Hull & Machinery Guide

advertisement

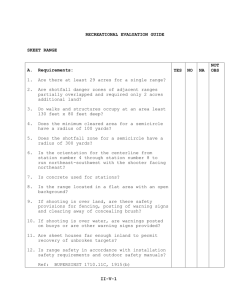

Compiled by Dinos Levantis Issued by BMT Marine & Offshore Surveys © 2011 All Data in this booklet should be used as guidance only No part of this publication may be reproduced, stored in a retrieval system, or transmitted by any form or means, electronic, mechanical, photocopying, recording or otherwise without prior written permission of BMT Marine & Offshore Surveys. Details correct at time of going to press. Introduction Marine survey reports frequently contain engineering terminology which can often be unfamiliar to the non engineers in the wider spectrum of the shipping industry. In an attempt to bridge this gap we have produced this small guide book which covers some of the common terminology used for ships, their engines and ship’s related operation, often encountered in survey reports. By no means should this booklet be considered a complete dictionary encompassing the entire terminology. Such a dictionary would in any case be rather large and cumbersome to use. The intention was to keep it simple and easy to use, providing a quick reference through easily understood illustrations. A blank page has been left next to each illustration for the user to write additional notes and queries they may have which our technical staff are more than happy to advise on. We would like to especially thank the Piraeus Office Administration staff for their enormous help and patience in preparing this booklet. This is the first version, (Ver. 01) of this booklet and we would gladly welcome any suggestions from the users which will help us enhance any future versions. Dinos Levantis MSc BMT Marine & Offshore Surveys (Incorporating The Salvage Association) 1 2 CONTENTS Page GENERAL BMT MARINE & OFFSHORE SURVEYS................................................................ GENERAL CONTACT DETAILS (HEAD OFFICE LONDON)……………………………............ GLOBAL SURVEYOR LOCATIONS………………………….………………................................ REGIONAL HUB OFFICES……………………………….………………….................................... UNITS……………………………………………………………………………....................................... NAVIGATION…………………………………………………………………….................................... COMMON NAVAL ARCHITECTURE DATA …………………………………........................... COMMON MARINE ENGINEERING DATA…………………………………............................ WEATHER DATA-BEAUFORT SCALE…………………………………….................................. CLASSIFICATION OF SHIPS………………………………………………….................................. SHIP CONSTRUCTION DATA (BOW CONSTRUCTION)……………………....................... SHIP CONSTRUCTION DATA (DOUBLE BOTTOM – DECK CONSTRUCTION)……………………………………………………………….................................. SHIP CONSTRUCTION DATA (STERN & RUDDER CONSTRUCTION)…..................... STEERNG GEARS..........................................................................................……..... ANCHOR & CHAINS…………………………………………………........…….............................. 3 4 5 6 8-9 10 11-13 14 15 16-17 18 19 20 21 22 HULL GENERAL CARGO CARRIER…………………………………………………................................. BULK CARRIER………………………………………………………………….................................... HATCH COVERS………………………………………………………………..................................... CONTAINER CARRIER………………………………………………………….................................. GAS CARRIER……………………………………………………………………................................... PASSENGER FERRY……………………………………………………………................................... OCEAN GOING TUG BOAT……………………………………………………................................ DOUBLE SKIN OIL CARRIER…………………………………………………................................. 24 26-28 30 32 34 36 38 40 MACHINERY TYPICAL ENGINES FOR PROPULSION………………………………………............................. CROSSHEAD TYPE ENGINE PARTS…………………………………………............................... TRUNK PISTON TYPE – V- ENGINES…………………………………………............................. TYPICAL PISTON & CRANKSHAFT ARRANGEMENT……………………........................... CAMSHAFT ARRANGEMENT……………………………………………….................................. TURBOCHARGER…………………………………………………….