Fire Apparatus Driver / Operator

advertisement

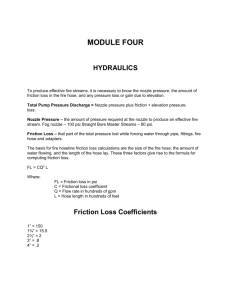

Fire Apparatus Driver / Operator - Engine Qualification Handbook Engines 2801 & 2811 General; • All East Dover Fire Company and Toms River Township Guidelines, Policies, and Requirements shall be met prior to qualifying as a fire company driver/operator – Engine. • Prior to operating Fire Company vehicles, the prospective fire apparatus driver / operator shall meet the performance requirements as it relates to all hand tools and equipment of that vehicle. This shall include the ability to know, use, recognize, and to correct and/or report deficiencies found on all hand tools and equipment. • All Danger, Warning, and Caution placards and indications will be heeded in all cases. These situations will be marked by the placards below: Requisite Knowledge – The apparatus operator must know how to: • Hydraulic calculations for friction loss and flow using estimation methods to determine pump discharge pressures for safe operations of handlines, fixed suppression systems, relay pumping and supplying master streams . • Equipment assembly procedures for all hose, nozzles, and appliances including foam devices. • A thorough understanding of the streets and neighborhoods in the East Dover area, as well as an operational knowledge of the main primary and secondary streets in the remainder of Toms River and our primary mutual aid areas (Island Heights, Seaside Heights, Lavallette, and Seaside Park). • A thorough understanding of firefighting strategies and tactics as it relates to proper apparatus positioning at the incident scene. • All hose capacities, bed layouts, deployment methods, strengths, and limitations. • Perform the routine tests, inspections, and servicing functions specified in the Driver / Operator Qualification Handbook as set up by this Fire Company by the Authority Having Jurisdiction (AHJ), so that the operational status of your qualification is verified. • Know the proper forms to document inspection and maintenance of Fire Company vehicles. Requisite Skills – The apparatus operator must demonstrate his/her ability to: • Safely and efficiently navigate to, and position an engine at an incident scene in a location that will enable efficient suppression/rescue operations as directed. • Power transfer from vehicle engine from road to pump. • Draft from a standing water source. • Smoothly transition between internal and external water sources. • Assemble hose lines, nozzles, valves, and appliances. • Produce a foam fire stream at proper proportion for the product being applied. • Supply water to fire sprinkler system and standpipe systems, given specific system information so the water supplied to the system is at the correct volume and pressure. INTRODUCTION: • This information is designed to give pump operators a quick and fairly easy process for determining fire ground hydraulics in the field. • Supplying water is a critical part of the control of the fire ground, and the efficient use of this water requires us to maintain appropriate pressures and flow rates. • Remember, like everything else there is an acceptable margin of error. This is because fire service hydraulics is not an exact science. If pressures are within 5 or 10 psi of the required psi, little of the effectiveness is lost. • Gauges are not precise. They vibrate with the engine and two people reading the same gauge will probably read slightly different pressures along with a combination of hose, adaptors and nozzles that are used in departments. • The objective is to enable the pump operator to solve any hydraulic problem within one minute. This, together with fire-ground experience and training, will enable the operator to supply a continuous flow of water at the desired pressure. General Knowledge Run Assignments Pump Type / Size Water Tank Foam Tank Use of Equipment Generator Cab Tilt Knowledge of Equipment on Truck Apparatus Operation Weekly/Check-Out