam MacPherson, Lean Transformation Sensei, The Lean Leadership Academy™ Bill Levealle, General Manager, Castle Metals Aerospace, Los Angeles, CA Robert Porter, Operations Manager, Timken Aerospace, Rutherfordton, NC (910) 217-LEAN www.leanleadershipacademy.com What is an Obeya? A Room with a View • • Toyota Thailand • The Obeya, or “The Big Room”, dates back to its early days of Toyota, in Japan. • First time visitors to Toyota’s Corporate HQ in Japan are surprised at the large open office areas and the lack of cubicles isolationism. • • The Theory behind Obeya is based on a simple idea: Dedicate time and space to coordination and problem-solving and organizational barriers will be minimized. The ability to maintain Proper Problem Awareness in Real-time, listen to Teammember concerns, make discoveries, resolve problems together, collaborate, accelerate leader and team-member development and reach our full potential is critical to a Lean Organization The Obeya promotes coordination, strategy and flexibility while leveraging the expertise and support of teammates from diverse areas. The Result: Effective solutions and actions that can be developed and implemented quickly. There is Always Room for Kaizen In Coordination! Types of Obeya Global Launch Obeya When developing a new vehicle, managers responsible for decision making in design, production engineering, and manufacturing gather in one place to shorten lead-time through real-time communications & simultaneous engineering Business Process Layout Obeya Business Obeya TMC Global Launch Obeya (Executive offices) Business Obeya (Sales) Centralized data collection, prioritizing and action planning Business Obeya Toyota University Global CamryCamry GlobalLaunch Launch Toyota TMM Australia Mfg Australia Business Obeya (Mfg) Toyota University (Engineering) Focus Obeya Project War Rooms SQDC/PDCA A3 Problem Solving Jishuken rooms Focus Obeya Focus Obeya Focus Obeya Focus Obeya Toyota Motor Sales Large Complex Obeya Toyota Motor Sales and Finance • Large Open Office areas • Accommodates dozens of team-members • Manufacturing Operations • Sales and Finance • Design Engineering • Manufacturing Engineering Potential Issues: • Risks being too formal and rigid • Interoperability of IT between operations • Sensory overload Gap Card Suggestions Anyone in the Toyota organization can enter the Obeya and contribute a suggestion by filling out a red card or red Post-it ® note. The purpose it to accept anyone’s input. An obeya or department leader is assigned to address the Gap and only when the gap is closed is the Gap Card taken down from the Obeya wall. Small-Focused Obeya • • • • • • • • Focused w/Defined Purpose Specific Projects Jishuken or Team room A3 Problem Solving away for noisy gemba environment Limits group size by design Economical Closed rooms melt down barriers Encourages idea contribution PDCA/Problem Solving Process Layout Model LEAN LEADERSHIP ACADEMY Obeya Operations Castle Metals Aerospace Los Angeles Background • Manufacturer of Aircraft Engine Parts, Various ‘Aero Structure’ Components, Aircraft ‘Complex Subsystem’ Components and Distributor of Exotic Alloys / Specialty Metals • Castle Metals Aerospace Began ‘Lean’ Journey in January 2012 • Los Angeles was chosen as “Pilot Facility” • Compelling Need for ‘Cost Basis’ Improvement and Improvement in Key Performance Metrics Why adopt ‘Advanced’ Lean Business Processes? (Zone Control & Obeya Operation) • Critical ‘End Use’ applications of our products: – Commercial & Business Airplanes: 737, 747, 767, 787, A320, A350, G150, G450, G550, G650 – Defense: F-35 JSF, F-15, F-18, C-17, C-130, Apache III – Space: Delta IV, Atlas V, Falcon, Dragon, SLS, New Shepard – Various other DoD applications • ‘-0- Defect’ Tolerance & 100% OTD of Parts and Product is Required by Customer Base Castle Metals Aerospace Obeya “Management Cadence” • 6:45 am ‘Hot Start’ • 9:20 am JSP Meeting • 11:30 am ‘Mid Day’ Huddle • 3:00 pm ‘PFEP’ Meeting • 4:00 pm End of Day Meeting Daily JSP Meeting (Joint Sales and Production) What We Learned in ‘Obeya’ Operations & ‘Zone Control’ Before: After: • Previously: Measured Shift Production only. • Did not Monitor the Use of Routine ‘Consumables’ in Production. • Applauded: ‘OverProduction’ when it infrequently occurred • Hourly Production Records by ‘Mfg. Zone’ increased Understanding of Production Rates per Shift and Variances • Better Utilization of Resources • Much better grasp of Internal ‘Costs’ per shift • Capacity, O/A Increased • WIP, Defects, and ‘Starving’ & ‘Waiting’ decreased What We Learned in ‘Obeya’ Operations & ‘Zone Control’ Before: After: • Patterns of Work & Production varied by Operator • Resulted in Inconsistent and Non Predictive Repair & Maintenance “pitch” • ‘Non Standard’ Work created variance in Part ‘Fit’ and ‘Tolerance’ • All Operators use same Machine ‘set-ups’ • Predictable R&M Schedule replaces Equipment ‘Wear’ Parts before breakdown reducing downtime • Predictable & Repeatable Tolerance on Parts eases ‘Part Fit’ at Customer Assembly Traffic Department “No Cubicles Walls” Environment In the “Information Flow” Realm, Our “No Cubical Walls” Obeya Deployment Reduces the “Waste” of Walking and Improves Communication through Face to Face communication, Administrative Team-member Problem Awareness and Engagement Obeya, Operations & Production Control Work in ‘Close Proximity’ Obeya Operations: “Sales” What We Learned in ‘Obeya’ Operations & ‘Zone Control’ “Sales” Before: After: • Salespeople measured on Monthly & Quarterly Basis • Sales “Pipeline” by Sales Person reviewed and Submitted Monthly with Wins & Losses reviewed • Monthly Conference Calls with Remote Salespeople only • All Inside Salespeople have Two Hour Takt Time for Order Entry. • “Top 5” Progress of “Pipeline” Opportunities discussed weekly with Outside Sales via Conference Call. • Also on Call: Discussion of Competitor Pricing, Significant Actions Reflections on Implementing Obeya & Zone Control • Mechanism for ‘Plant Shop Floor’ Problem Identification and Problem Resolution. – Makes Problems Visible – Must be prepared to Address all Problems that may arise – Reduced ‘Un-Planned’ Downtime by 71% – Reduced ‘Key Value Stream’ Cycle Time from Order to Cash by 62% initially, with ongoing improvements. • Reduces Operator “Struggles” and Improves Morale • Requires Daily Commitment & Diligence from Management – Requires GM, Regional Operations Manager, Area Manager, Group Leader, Team Leader have “Deep” Job Knowledge • Builds Teamwork and Improves ‘Associate’ Relations reflected by Vastly improved ‘Employee Engagement’ Survey Results ‘Obeya’ Operations & ‘Zone Control’ = Breakthrough Performance Improvement & Sustainability “Happy” Faces on our Customers!! LEAN LEADERSHIP ACADEMY Zone Control Timken Shiloh, Rutherfordton, NC 4. Team Leader Response 3. Audible Alarm 5. Op Center Communication 6. Response Team 2. Visual Identification 7.Problem Solving Tools 1. Notification of Problem 10. Problem prevention re-occurrence 9. Data Analysis 8. Data Collection Background • 3 distinct flow paths serving different markets and sales networks, Distribution and OE • Timken Shiloh began ‘Lean’ Journey in December 2010 • Machine Tool Value Stream was chosen as the plant pilot flow path • Compelling Need for step improvement in production output, productivity, cost, customer service, schedule attainment and On time delivery to promise Why accept the challenge of a lean transformation? • Cyclical demand cycles of three distinct product platforms: – Aerospace: OE customer base, complex long lead-time supply chain and demand profile. Customer requirements, significant and variable customer to customer – Machine Tool: High precision product ABEC 9, tied into automotive business cycles, primarily a distribution supply chain requiring short lead-times with little forecast visibility or accuracy – Commercial: Largely off highway, distribution stocking and lower complexity, less demand variability • ‘-0- Defect’ Tolerance , High Customer Service expectation across multiple customer profiles and significant competition to reduce cost Timken Shiloh “Management Cadence” • 7:45 am ‘Plant Fast Response Meeting’ • 10 -11 am Line PDCA’s • 11-12 am Critical Point Gemba walks • 3:30 pm JSP review • 7-8 pm Line PDCA’s • Bi-Monthly Process Reviews • Monthly Hoshin/Kojo Kanri reviews Daily Joint Sales & Production PDCA Materials Engineering Quality Scheduling Operations Manager Cross functional team PDCA meeting - Daily Production Plan - Ahead or Behind - Line Down A3 Report Outs 27 Team Leaders Group Leaders Plant Manager Lean Analyst What We Learned in ‘Obeya’ Operations & ‘Zone Control’ Before: After: • Help chain was 4 hours, loosely followed • Rarely produced objective results • Did not realize deviations from plan in real time reducing opportunity to drive mitigation and corrective action • Help chain 1 hour with rigid operator and support compliance • Documented processes driving A3 thinking and prevention reoccurrence • Hour by hour tracking and reporting driving action at the time and point of occurrence Before 240 Minute Chain of Response After 60 Minute Chain of Response 29 Help Chain In Action What We Learned in ‘Obeya’ Operations & ‘Zone Control’ Before: After: • Little understanding of actual performance to standard • Quick fix to “get back running” • ‘No standard work leading to variation in output, flow and product • All Operators use same Machine ‘set-ups’ • Robust repairs with corrective actions developed to prevent reoccurrence where possible • Standard work for operating associates and leadership driving consistent and rhythm Before