NOVEMBER/

DECEMBER 2015

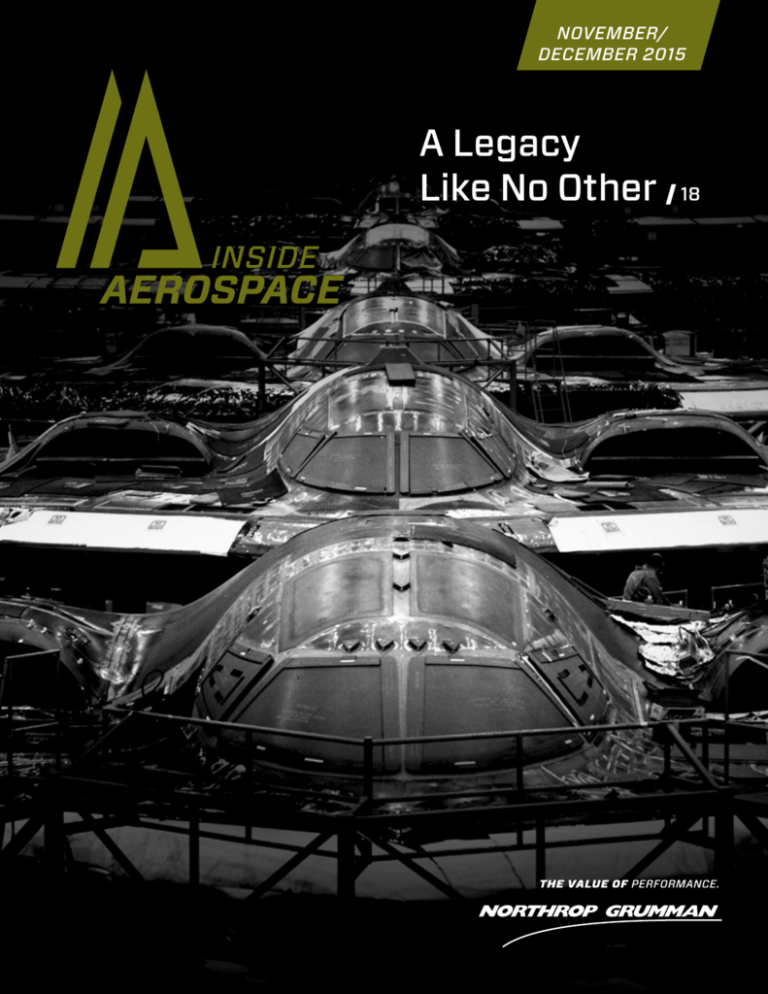

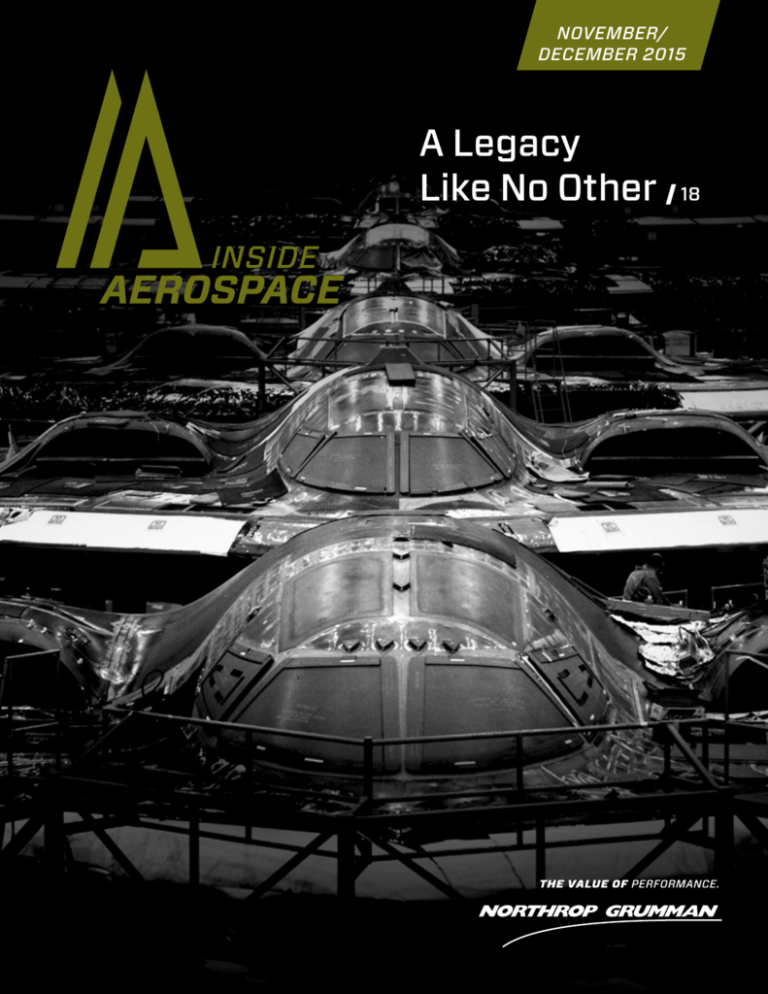

A Legacy

Like No Other

18

FUTURE

WHEN THE WORLD CALLS FOR THE

©2015 Northrop Grumman Corporation

PERSPECTIVES

OUR YEAR

CONTENTS

5

PERSPECTIVES

6

HEADLINES

8

HERITAGE

10

PERFORMANCE

18

COVER STORY

A View from Leadership

Northrop Grumman in the News

Milestones in Northrop Grumman History

Products and Program Updates

A Legacy Like No Other

20

INGENUITY IN ACTION

22

ACROSS THE SECTOR

30

COMMUNITY

Our Latest Innovative Solutions

You Make A Difference

COVER STORY

“Our team has the resources in place

to execute this important program,

and we’re ready to get to work.”

—Wes Bush, chairman, chief

executive officer and president

of Northrop Grumman

Palmdale, Calif., home of the legendary B-2

stealth bomber, a key component of the

nation’s long-range strike arsenal and

one of the most survivable aircraft in

the world. Tom Vice

Corporate Vice President and President, Northrop Grumman Aerospace Systems

This has been an incredible year.

I am in awe of what we have

accomplished together. What

began as a year of LIMITLESS

possibilities has concluded as

one of amazing achievements.

We have created a culture that

thrives on innovation, invention

and creativity. Our culture has

fueled our success on so many

levels, in countless domains.

amazing time machine, the

James Webb Space Telescope.

Our Global Hawk team has made

tremendous strides in operational

performance shattering cost

curves in the process, as well as

collecting prestigious accolades

along the way including the

James Roche Sustainment

Award — winning this for a

record third time!

These are historic accomplishments.

We embarked on this journey with

a bold strategy. And, our strategy

is working.

We have ignited new ways of

thinking — initiatives like Busting Bureaucracy, NG NEXT,

and NEST for ourselves, for

our customers, for our future.

We celebrated top industry

honors from Aviation Week’s

Program Excellence awards

for our Protected Satellite

Communications Payloads

Orbital Operations and the

X-47B program teams.

You are an amazingly gifted team.

We have achieved what many

thought impossible.

We have grown globally with

successful captures in Japan

and the Republic of Korea with

franchise programs — the E-2D

Advanced Hawkeye and the

RQ-4 Global Hawk. We received

notification of a sole source

contract for AMP-2, completed

the operational assessment of

the MQ-8C Fire Scout, won two

contracts in directed energy

and demonstrated autonomous

aerial refueling with an unmanned

system — the incredible X-47B

unmanned combat air system.