………….................................. ENGINE SCAVENGE AIR & EXHAUST ARRANGEMENT…………………......................... PROPELLERS & TAILSHAFT…………………………………………………................................. WATER JET THRUSTERS………………………………………………………................................ STEAM TURBINE………………………………………………………………................................... VERTICAL OIL FIRED & COMBINED BOILER…………………………….............................. 42 44-46 48-50 52 54 56 58 60 62 64 66 REFERENCES…………………………………………………………………….................................... 68-69 GENERAL BMT Marine & Offshore Surveys Ltd (Incorporating The Salvage Association) 3 BMT Marine & Offshore Surveys Ltd is a leading international marine surveying and technical consultancy, operating from a worldwide network of offices. The company incorporates the world-renowned casualty expertise of The Salvage Association and BMT Murray Fenton. The Salvage Association was founded in 1856 in London and has been closely operating with the London insurance market. Our services include casualty surveys, report and investigations work on behalf of Hull & Machinery, P&I, Liability and cargo insurers. Our spectrum of work includes surveys of incidents affecting every type of vessel from a yacht to the largest ULCC and the most complex LNG or chemical carrier. BMT Marine & Offshore Surveys Ltd is a leading marine consultant providing warranty services for the Cargo, Offshore Energy, Construction, Liability and Hull & Machinery insurance markets. Additional services include; risk management, risk assessments including environmental and emissions risks, feasibility studies; risk audits of vessel and engine room operations, shipbuilding and repair facilities and their procedures; assessments of port operations, wreck removal and navigation. Our global network of surveyors are ready to immediately assist in the event of marine casualties, collisions, stranding, sinking’s, salvage, wreck removal, machinery investigations, warranty, P&I and risk assessment. 4 CONTACT DETAILS FOR PIRAEUS & VARNA LONDON Office – HEAD OFFICE Marlow House 1A Lloyd’s Avenue London, EC3N 3AL United Kingdom Tel: +44 207 648 9650 Fax: +44 207 929 5564 Email: london@bmtmarinerisk.com Global Support Services London Tel: +44 (0)020 7648 9655 Mobile: +44 (0)7831 879675 Email: gss_staff@bmtmarinerisk.com Email: smartin@bmtmarinerisk.com Global Support Services New York Tel: +1 212 587 9307 Mobile: +1 646 283-0626 Email: grocco@bmtmarinerisk.com For direct contact with our regional offices please refer to page 6 of this guide or visit our website to download our International contact directory www.bmtmarinerisk.com GENERAL GENERAL GLOBAL SUVEYOR NETWORK Marine Expertise: Anytime, Anywhere Global Surveyor Network 5 6 REGIONAL HUB OFFICES GENERAL GREECE Hellas Branch 5-7 Fillelinon Street 185 36 Piraeus Greece SOUTH AFRICA 13 Foregate Square Table Bay Boulevard Cape Town 8000 South Africa Tel: +30 210 42 92 690 Fax:+30 210 42 92 691 Email: piraeus@bmtmarinerisk.com or hellas@bmtmarinerisk.com Tel: +27 21 421 3172/3 Fax: +27 21 421 3166 Email: cape_town@bmtmarinerisk.com NEW YORK 20 Broad Street 7th Floor, Suite A New York, NY 10005-2615 USA SINGAPORE 3 HarbourFront Place No 03-01/04 HarbourFront Tower Two Singapore 099254 Tel: +1 212 587 9300 Fax: +1 212 587 9301 Email: new_york@bmtmarinerisk.com Tel: +65 6517 6860 Fax: +65 6274 4881 Email: singapore@bmtmarinerisk.com DUBAI Dubai World Trade Centre Building 13th Level, PO Box 9222 Dubai United Arab Emirates Tel: +971 4 331 3100 Fax: +971 4 331 4121 Email: dubai@bmtmarinerisk.com For further information please visit our website www.bmtmarinerisk.com GENERAL NOTES 7 8 UNITS GENERAL Length 1 nm = 1852 m = 1.852 km 1 yd = 3 ft = 36 in = 0.9144 m 1 m = 100 cm = 10 dm = 1000 mm = 3,2808 ft 1 μm =0.001 mm 1 cable = 185.20 m = 0.1 nm 1 fn = 1.8288 m 1 shackle of anchor cable = 15 fm = 27.5 m Nm km m cm dm mm μm ft in yd cable fn Nautical mile kilometer meter centimeter decimeter millimeter micron foot inch yard cable length (international) fathom lit gal pt barrels litre gallon (UK) pint (UK) barrels (US) Kgf Lbf Kpond N KN Kilogram force Pound force Kilopond Newton