water mist fire protection reliability analysis

advertisement

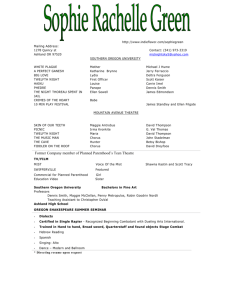

WATER MIST FIRE PROTECTION RELIABILITY ANALYSIS Shuzhen Xu Research – Risk and Reliability Area FM Global Norwood, Massachusetts 02062, USA David Fuller Engineering Standards FM Global Norwood, Massachusetts 02062, USA Abstract This paper presents results from a reliability study of water mist fire protection systems conducted at FM Global. The study includes a detailed Failure Modes and Effects Analysis (FMEA) to identify all the major potential failure modes, which include demand, quiescent and operational failures. Fault trees are then constructed for typical water mist system configurations to evaluate their failure probabilities. Due to the short history of industrial application of water mist systems, no specific reliability data are available. Therefore, in the calculation of system failure probabilities, the component failure data are obtained from other applications. The failure probabilities and their confidence bounds of typical water mist system arrangements listed in Standard 750 of the National Fire Protection Association are compared to automatic sprinkler systems in the paper. The major failure modes are identified through an importance analysis. Nomenclature F(t) Cumulative distribution function, cdf (---) P(...) Probability (---) R(t) Reliability function (---) t Time (time units depend on the application, hours, days, years). λ Failure rate for the exponential distribution, assumed constant (time-1) Introduction Automatic sprinkler protection has proven to be a highly reliable and effective means of reducing property loss and business interruption due to fire. To date, water mist systems have been classified by the loss prevention industry as special fire protection systems and have been limited to very specific hazard applications. Automatic sprinklers continues to be recommended for general building protection—even when specific hazards in the building are protected by water mist systems—due to concerns about their reliability. If their reliability was equivalent to automatic sprinkler systems, the potential would exist to reevaluate the requirement for general building sprinkler protection and to further expand water mist applications. In order to make this evaluation possible, a methodology that allows for the direct comparison of the relative reliability of water mist and sprinkler systems was needed. This paper presents the methodology and some results from a reliability analysis of water mist fire protection systems. In this analysis, system failure is defined as insufficient water supply in a fire event, i.e., insufficient water flow or amount, delayed water supply or no water supply on demand. The analysis includes a detailed Failure Modes and Effects Analysis (FMEA) to identify all the major potential failure modes, which include demand, quiescent and operational failures. Based on the FMEA, various fault trees are then constructed for typical water mist system configurations identified in the National Fire Protection Association Standard 750, Water Mist Fire Protection Systems. The reliability assessment is carried out on these typical water mist systems. However, due to the short history of industrial application of water mist systems, no specific component reliability data is available. Therefore, in the calculation of system failure probability, the component failure data is obtained from related applications. The calculated failure probabilities results and the confidence bounds of the selected water mist systems should be considered as preliminary estimates because the data used for the component failure modes are mainly from sprinkler systems. Therefore, the results are presented as relative failure probabilities compared to those of automatic sprinklers. The relative failure probability for each type of system is defined as the ratio between the failure probability of the water mist system and the lowest of the automatic sprinkler systems. The major failure modes are identified through an importance analysis and are discussed in the paper. Water Mist System Description Water mist systems are fire protection systems which use water in small droplets to extinguish fire. The mechanisms of extinguishment include flame cooling by droplet heating and evaporation, oxygen depletion by steam expansion and combustion products, and wetting of surfaces. While the water mist fire suppression system has been studied for at least 50 years, its practical application is relatively new. The designs of commercially available systems are distinctly different. Generally they can be categorized as follows[1]: 1. Type of atomization method: single fluid, twin fluid. 2. Delivery type: wet pipe, dry pipe, pre-action and deluge system. 3. Pressure supply method: gas propellant, pumps. 4. Operation pressure level: low pressure (≤12.5 bar), medium pressure (>12.5 bar and <34.5 bar), high pressure (≥34.5 bar). 