Applied Ergonomics 34 (2003) 23–28

Technical note

Corporate ergonomics programme at Ford Motor Company

Bradley S. Joseph*

Ford Motor Company, Health Protection Services, WHQ 532-B6, P.O. Box 1899, Dearborn, MI 48120-1899, USA

Abstract

The use of ergonomic principles in automobile assembly and manufacturing operations has become an important part of a

comprehensive health and safety process as well as an integral part of the engineering systems. Ford Motor Company has developed

an ergonomics process to manage issues related to injury and illness (e.g., musculoskeletal diseases) and to ensure the appropriate

use of human resources on the plant floor. The ergonomics programme uses joint labour and management teams to identify and

evaluate jobs and develop and implement solutions. This paper summarises the efforts of the Ford Motor Company in implementing

and maintaining the programme. Key strategies are outlined that provide important links to internal organisational units that are

critical to fully utilise the ergonomics process. In addition, the paper outlines differences between proactive and reactive efforts and

shows the importance of using the information generated by the initiatives for process improvement.

r 2002 Elsevier Science Ltd. All rights reserved.

Keywords: Ergonomics process; Proactive; Reactive; International

1. Background

Ford Motor Company is the largest producer of

trucks and second largest producer of vehicles in the

world. They produce 70 different vehicle types in over 30

countries including Jaguar, Lincoln, Volvo, Mercury,

Aston Martin and Ford. Ford has over 300,000

employees world wide. In the United States, Ford has

approximately 100,000 hourly employees and vehicle

sales over 3,000,000 units.

The United Auto Workers (UAW) is the primary

labour union that represents Ford hourly employees in

the United States. In the early 1980s, Ford Motor

Company and the UAW came to the understanding that

sharing responsibility for certain aspects of the business

was mutually beneficial to both parties. This understanding developed into the development and implementation of several joint programmes. These

programmes are assigned full time Company and Union

people to manage the process and to ensure joint

ownership.

One of the larger joint programmes is health and

safety. This programme designs, develops and implements comprehensive Union and Company programmes

to ensure the health and safety of the employees. The

*Tel.: +1-313-594-6957; fax: +1-313-594-2501.

E-mail address: bjoseph@ford.com (B.S. Joseph).

health and safety programme is managed by a joint

labour/management team called UAW-Ford National

Joint Committee on Health and Safety (NJCHS). This

team has sponsored the development and implementation of Ford’s ergonomics process.

2. The Ford ergonomics process

The UAW-Ford Ergonomics process began in the

United States with a number of research projects to

evaluate the effectiveness of using ergonomics within

Ford’s operations. The research included the following

groups: vehicle operations (vehicle assembly, metal

stamping), powertrain operations (engine and transmission manufacturing and assembly) and The University

of Michigan in Ann Arbor.

The outcomes of the research projects showed the

positive impact that can occur when ergonomics is

applied in manufacturing operations. It also showed

that ergonomics can be implemented with workers and

management problem solving teams if they are trained

properly and given appropriate plant support. Consequently, in the third quarter of 1989, the UAW-Ford

National Joint Committee on Health and Safety funded

the development and implementation of the Ford plant

ergonomics process. Formal training for the US plants

began in the spring of 1989.

0003-6870/02/$ - see front matter r 2002 Elsevier Science Ltd. All rights reserved.

PII: S 0 0 0 3 - 6 8 7 0 ( 0 2 ) 0 0 0 8 0 - 7

B.S. Joseph / Applied Ergonomics 34 (2003) 23–28

24

The customers for the ergonomics process are the

plant production workers assigned to the plant floor.

Customer needs and expectations will vary within each

facility. To facilitate making the programme work, Ford

developed a simple corporate vision statement and

presented it to senior management and labour representatives for approval. The Ford ergonomics vision

states:

Through the effective use of ergonomics, Ford will be

a global leader in providing a highly productive work

environment for all employees world wide that is safe,

injury/illness free, and facilitates continual improvement of quality and total cost for today and in the

future.

In order to achieve this vision, three requirements

were identified:

*

*

*

ergonomics would be available to all levels of the

company,

ergonomics would co-exist with existing processes,

ergonomics would be developed with a participative

approach.

The Ford ergonomic process involves the use of plant

union and management teams called Local Ergonomics

Committees (LECs). These teams are responsible for

identifying and evaluating problem jobs and developing

and implementing solutions. Each team develops a

yearly action plan to manage key process items

including prioritising concerns. There are three ways

to identify concerns: informal reporting from the plant

floor, jobs with medical cases, and risk assessment. In

general, jobs that have injuries are set at the highest

priority.