We made great progress across

our broad space portfolio —

making advances in Advanced

EHF and remaining on track for

a 2018 launch for the world’s

We are leaders — number one in

Space, number one in Unmanned

Systems and number two in Manned

Aircraft. And we are continuing to

innovate and invest for export to

expand our global operations.

And think about this, we’ve only

just begun.

We are shaping wins for the

Joint STARS recapitalization,

unmanned carrier-based strike

system, and the Trainer-X

programs, and launching

new captures for the U.S. Air

Force’s and U.S. Navy’s next

generation fighters.

Our investment in basic and

applied research will drive new

technology advancements for

future systems.

And, we won the contract for the

nation’s critical new Long-Range

Strike Bomber.

INSIDE AEROSPACE

NOVEMBER/DECEMBER 2015

5

32

HEADLINES

Protected Satcom,

UCAS-D Win Aviation

Week Awards

Sector Vice President, Communications

Cynthia Curiel

Director, Enterprise Communications

Cyndi Wegerbauer

Manager, Employee Communications

Ann Akutagawa

Executive Editor

Kathy Ford

Managing Editor

Linda Javier

Creative Director

Adam Ugolnik

Art Director

Antoinette Bing Zaté

Advertising Director

Darrell Brock

Contributors

Ann Carney, Tom Henson, Linda Javier,

Sally Koris, Brooks McKinney, TJ Ortega,

Bonnie Poindexter, Alan Radecki,

Celina Ramirez, Mark Root

Editorial Board

Jessica Burtness, Alex Evers, Steve Fisher,

Kathy Ford, Linda Javier, Sally Koris,

Christina Thompson, Katherine Thompson,

Adam Ugolnik, Antoinette Bing Zaté

Inside Aerospace magazine is published

for employees by Aerospace Systems

Communications. Archives are available

on the intranet. Please contact Kathy Ford

(kathleen.ford@ngc.com) for permission to

reprint, excerpt material, request additional

copies, or to provide story ideas.

All photography courtesy of Northrop Grumman

unless otherwise indicated.

Inside Aerospace

© 2015 Northrop Grumman Corporation

All Rights Reserved. Printed in USA

6

32

The Palmdale Aircraft Integration Center of Excellence is the first aerospace

manufacturer in the country to be a certified Zero Waste facility.

Dr. Sudhakar Rao wears the Professor S.N. Mitra memorial medal presented to him in

India for his pioneering work in multi-beam payload technology.

Photo by Alan Radecki

Photo by Alex Evers

Palmdale First Zero

Waste Facility

Being the first in the nation to

reach a goal designed to help

the environment is quite an

achievement. And that lofty

challenge was recently met by

the Palmdale Aircraft Integration

Center of Excellence (CoE).

In September, the CoE was

recognized at a ceremony by

the United States Zero Waste

Business Council for being the

first aerospace manufacturer in

the country to be a certified Zero

Waste facility. By diverting 90

percent of its waste from landfill,

incineration and the environment,

the CoE took a strong stand and

set an outstanding example.

Local public officials and media

joined Palmdale, Calif., employees at the ceremony, where

Andy Reynolds, vice president,

Manufacturing Operations and

Palmdale site manager, was

presented the Silver Zero

Waste certification and plaque.

In accepting the award, Reynolds

remarked, “We want to be good

stewards of the environment.

We realize the importance of that

opportunity and responsibility.”

INSIDE AEROSPACE

“Northrop Grumman is a great

example of what type of impact

we can make,” said Palmdale City

Mayor Jim Ledford, “not only in

our own neighborhoods, but for

the environment.”

— Celina Ramirez

Rao Receives India’s

Top Technology Award

Dr. Sudhakar Rao, Northrop

Grumman Fellow in Engineering’s Electronics and Payloads

directorate, was honored in

September by the Institution of

Electronics and Telecommunication Engineers (IETE), India’s

top professional society for

the advancement of science

and technology in electronics,

telecommunication and information technology.