Procedure Engine Start-Up Emergency Lights Cab Controls Driving Capability / Hours Completed Laying of Supply Line(s) Hydraulics Nozzle Types Tip Sizes / GPM Hose Size & Amount Friction Loss Calculations Pump Controls Pumping Pre-Connects Foam Operations Hydrant Operations Drafting Operations Standpipe Operations Sprinkler System Operations Pumping to Ladder Pumping to Another Engine (Relay) Positioning of Apparatus Structure Fires Vehicle Fires Hydrant Spotting Hydrant Spotting Front Suction Hydrant Spotting Side Suction Signatures Fire Fighter:____________________ Officer/Qualifier:_________________ Complete Comments Date(s) Comments ENGINE – 2801/11 INFORMATION SHEET General Manufacture Model Cab Seating Pierce (2801-2010 / 2811-2005) Quantum 8 persons FIREFIGHTING SYSTEM Water Tank Capacity Fill Connection 2801-750 / 2811-1000 Gallons 1 – 2 ½” Left Side Foam Tank (2801 Only) Capacity 30 Gallons Water Pump Type Pump Size/Capacity Waterous - Centrifugal 2000 GPM Foam Proportioning System Type Metering Percentage Husky – Direct Injection Variable Hose 5” 2.5”” 2 ½” Preconnect 2 – 1 ¾” Preconnects 1 – 1 ¾” Bumper Line 1 – 1 ¾” High Rise Pack 1 – 1 ¾” Dead Load 1000’ 500’ 200’ (2801 only) 200’ ea. 100’ 100’ 500’ (2801) / 250’ (2811) Generator Make Rating Harrison 8KW Ladders Construction Extension Ladder Roof Ladder Attic Ladder Aluminum 35’ (2811) / 28’ (2801) 14’ 10’ Command Lite (2801 Only) Model Watts of Light SAFETY SYSTEMS: Both 2811 and 2801 are equipped with numerous safety systems and interlocks to prevent dangerous situations from occurring where possible. These systems include: • Anti-lock brakes • Auxiliary Braking System (Compression or Jake Brake) • Command Zone • Hand and Grab Rails • SCBA Securing Systems • Vehicle Data Recorder (2801 Only) • Seatbelt Indicator (2801 Only) CAB CONTROLS: The following section details the controls inside the cab: Battery Switch (on/off position) Ignition Switch (transmission in neutral , parking brake set to operate) Transmission Control To check oil level depress both arrows once and release. OLOK is full OLTL is not up to temperature. Load Manager • Load manager control – the load manager monitors voltage and turns off loads that are not necessary to maintain adequate voltage on scene. • Load manager takes over at 12.9 volts and will shed loads as needed. • Load manager will turn loads back on if voltage increases. The remaining switch and pump panels are similar on both engines, however the operator / operator in training should get familiar with the location of various control switches in each vehicle on their own. Specific switch panels will not be detailed here, but can be found either by viewing the actual apparatus or the training PowerPoint which goes into more detail. DETERMINING PUMP PRESSURE: In fire ground hydraulics the basic pump pressure formula for a level lay is: Pump Pressure = Nozzle Pressure + Total Friction Loss. This equation is: PP = NP + TFL The pressure registering on the pump pressure gauge will not be the same at the nozzle because energy (pressure) is being used up overcoming friction within the hose. Friction loss is determined by recognizing that water, as a non-compressible fluid, exerts pressure equally against its confining material. Therefore, fluid pressure must be determined as a rate of water flow versus the friction index of the substance it is flowing through. Fortunately, in the case of fire hose, the friction loss rate (FLR) is a simple function of the square of the amount of water flowing. Specifically, the total gallons per minute (gpm) divided by 100 and then squared and then doubled, have been found to be an adequate fire ground formula for computing the friction loss rate in 2 ½” Hose. Similar rules of thumb for field calculation of friction loss in 1 ¾” and 5” hose have been provided during your pump school training. FL = 2Q2 L Where Q = gpm 100 As a pump operator, you must have certain facts to determine pump pressure (PP). These facts are listed in order of importance for calculating the pump pressure: Nozzle Pressure GPM flowing or Size of the nozzles tip Size of hose Length of hose in lay Elevation differential between pump and nozzle Appliance Loss Sprinkler System or Stand Pipe Loss, The first five facts are needed, in all cases, to solve pump pressure. NOZZLE PRESSURE: The next step in the simplification of fire ground hydraulics is to establish nozzle pressures for all nozzle streams. The Fire Service has established the following as the desired Nozzle Pressures (NP): NOZZLE PRESSURE NOZZLE TYPE 50 psi Hand lines with smooth bore nozzles 80 psi Deluge sets, monitor nozzles, or water tower equipped with a smooth bore tip 100 psi All adjustable or fog nozzles 100-200 psi Foam application (Depending on system) 50 psi Low Pressure Fog nozzles SIZE OF HOSE: Fire hose is limited in the amount of pressure it can sustain. Because of this, the maximum pressure we can pump to any given hose is its annual service test pressure. Today there are approximately fourteen different hose sizes used in the fire service. The maximum Pump Pressure for fire hose is: TYPE SIZE COLOR SERVICE PRESSURE & MAXIMUM PUMP PRESSURE Cotton/Rubber Jacket (Wild land) 1 ½” RED/WHITE 300 PSI / 275 PSI RED Synthetic Double Jacket (Attack Line) 1 ¾”, 2 ½” YELLOW WHITE 400 PSI / 250 PSI Rubber Jacket hose (Supply Line) 5” Yellow 200 PSI / 150 PSI Hard Suction 6” CLEAR 150 PSI REMEMBER: When pumping through a combination of hoses, the lowest pressure hose is the determining factor for maximum pump pressure. Tip Sizes / Nozzle Pressures / GPM: SMOOTH BORE TIPS - Hand Lines NP GPM 3/16" TIPS FOR 50 psi 7 1/4" WILDLAND 50 psi 13 3/8" USE 50 psi 30 1/2" 50 psi 50 5/8" 50 psi 80 3/4" 50 psi 120 7/8" 50 psi 160 1" 50 psi 210 1 1/8” 50 psi 270 NP GPM 1 1/8" 80 psi 300 1 1/4" 80 psi 400 1 3/8" 80 psi 500 1 1/2" 80 psi 600 1 3/4" 80 psi 800 2" 80 psi 1000 SMOOTH BORE TIPS - Appliances When calculating gpm round off to the nearest 1 gpm. When calculating gpm round off to the nearest 10 gpm. When calculating gpm round off to the nearest 100 gpm. Hand lines – Multiple 1 ¾” Hose lines: PUMP TO THE HIGHEST LINE AND GATE DOWN THE SECOND LINE * Example: Two 1 ¾” hand lines, one 200’ and 175 gpm, the second is 150’ and 150 gpm. Initial pump pressure - NP = 100 PP = NP + FL (a) PP = 100 + 50 (b) PP = 100 + 27 * PP = 150 psi 2nd or GP = 127 (a) Pump Pressure = 150 (b) Gated Pressure = 127 psi EXAMPLE OF FIRE GROUND HYDRAULICS: DROP 10 METHOD FOR 2 ½ FIRE GROUND CALUCLATIONS The following example will show how fire ground hydraulics is tied directly to written hydraulics: 250 gpm nozzle, 250 gpm setting, 450' of 2 ½" hose, PP =? Initial pump pressure = 100 psi In fire ground hydraulics the pump pressure formula for a level lay using the Drop 10 Method Working this out step-by-step would look like this: Step One: Determine the Nozzle Pressure (NP) for a fog nozzle. NP = 100 psi Step Two: Determine the GPM Flow = 250 gpm Step Three: Drop the last number off = 25gpm Step Four: Subtract 10 from the number = 15 psi per 100 ft GPM = 250 -10 FL = 15 psi PP = NP + TF PP = 100 + 60 PP = 160 psi AFTER 400 GPM THE FORMULA IS NOT ACCURATE EXAMPLE OF FIRE GROUND HYDRAULICS: CONVERTING 3” HOSE RULE OF THUMB METHOD If 300 gpm is flowing from a nozzle. What is the total friction loss for the hose with 2 ½ couplings at 200ft. When using 3“ hose we must know three things We need to know the length of the hose lay, size of the hose and the GPM we wish to flow. To use the 3” Rule of Thumb we take the GPM, drop off the last two digits and square the remaining number. Step 1 : GPM is 300 gpm Step 2 : our new number is now 3 Step 3 : Take 3 and times it by itself gives us 9. So if we flow the 300 gpm through one 3 ” line the our friction loss be 9 psi per 100ft PP= NP + FL PP = 100 + 18 PP = 118 PSI ROUND UP PP = 120 PSI AFETR 800 GPM THIS FORMULA IS NOT ACCURATE EXAMPLE OF FIRE GROUND HYDRAULICS: CONVERTING 