Kilo-Newton atm bar KPa psi in Hg mm Hg Atmosphere Bar Kilo-Pascal Pound per square inch Inches of Mercury Millimeters of Mercury Volume 3 3 1 m = 1000 dm = 1000 lit = 219.9692 gal (UK) = 1759.7547 pt (UK) 3 = 35.31467 ft = 6.2898 barrels (US) Force 1 Kgf = 9.80665 N = 2.2046 lbf = 1 Kpond 1 tonf = 1000 Kgf = 9806.65 N = 9.80665 KN 1 tonef (UK long tons) = 1.01605 tonf (metric) Pressure / Stress 1 atm = 1.01325 bar 2 = 101325 N/m 2 = 0.101325 N/mm 2 = 1.03322 Kgf/cm 2 = 10332.27 Kgf/m = 101.325 KPa 2 = 2116.21658 lbf/ft 2 = 14.6959 psi (lbf/in ) = 29.9213 in Hg = 760.0021 mm Hg GENERAL UNITS Temperature 1 C° = 33.8 F° = 274.15 K 9 C° F° K Degree Celsius Degree Fahrenheit Degree Kelvin W HP PS Watt Horse Power Metric Horse power Flow rate 3 1 lit/min = 0.000589 ft /sec 3 = 0.0000167 m /sec 3 = 0.06012 m /hr = 13.1981 gal/hr (UK) Velocity 1 Knot = 0.51444 m/s = 1.852 km/hr = 1.6878 ft/sec Power 1 KW = 1000 W = 1.3410 HP = 1.3596 PS (Metric Horse power) Moment / Torque 1 Kgf m = 9.80665 Nm = 0.009807 KNm = 7.233 lbf ft = 0.001 tonf m 10 NAVIGATION GENERAL Parallels of Latitude Meridians of Longitude o LONDON 51 30’ North N o NEW YORK 74 00’ West S W E LONGITUDE LATITUDE 30o 15o 0o 15o 30o 0 o CAPE TOWN 33 55’ South GREENWICH MERIDIAN o CAPE TOWN 18 22’ East Most charts are drawn to MERCATOR’s PROJECTION, to represent the spherical world on a flat sheet of paper with all the meridians of longitude made parallel. To keep the same land shapes the parallels of latitude are increased in proportion. This gives rise to say 600 sea miles being measured on a chart being a bigger measurement at the top of the chart than at the bottom. This is because 1 sea mile = 1 minute of latitude and the latitude scale gradually increases towards the top of the chart. This is why distances are ALWAYS measured on the latitude scale opposite your position. [Ref. 1] 0 10 Rise of Floor Frame Numbers Aft Peak Bulkhead WL Main Deck Summer Load line Main Deck Beam 100 Bilge Keel Camber Lbp (Length between perpendiculars) Loa (Length Overall) Draft Freeboard Base Line Depth Collision Bulkhead Sheer forward 200 WL GENERAL COMMON NAVAL ARCHITECTURE DATA 11 12 COMMON NAVAL ARCHITECTURE DATA GENERAL Wave length Wave crest Wave trough Wave height Main Deck structure in tension Bending HOGGING CONDITION Bottom structure in compression Main Deck structure in compression Bending SAGGING CONDITION Bottom structure in tension Buoyancy Buoyancy Buoyancy Buoyancy Buoyancy Shear Force Shear Force Weight Weight Weight Weight Weight The ocean wave geometry resembles a trochoidal shape. The ship structure is designed to withstand the extreme stresses due to the applied forces when balanced on such a wave having the ship’s length in both hogging and sagging conditions. In a sea way, the structure will be continuously subjected to deformation in all directions. The generated stresses will alternate and the material forming the structure will therefore be subjected to fatigue. A well designed structure having a well conceived geometry and being of suitable material is expected to withstand the fatigue stresses for a substantial period of time. GENERAL COMMON NAVAL ARCHITECTURE DATA 13 Δ = DWT + Lightship Where Δ is the displacement, DWT is the deadweight, (cargo capacity including fuel and stores, crew and effects), and the Lightship is the weight of the structure as built including, water in the boilers and lubes in machinery to working level. In all normal calculations the lightship figure is taken to be the same as stated in the vessel’s approved trim and stability booklet. The lightship is also the figure used for scrap estimations. Δ = Lbp x B x Tm x ρ x Cb Where Lbp is the length between perpendiculars, B is the beam, Tm is the mean draft, ρ is the density of sea water (about 1025 Kg/m3) and Cb is the block coefficient, (for most cargo type ships between 0.65 to 0.9 – passenger cruisers, 0.55 to 0.63). The larger the block coefficient the more box shaped the vessel is. Thus for a perfect box type structure Cb is 1, and off course the resistance is larger. Tm = (Tf + Ta)/2 Where Tm is the