Solutions can arise from a number of strategies. They

are separated into two categories: engineering controls

and administrative controls. Engineering controls are

changes to tools, work station layout and possibly,

depending on timing and budget, product design.

Administrative controls are changes to the work

organisation job cycle time, job rotation, or job

enlargement. Ford’s primary control strategy is to use

engineering controls. However, the most effective

controls often involve a combination of both engineering and administrative controls.

3. Ford global ergonomics process

In 1995, the Ford Corporate Occupational Safety and

Health Department began to look into better coordination and globalisation of health and safety services.

Ergonomics was chosen as one of several areas to

globalise. A Global Ergonomics Design Team, consisting

of representative from operations, safety, industrial

hygiene, and medical departments was formed to

evaluate the current state of the ergonomics process in

the United States and in other areas around the world.

In 1996 a plan was presented to senior management of

Occupational Safety and Health and included plans to

globalise ergonomics by establishing LECs in every

manufacturing, assembly and warehousing facility

world wide. Several pilots were conducted in manufacturing operations in Europe to demonstrate the benefits

of using ergonomic principles on the plant floor. They

yielded positive improvements in employee health and

safety while increasing product quality and productivity.

Full implementation began in 1998 and continues till

today. Below is a summary of key elements of the Ford

Global Ergonomics Process.

The Ergonomics Process needs to be constantly

reviewed and updated. Best practices from all areas of

the Company need to be incorporated into the Process.

Global and local regulations will have to be evaluated

and implemented on a timely basis. These activities are

referred to as Global Strategies. It is a system of

constant evaluation and process improvement.

Much thought has already been given to long-term

strategies of the ergonomics process. Three critical

conditions for improvement are identified:

*

*

*

A need for specialised training as the process

matures. Participants will require advanced and

specialised ergonomics training.

A need to communicate ergonomics. A main reason

for bringing together the ergonomics committee is the

multi-disciplinary nature of the science. Successful

implementation of ergonomic principles is both

reactive and pro-active. Successful activities in

identifying and correcting poorly designed jobs must

be communicated to the engineers and others who are

responsible for developing new processes in plants, so

the same ‘‘mistakes’’ will not be repeated.

A need to constantly review and improve the process.

As time goes on, many Ford sites will recognise the

benefits of ergonomics. They will want to increase

their plant’s level of activity.

3.1. Summary of tasks involved in developing and

implementing global strategies

Co-ordinate the development and maintain world

wide ergonomics process recording, data collection,

and communication systems:

3 Work with Health Care Management (HCM)

to implement an Ergonomics Web Page for the

Ford IntraNet and link to appropriate Web

sites inside and outside the Company.

3 Work with HCM to implement and maintain

computerised evidence book and incident response recording system and tie it to the

Corporate Lessons Learned and Best Practices

Data Base.

B.S. Joseph / Applied Ergonomics 34 (2003) 23–28

3 Develop a formal organisational and reporting

process to ensure communications and feedback.

Work with the Ford facilities management group

(Ford land) to develop and maintain an Office

Facility Managers Manual.

3 Ensure ergonomics issues are appropriately

represented by reviewing furniture and seating

guidelines for administrative workplaces.

3 Participate in Ford land value-analysis teams

to ensure the best value furniture that includes

ergonomic considerations.

3 Design new production facilities to ensure

flexibility and lean layout.

3 Evaluate offices where employees exhibit issues

and report them to medical services.

Provide technical support and act as resource to

advance manufacturing cross functional teams,

manufacturing forums, vehicle centre teams, and

simultaneous engineering teams.

Work with ergonomics co-ordinators to develop

pre-programme guidelines that can be published

and distributed to appropriate engineering functions to help evaluate and prioritise ergonomics

issues during product and production design. These

guidelines will help guide engineers into better

designs that ease the assembly process.

Participation in the development and deployment of

advanced ergonomic analysis tools (e.g., simulation

and other related evaluation tools) to support

proactive analysis process. This involves leveraging

opportunities by identifying common needs and

focusing efforts on a single corporate wide solution.

Some of the current efforts are outlined below:

3 manual material handling process improvement research,

3 connector insertion forces measurement and

evaluation process,

3 developing an improved risk assessment tool

for plant floor surveillance of existing jobs.

Improvement Guide. In addition, Ford recently published an updated policy document that outlines and

specifies the ergonomics process.

5. The job improvement cycle

The manage events process uses a problem solving

circle called the job improvement cycle. Fig. 1 shows the

sub-steps of the cycle. It is a six step approach to

practical ergonomics that includes methods for identifying priority jobs to fix, evaluating job stresses, developing and implementing job improvements, and

documenting and following up on individual projects.

Since the cycle is so important, the job improvement

guide was written to explain, in detail, each of the six

steps.