Dr. Rao received IETE’s prestigious

Professor S.N. Mitra Memorial

Award for his pioneering work

throughout his career in multibeam payload technology using

high gain multiple spot beams

for military and commercial

communications satellites.

Dr. Rao’s design, analysis and

development methods power

more than 65 communications

satellites in use worldwide,

including high capacity satellites

NOVEMBER/DECEMBER 2015

with more than 100 GHz capacity

for personal communications.

of the Society of Women Engineers

(SWE) held in Nashville, Tenn.

“This is the best and most

meaningful award among those

I’ve received,” said Dr. Rao. “It

was wonderful to have my wife

by my side as I was honored in

my birth country. It was also very

special to reunite with classmates

and inspiring professors whom I

have not seen in 40 years since

relocating to the United States.”

SWE awards recognize individuals

who enhance the engineering

profession through contributions

to industry, education and the

community.

An originator and master innovator, Dr. Rao holds 44 U.S. patents

related to satellite antennas,

payloads and high-power test

methods and has published

165 technical papers and three

textbooks on his expertise. From

television viewers and Internet

users to soldiers on the battlefield,

people around the world directly

benefit from Dr. Rao’s technical

innovations.

— Bonnie Poindexter

Petryszyn, Medalle

Honored at SWE

Conference

Two Northrop Grumman leaders,

Mary Petryszyn and Katherine

Medalle received awards in

October at the annual conference

Petryszyn, Aerospace Systems

vice president, global strategy

and mission solutions, received

the Global Leadership Award

for outstanding contributions

in engineering and technical

management in an international setting.

A fellow life member of SWE,

Petryszyn serves on the SWE

Corporate Partnership Council.

In 2005, she received the SWE

Upward Mobility Award for her

contributions to the engineering field.

Medalle, Electronic Systems

director of airborne tactical

sensors product support,

received an Emerging Leader

award for her active engagement

in engineering and outstanding

technical accomplishments. She

is responsible for international

and domestic customer support

and sustainment of a Northrop

Grumman sensor providing mission

critical support to customers.

— Mark Root

Two Northrop Grumman

programs—Protected Satellite

Communications Payloads

Orbital Operations and Unmanned

Combat Air System Demonstrator

(UCAS-D)—received Program

Excellence awards from Aviation

Week in November. The awards

celebrate the “best of the best

programs” that are delivering

results and finding new ways to

be more innovative, efficient

and better at delivering value

to customers.

Northrop Grumman has built

and sustained protected satellite

communication payloads for more

than 21 years. Collectively, the

payloads have provided more

than 750,000 hours of service

with more than 99 percent

availability in operational service.

The program is led by Peggy Paul,

the first program manager in

the history of the Aviation Week

Program Excellence Awards to win

twice. The magazine recognized

Paul and the Defense Support

Program team in 2007.

The U.S. Navy UCAS-D/Northrop

Grumman team, led by program

manager Pablo Gonzalez, won

for performing the first ever

autonomous aerial refueling of an

unmanned aircraft demonstrating

the system’s capability of extended

range and endurance.

— Sally Koris and TJ Ortega

7

32

HERITAGE

1943

By Alan Radecki

A LOOK BACK AT GRUMMAN ON LONG ISLAND

President and CEO Wes Bush

recently announced Northrop

Grumman’s realignment of its

operating sectors, which will

move the legacy Grumman facility

at Bethpage, Long Island, N.Y.,

from Aerospace Systems to the

new Mission Systems sector in

early 2016. Inside Aerospace would

like to pay tribute to the legacy of

these sites.

Although the Long Island presence

of Grumman started at the beginning of 1930, the company hit

its stride during World War II

when a number of additional

plants opened to handle the

wartime workload.

A 1940’s aerial view looking northwest at the Grumman Bethpage airfield.

Photo courtesy of Paul Freeman, www.airfields-freeman.com

This set of color images from a 1943 Grumman calendar

gives a rare glimpse into what it looked like during the

peak of Grumman’s wartime production.