midship draft, Tf and Ta are the drafts forward and aft, respectively. Heel angle, (radians) = wl / GMT x Δ Where wl is the moment of the weight causing the heel, (the weight times the transverse distance from midship), GMT is the transverse metacentric height and Δ is the total displacement. The formula works in radians, (1 rad = 57.3 degrees) and can be accurate for small angles. Ship’s motions at sea The ship’s centre of gravity has six degrees of freedom, three linear and three angular as illustrated in the fig below. In a seaway it can experience all six motions simultaneously. An object resting anywhere in the structure is subjected to forces resulting from these motions. The magnitude of these forces are calculated using Newton’s well known formula F = m x α, where “m” is the mass of the object and “α” is the acceleration of its centre of gravity. Yawing motion Rolling motion Pitching motion Heaving motion Vertical axis G 14 COMMON MARINE ENGINEERING DATA GENERAL Indicated Power (KW) = Pm x A x L x N x K x n / 0.6 Where Pm is the mean indicated pressure per cylinder in Bar A is the sectional area of the cylinder in m2 L is the length of stroke in m N is the engine speed in rpm K is the type of stroke per revolution (i.e. 1 for two stroke engines and 0.5 for four stroke engines) n is the number of cylinders Brake Power = Mechanical efficiency x Indicated power The mechanical efficiency of a well designed turbocharged engine can be 90% Bunkers Bunker fuel is technically any type of fuel oil used aboard ships. In the maritime field the type of classification used for fuel oils is: IFO (Intermediate fuel oil) A blend of gasoil and heavy fuel oil, with less gasoil than marine diesel oil o IFO 380 - Intermediate fuel oil with a maximum viscosity of 380 Centistokes at 50°C o IFO 180 - Intermediate fuel oil with a maximum viscosity of 180 Centistokes at 50°C o LS 380 - Low-sulphur (<1.5%) intermediate fuel oil o LS 180 - Low-sulphur (<1.5%) intermediate fuel oil HFO 380 (Heavy fuel oil) - Pure or nearly pure residual oil with a maximum viscosity of 380 Centistokes MGO (Marine gas oil) - made from distillate only MDO (Marine diesel oil) - A blend of heavy gasoil that may contain very small amounts of black refinery feed stocks, but has a low viscosity up to 12 cSt so it does not need to be heated for use in internal combustion engines. Parameter Unit 3 Max Density at 15°C kg/m Max Viscosity at 50°C mm²/ s °C Max Pour point, Winter MGO MDO IFO 180 RMH 380 RMK 380 890.0 900.0 991.0 991.0 1010.0 6.0 11.0 180.0 380.0 380.0 Ambient Ambient 30 30 30 General recommended cSt Ambient Ambient 10~15/ 10-15/ 10-15/ injection viscosity and /°C 110~ 118 130 ~ 142 130~142 temperature 1 mm²/s = 1 cSt Viscosity (Kinematic) is a measure of the resistance of the fuel. In everyday terms viscosity is "thickness". TYPICAL ENGINE OPERATING PARAMETERS Parameter Unit Values Max Exhaust Temperatures °C 500 General recommended Lub. Oil pressure for 2-stroke engines Kg/cm2 3.5~4.2 General recommended Lub. Oil pressure for 4-stroke engines Kg/cm2 2.0~3.0 Jacket water outlet temperature °C 65~68 Type of system oil used for 2-stroke engines SAE Viscosity 30 Type of cylinder oil used for 2-stroke engines* SAE Viscosity 70 or 50 Type of system oil used for 4-stroke engines SAE Viscosity 40 *Changeover from TBN 70 to TBN 50 only when operating for more than one week on <1% sulfur GENERAL Beaufort Number WEATHER DATA – BEAUFORT SCALE Descriptive Term Mean wind speed equivalent Knots Deep Sea Criterion m/sec 0 Calm <1 0-0.2 1 Light air 1-3 0.3-1.5 2 Light breeze 4-6 1.6-3.3 3 Gentle breeze 7-10 3.4-5.4 4 Moderate breeze 11-16 5.5-7.9 5 Fresh breeze 17-21 8.0-10.7 6 Strong breeze 22-27 10.813.8 7 Near gale 28-33 13.917.1 8 Gale 34-40 17.220.7 9 Strong gale 41-47 20.824.4 10 Storm 48-55 24.528.4 11 Violent storm 56-63 28.532.6 12 Hurricane 64 and over 32.7 and over Sea like a mirror Ripples with the appearance of scales are formed without foam crests Small wavelets, still short but more pronounced crests have a glassy appearance and do not break Large wavelets cress begin to break