In 1991, an important addition to the process was the

development and launch of a new comprehensive

documentation system to record information about the

plant ergonomics process, the Ergonomics Evidence

Book. The Evidence Book is similar in design to

evidence documents used for ISO 9000 and 14,000

audits and is used as part of the Ford production system

review. All necessary documents are available in one

place. In order to more readily share this information, a

computerised version was developed and launched in

over 50 plants in the United States. Below is a summary

of the steps that were required to successfully implement

ergonomics in a new region:

Step 1: Securing Leadership Commitment (plant

management and key employee representatives). A preliminary leadership orientation meeting must be scheduled and organised to make the leadership aware of the

incoming ergonomics process. The meeting should be

The Job Improvement Cycle

Identify

Priority

Jobs

4. Managing ergonomics events

Managing events involves the identification, evaluation, and fixing of existing jobs that exhibit ergonomic

risk. As stated above, the agreed upon system is based

on the UAW-Ford Ergonomics Process that was

launched in 1989 in the United States (The UAW-Ford

National Joint Committee on Health and Safety; 1988).

The process is discussed, in detail, in a book called An

Ergonomics Process. The process consists of two parts,

process implementation and job improvement process.

Two publications are available to aid facilities in

developing the programme and implementation plan:

The Ergonomics Implementation Guide and The Job

25

Follow-up

on Projects

Evaluate

Job

Stresses

Document

Projects

Develop

Solutions

Implement

Solutions

Fig. 1. The job improvement cycle.

26

B.S. Joseph / Applied Ergonomics 34 (2003) 23–28

approximately 2 h long and have the following objectives:

*

*

*

*

*

To create an awareness among local leadership of

what ergonomics is, why it is important, and why the

facility needs it.

To provide the leadership with an overview of the

design and structure of the process and to inform

them of their roles and to solicit and gain leadership

support for the process. Leadership support will be in

the form of sufficient time allocations for the LEC

members to complete job analysis and to attend

regular LEC meetings. In addition, support will be

required for resources to implement job modifications

where ergonomic hazards have been identified and

require engineering changes, changes to the job

process, or administrative controls.

To discuss and review local laws and contracts that

may affect the implementation of the process.

Step 2: Development of the committee. Shortly after

the preliminary leadership orientation meeting, members of the local ergonomics committee should be

selected and trained in the process. The core of the

manage ergonomic events process is a joint employee–

management team. This team consists of carefully

selected individuals who will meet regularly as your

local ergonomics committee. The committee should

represent both labour and management equally. Exact

membership, location, and reporting requirements of

the committee will depend on the facility and its

relationship with labour and current organisational

structures. However, at a minimum, it is recommended

that members represent a variety of disciplines within

the facility including engineering, safety, supervision,

production employees, skilled trades, and key employee

representatives.

Step 3: Development of a mission statement and

teamwork process. A Mission Statement sets the direction of the committee. Key elements of a mission

statement include:

*

*

*

overall goal of the ergonomics process,

the objectives toward which your LEC will work,

the strategies by which the team will meet the

objectives.

*

release time for the committee to attend meetings and

complete assignments,

setting concise agendas and recording meeting

activities,

updating the Ergonomics Committee Evidence Book

and other related documentation.

Step 4: Adjustment of the process. After the facility has

gained experience in the deployment of the LEC process,

it is recommended that another leadership meeting take

place to review results and make adjustments. Modifications of the process should be made at this time before

facility wide implementation.

Step 5: Evaluation and auditing. The manage events

ergonomics process is evaluated at two levels, the

process level (voice of the process, VOP) and the

customer level (voice of the customer, VOC). The

process evaluation (VOP) is conducted using the audit

process contained within the Ford production system.

The Ford production system (FPS) is a comprehensive

methodology to transform Ford facilities into more

efficient and lean manufacturing system. FPS reviews

several critical areas of the manufacturing system

including, but not limited to, material flow, layouts,

and product design feasibility. In addition, health and

safety metrics are included in the process to that to

ensure health and safety, is considered as an integral

part of the manufacturing system. It is recommended

that the process audit is conducted at least once a year.

The results from the audits will be used to meet the

requirements for Ford production system checkpoints

and to coach plants on process improvements.

Evaluation of the customer’s needs will depend on a

set of measures that are part of the facility mission

statement and action plan. These actions plans are

developed annually by the first quarter of each new year.

The results of the action plans are collected and reported

through division channels to the ergonomics champions.

A summary is made and presented to the Corporate

office. The Corporate office then develops an annual

corporate ergonomics action plan to support and

improve the ergonomics process. In general, and at a

minimum, injury/illness and absenteeism data is reviewed and targets are set.