32

April 1937 saw Grumman, which had

grown to 350 employees, arrive at its

new home in Bethpage, Long Island,

with the opening of Plant 1. Many

of Grumman’s legendary aircraft,

starting with the F-4F Wildcat, were

born at this Bethpage plant.

The Babylon plant produced the

wiring harnesses used in all of

Grumman’s aircraft. The original

caption for this photo reads, “A

hundred women set up the electric wires for Grumman planes. They

plot the path of every electric impulse right up to the trigger-switch.

They are truly the women behind

the man behind the gun.”

Grumman’s success led to rapid

growth and the need for a bigger

facility, and the abandoned Curtiss

Airport at Valley Stream was ideal.

Here, Grumman’s first retractable

gear fighter, the JJ-1, was born.

8

THREE CENTS

The Amityville Plant 12 was home to

the Grumman War Production Corps

and specialized in parts to support

the production of the F-4F Wildcat

fighter.

INSIDE AEROSPACE

NOVEMBER/DECEMBER 2015

9

32

IT’S IOC FOR

AEHF

By Sally Koris

The announcement by U.S. Air Force

General John E. Hyten, Commander of

Air Force Space Command, in July that

the Advanced Extremely High Frequency

(AEHF) satellite system had achieved

Initial Operational Capability (IOC) marked

the culmination of years of hard work

by employees throughout the sector to

deliver a new capability to the warfighter.

The AEHF Flight 3 satellite being

encapsulated for placement atop an

Atlas V launch vehicle.

Photo courtesy of Lockheed Martin

Word spread quickly among the

hundreds of employees on AEHF

who are building the payloads

and associated systems as well

as among the alumni of Milstar,

its predecessor program and

earlier programs that built the

sector’s MILSATCOM heritage

and capabilities.

“Drawing on two generations of

Milstar expertise, developing

10

32

AEHF payloads has had a profound impact on the sector,” said

Peggy Paul, director, Protected

Satcom Orbital Operations. “It’s

helped to build our unique skills

and technology base, created

a cadre of leadership that has

strengthened the sector and

the company, produced valuable

intellectual property and patents,

and contributed to the company’s

financial returns.”

AEHF delivers the critical strategic

and tactical information to the

National Command Authority

and the Air Force, Army, Navy,

Marines and several allied nations.

The system delivers the flexible

connectivity-on-demand needed to

achieve swift, decisive outcomes

based on information dominance.

The company produces the

Extended Data Rate (XDR)

payloads on AEHF in addition to

the Low Data Rate and Medium

Data Rate payloads on AEHF and

its predecessor system, Milstar,

for prime contractor Lockheed

Martin. Each AEHF payload

consists of processor hardware

and software, antennas, radio

frequency subsystems and

crosslinks. The payload provides up

to 10 times greater capacity than

its predecessor Milstar II and channel data rates six times higher.

Achieving IOC means the AEHF

system demonstrated that it meets

its requirements—transmitting

critical information, text, voice,

video, maps and other strategic

and tactical data to users

PERFORMANCE

worldwide with communications

that are protected against enemy

jamming, spoofing, detection

and interception.

Complex tasks had to be performed leading up to IOC: AEHF

satellites had to be designed,

built and launched; the satellites

had to be integrated with, and

fully backward compatible with

the existing Milstar system; the

mission control element had to be

upgraded to handle XDR data; and

fixed and mobile terminals had to

be modified or built to handle the

new XDR capability.

“AEHF is the most advanced and

complex communication payload

in the world and provides U.S.

national and defense leaders

assured communications day

or night, without detection or

interception under any level of

military conflict,” said Tim Frei,

vice president, Communication

Systems.

“It took the work

of a committed and

talented government

and industry team

to bring AEHF to

IOC. We are proud

of our contributions

to this system.”

waveform design, and onboard

software-based communication

networks.