5” SUPPLY HOSE RULE OF THUMB METHOD Again we need to know three basic things to supply 5” hose. We need to know length of hose, hose size and gpm to be flowed. We know we can calculate the friction loss for the hose using the formula FL = CQ2 L but we may not know the coefficient to be used and there is a easier way to calculate the friction loss. To calculate the friction loss all you need to do is drop the last two numbers for the desired gpm to be flowed starting at 500 gpm. GPM = Friction loss 500 gpm = 5 psi 1000 gpm = 10 psi 1500 gpm = 15 psi EXAMPLE OF FIRE GROUND HYDRAULICS: Appliances (Heavy Stream) – Apparatus Deck Gun Example: 2” tip from apparatus mounted deck gun, PP =? Initial pump pressure = 80 *ALLOW 15 PSI APPLIANCE LOSS WHEN USING A DELUGE SET OR MONITOR NOZZLE* Step One: Flow = 1000 gpm HINT Nozzle Pressure = 80 DISCHARGE IS DIRECTLY OFF THE PUMP. *Appliance Loss = 15 NO HOSE FRICTION LOSS CALCULATIONS NEED TO BE MADE. PP = NP + AL PP = 80 + 15 PP = 95 psi EXAMPLE OF FIRE GROUND HYDRAULICS: Siamese Lines (Equal Length) Using the Rules of Thumb Example: 1 1/8" tip, 50 psi NP, One 100' lines of 5" hose into two 100' line of 2 ½" hose. PP = ? Initial pump pressure = 50 psi If I know my 1-1/8 tip flows 266 gpm round the number up to 270 gpm. Then take that number to figure out your 2 ½ inch lines by dropping the zero on the gpm and subtract 10 from the number giving me 17 psi per 100 ft for friction loss for the 2 ½ . Now I can calculate the loss for my 5” hose which is 1 after dropping the two zeros. Now all I have to do is add 10 psi for the appliance which gives me my pump pressure. PP = NP + FL in 2 1/2 + FL in 5” hose + Appliance PP = 50 + 17 psi for 2 ½ hose + 1 psi for 5” + 10 psi appliance PP = 71 psi round it up to 80 psi pump pressure ELEVATED MASTER STREAMS: One of the most important uses of an aerial unit is to provide an elevated stream for fire attack and exposure protection. Elevated streams can be effectively directed into or onto the upper portions of tall buildings, which are beyond the reach of ground mounted devices. The ground or apparatus mounted devices are usually only effective to about the third floor. Heavy streams from aerial devices (especially tower ladders) can also be very effective in controlling volume fires on the lower or ground floors. When setting up aerial devices, consideration must be given to wind direction and exposure protection. Officers should anticipate the need for elevated master streams during escalating fires. Consideration should be given to initial truck placement for rescue, ventilation, etc., and the potential need to relocate for master stream operations. If possible, spot the apparatus for current tactical assignments, and future needs. Building collapse may be a possibility, so the truck and personnel should be placed outside the potential collapse zone. Aerial units should be provided with their own supply engine not more than 100 feet from the vehicle. If a hydrant is not available within that distance, another engine should be used to relay water to the unit supplying the aerial. When requesting a truck for master stream operations, consideration should be given to requesting an additional engine to be dedicated to the truck for water supply. At least two 21/2” supply lines or one 5 inch supply line should be used to supply the aerial device. A spotter remote from the turntable may be necessary to ensure the stream is hitting the desired target or opening. When using fog streams, the nozzle should be placed at the center of a window opening and set at a 30 degree pattern. It should be aimed first at the upper part of the room where the concentration of heat is the greatest and then swept downward. When using solid streams, the stream should be placed so that it enters the windows at an upward angle. This will allow the stream to strike the ceiling, break up and spread water over a wide area. An improper entry angle will result in loss of