foam of glassy appearance, perhaps scattered white horses Small waves becoming longer fairly frequent white horses Moderate waves taking a more pronounced long form many white horses are formed (chance of some spray) Large waves begin to form the white foam crests are more extensive everywhere (some spray) Sea heaps up and white foam from breaking waves begin to be blown in streaks along the direction of the wind Moderately high waves of greater length edges of crest begin to break into spindrift foam is blown in well marked streaks along the direction of the wind High waves dense streaks of foam along the direction of the wind crests of waves begin to topple, tumble and roll over, spray may affect visibility Very high waves with long overhanging crests the resulting foam in great patches is blown in dense white streaks along the direction of the wind on the whole, the surface of the sea takes a white appearance the tumbling of the sea becomes heavy and shock like visibility affected Exceptionally high waves (small and medium sized ships might be for a time lost to view behind the waves) the sea is completely covered with long white patches of foam lying along the direction of the wind everywhere the edges of the wave crests are blown into froth visibility affected The air is filled with foam and spray sea completely white with driving spray visibility very seriously affected 15 Probable mean wave height* in metres 0.1 (0.1) 0.2 (0.3) 0.6 (1) 1 (1.5) 2 (2.5) 3 (4) 4 (5.5) 5.5 (7.5) 7 (10) 9 (12.5) 11.5 (16) 14 (-) [Ref. 2] Cushion Approximate speed range potential Knots 80-100 Sea Air Surface effect Aerostatic c Aircraft Submerged toils 60-40 Surface piercing Hydro toil 40-25 Planing hull Hydrodynamic support BERNOULLI ARCHIMEDES Conventional Displacement 30-15 Submersibles Small water plane CLASSIFICATION OF SHIPS Submarine 15 Deep displacement Special Displacement Catamaran (Multi hull) Hydrostatic support (Displacement) SEAGOING VESSELS (Surface, Surface Effect, Sub-surface) 16 GENERAL [Ref. 3] GENERAL CLASSIFICATION OF SHIPS 17 The terms below refer to design restrictions imposed on a vessel, in order to be able to trade within standard geographic areas TYPE DESIGN RESTRICTIONS HANDYSIZE DRY CARGO DWT about 15,000 to 40,000 mt HANDYMAX DWT about 41,000 to 55,000 mt SUEZMAX DWT up to 150,000 mt PANAMAX DWT 60,000 – 80,000 mt POST PANAMAX And CAPESIZE DWT 81,000 – 250,000 AFRAMAX (Crude and Product Oil tankers) TANKERS DWT between 75,000 – 120,000 mt COMMENTS It is numerically the most common type of Bulk carrier and in most cases is fitted with cranes Most commonly they have 5 Cargo holds and 4 cranes of 30tonnes lifting capacity Maximum permissible size which can cross the Suez Canal Maximum permissible size which can cross the Panama Canal Capers do not cross any of the world’s canals Are largely used in the basins of the Black Sea, Caribbean, China Sea and the Mediterranean Non-OPEC exporting countries mainly require the use of AFRAMAX tankers , because their harbours and canals are too small to accommodate VLCCs and ULCCs Maximum permissible size which can cross the Suez Canal Do not cross any of the world’s canals SUEZMAX Similar size as the respective bulk carrier. VLCC Very large crude oil carrier (super Tanker DWT between 150,000 – 320,000 mt) Ultra large crude oil carrier (super Tanker Do not cross any of the world’s canals DWT between 320,000 – 550,000 mt) CONTAINER VESSELS Up to 13,500mt Used when economic and size restrictions (up to 1000 TEU) imposed for larger sizes Approx. between Used when economic and size restrictions 13,500-31,000mt imposed for larger sizes (1,000-2,500 TEU) Approx. between Can cross Panama Canal 31,000-59,000mt (2,500-5,000 TEU) Approx. between Cannot cross Panama Canal 59,000-113,000mt (5,000-10,000 TEU) Approx. between Can cross Suez Canal 113,000-137,000mt (10,000-12,000 TEU) Above 137,000mt Cannot cross Suez Canal (Above 12,000TEU) ULCC SMALL FEEDER FEEDER PANAMAX POST-PANAMAX SUEZMAX POST-SUEZMAX 18 SHIP CONSTRUCTION DATA (BOW CONSTRUCTION) Anchor chain Hawse pipe Anchor Windlass GENERAL Bulwark