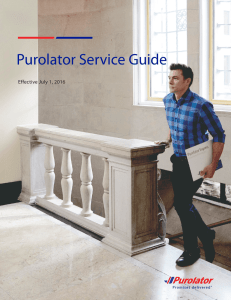

Delivering on promises coast to coast

advertisement

Customer Success Story “Through Purolator’s distribution and warehouse solutions, we have grown our Western sales by $300,000.” Victor Levis, Controller and Member of Executive Committee, Freemark Apparel Brands Inc. Delivering on promises coast to coast Purolator helps FAB stay fashion-forward with new distribution model When your business is fashion, timing is everything. Fashion styles can come and go and buyers are steadfast on keeping up with what’s on trend. So when demand for Freemark Apparel Brands (FAB) names like Bench exploded, the company looked to Purolator to help meet its growing–and changing–supply chain needs. Industry • Fashion apparel Customer: Freemark Apparel Brands (FAB) • Wholesale and retail distribution • Brands include Bench, Scotch & Soda, Super Trash, Garcia, Silvian Heach • Renowned for customer service and industry expertise Challenge In-demand styles pose logistical challenges Until 2009, FAB operated exclusively in the wholesale market, servicing its extensive customer base–independent boutiques, specialty chains, department stores and mass merchants–out of its home-base Montreal, Quebec distribution centre. Seeing a major opportunity to grow their brands and their bottom line, the company entered the retail arena, which it also serviced out of Montreal. While this distribution model met wholesale needs, it began to pose speed-to-market challenges for the booming retail segment, specifically on the West coast. •M eet growing capacity needs of multiple distribution channels Solution • Purolator warehousing and distribution Results • $300,000/ year sales boost • $250,000+ profit increase P u r o l a t o r | C u s t o m e r S u c c e s s S t o r y – Fr e e m a r k A p p a r e l B r a n d s P u r o l a t o r | C u s t o m e r S u c c e s s S t o r y – Fr e e m a r k A p p a r e l B r a n d s By 2012, FAB had opened 11 retail stores in Western Canada and 18 in the East. By early 2015, that number will have reached 42–a 44% growth in a three-year period. Since most of FAB’s merchandise is sourced from overseas, shipments destined for Western customers needed to bypass the West coast to arrive in Montreal, only to be distributed back to Western retail stores. And in an industry like fashion, that extra transit time can lead to missed opportunities and lost revenue. Purolator Logistics™ optimizes Western supply FAB knew the supply chain needed to be re-examined to better support wholesale and retail customers cross-country. Purolator had long been FAB’s freight carrier, but after examining the various business channels’ objectives and challenges through a consultative approach, Purolator recommended its multi-client warehouse capabilities to get Western-bound products to market quicker. Purolator became the third-party logistics provider for Western retail stores, handling both warehousing and distribution out of a Purolator facility in Vancouver, British Columbia. Strong returns and peace of mind Leveraging Purolator’s warehouse and distribution services out West, FAB eliminated the need for additional warehousing overhead, transport and labour. Speed to market in Western retail stores has increased by 10–12 days– which can make all the difference for an apparel distributor. “Having the capability to stop our products destined for Western stores in Vancouver, and having (those products) sorted and store orders processed by Purolator, offers us the ability to reach the market faster than we ever could from Montreal,” says Victor Levis, Controller and Member of Executive Committee. By optimizing multiple business areas across the supply chain, FAB calculates that it is adding over $250,000 annually to the bottom line of its Bench Canada division, between reduced freight costs and earlier arrival in store of both initial and replenishment goods. Joining forces with Purolator for both transportation and logistics, FAB now has peace of mind that all of its business channels are being handled with professionalism and care –and can get back to scouring the globe for tomorrow’s biggest trends. FAB calculates that it is adding over $250,000 annually to the bottom line of its Bench Canada division.