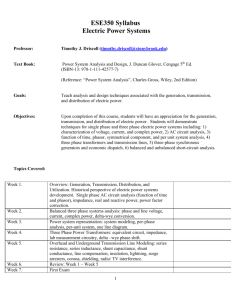

Evaluation of Run Length and Available Current on Breaker Ability

advertisement