/ Innovative approaches were

developed for building and

operating the payloads using

high fidelity engineering test

beds to realize cost, schedule

and risk reduction benefits

throughout the program’s

life cycle.

/ Engineering and software experts

continue to provide support to

operational users, leveraging

highly specialized skills devel oped during design, production

and ground test.

/ The team made technical

advances and innovations

across the company’s portfolio

and industry that have enabled

the sector to expand into

adjacent business areas,

such as Low Cost Terminals,

Enhanced Polar System

payloads, and several

restricted programs.

/ Awards in recognition of

achievements have been

received from sector,

company and external

organizations.

/ The most knowledgeable

personnel from Milstar were

used, with direct experience in

the development, ground test

and operations of the payloads,

to help with the ongoing AEHF

payload production effort.

/ All four payloads were delivered

early, before their scheduled

delivery date.

Four AEHF payloads have been

delivered and two more are

well into production. Among

the many accomplishments

on the AEHF program:

/ New capabilities were

established for space-based

signal and data processors,

low-noise high frequency

electronics, 60 GHz crosslinks,

phased array antennas,

protected communications

INSIDE AEROSPACE

NOVEMBER/DECEMBER 2015

11

32

PERFORMANCE

OKLAHOMA

KEEPS THE B-2 OK

By Brooks McKinney

In July, Aerospace Systems used a B-2 bomber

flight demonstration at Edwards Air Force Base

to highlight Northrop Grumman’s leadership in a

new U.S. Air Force architectural standard called

Open Mission Systems (OMS).

Underpinning that success was a

concentrated effort by the sector’s

B-2 team in Oklahoma City. In

just six weeks, they developed,

integrated, tested and delivered

to Edwards Air Force Base (AFB) a

stand-alone subsystem that would

allow the B-2 to communicate with

other OMS-compliant systems. In

the past, such an engineering task

would have taken many months, if

not years, to achieve.

powerful, most revered weapon

system in the nation’s long-range

strike inventory.”

“The successful B-2 OMS flight

tests proved two important things

about our company,” said Pat

McMahon, sector vice president

and general manager, Military

Aircraft Systems. “One, that we’re

well positioned to develop and help

deploy OMS-compliant systems on

both legacy and future systems;

and two, that our Oklahoma City

employees play a pivotal role in the

success of the B-2 as the most

The team provides engineering

and support services for B-2

sustainment and modernization.

Its sustainment tasks include

hardware and software sustaining

engineering—helping the Air Force

troubleshoot hardware or software

glitches on the jet, managing

inventories of consumable materials used to maintain the B-2,

and helping identify and acquire

adequate stores of replacement

12

32

Aerospace Systems’ presence

in Oklahoma City comprises

approximately 350 employees,

all of them supporting B-2, spread

across 255,000 square feet of

office, engineering and laboratory

space in facilities on or near

Tinker AFB.

The Autonomy Challenge winning team.

Photo by Dave Buchanan

parts for B-2 avionics that have

become obsolete.

integration and testing of new

avionics subsystems.

“We work closely with our U.S.

government counterparts at Tinker

to manage and help resolve the

logistic challenges of sustaining

a low density, high demand fleet

of 25-year-old aircraft,” said Mark

Johnson, Aerospace Systems’

director of B-2 product support.

The WSSC includes facilities that

duplicate the characteristics and

operational behavior of the jet—

among them a full motion B-2 flight

simulator, a mock B-2 weapons bay

and a full scale mock-up of the B-2

hydraulic flight control system.

Oklahoma City is also the gateway

to B-2 modernization. Every new

capability proposed for the jet

begins life in a government facility

at Tinker called the Weapon

Systems Support Center (WSSC).