penetration into the building. An incorrectly used aerial stream can cause unnecessary property loss and injury to firefighters and possible collapse of the fire building. The 2 most common errors are directing streams through roof ventilation holes and directing them toward firefighters advancing interior handlines. There are 5 factors that will determine the correct pump pressure when pumping a ladder pipe. 1. Nozzle Pressure (depending on type of nozzle used) 2. Friction Loss in hose going to aerial ladder 3. Friction Loss in ladder and siamese 4. Elevation Loss due to height of ladder 5. Friction Loss in hose between siamese and pumper. For fireground operations, 150 psi as the siamese can be used as a starting pressure; however, the proper operating pressure should be determined as soon as possible, to ensure adequate nozzle pressure and reach and if the engine supplying the aerial will be doing the work or will be using the aerial ladders pump. Collapse Zone Or 1 ½ x’s the height of the building APPLIANCES (HEAVY STREAM): Example: 1 ¾" tip, ladder pipe elevation, 70' up, 200' of 5" hose line is supplying the ladder. What is the pump pressure to feed the ladder ? Step One: 1 ¾” tip @ 80 psi Flow = 800 gpm Rule of Thumb FL = through 5" hose = 8psi per 100 ft Step Two : PP = NP + FL + EL PP = 80 + 16 + 35 PP = 96 + 35 PP = 131 psi or 130 psi Standpipe Operations; Standpipe operations involve many factors, to include the friction loss in the standpipe. In layouts involving hose lines and building systems, the pump pressure must be sufficient to: 1. 2. 3. 4. 5. Overcome friction loss in the attack line Provide the proper nozzle pressure Overcome the elevation loss in the standpipe Overcome the friction loss in hoselines to the siamese Overcome the friction loss in the siamese, standpipe, and riser valve There are long hydraulic formulas for figuring friction loss in risers, siamese connections and hose outlets but they are not practical for fireground operations. Therefore, a quick and easy method can be adopted as follows: Standard Pump Pressure for standpipes is 150 psi + 5 psi/floor above the siamese + the friction loss in the hose lines to the siamese (which is usually very minimal). Maximum pump pressure is 200 psi. DO NOT COUNT THE FIRST FLOOR! EXAMPLE: Fire Reported on 5th Floor 150 + 20 (4 floors above siamese x 5) = 170 psi Pump Pressure EXAMPLE: Fire Reported on the 9th Floor 150 + 40 (8 floors above siamese x 5) = 190 psi Pump Pressure EXAMPLE: Fire Reported on the 18th Floor 150 + 85 (17 floors above the siamese x 5) = *235 Pump Pressure *Pump Pressure above 200 psi is unsafe operating pressure.* This procedure will ensure proper NP for the various high-rise packs used. EXAMPLE 1: 150' of 1 ¾ " Hose flowing with 15/16 tip 185 gpm 50 psi NP 50 FL in Hose 10 FL in Standpipe & Gated Wye 150 psi plus 5 psi/floor above the Siamese EXAMPLE 2: 150' of 1¾" Hose with TFT flowing 150 gpm 100 psi NP 50 FL 10 FL in Standpipe & Gated Wye 150 psi plus 5 psi/floor above the Siamese Sprinkler System: Example: Twenty heads are fused on the 8th floor; sprinkler system is supplied by two 500' lengths of 2 1/2" hose. PP = ? Initial pump pressure = Maintain 150 psi at the pump until proper pump pressure can be determined. IN RAPID METHOD HYDRAULICS ALLOW 30 GPM PER SPRINKLER HEAD.* IN RAPID METHOD HYDRAULICS 25 PSI CAN BE CONSIDERED AS EFFECTIVE SPRINKLER NOZZLE PRESSURE.** ALLOW 25 PSI LOSS FOR SPRINKLER SYSTEM (SPR. L)*** ALLOW 5 PSI PER FLOOR FOR GRAVITY LOSS, INCLUDING THE FIRST FLOOR.*** Sprinkler System: Step One: Flow = 30* x 20 Flow = 600 gpm Flow through one line = 600 2 Flow through one line = 300 gpm Step Two: FLR = 2Q2 FLR = 2 (gpm)2 100 FLR = 2 (300)2 = 3 100 FLR = 2(3)2 FLR = 2 x 9 = 18 FLR = 18 psi Step Three: L = total feet 100 L = 500 100 L=5 Step Four: TFL = FLR x L TFL = 18 x 5 TFL = 90 psi Step Five: **GL = 5 x 8 GL = 40 psi PP = NP** + TFL + Spr. L*** + GL**** PP = 25 + 90 + 25 + 40 PP = 180 psi WATER HAMMER