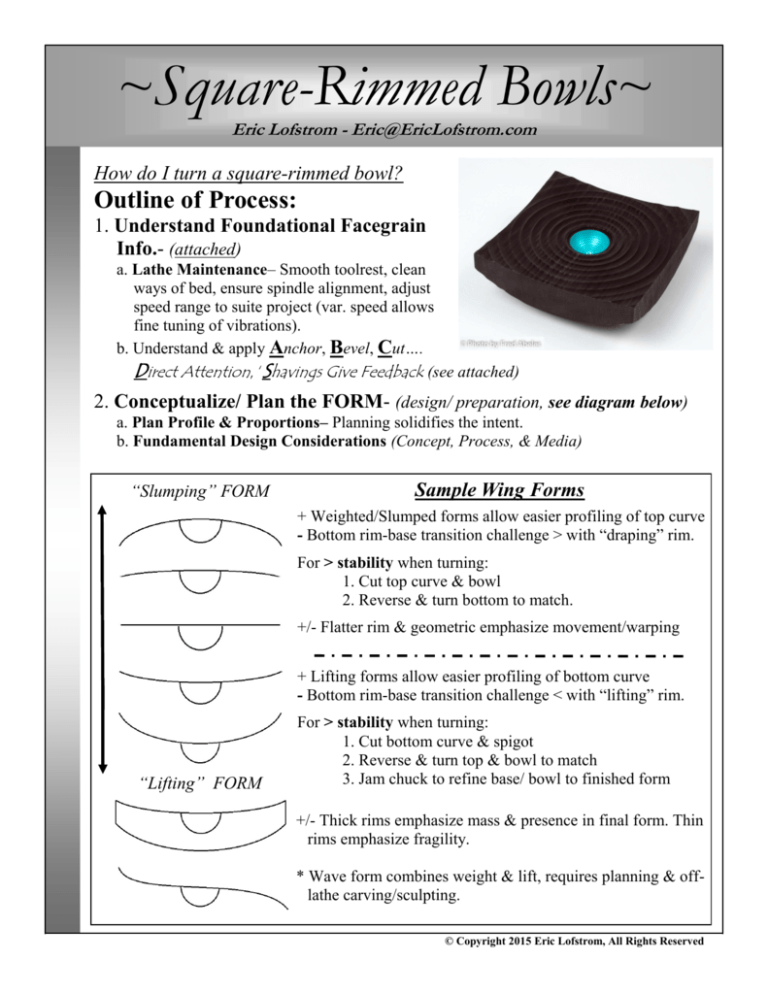

~Square-Rimmed Bowls~

Eric Lofstrom - Eric@EricLofstrom.com

How do I turn a square-rimmed bowl?

Outline of Process:

1. Understand Foundational Facegrain

Info.- (attached)

a. Lathe Maintenance– Smooth toolrest, clean

ways of bed, ensure spindle alignment, adjust

speed range to suite project (var. speed allows

fine tuning of vibrations).

b. Understand & apply Anchor, Bevel, Cut….

Direct Attention, ‘Shavings Give Feedback (see attached)

2. Conceptualize/ Plan the FORM- (design/ preparation, see diagram below)

a. Plan Profile & Proportions– Planning solidifies the intent.

b. Fundamental Design Considerations (Concept, Process, & Media)