Chain Stopper Forecastle deck Main deck FOREPEAK Soft nose plating FOREPEAK Chain locker TANK TANK Flame area [Ref. 4] SHIP CONSTRUCTION DATA (DOUBLE BOTTOM –DECK CONSTRUCTION) GENERAL 19 Hold Frames (Transverse) Inner – bottom Longitudinal Hold Frames (Transverse) Side Shell Margin Plate Inner – bottom plating Center Strake Frame Bracket Side Girder Bottom Longitudinal Solid Floor Center Girder Transversely Longitudinally Solid Floor Nontight Side Girder Framed Framed Built up Section Flat Bar Inverted Angle Bulb Plate Tee or Part I H-Beam with Flanges Removed Additional Face Plate if needed Flange Plate [Ref. 5] 20 SHIP CONSTRUCTION DATA (STERN - RUDDER CONSTRUCTION) GENERAL BALANCE RUDDER WITH HEEL PINTLE Steering Gear Flat Rudder Stock Stock Palm Upper Pintle After Peak Tank Rudder BLADE Stern Tube Stern Frame Heel Pintle Frame 0 Skeg SEMI SPADE RUDDER Rudder Stock Steering Gear Flat Neck Hearing After Peak Tank Rudder Blade Stern Frame Stern Tube Horn Pintle Rudder Horn Frame 0 GENERAL STEERING GEARS 21 RAM STEERING GEAR SYSTEM Hydraulic Cylinder Ram Rudder stock Yoke [Ref. 6] ROTARY VANE STEERING GEAR SYSTEM Rotor Stator Vanes Rudder stock [Ref. 7] 22 ANCHOR & CHAINS GENERAL Ring (Shackle) Shank Fluke / Palm Bill/Pea Arms Throat Crown Blade [Ref. 8] Connection to Anchor Common Link Common Link End Link Common Link Enlarged Link Kenter Joining Shackle Anchor Crown Shackle Jaw and Jaw Swivel Anchor Shank Connection to Chain Locker End Link Common Link Enlarged Link Clinch Shackle [Ref. 9] GENERAL NOTES 23 Bilge plating Vertical welding seams Deck plating [Ref. 4] Keel plating Tank top plating Tween deck hatch [Ref. 10] GENERAL CARGO CARRIER Shell frame Longitudinal welding seams Sheer strake plating 24 HULL HULL NOTES 25 BULK CARRIER HULL [Ref. 11] 26 HULL NOTES 27 28 BULK CARRIER – HOLD ARRANGEMENT Side transverse HULL Deck longitudinal Deck transverse (Topside) bottom transverse Hatchside coaming Hatchend coaming Hatchend beam Side longitudinal (Topside) bottom longitudinal Cross deck beam Topside tank bottom Hold frame Bilge hopper Bottom transverse Bilge hopper transverse Side transverse Lower stool Bilge hopper Longitudinal Center girder Inner bottom Side girder ( tanktop of double bottom) Solid floor Side longitudinal Bottom longitudinal Tanktop (inner bottom) longitudinal Transverse ring in bilge hopper [Ref. 12] Topside tank transverse web frame Deck plating Deck longitudinal Hatch side coaming Topside tank plating Vertical strake Corrugated type bulkhead Topside tank Topside tank slopping plating Side shell longitudinal Topside tank slopping plating longitudinal Bracket Cargo Hold Side shell plating Hopper Transverse web frame Side shell frame (Hold frame) Where the cargo hold is used for heavy ballast condition, the shell frames have larger scantlings. The same applies for tank top plating if discharging is by means of heavy crabs. Bracket Hopper tank Sloping Hopper tank sloping plating longitudinal Double bottom tank Bottom side girder Side shell longitudinal Inner bottom longitudinal Bottom center girder Inner bottom plating (Tank top) Bilge plating Bilge Keel Bottom longitudinal Hopper tank Bottom shell plating Floor Keel plate [Ref. 13] HULL NOTES 29 30 HATCH COVERS HULL Transverse opening hatch cover OPEN PANELS Longitudinal direction [Ref. 5] Longitudinally opening hatch covers PANELS Hatch coaming brackets Hatch coaming Longitudinal direction [Ref. 4] HULL NOTES 31 [Ref. 10] CONTAINER CARRIER [Ref. 14] Double bottom 32 HULL HULL NOTES 33 Water ballast The membrane type tank is based on having a thin membrane supported by a layer of insulation within the confines of the ship’s hull. Saddles Aluminium alloy tank plating [Ref. 10] CARRIER Insulation Cargo temp below -100 o C Protective steel Dome GAS Types A, B and C tanks are known as independent tank types, categorised in accordance to their design pressure. They are completely self supporting and do not form part of the ship’s hull. 34 HULL HULL NOTES 35 Retractable Stabilizer Fin P&S Inner ramp to lower car deck [Ref. 10] Bow Thrusters PASSENGER FERRY Stern Ramp Inner ramp