IPL Integrated Porosity Lithology

advertisement

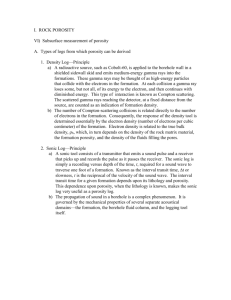

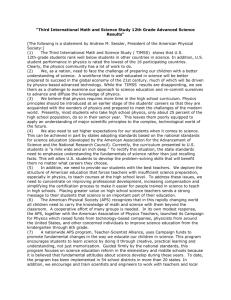

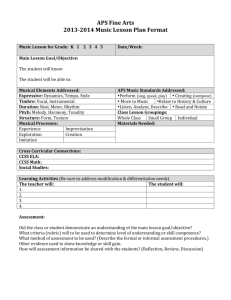

Porosity and Lithology in Complex Environments Integrated evaluation for more accurate answers Applications ■ Formation evaluation in complex environments, such as shaly sands, mixed-lithology carbonates, high-salinity fluids and micaceous sands ■ Stand-alone gas identification ■ Porosity measurement ■ Lithology identification ■ Thin-bed analysis Benefits ■ Improved gas detection in shaly reservoirs ■ Improved reserve estimates ■ Identification of thin pay-zones ■ Efficient wellsite operation saves rig time ■ Reduced radiation hazard with sourceless porosity measurement Features ■ Combinability with ECS* Elemental Capture Spectroscopy sonde to provide robust petrophysical properties ■ High-yield pulsed-neutron generation ■ Thermal neutron and epithermal neutron porosity measurements ■ Real-time correction to reduce environmental effects ■ Improved vertical resolution ■ Sigma measurement ■ High-efficiency gamma ray detectors ■ Enhanced data validation and quality control ■ Modular tool design Simplified porosity and lithology evaluation in difficult reservoirs The IPL* Integrated Porosity Lithology system provides accurate formation porosity and lithology information, even in reservoirs that are difficult to evaluate with standard tools. This system acquires new-generation neutron porosity, natural gamma ray spectrometry, density and photoelectric effect measurements using one modular tool. Neutron porosity measurement The APS* Accelerator Porosity Sonde, which uses an electronic neutron source instead of a chemical source, is the heart of the IPL system. Because the neutron source has a large yield, it allows the use of epithermal neutron detection and borehole shielding to obtain porosity measurements that are affected only minimally by the borehole environment and formation characteristics, such as lithology and salinity. Five detectors provide information for porosity evaluation, gas detection, shale evaluation, verticalresolution improvement and borehole corrections. measurement stability. This sonde records the full pulse-height spectra from both detectors and processes information into windows. Bulk density and photoelectric effect (Pe) information are derived conventionally. The spectral information available is used for improved log and calibration quality control. Full modularity The control electronics for the IPL system sensor array are compact, yet fully modular. They allow the tool to be run as a stand-alone platform or the individual sensors to be run in combination with other Schlumberger platforms and tools. Solutions for tough problems The IPL system and tool combinations provide interpretation solutions in many conditions that are difficult to evaluate with traditional wireline measurements, such as thin beds, shaly sands, mixed-lithology carbonates, high-salinity fluids, micaceous sands and rough or difficult hole conditions. Thin beds Natural gamma ray measurement The HNGS Hostile-Environment Natural Gamma Ray Sonde incorporates technology that enhances answer quality. Increased detection efficiency with spectral processing significantly improves measurement precision and reduces environmental corrections. Sensitivity to the barite content of mud is eliminated by using only the high-energy gamma rays for analysis. The MAXIS* Multitask Acquisition and Imaging System corrects for borehole size and the borehole potassium contribution—in real time. The APS porosity measurement’s improved vertical resolution and lower sensitivity to clay make identification and evaluation of thin beds much easier. The thermal neutron formation capture cross section (sigma) measurement can be used to greatly improve the vertical resolution of the shale evaluation usually obtained from gamma ray information. When the APS sonde is run with the AIT* Array Induction Imager Tool or ARI* Azimuthal Resistivity Imager, the combination provides a vertical resolution of about 1 ft. Shaly sands Density and photoelectric effect measurements The Litho-Density* sonde has a pad with a gamma ray source and two detectors. Magnetic shielding and highspeed electronics ensure excellent Because clay has little effect on the APS neutron-porosity measurement, the gas effect in shaly sands is more visible. This reduces the chance of missing a pay zone. Mixed-lithology carbonates Micaceous sands The degree of dolomitization in a formation has little influence on the APS carbonate porosity response. As a result, the APS neutron porosity measurement in carbonates with unknown or variable dolomitization is the closest to true formation porosity. The high-quality HNGS measurements of natural radioactivity, together with the APS formation sigma, improve evaluation of micaceous sands. IPL tool string. Rough hole conditions Using the APS epithermal array detectors to correct for tool standoff improves results in rugose hole sections. High-salinity fluids APS epithermal neutron detection and borehole shielding minimize the effects of formation and borehole fluids that have high salinities. When conventional