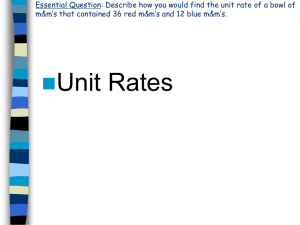

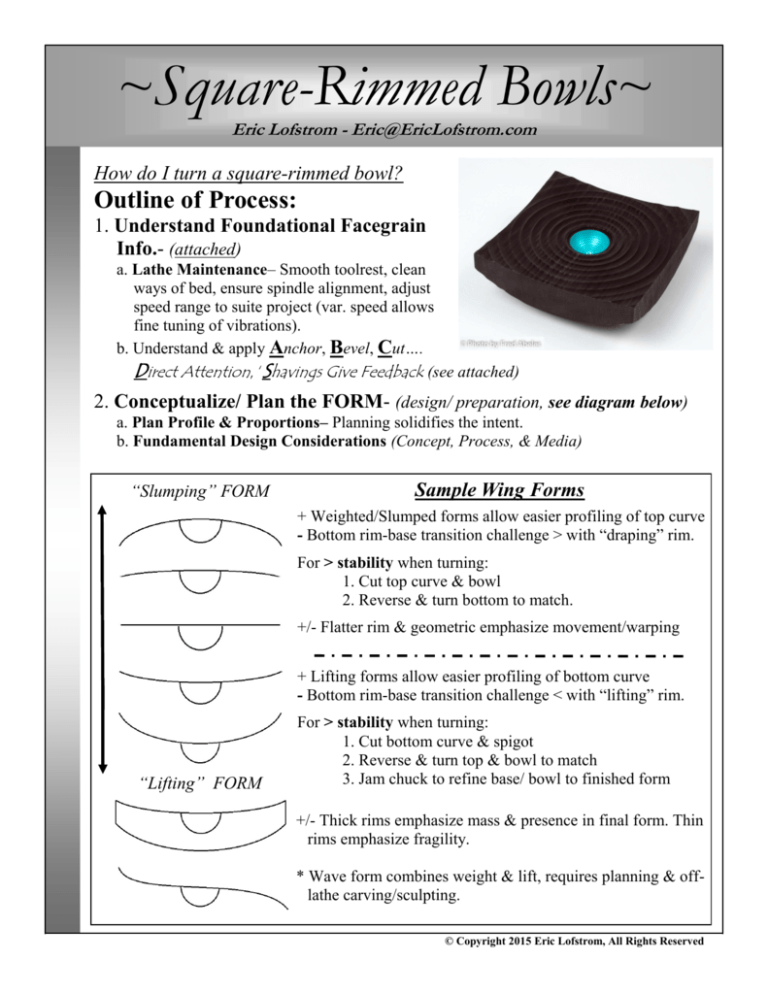

“Slumping” FORM

Sample Wing Forms

+ Weighted/Slumped forms allow easier profiling of top curve

- Bottom rim-base transition challenge > with “draping” rim.

For > stability when turning:

1. Cut top curve & bowl

2. Reverse & turn bottom to match.

+/- Flatter rim & geometric emphasize movement/warping

+ Lifting forms allow easier profiling of bottom curve

- Bottom rim-base transition challenge < with “lifting” rim.

“Lifting” FORM

For > stability when turning:

1. Cut bottom curve & spigot

2. Reverse & turn top & bowl to match

3. Jam chuck to refine base/ bowl to finished form

+/- Thick rims emphasize mass & presence in final form. Thin

rims emphasize fragility.

* Wave form combines weight & lift, requires planning & offlathe carving/sculpting.

© Copyright 2015 Eric Lofstrom, All Rights Reserved

~Square-Rimmed Bowls~

Eric Lofstrom - Eric@EricLofstrom.com

3. Rough the Exterior Profile/ Underside of

Rim/ Wing- (screw chuck/ between centers allows

for max. degree of adjustments)

uppor

t

ed fib

ers

Mark Center

Cut s

a. Initial Roughing– May be done with the bandsaw,

especially if the blank needs balancing of mass/wt.

b. Rough Shape– Fingernail Grind Bowl Gouge (see attached) is the most versatile cutting tool for this job. If

turning a thin, weighted/ slumped –wing, leave the

wing nearest the bowl thick, to allow support during

refining/ finish cuts for the top surface of the wing.

c. Refine Underside of Rim/ Wing– Shear-cut the surface w/ bowl gouge wing, then shear scrape to refine

surface.

d. Turn Spigot & Base (see diagram below)- Profile/

dia. shape to match jaw profile & register on jaw face.

The holding integrity of chuck relies completely on spigot-jaw dia. & profile match.