to upper car deck Main Deck (Garage Deck) Bow Door & Ramp 36 HULL HULL NOTES 37 38 OCEAN GOING TUG BOAT Propeller fitted in Kort nozzle Towing winch HULL Bow Thruster [Ref. 5] Towing Hook Towing wire HULL NOTES 39 Floor plating End bracket Vertical web cargo tank Bracket toe End bracket S S S Longitudinal bulkhead Face S plating ‘ Web plating ‘ Centerline girder Outboard girder Bilge keel Bilge plating Wing ballast space Side longitudinal Side shell Sheer strake Deck Stringer plate Double bottom ballast space Hopper plating Inner hull longitudinal bulkhead longitudinal Wing cargo tank Inner Hull longitudinal bulkhead Deck longitudinal Deck plating Bottom Keel longitudinal plating Bottom shell plating Inner bottom End longitudinal bracket Inner Bracket bottom toe Centre cargo tank Longitudinal bulkhead longitudinal Cross tie Radius face plate Web Stiffening ‘ [Ref. 15] [Ref. 10] DOUBLE SKIN OIL CARRIER Outboard girder Hopper web plating Horizontal girder in wing ballast tank Vertical Web in wing ballast tank Wing cargo tank Deck transverse Centre cargo tank deck transverse Section x-x 40 HULL HULL NOTES 41 Four stroke Trunk Piston Medium speed engine Range 200 – 850 rpm Reduction Gear Box required Type [Ref. 16] Crankcase inspection doors TYPICAL ENGINES FOR PROPULSION Two stroke Crosshead Type Slow speed engine Range 80 – 180 rpm Crankshaft Connecting Rod Crosshead Piston Rod Piston Turbocharger 42 MACHINERY MACHINERY NOTES 43 44 CROSSHEAD TYPE ENGINE PARTS MACHINERY Cylinder block Engine frame Crankcase inspection doors Main Bearing Keep Bed plate Crankshaft line [Ref. 17] MACHINERY NOTES 45 46 CROSSHEAD TYPE ENGINE PARTS MACHINERY ` Piston rings Piston Cylinder liner Piston grooves Stuffing box [Ref. 18] Piston rod Crosshead pin Crosshead bearings Sliding shoes Connecting rod Crosshead assembly Stuffing box unit [Ref. 16] Crankshaft MACHINERY NOTES 47 Lube Oil suction Camshaft Lubrication [Ref. 16] ENGINE Lube oil first enters the main bearing journals, then to crankpins, then through connecting rod to Gudgeon pin and piston / liner Lube Oil Filter Camshaft TRUNK PISTON TYPE – V- Lube oil Cooler Oil Pump Pressure Reduction Valve Lube Oil to rocker arms Cylinder Cover (Head) 48 MACHINERY MACHINERY NOTES 49 50 TRUNK PISTON TYPE – V- ENGINE PARTS MACHINERY Slave piston Master piston Master and slave piston articulated Type joint Two connecting rods on one crank pin [Ref. 16] MACHINERY NOTES 51 TYPICAL PISTON & CRANKSHAFT ARRANGEMENT 52 MACHINERY [Ref. 20] Piston rings Piston Gudgeon pin Connecting rod top end Gudgeon pin bearing Connecting rod Thrust pads Bearing shells Crankpin Connecting rod big end Big end bearing keep Main Journal Timing gear MAIN BEARING SHELLS [Ref. 19] MACHINERY NOTES 53 CAMSHAFT CAMS CAMS CAMSHAFT driving gear [Ref. 16] 54 CAMSHAFT ARRANGEMENT MACHINERY MACHINERY NOTES 55 56 TURBOCHARGER MACHINERY Compressed air outlet – into the Engine Engine Exhaust gas inlet Engine Exhaust gas outlet Turbine wheel Compressor wheel Air Inlet Filter Air Inlet Turbocharger rotational speed up to 20,000 rpm [Ref. 20] MACHINERY NOTES 57 ENGINE SCAVENGE AIR & EXHAUST ARRANGEMENT 58 MACHINERY Rocker arm Exhaust to chimney Exhaust valve Protection grids Push rod Air Cooling water space Turbine wheel Cylinder liner Exhaust gas Compression wheel Compressed air Piston Scavenge air inlet ports Intercooler Scavenge manifold [Ref. 16] MACHINERY NOTES 59 60 PROPELLERS & TAILSHAFT MACHINERY FIXED PITCH PROPELLER Propeller Adjusting Ring For Alignment Aft Seal Aft Bulkhead Stern Frame Fwd Seal Coupling Rope Guard Propeller Shaft Stern Tube Aft Bearing Stern tube Fwd Bearing Stern Tube [Ref. 19] CONTROLLABLE PITCH PROPELLER Propeller rotating blade Moving piston Hub body Blade carrier Tail shaft Piston rod Crankpin of blade carrier [Ref. 21] MACHINERY NOTES 61 Outlet Reversing Bucket Pump impeller Shaft & Bearing Steering hydraulic rams Duct Suction WATER JET THRUSTERS [Ref. 22] Rotation is one direction Reversing is by change of flow via vertical movement of bucket Steering is by side way movement of outlet nozzle Flange connection to hull Inlet