6. Ergonomic prevention process

The mission statement should be updated at least

yearly to ensure the LEC is efficiently using its

resources.

Each facility is responsible for handling the day to day

activity of the ergonomics process. It is important for

the LEC to identify a working process that will enable it

to effectively make progress toward its objectives. Some

issues that need to be considered in developing an

effective teamwork process are:

A more effective and cost-efficient approach is for the

process to be pro-active, that is for ergonomic principles

to be applied during product research, design, and plant

layout in order to prevent ergonomic stress. In this way,

problems will be designed out of the product and

process before reaching the operation phase. However,

in order for the proactive process to be successful,

it is essential that all parts of product and process

B.S. Joseph / Applied Ergonomics 34 (2003) 23–28

development are linked to and communicate with the

ergonomics process.

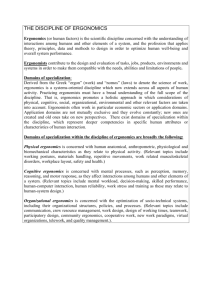

Fig. 2 is a flow chart that identifies opportunities for

ergonomic (and other safety and health) input during

the product and manufacturing development process.

Future product and process development is made up of

a series of specialised functions in separate organisational units that work together in co-located teams

called vehicle centers. Units at the division level typically

perform design and planning functions; and units at the

plant perform operation and maintenance functions.

Often, these units are separated geographically and

organisationally (e.g. division and plant) making it

difficult to co-ordinate efforts. This figure illustrates that

there are several points in time where the ergonomics

data can be applied.

Ford uses a process called design for ergonomics

(DFE). Design for ergonomics links Advanced Manufacturing Engineering and the individual vehicle centers

together to influence the Ford product development

process and the ford production system.

27

The design for ergonomics process must be implemented early in the development cycle. Implementation

involves similar steps outlined above in that a team

needs to be identified and trained to identify potential

ergonomic issues in product and process design. In order

to support the design for ergonomics process, Ford has

developed a training course called design for ergonomics. It outlines a process by which engineers,

equipment suppliers and others work together to

identify, evaluate, develop and implement solutions on

new productions systems.

7. Results

In general, the ergonomics process at Ford has been

successful at altering the engineering process to better

involve the human element in job design. However, as a

whole, it is very difficult to measure the costs and

benefits of ergonomics. However, individual case studies

by plant and by job have shown the following: In a

Current Level of Integration of Ergonomics Info. into World Class Timing

Product Development

Program

Approval

Process Development

Appearance

Approval

Product

Sign-off

Ergo. Issues that

are product related

YES

Done

Launch

Sign-off

JOB #1

Final Program

Status

Lessons learned

are Identified

and Fed Forward

for Continous

Process

Improvement

Ergo. Issues that

are process related

Processor Assigns to

appro. PMT for

evaluation and

resolution

PMT #1

Product Sign-off

Engineering/

Manufacturing

Design Sign-off

Existing Job

PMT #2

PMT #N

Can the issue

been resolved by

product

redesign?

NO

Assigned to Process

Engineers/Product

Specialists for evaluation

and resolution

Current

Production

Jobs

in Plant with

similar vehicle

Local

Ergonomics

Committee

Based on Risk Assessment, do

you fixed Job or wait to next

model launch?--interim or

permanent solutions

TGR/TRW

TGR/TRW

Matrix

TGR/TRW

Matrix

RPN

TGR/TRW

Matrix

RPN

Matrix

RPN

RPN

Fig. 2. Product/process design process with key timing points. Abbreviations: PMT—product module team, TGR/TGW—things gone right/things

gone wrong. A metric of how well a specific process or procedure went after launch. RPN—risk priority number. A risk assessment score that

evaluates both the severity of the event as well as the frequency of the event.

28

B.S. Joseph / Applied Ergonomics 34 (2003) 23–28

1 year time period, over 1500 ergonomic issues have

been identified and resolved in the plants in the United

States. Past data has shown that these solutions for each

problem help, on average, two employees.

*

*

*

In some US based plants an overall reduction of up

to 30 percent in workers compensation costs have

been recorded and a similar reduction in the lost time

case rate. Plants outside the US have recorded similar

results in absenteeism and insurance costs.

Reducing ergonomic risk on jobs has been correlated

with a subsequent increase in product quality.

During a recent launch of a new engine line, the plant

went over 6 months without a lost time upper

*

extremity musculoskeletal disorder. Today, this

plant’s overall rates are lower than similar plants in

the system.

Launching a new vehicle assembly line required less

re-work of the workstations and an overall reduction

in worker absenteeism and worker injury.

Acknowledgements

The UAW-Ford National Joint Committee on Health

and Safety.