The Evolution of GAP standards in the global poultry sector Ed Dean

advertisement

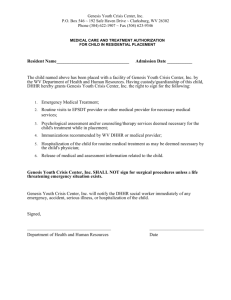

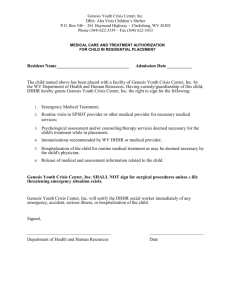

AVI AFRICA 2015 The Evolution of GAP standards in the global poultry sector Ed Dean Genesis Standards (UK) Content 1. Background of Farm Assurance 2. Drivers for Assurance 3. Confidence in the industry 4. What is Genesis GAP? 5. Whole Chain 6. Genesis GAP Poultry 7. Genesis GAP Standards 8. Analysis & Development 9. NSF 10.The Audit 11.Top Non-compliances Back Ground of Farm Assurance in the UK History & Benefits. • In the 1990’s Confidence in British farming was at a low due to a number of high profile food scares which damaged customer confidence. • To improve customer confidence a number of assurance schemes were introduced mainly by retailers which set and monitored the compliance of responsible production standards for farmers and producers. • Todays recognized schemes have reduced the number of retail driven audits plus some Government inspections are now linked to farm assessments due to “Earned Recognition”. • Standardization is achieved by following assured schemes which has benefits to the business by enabling all levels of management and staff to follow set procedures and documentation. Market and Customer Drivers for Assurance Summary of major customer requirements • • • • • • • • Legislation. Welfare. Product quality. Traceability. Unique Selling Point. Marketing tool – Logo. Customer Confidence. Food Safety. How inspections and certification has improved consumer confidence in the industry. • • • • BEIC – Salmonella Traceability – full supply chain Welfare – Stocking rates, staff training, leg strength, growth rates Food safety What is Genesis GAP The set of standards are based on: • Good Agricultural Practice • Animal Welfare • Environment • Traceability • Food Safety • Covers legislation • Bio-security • Training • Sustainability Whole Chain Genesis GAP covers the whole of the poultry chain: • Breeding Farms (Rearing and Layers) • Hatcheries • Broiler Sites • Catching • Transport • Slaughter • Product Trace Genesis GAP Poultry Genesis GAP is UKAS accredited to EN45011/ISO17065 and is accepted by major European retailers and food service companies. All of the Thailand members export their product into Europe and other parts of the world. 600 Chicken members. 35 Duck members. Active Genesis GAP Standards • Chicken GAP Production – NSF Certification accredited • Duck GAP Production – NSF Certification accredited • Pig GAP Production – NSF Certification accredited • Beef & Sheep GAP Production Ready • Combinable Crop GAP Production • Wholesale storage and distribution • Hazardous Materials Security • Bovine Milk Production • Deer, Goat and Camelid Production Development • Egg Production • Livestock transport • Livestock markets • Entry Level for the GAP standards Analysis For performance improvement: • Pre-certification audit packages • Benchmarking audit results • Positive compliance risk rating Genesis GAP Development Website www.genesisstandards.com Member Checker NSF Genesis GAP standard is an independently run subsidiary of NSF who have audited, certified & administered the UK Red Tractor scheme since its inception in 1988. NSF also operates the Lion Code scheme on the behalf of the British Egg Industry Council, BEIC, and is the UK government Department of Environment, Food and Rural Affairs’ salmonella control body, authorised to take litter samples to validate the salmonella-free nature of UK produced eggs. The Audit On Farm Preparation Auditor will want to see: • The birds • Buildings and equipment • Feed and water systems and back up • Ventilation and alarms and back up • Bio-security, site security • Staff facilities On Farm Preparation • Medicines usage & storage • Feed storage • Poultry loading & handling • Dead storage • Waste storage • Chemical and Fuel stores Office Preparation Paperwork needed: • Standards • Site plan • Internal audit • Visitors book • Movement records, traceability • Vet plan and visit • Production records • Training records Office Preparation • Medicine, vaccination records • Feed records • WTN • Complaints record • Policies • Manure Management plan • Pest control records • Alarm records • Emergency action plan • Data sheets Top Non-compliances NSF Chicken members Oct 2013 – Oct 2014. 1.Approved Training ( Poultry Training Record PTR) (PO6.5)15.8% Top Non-compliances 2. Barrier system (PO5.5) 9.2% Top Non-compliances 3. Maintenance (AL4.1) 9% Top Non-compliances 4.Pest Control. (AF1.6) 6% Top Non-compliances Top Non-compliances 5. Pesticide Spray Training (AF3.12) 4.5% Top Non-compliances 6.House keeping. Long vegetation and or accumulated debris that could provide cover for vermin (AF1.5) 3.8% Genesis GAP See us on the NSF International stand 149 Any Questions? Thank you for listening