duct optimized for each type of vessel 62 MACHINERY MACHINERY NOTES 63 64 STEAM TURBINE MACHINERY Steam outlet Steam Valves Steam Inlet Turbine Upper casing Rotor shaft with Blades Glands Fixed blades (Nozzles) Turbine Lower Casing [Ref. 23] MACHINERY NOTES 65 VERTICAL OIL FIRED & COMBINED BOILER 66 Engine exhaust inlet MACHINERY Engine Exhaust Outlet Hot Gas Burner Burner Vertical water tubes [Ref. 24] MACHINERY NOTES 67 68 REFERENCES 1. The Royal Yachting Association. (1988). Day skipper Shore Based course notes. Hampshire: RYA 2. Stormfax Weather Almanac (2010). Beaufort Wind Scale [Online]. Available from http://www.stormfax.com/beaufort.htm. [Accessed on 7th December 2010] 3. MAN B&W Diesel A/S. Propulsion trends in container vessels. [Online]. Available from: http://www.manbw.com/files/news/filesof4672/P9028.pdf. [Accessed 7th December 2010] 4. Kolliniatis, I. (2001). Naval Architecture. Athens: Evgenides’ Institution 5. Taggart R. (Editor) (1980). SNAME-Ship Design and construction. New York: The society of Naval Architects and Marine Engineers. 6. Transportation Safety Board of Canada (2009). Marine reports – 2007 – M07L0040 [Online]. Available from http://www.tsb.gc.ca/eng/rapportsreports/marine/2007/m07l0040/m07l0040.asp. [Accessed 3rd November 2010] 7. Rolls Royce plc. (2010). Rotary vane RV/IRV steering gear [Online. Available from: http://www.rolls-royce.com/marine/products/stabilisation_manoeuvring/steering_gear/rv_irv/. [Accessed: 2nd November 2010] 8. McClain R. Photography website - Nautical Sailing Terms & Nomenclature[Online]. Available from http://www.photographers1.com/Sailing/NauticalTerms&Nomenclature.html. [Accessed 9th November 2010] 9. Marine Hub (Marinehub group). Marine and Offshore Equipment systems – Technical book. Singapore: Marinehub group 10. Tupper, E. (2004). Introduction to Naval Architecture. 4th Edition. Great Britain: Elsevier Butterworth Heinemman 11. Kaupp R. (2006). Wikimedia commons website - File:Bulk carrier general arrangement english.png. [Online]. Available from: http://commons.wikimedia.org/wiki/File:Bulk_carrier_general_arrangement_english.png. [Accessed 8th November 2010] 12. British Maritime and Coastguard agency (MCA),(1999). Marine guidance note MGN107(M) - The Merchant Shipping (Carriage of Cargoes) Regulations 1999 [Online]. Available from http://www.mcga.gov.uk/c4mca/mgn107.pdf [Accessed 7th November 2010] 13. Eyres, D.J. (1978). Ship Construction. 2nd Edition. London: Heinemman 14. British Association of Cargo Surveyors (1999). Lloyd’s survey handbook. London: LLD Defence Publishing 15. ABS (2003). Surveyor’s glossary – Hull terms & Hull survey terms – Recommendation 82. American Bureau of Shipping 16. Vousouras, E. (1994). Internal Combustion Engines. Athens 69 REFERENCES 17. Woodword D. (Editor) (2004). Pounder’s Marine Diesel Engines and Gas Turbines. 8th Edition. Great Britain: Elsevier Butterworth Heinemman 18. Wartsila Corporation. (2004). Sulzer RTA84T. [Online]. 2004. Available from: http://www.wartsila.com/Wartsila/global/docs/en/ship_power/media_publications/brochures/ product/engines/low_speed/rta84t_tr.pdf. [Accessed 3rd November 2010] 19. Mostratos K.A. (2005). Ships and technique. Volume II (Engine room). Piraeus: Emmanuel Stavridakis Technical publications 20. Knak, C. (1990). Diesel Motor Ships Engines and Machinery. Volume II (Diagrams). London: The Institute of Marine Engineers 21. Ulstein Propulsion AS – Ulstein propulsion marketing leaflet. Ulstein propellers. Norway: Ulstein propulsion AS 22. Rolls Royce plc. (2008). Introduction of the new Rolls-Royce range of waterjets – Kamewa S3. [Online]. 2008. Available from: http://www.rollsnd royce.com/Images/RR%20Kamewa%20S3_0908_tcm92-8663.pdf. [Accessed: 2 November 2010] 23. McClearn S. (2006). The Canadian Navy of yesterday and today – Tribal Class Machinery (Draft). [Online]. Available from http://www.hazegray.org/navhist/canada/systems/propulsion/haida/haida-turbine-diagram.jpg. [Accessed 11th November 2010] 24. Daniel, J. & Mimikopoulos, K. (1994). Marine Steam Boilers. Athens: Evgenides’ Institution NOTES 70 NOTES 71