After Grind wheels in workstation Grind wheels at distance Audit Process – Operator Owned No Audit Process, No SUSTAIN 5S Event: Machine Tool Team: Zone Team Leader, Operators 32 Reflections on Implementing Obeya & Zone Control • Implementation of Andon system. – Required a change in culture, thinking and discipline at all levels of the organization – Absolute support top down – Within 60 days, achieved • 29% improvement in output • 17% improvement in productivity • 12% improvement in schedule attainment and on time delivery. • Improved associate engagement and morale • Continue to build and improve problem solving skills across the organization – Tendency to revert back to what we are good at, used to, quick fix versus permanent, robust repair solutions The Shiloh Operations Leadership Team Establishing an Operations Obeya Management Leadership at the Source “TPS style improvement depends on the creative efforts of people led by managers and work team leaders with extreme attention to detail in the execution of daily management techniques.” “Having (a) proper awareness of problems and an extremely low tolerance for the current condition is a proper attitude.” -Isao Kato: Father of Standardized Work and Toyota’s Supervisor Leadership Development Program How to Build Your “Big Room” A Phased Implementation Approach in Your House of Lean Phase 5 Obeya Phase 4 Obeya • Deployment Focus • TPS Integration • External Connections • Full SQDCPM Phase 2 Obeya • Flow Focus • Standardized Work • TPM Integration • Level Production • Full Hoshin Integration • Sales Obeya • Engineering Obeya Obtain a Profit and Grow by Increasing Customer Value Through the Elimination of Waste, Burden, and Fluctuation Highest Quality - Lowest Cost - Shortest Lead Time Just-In-Time “Right part, right amount, right place, right time” Phase 3 Obeya • Full SQDCPM • Organizational Problem Solving • A3 Management Phase 1 Obeya • Process Stability • Work Standards • Schedule Attainment Focus Takt-time: Produce at the Pace of Sales “Continuous Flow” “Pull System” In sequence of demand Small lot sizes, frequent Change-overs Respect for Others Jidoka Respect Teamwork “Intelligent Automation” Continuous Improvement Spirit of Challenge Kaizen – Continuous Improvement Genchi-Genbutsu – “Go and See” Leveled Production (heijunka) Kaizen “Quality from the Source” (In-station Process Control) “Make Each Process The Customer” “Make Problems Visible” “Stop and notify about Abnormalities” “Error-Proof” “Separate Man from Machine” Standardization Stability and Reliability in Man, Machine, Methods, Materials Start with Visual Management for of each level of the House of Lean. As you mature each level “The House” the nature of the Obeya Evolves and Transforms. The Truth Telling Room Open Visual meeting space and Office Environment adjacent to senior executives desks No Walls - Direct Communications between customer service, production control, lean supply chain/materials management/production engineering GTS>PDCA Flow Visual Connection to Hoshin Production Status Board Integrated with Andon System Break Down Maintenance/Quality Dispatcher System Extreme Problem Awareness and Urgency Dynamic Leadership Obeya Director Leadership Engagement Next 24 Shift Activity Breakdown Visual 30-60-90 Day Demand Planning Area Joint Sales and Production (JSP) Team Planning Operations Center Obeya Model Dispatcher Operations Current Operations Production Status Board “Yamazumi Board” ANDON Status Countermeasure Progression (PDCA) Quality Advancement Plan (Do it Right) Dashboard Hoshin , Kojo, and Baby A3 Plans Gemba Kanri Plans For Zones and Value Streams Equipment Reliability (Fix it Right) 10-10-10 Day Master 30/60/90 Day Month Schedule Master Schedule 10 day three day out Breakdown Schedule Quality Delivery Price Service Innovation Growth Safety Quality Delivery Cost Productivity Morale TPM Advancement Plan Voice of the Customer Management Cadence Kami Shibai Visual Control Board Obeya Operations Center in Action Maintenance Mgr And Operations Center Director Andon Status Awareness Plant Quality Manger And Scheduler at the Gemba Obeya Team conducts PDCA daily to improve Obeya Operations Plant Operations Manger Discussing Hourly Production Status Update by Group Leader with Value Stream Managers at Obeya Production Status Board Single Minute Breakdown Response Team PDCA’s Red Zone response performance Obeya Team prepares to Go to the Gemba for Red Zone Condition Obeya Just in Time and Jidoka “I think the ideal situation of the Obeya should be the full integration of People and Data which mimics the process. Utilizing the latest technology of human interface communication to promote ‘Just in Time’ in human processed information with Jidoka considerations.” Casey Ng Retired General Manager Toyota Motor Manufacturing Australia