Stretching Rubber Bands

advertisement

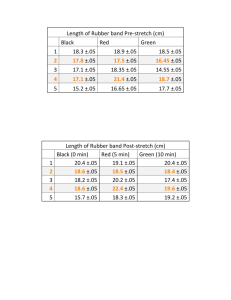

Stretching Rubber Bands Understanding Hooke's Law Experimental Write-up Introduction The reason that we can see rubber bands stretch when we pull on them, but pulling as hard as you can on your table will probably have no effect, is due to is a constant called Young's Modulus, or simply 'Y.' Every solid has it's own unique Y, and the Y tells us how 'stretchable' the solid actually is. Here is the formula for Young's modulus: / ∆ / F = Force applied to solid [N] A = Cross-sectional area of solid [m2] L = stretched length of solid [m] Lo = original length of solid [m] A simple way to understand this formula is to think: Y = stress/strain. The stress is the amount of force applied to the object, per unit area. The strain is the change in the length of the solid. Therefore, a solid with a greater value of Y will stretch less than a solid with a smaller Y, when the same force is applied. Rubber bands are elastic solids; they are interesting because they are thought to follow a simplified version of Young’s modulus. Hooke's Law (below) is classically applied to spring systems. However, it can also, to some extent, describe the stretch patterns observed for rubber bands. F = k ΔL F = Force applied to elastic material [N] k = spring constant [N/m] ΔL = change in length of the elastic material [m] Methods This experiment investigated the stretching of rubber bands in an attempt to determine the conditions under which Hooke’s Law applies their action. The first step was to select three rubber bands of differing lengths and widths. Table 1. Characteristic of elastic bands used for measurement of stretch due to an applied force. Band Length (cm) Height (mm) Width (mm) 1 7.9 ± 0.1 1.0 ± 0.1 1.0 ± 0.1 2 9.2 ± 0.1 1.8 ± 0.1 1.0 ± 0.1 3 9.4 ± 0.1 6.2 ± 0.1 0.8 ± 0.1 Several household items of known weights were chosen, and these items were attached to the end of each rubber band by a small hook. In this way, the applied force was due to the weight of these items, so Fapplied = mg. Several data points were collected for items of different weights, and the results were used to graphically determine the spring constant for each rubber band, k. Items of differing mass were selected and the stretch of the rubber band due to each item was measured and recorded. In some cases, two items were attached to the band to give a desired weight. The value of weight for each item was verified with a kitchen scale, and the difference between the kitchen scale reading on the given mass on the package is presented as the error of the mass. Table 2. Household objects and their masses. These were used to generate applied force due to gravity. Item Description Mass (g) Error (g) Quaker Fibre and Omega‐3 Granola bar 35 ± 1 Cliff bar – Black Cheery Almond 68 ± 2 Quaker bar + Cliff Bar 103 ± 3 Quaker rice cakes 140 ± 7 Cliff bar + Rice cakes 208 ± 9 Western Family Egg Noodles 375 ± 6 Organic Brown Rice Fusilli pasta 454 ± 2 Results and Discussion For each rubber band listed in Table 2, the change in length was recorded using each household item, or combination of items (Table 1), to provide the applied force due to gravity. A graph of change in length (ΔL) against applied force was attained for each rubber band. For all three rubber bands, a linear relationship was obtained for relatively small applied forces (first three or four data points), and a second graph was generated from these points. The slope of the line of best fit for this second graph was determined. (You don’t need a computer for this. A manual plot will also give you a reasonable estimate.) This slope corresponded to an estimate of the spring constant, k, for each rubber band, determined from the algebraic transformation of Hooke’s Law, as shown below. Note that the negative sign has been omitted for simplicity. ∙∆ Since the applied force is due to the weight of the objects hanging from the rubber bands, we can write: ∆ Band 1 was the skinniest and shortest of the three. For this reason, it was predicted to have a relatively small spring constant, as its smaller width was predicted to yield a greater stretch for a given weight. Band1‐ Alldata Band1‐ LinearRegion 5.00 1.20 4.50 1.00 4.00 0.80 3.00 Force(N) Force(N) 3.50 2.50 2.00 1.50 1.00 0.60 0.40 0.20 0.50 0.00 0.00 y=34.838x+0.2549 R²=0.9945 0.10 0.20 ΔL(m) 0.30 0.00 0.00 0.01 0.01 0.02 ΔL(m) 0.02 0.03 Figure 1. Measurement of change in length (ΔL) for Band #1. For the graph on the right, the slope is equal to the spring constant of the