neutron porosity tools are used, these effects are much greater and are dependent on lithology, invasion characteristics and hydrocarbon saturation. HNGS sonde Thorium, uranium and potassium concentrations Difficult hole conditions Since its neutron porosity measurements do not require a radioactive source, the APS sonde can be used in wells with difficult borehole conditions where tool sticking might be a problem. APS sonde Epithermal neutron porosities IPL Hardware Specifications Hardware HNGS sonde APS sonde IPL cartridge Litho-Density sonde Length (ft) 8.5 13 8 11 Weight (lbm) Diameter (in.) Temperature (°F) Pressure (psi) 203 222 128 292 3 3⁄4 500 350 350 350 25,000 20,000 20,000 20,000 3 5⁄ 8 3 3⁄ 8 4 7⁄16 Epithermal neutron slowing time Invaded formation sigma Detector standoff IPL Logging Specifications Logging Mode Sampling Rate (in.) Logging Speed (ft/hr) Standard High speed High resolution Density Neutron porosity Natural gamma ray spectroscopy 6 6 1800 3600 1 2 6 900 IPL cartridge Raw data spectral and time distribution transmitted to surface Improved log quality control IPL General Specifications Specifications† APS measurement Near-to-array epithermal porosity Litho-Density measurements Bulk density Photoelectric factor HNGS measurements Thorium Uranium Potassium †8-in. Range Accuracy 0–7 p.u. 7–30 p.u. 30–60 p.u. ±0.5 p.u. ±7% ±10% 2.0–3.0 1–6 g/cm3 borehole filled with fresh water, with no tool standoff, at standard pressure and temperature conditions Litho-Density sonde ±0.01 g/cm3 Compensated bulk density ±10% Photoelectric factor ±2% ±2% ±5% Borehole diameter Quicklook lithology evaluation In the lower shale section (A), the APS porosity and bulk density curves display shale separation in a conventional manner, although the separation is less than half that of CNL* Compensated Neutron Log porosity and bulk density curves. The ability of the APS sonde to measure total formation hydrogen index greatly simplified this quicklook lithology evaluation in a 12-in. borehole, which had been drilled through a shaly sand formation using 11.1-lbm/gal mud weighted with small amounts of barite. Above X240 ft, the cuttings analysis describes the formation as sandstone with a varying amount of shaliness. Both gamma ray and Pe measurements show this potential bed as shaly, yet the IPL neutron-density separation is larger than the separation in the lower, cleaner sands, indicating a gas effect. This quicklook lithology evaluation demonstrates the ability of the IPL tool combination to improve lithology and porosity evaluation and gas detection in shaly sands. X150 X200 X250 (A) X300 10 Caliper (in.) 1:240 ft APS Array Porosity 20 45 (p.u.) –15 15 45 CNL Thermal Neutron Porosity (p.u.) –15 Total Formation Gamma Ray 0 (GAPI) Bulk Density Standoff –1 (in.) 9 (g/cm3) 1.95 Photoelectric Factor 0 (in.) 2.95 Density Correction 10 – 0.25 Gas (g/cm3) 0.25 Gas detection in thin, shaly sands sand more clearly than either the gamma ray or spontaneous potential measurements do. The density measurement, together with the APS neutron porosity profile, which is sensitive only to variations in formation hydrogen index, pinpoints tight In this thinly bedded, shaly sandstone, the AIT and IPL combination detected several gas zones that conventional logging technology would have missed. The formation sigma measurement defines the overall extent of the shaly streaks and a 2-ft gas zone. The AIT 1-ft-resolution resistivity measurement also shows this zone. Formation matrix density variations make the CNL porosity profile comparatively insensitive to the presence of gas in the formation. A plug-and-abandon permit was issued after this shale and shaly sand interval was logged with DIL* Dual Induction Resistivity Log, Litho-Density and CNL tools. A subsequent evaluation of the same interval with an AIT and IPL combination pinpointed five gas-bearing intervals that had been overlooked. This was confirmed by formation test samples, and the well was completed. It is expected to provide a 10-fold return on investment. X880 Producing gas at 1.6 MMcf/D X900 Caliper (in.) 6 AIT 90-in. Resistivity 16 0.2 Uranium-Free Gamma Ray 0 (GAPI) (mV) 150 0.2 20 1.65 (c.u) (ohm-m) 20 Bulk Density Sigma 0 20 DIL Deep Resistivity Spontaneous Potential –80 (ohm-m) (g/cm3) 2.65 CNL Thermal Neutron Porosity 40 60 (p.u) 0 APS Array Porosity 60 (p.u) 0 Gas detection without a chemical source The APS sonde uses an electronic source, not a chemical one, so the APS neutron-sonic combination is useful for gas detection in problem holes. In this shaly sand example, overlaying the epithermal neutron and sonic curves reveals a crossover profile in the gas zones. Both the APS neutron-density and APS neutron-sonic logs identified all the gas zones in this interval. The lack of gamma ray contrast, shown in the depth track, indicates very shaly sands. X650 X700 X750 X800 X850 Bulk Density 1:240 ft Rxo, Invaded Zone Resistivity 1.7 (g/cm ) 60 APS Array Porosity (p.u.) 2.7 Formation 0.2 Gamma Ray 0 0.2 0 150 (GAPI) Rt, Formation Resistivity (ohm-m) 3 Gas (ohm-m) Compressional ∆t 20 220 (µs/ft) 70 20 60 APS Array Porosity (p.u.) 0 Gas www.connect.slb.com SMP-5167 ©Schlumberger August 2002 *Mark of Schlumberger