5. Water source: self-contained water tank/cylinders, private water source, public water source. 6. Mist discharge type: continuous discharge, cyclical discharge. Although differences exist in the various products, there are eight typical configurations which are commonly used and listed in the National Fire Protection Association Standard 750 [1]. The characteristics of these eight systems are simplified as follows: System A: high pressure and gas driven system with stored water. System B: high pressure and gas driven with multiple accumulator units. System C: low pressure twin fluid water mist system. System D: single fluid mist system. System E: pump driven water mist system. System F: positive displacement pump assembly with unloader valves on each pump and pressure relief valve on discharge manifold. System G: gas pump unit for machinery spaces and gas turbine enclosure. System H: gas pump for light hazard applications. Failure Modes and Effects Analysis Failure modes and effects analysis is a qualitative inductive method to systematically analyze all contributing components failure modes and identify the resulting effects on the performance of the system [2]. It is frequently used to assist development of a fault tree analysis. In this study, the following general assumptions are made to facilitate the analysis: 1. All systems and components have been adequately designed and manufactured. For example, this means that pipes can withstand anticipated internal and external forces and manufacturing defects are not a cause of failure. 2. The systems under analysis have been operating and/or tested over a sufficiently long period of time such that they have passed the early failure period but have not reached the wear-out failure period. 3. No positive intervention is assumed to occur after the water mist system is demanded to function. For example, manual intervention in the form of opening an improperly closed valve during the fire is not considered. The FMEA used in this study is illustrated in Table 1. Most failure modes identified in the FMEA can be categorized into three types: operation failures, demand failures and quiescent failures. The categorization is motivated by the way data is presented in the literatures. • Operation failures apply to components in continuous service such as the mode of ‘rupture of water control valve’ shown in Table 1. • Quiescent failures modes are those of components which are normally dormant or in standby until tested or demanded (such as flow transmitter). They are characterized by a time variant function. • Probability of demand failure is time invariant and denotes the probability of the standby system to operate when demanded. Table 1 Examples of FMEA of water mist systems Item Failure Modes Electric Insufficient water pump drive supply when required No water supply when required Water Leak control valve Inappropriately closed Pressure/ No signal flow transmitter …… …… Main Effects Main Causes Control Insufficient water discharge Failure to operate Inspection during fire event No water discharge Failure to start Inspection No power supply Insufficient water Rupture during Discharge test discharge operation No water discharge Human error Inspection No water discharge Wrong setting on demand Device failure Inspection …… …… …… Reliability Data The quantitative analysis of water mist systems requires knowledge of the reliability data associated with the failure modes for each component considered. Due to the relatively short use of commercial water mist fire protection systems, no specific reliability data were found during this study. Therefore, the reliability data from outside sources and other field applications [2-4] are used by assuming that the failure data of the components in water mist systems components are equal to those of the same components when used in other applications. Component Reliability The estimation of system failure probability is based on the basic events failure probability calculations. • For the operational failure modes, the failure probability calculation is given by: (1) F (t 0 ) = 1 − e − λ 0 t 0 • • • Where t0: duration of the fire event. For quiescent failure modes, the related failure probability depends on how long the components have not been inspected when the system is demanded. So the failure probability of this type is represented by its mean value, F (t i ) , in one inspection interval calculated using the following equation: e − λs ti − 1 1 ti 1 ti (2) F (t i ) = ∫ F (t s )dt s = ∫ (1 − e −λs t s )dt s = 1 + ti 0 ti 0 λs ti Where: ti: inspection interval, ts: the time that the components has not been inspected when the system is demanded, F(ts): failure probability at the time ts The data associated with demand failure modes are probabilities, therefore there is no need for further calculation. However, for the failure modes of “no power” in utilities, a different formula is used to incorporate the redundancy and repair