Preliminary Economic Assessment (March 2014)

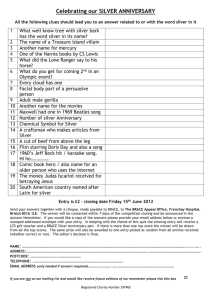

advertisement