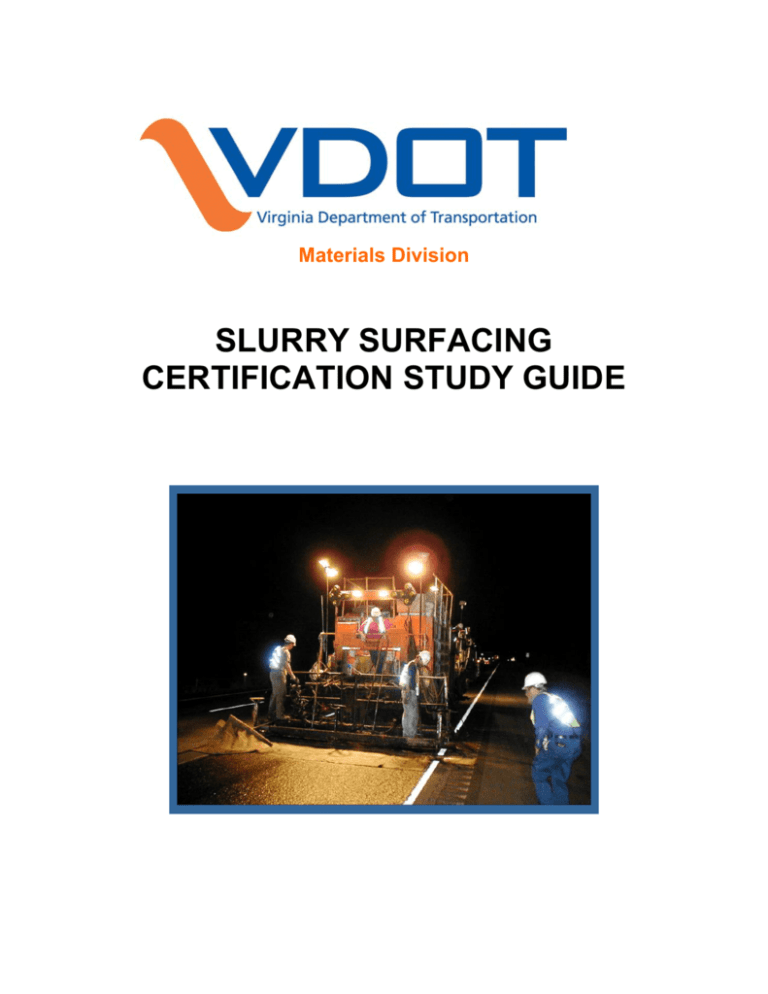

SLURRY SURFACING CERTIFICATION STUDY GUIDE

advertisement