Green Adsorbents for Wastewaters: A Critical Review

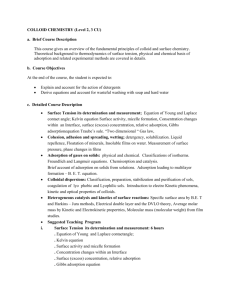

advertisement