elastic band, so k1 = 38.8 N/m. The graph of all measurements, on the left (Figure 1), indicates that the first three data points demonstrated a linear relationship. These points were assumed to correspond to the application of Hooke’s law at the given applied force. The slope of the line of best fit for these three points was determined in the graph on the right, and it was found to be 38.8 N/m. Band 2 had a larger cross-sectional area than Band 1; therefore, it was predicted to display a slightly greater spring constant than Band 1. Surprisingly, the change in length for Band 2 was greater than most to of the ΔL values for Band 1. Again, the first three data points demonstrated a strong linear relationship, and the slope of these points was determined to be 30.7 N/m. 5.00 4.50 4.00 3.50 3.00 2.50 2.00 1.50 1.00 0.50 0.00 0.00 Band2‐ LinearRegion 1.20 1.00 Force(N) Force(N) Band2‐ Alldata y=30.7x+0.1715 R²=0.9703 0.80 0.60 0.40 0.20 0.10 0.20 ΔL(m) 0.00 0.00 0.30 0.01 0.02 0.03 ΔL(m) Figure 2. Measurement of change in length (ΔL) for Band #2. The slope of the graph on the right is equal to the spring constant, k2, of the rubber band, which is 30.7 N/m. Band 3 was the largest in cross-sectional area, and also the shortest in length. It’s spring constant was hypothesized to be much greater than that of the first two band, and the results Figure 3 correspond to this prediction; the slope was determined to be 81.4 N/m. Interestingly, the first four points demonstrated a linear relationship, unlike the results for Band 1 and Band 2, where only the first three points were used to determine the spring constant. It seems that, for rubber bands of larger crosssectional area, Hooke’s Law holds over a greater range of applied force. 10.00 9.00 8.00 7.00 6.00 5.00 4.00 3.00 2.00 1.00 0.00 0.00 Band3‐ LinearRegion 1.60 1.40 y=81.394x+0.1762 R²=0.9764 1.20 Force(N) Force(N) Band3‐ Alldata 1.00 0.80 0.60 0.40 0.20 0.10 0.20 ΔL(m) 0.30 0.00 0.00 0.01 0.01 ΔL(m) 0.02 0.02 Figure 3. Change in length (ΔL) for Band #3. The slope of the right‐side graph, k, is equal to the spring constant, so k3 = 81.4 N/m. The results for all three rubber bands indicate that Hooke’s Law only holds for small applied forces, or small weights. Once the applied force was increased to a certain point, the stretch that would be predicted by Hooke’s Law greatly exceed the observed stretch, and slope of the graph decreased. Interestingly, a linear relationship does seem to exist for these larger applied forces, but this would have to be verified with further experimentation. The reason for rubber band deviation from Hooke’s Law at greater applied forces could be due to the deformation of rubber band structure. Hooke’s law is intended to describe the action of a spring, and a rubber band does not seem to exhibit the same recoil properties as springs. This may occur because the structure of a rubber band at the molecular level is not maintained when the band is exposed to a large applied force. This likely affects the way in which the band stretches, causing it to deviate from the pattern predicted by Hooke’s Law. Several sources of error could have affected the results of this experiment. Firstly, a ruler was used to determine stretch, and this method of measurement is not incredibly accurate. In addition, the same rubber band was used for all weights tested, and the band may have been deformed from earlier stretching, especially for later measurements of greater applied force. This would have been most of a concern for the thinner rubber bands. Finally, choosing several data points from which to determine the spring constant may not have exactly correlated to Hooke’s Law, and a point at which Hooke’s Law actually applied may not have been taken into consideration. This could explain why a smaller spring constant was calculated for Band 2, when a larger value of k was expected due to its cross-sectional area. It is also possible that Band 2 was older than the other band or was made of a slightly different rubber. Conclusion The stretching action of rubber bands follows Hooke’s Law, F=k x, for small applied forces. The limit of force for which the rubber band follows Hooke’s law depends on the physical properties of the band, such as cross-sectional area. Rubber bands of larger cross sectional area, with larger values of k, follow Hooke’s Law for a greater applied forces than do bands of smaller cross-sectional area. For more details and an interesting discussion see: http://www.wired.com/wiredscience/2012/08/do-rubber-bands-act-like-springs/