characteristics as follows: (3) F = 1 − P ( A) P( A) = P( A B) P( B) (4) P( B) = 1 − λsTr (5) P ( A B ) = e − λs to (6) Where: Event A: the power or fire service main is available during the time of the fire event. Event B: the power or fire service main is available to the system at the time when the fire started. failure rate of power utility or fire service main. λs : Tr: repair time. the time fire event lasts. t0 : System Failure Probability Once the failure probability of every component is calculated, the failure probabilities of the systems can be estimated by using fault trees analysis (FTA) based on the FMEA. Failure in this study is defined as insufficient water discharge in a fire event, i.e., insufficient water flow or amount, delayed water discharge or no water discharge on demand. The calculation of the systems failure probabilities is conducted on eight typical systems configurations listed in the National Fire Protection Association Standard 750 [1] assuming a one year inspection interval. The results obtained are preliminary due to the fact that the component reliability data used are from other applications. Therefore the results are presented as the relative failure probabilities compared to the automatic sprinkler systems failure probabilities obtained from an unpublished prior study. The relative failure probability for each system is defined as the ratio between the Relative failure probability failure probability of water mist systems and the lowest of the automatic sprinkler systems. Figure 1 shows the 90% confidence bounds and mean value of the relative failure probability for each system assuming one year inspection interval. As can be seen in Fig. 1, the failure probabilities of water mist systems vary depending on the design. Systems E and F have higher failure probability than the rest of the systems studied. However, the values in Fig. 1 can vary depending on the design of components. For example, if the water control valve selected for the calculation in Fig. 1 doesn’t have a position indicator of open/close, then its failure probability will be higher than if it has such an indicator. 12 10 8 6 4 2 0 A B C D E F G H NFPA-750 systems Figure 1 90% confidence bounds of relative failure probabilities of typical water mist systems ■ mean value; ▐ 90% confidence bound; ··· the range of relative automatic sprinkler systems probabilities relative to the lowest level. Importance Analysis Fussell-Vesely (FV) importance is utilized to perform the importance analysis on the above water mist systems. The FV importance measures the probability contribution of a basic event to the system failure, given that the system has failed. Therefore, the importance measure is an indicator of the failure modes which are most likely to result in the water mist systems failing to provide adequate water discharge on demand. SAPHIRE software [5] was used for the importance analysis. It is found that the significance of each failure mode depends on the design of the system, however the more common failure contributors are empty water tank, low gas propellant pressure, improper control settings, control panel or wiring failure, shut water control valve and fire detector failure. Human error, such as empty gas or water cylinders, or wrong settings is a common factor resulting in system failures. The control panel and wire connection (cable), if they are used, always appear in the list of the first five contributors to the system failure. When the water mist system shares the water supply with the sprinkler system, the importance of maintaining the reliability of the common water source is highlighted. Conclusions The reliability of water mist systems is assessed by using FMEA and FTA techniques and compared with that of automatic sprinkler systems. This assessment is conducted on eight typical water mist systems listed in NFPA-750. In the calculation of failure probabilities, the primary source of the data used is from other applications since no specific reliability data are available due to the short history of industrial application of water mist systems. Therefore, the relative failure probability for each system studied is presented. The importance analysis shows that problems with human error, control panels, cables, and fire detectors are the most significant contributors to the water mist system failure to perform adequately in a fire event. Reference [1] NFPA-750, 2003, National Fire Protection Association Standard on Water Mist Fire Protection Systems, Quincy, MA. [2] McCormick, N.J., 1981, “Reliability and Risk Analysis,” Academic Press, San Diego, CA. [3] NPRD, 1995, “Nonelectronical Parts Reliability Data,” Reliability Analysis Center, Rome, NY. [4] PERD, 1989, “Process Equipment Reliability Data with Data Tables,” Center for Chemical Process Safety of the American Institute of Chemical Engineers, New York, NY. [5] Smith, C., Knudsen, J., Wood, T., 2006, “Advanced SAPHIRE”, Idaho National Lab, ID.