Manufacturing of CDs and DVDs Christie Nickson

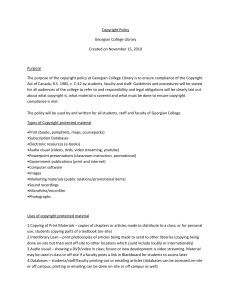

advertisement

Manufacturing of CDs and DVDs Christie Nickson Introduction z Compact Discs y Digital technology y Excellent sound quality y 650 MB storage z DVD y Excellent sound and video quality y More storage, 4.7-17 GB z Manufacturing Process z z z z z Premastering Mastering Plating/Electroforming Injection Molding Metallization/Spin Coating z Lacquering z Screen Printing/Packaging Premastering z Information inspected and prepared for CD or DVD. z Audio premastering y PQ Encoding y Digital Audio Editing z DVD premastering y Authoring Mastering z Transfer data onto glass master by laser beam. z Laser creates pits on a film on the glass. z 2 techniques y Photo Resist y Dye-Polymer Photo Resist z Thin layer (0.12 micrometer) of photo resist spin coated on highly polished glass surface. z Laser beam recorder exposes areas on the photo resist layer. Photo Resist z Photo resist chemically developed to create pits in exposed areas. z Developed photo resist vacuum coated with thin layer of nickel or nickel alloy. Dye-Polymer Process z Dry process - no chemical developing. z Dye material used on glass that vaporizes when heat of recording laser is absorbed creating the pits. z Advantage is another laser can check pit size and depth during recording and errors found immediately. Plating/Electroforming z Negative copy of master is made out of metal. z Glass master placed in tank of nickel plating solution. z 0.3-0.4 mm thick layer of metal forms on master. z Plating/Electroforming z Metal and master are separated creating negative copy (father). z Father is then used to create metal copy of master (mother) by same method. z Mother is then used to create many metal stampers. z Each stamper can be used to produce several thousand discs. Injection Molding z Stamper is installed in plastic injection molding machine. z Polycarbonate resin is injected into mold under pressure. z Resin cools, solidifies and is removed from mold. Metallization/Spin Coating z Discs are transparent after molding. z A thin layer of aluminum is applied by vacuum deposition. z Metallization is necessary to get a mirror surface which will reflect laser light and read pits. Lacquering z A layer of lacquer is applied by spin coating. z Lacquer protects aluminum from oxidizing, which would make the disk unreadable. z Lacquer is cured by ultra-violet light. Screen Printing & Packaging z Upper surface can be printed with up to 5 colors. z Flat silk screen process used and ink is cured with UV light. z Disks are packaged for protection and marketing and shipped to customer. Quality z Mastering y Disc master/stamper player y Pit geometry checked with high power microscope y PQ testing Quality - Replication z Samples from each run tested. z Physical dimensions: y thickness y center hole diameter z Analysis of electrical signals. z Mechanical tests. QA Tests & Signals z Samples from each press for each run tested y y y y y Reflectivity Asymmetry Push Pull Cross Talk Birefringence Mechanical Tests z Mechanical tests that are run with the signal tests include: y y y y Radial noise Eccentricity Track pitch Scan velocity DVD Manufacturing z DVDs are more difficult to manufacture y Shallower pits and smaller pit size y Smaller track pitch y Tighter tolerances Pit Sizes on a CD DVD Bonding z DVDs consist of 2 substrates bonded together. z 3 processes can be used for bonding: y Hot melt bonding y Radical UV cured bonding y Cationic UV bonding CD & DVD Formats z CD z DVDs y y y y 650 MB Single layer, single sided 4.7 GB Single layer, double sided 9.4 GB Dual layer, single sided 8.5 GB Dual layer, double sided 17.0 GB DVD Formats z Single layer, single sided DVDs - active substrate is metallized and bonded to blank substrate. DVD Formats z Single layer, double sided DVDs - both substrates are metallized and bonded together. DVD Formats z Dual layer, single sided DVDs - one substrate has 2 metallization layers. DVD Formats z Dual layer, double sided DVDs - both substrates have 2 metallization layers. Future z New technologies like blue lasers will increase capacities. z By 2005, it is predicted DVDs will have capacities of 50 GB per side.