3 Budgeting for a Competitive Advantage!

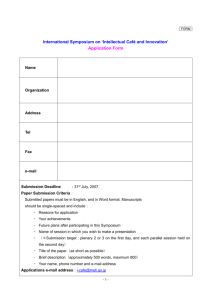

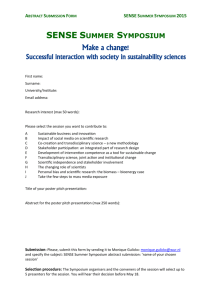

advertisement

Budgeting for a Competitive Advantage! Schalk van Wyk SACEA Technical Symposium 2007 Topics of Discussion n n n n n n n Introduction Objective of this presentation Investigating different approaches Integrating these approaches into a model Applying the integrated model Linking competitive advantage with maintenance budgeting Conclusion 2 SACEA Technical Symposium 2007 Introduction n n n n n n n n Adapting to change fast! Globalisation of SA economy Mechanisation – 2/3 of budget! Never cancel – optimise maintenance costs! Budgeting process is tedious! “Gaming”, company politics, “horse-trading” “Fat cutting”, “gut feeling”, “thumb sucking” Severe oversights and “surprises” 3 SACEA Technical Symposium 2007 Objective of this presentation “What can be done to change the perceived status of the maintenance budget from something based on a “thumb suck” to something more scientific, and which is aligned with market reality giving the business a competitive advantage?” n n n n Providing a theoretical model Compiling a realistic maintenance budget Aligned with current market reality Competitive advantage 4 SACEA Technical Symposium 2007 Investigating different approaches n n n n n n n Traditional budgeting Activity-based budgeting Zero-base budgeting Quality function deployment Target budgeting Life-cycle costing Rolling budgeting 5 SACEA Technical Symposium 2007 Integrating these approaches into a model Software interface Software interface Software interface Software interface 6 SACEA Technical Symposium 2007 Applying the integrated model n STEP 1: u n STEP 2: u n Develop a maintenance strategy STEP 3: u n Set goals and objectives Prepare a cost breakdown structure STEP 4: u Develop expected component lives 7 SACEA Technical Symposium 2007 Applying the integrated model (continued) n STEP 5: u n STEP 6: u n Schedule future repairs/replacements STEP 7: u n Establish the starting point for the scheduler Have maintenance budget approved STEP 8: u Continuous updating of maintenance budget SACEA Technical Symposium 2007 8 Linking competitive advantage with maintenance budgeting n n n n n Engineering decisions are cost benefit or ROI decisions Decisions normally based on component life cycles – long-term impacts Skillfully smooth-out peaks and valleys Asset management – lowest combined cost Market changes to consider: Exchange rate u Inflation rates u Steel pricing, etc. u n Real-time budgeting/forecasting 9 SACEA Technical Symposium 2007 Conclusion n n n n n Maintenance budgets to be aligned with maintenance strategies Manage evolution of budgeting systems Real-time budget updating remains a challenge Embrace technology to quickly capture and disseminate raw data Change management principles to be incorporated 10 SACEA Technical Symposium 2007 Component failures Failure frequency (Qty) Consistent Mean Standard deviation 11 SACEA Technical Symposium 2007 Expected component life improvement Mean B Failure frequency (Qty) Mean A Opportunity 15% 70% Life achieved (Tons) SACEA Technical Symposium 2007 15% 12 Optimal component replacement point Detection Inspection interval Performance interval JIT! FAILURE!! Source: Adapted from Moubray (1997:60) Time 13 SACEA Technical Symposium 2007 Expected component lives Description (A) Cylinders Steer Cylinder L/H Steer Cylinder R/H Hoist Cylinder L/H Hoist Cylinder R/H Steering Ball Stud L/H Steering Ball Stud R/H Steering Line Boring Hoist Cyl Bearing Set Hoist Cyl Line Boring Expected Life (Hours) (B) 15,000 15,000 15,000 15,000 7,500 7,500 5,000 7,500 7,500 14 SACEA Technical Symposium 2007 Expected component price improvement Mean C Failure frequency (Qty) Mean A Opportunity 15% 70% Component repair cost SACEA Technical Symposium 2007 15% 15 Cost breakdown structure Description (A) Cylinders Steer Cylinder L/H Steer Cylinder R/H Hoist Cylinder L/H Hoist Cylinder R/H Steering Ball Stud L/H Steering Ball Stud R/H Steering Line Boring Hoist Cyl Bearing Set Hoist Cyl Line Boring Current Cost (Rand) (D) 14,270 14,270 26,850 26,850 7,115 7,115 3,500 9,200 3,500 16 SACEA Technical Symposium 2007 Failure frequency (Qty) Expected total improvement Mean Mean Mean Future Cost Current Situation Future Life Opportunity GAP Component life/repair cost 17 SACEA Technical Symposium 2007 Establish starting point for scheduler Machine Number: Machine Type: Current Exch Rate (R/$): Remain Budget Hours Description (A) Cylinders Steer Cylinder L/H Steer Cylinder R/H Hoist Cylinder L/H Hoist Cylinder R/H Steering Ball Stud L/H Steering Ball Stud R/H Steering Line Boring Hoist Cyl Bearing Set Hoist Cyl Line Boring BF 002 CAT 789 6.30 1,354 Expected Current Life (Hours) Life (Hours) (B) (C ) 15,000 15,000 15,000 15,000 7,500 7,500 5,000 7,500 7,500 10,575 1,020 8,759 12,228 541 541 541 541 541 18 SACEA Technical Symposium 2007 Budget for the first period Machine Number: Machine Type: Current Exch Rate (R/$): Rem ain Budget Hours Description (A) Responsible Code: Cylinders Steer Cylinder L/H Steer Cylinder R/H Hoist Cylinder L/H Hoist Cy linder R/H Steering Ball Stud L/H Steering Ball Stud R/H Steering Line Boring Hoist Cyl Bearing Set Hoist Cy l Line Boring Sub-total BF 002 CAT 789 6.30 1,354 Expected Current Current Life (Hours) Life (Hours) Cost (Rand) (B) (C ) (D) 470512 15,000 15,000 15,000 15,000 7,500 7,500 5,000 7,500 7,500 10,575 1,020 8,759 12,228 541 541 541 541 541 14,270 14,270 26,850 26,850 7,115 7,115 3,500 9,200 3,500 112,671 R/Hr Rate (E) 0.95 0.95 1.79 1.79 0.95 0.95 0.70 1.23 0.47 Period 1 Budget Hours: Exch Rate: 6.30 PPI: Import Start Exp. Repair Budget Factor Life Cost (Rand) Cost (F) (G) (H) (I) 0.75 0.75 0.75 0.75 1 1 0 1 0 11929 2374 10113 13582 1895 1895 1895 1895 1895 14,466 14,466 27,219 27,219 7,115 7,115 3,693 9,200 3,693 14,466 0 0 27,219 0 0 3,693 0 0 45,378 3836 0.055 R/Hr (J) 3.77 0.00 0.00 7.10 0.00 0.00 0.96 0.00 0.00 11.83 19 SACEA Technical Symposium 2007 Cost smoothing L if e C yc le C o s t in g 14 PEAKS 12 10 (R and million) Maintenance Costs U n -S m o oth ed C o st C u rve 8 6 S m oo the d C o st C u rve 4 2 V A L L E YS 0 1 2 3 4 5 6 7 8 9 10 P e rio d s (Ye a r s ) 20 SACEA Technical Symposium 2007 Lowest combined cost Source: Wireman (1998:5) 21 SACEA Technical Symposium 2007 Thank you! Any questions?? SACEA Technical Symposium 2007