4. Hollow the Interior- (chuck/ faceplate mounted)

1

s

ep 3

St 2

rs

d fibe

pporte

Cut su

a. Cut the Rim/ Wing– Take rim/ wing to finish thickness

using sweeping cuts.

b. Use a Step Technique (see diagram)– Cut the interior

bowl in steps. Stop to check the profile & wall thickness frequently. BLEND EA. SECTION W/ THE PREVIOUS– AS

YOU PROGRESS.

c. Finish Bowl Interior– Use a bowl gouge w/ appropriate

bevel angle to allow bevel support throughout the cut & use

a negative rake scraper to refine the interior curve. Rehearse

cuts before applying.

d. Measure & Note the Finished Bowl Depth– Mark on

exterior of blank for reference during reverse turning (Step5)

e. Refine Top Rim/ Wing Surface– Use a shearing cut,

shear scraping & sanding. Finish to desired refinement.

© Copyright 2015 Eric Lofstrom, All Rights Reserved

~Square-Rimmed Bowls~

Eric Lofstrom - Eric@EricLofstrom.com

5. Refine the Exterior/ Underside & Foot-

ot

Remove spig

Jam / Vacuum Chuck

(reversed, jam / vacuum chuck)

a. Reverse Turn– Using a jam / vacuum chuck, align using center mark from roughing between centers.

b. Refine the Curve- Shear cut/ scrape to follow exterior

curve THROUGH the spigot.

c. For Complete Access to Base- Use a vacuum chuck,

friction-drive jam chuck, Longworth, or Cole jaws for

complete access to underside without the need for tailstock during final blending of curve. If turning a thick

wing, the complete underside can be re-turned with

choice of effect. If turning thin, consider the fragility &

how this will effect the finish turning process!

c. Complete/ Refine Bottom Profile with shear scraping

& sanding. Finish to desired refinement.

6. Finish/ Embellish as Desired- (according to personal taste, wood, & intent)

A Few Favorite Embellishments for Square & Flat Rims

Crisp coves, echoing as ripples.

Pyrography/ carved quilt pattern.

When embellishing, explore

a concept & have FUN!

Thin rim, geom. pierced & heat-warped.

© Copyright 2015 Eric Lofstrom, All Rights Reserved

~Foundational Facegrain Info.~

Eric Lofstrom - Eric@EricLofstrom.com

ABC...D’S of Controlling the Cut:

A = Anchor tool on toolrest.

B = Bevel glides across wood, directing tool.

C = Cut supported fibers when possible.

D = Direct attention ahead of the cut.

‘S = Shavings are feedback on quality of cut.

3+ Anchor Points = Stability

Cutting vs. Scraping:

Cutting = Bevel glides across wood.

Scraping = NO bevel/ relief contact;

drawing the burr/ edge across the wood.

Shearing = edge angle approaches parallel to surface movement of wood, decreases resistance to the cut.

Using a Shearing angle will result in the

Three points of contact (tripod) yields control cleanest cut/ scraped fibers.

& stability; 1)toolrest, 2)body, & 3)bevel.

Cut when you can cut & scrape when you

Maintain bevel contact by steering the bevel are unable to maintain bevel contact, or to

where you want the tool to travel.

refine the curve.

Use the tool as an extension of your body.

Grain Orientation Matters!

rs

p

sup

or

e

fib

ted

su

pp

or

ted

fib

e

rs

Fundamentally, wood is a bundle of straws; which flex & tear if there

is no support behind them, resulting in torn grain (a.k.a. “tear-out”).

Cutting “supported fibers” gives a cleaner surface & less sanding.

Face Grain Turning = fibers lay perpendicular to axis of rotation

Direction of cuts:

OUTSIDE of bowl (convex curve) = cut SMALL dia. to LARGE

INSIDE of bowl (concave curve) = cut LARGE dia. to SMALL

When turning THIN- Cut in STEPS from rim to center–

ONCE YOU GO THIN, DON’T GO BACK!

My Basic Bowl Turning Tools:

Negative Rake Scraper– Top

Fingernail Bowl Gouge– Side

<9

0ͦ

~55ͦ

- used to remove nearly all wood inside

& out, shear cut & shear scrape exterior.

Profile– Side

~70ͦ

- used to refine

interior form of

bowls, scrape

broad coves &

blend multifaceted concave

surfaces.

© Copyright 2015 Eric Lofstrom, All Rights Reserved