There, in a series of laboratories,

Aerospace Systems employees

pursue B-2 engineering activities

such as software development,

defining and testing new ways to

deliver weapons, and complete

“In the WSSC, we stage, integrate

and test all of the software and

hardware required for every

proposed B-2 upgrade,” explains

Ron Naylor, Aerospace Systems’

Oklahoma site lead and director of

B-2 modernization. “Our integration process includes rigorous

hardware/software compatibility

testing, functional testing, and a

thorough government vetting and

certification process. Only then is

each upgrade formally released

and delivered to Edwards AFB for

flight testing.”

Oklahoma City employees are

invested not only in the future of

the B-2, but also in the future of the

company and their community.

“The aerospace community in

Oklahoma City is small, but very

tight-knit,” says Naylor. “Through

Connect1NG, our employees support

both urgent and ongoing community

needs. They’re as likely to be found

helping provide disaster relief after

a tornado or wildfire, as delivering

supplies to a women’s shelter,

running a blood drive, or manning

an aid station at the Oklahoma

City Marathon.”

Oklahoma City employees can

also be found at home working

on Northrop Grumman’s “next

big thing.” In October 2014, and

again in April 2015, a team of local

engineers—Steven Adams, Matt

Blair, Zachary Dennis, and Jeremy

INSIDE AEROSPACE

Lakes—took top honors in the

sector’s Autonomy Challenge, an

engineering competition designed

to develop software algorithms

for fleets of autonomous iRobots

engaged in missions of interest

to Northrop Grumman and its

customers.

“I’m proud of all the

things our Oklahoma

City employees

have achieved by

partnering with our

U.S. government

stakeholders,” adds

Naylor. “The team is

doing amazing work,

both in the community

and around the world.

NOVEMBER/DECEMBER 2015

13

32

PERFORMANCE

THE

CHOICE

IS YOURS

By Bonnie Poindexter

What better way to select top performers than by

asking employees themselves to choose individuals

on their teams who are demonstrating the best of

the best.

That’s what the Engineers Choice

Awards is all about.

Engineering and Global Product

Development’s (E&GPD) peerrecognition program identifies

and celebrates individual engineering employees as well as

engineering teams for exemplary technical accomplishments

and demonstration of leadership, innovation, affordability,

collaboration and execution

of key objectives.

“Game changers” is how Stuart

Linsky, sector vice president,

Engineering and Global Product Development, described

Aerospace Systems engineers in

his opening remarks as host of the

company’s third annual Engineers

Choice Awards luncheon held in

November in Marina del Rey, Calif.

“The work we do in engineering

helps preserve freedom. People’s

lives depend on our performance,”

said Linsky. “That is an incredible

responsibility in which we all

take great pride. The Engineers

Choice Awards recognize our

employees’ exemplary engineering

performance, often demonstrated

under great challenge and with

high levels of scrutiny.”

Linsky recognized 39 winners with

trophies and special prizes during

the luncheon. Attendees spent

valuable time networking with

sector and Engineering leadership.

So, how do you earn an Engineers

Choice Award?

E&GPD employees nominate

individuals and/or teams in a

variety of award categories within

each Engineering directorate

in July. Engineering leadership,

including Distinguished Technical

Leaders and Chief Engineers,

review the submissions and

select up to three finalists in each

category. Finalists are announced

and E&GPD employees vote online

to determine the winners.

This year, close to 600 engineering employees were nominated

for 28 awards in seven different

categories and the competition

was fierce. In all, close to 7,500

votes were cast to determine

this year’s winners, a 32 percent

increase over last year.

As recent program wins continue

to create many new engineering

career opportunities within the

sector, the annual peer-recognition program highlights employee

development while celebrating

some of the top engineering work

performed in the organization.

“

From enabling fundamental scientific

advancements in R&D to implementing disruptive

design and manufacturing capabilities to win new

business, Aerospace Systems’ Engineering team

generates game-changing results worthy

of recognition and celebration.

”

—Stuart Linsky

sector vice president, Engineering and Global Product Development

2015 Engineers Choice Award winners join Stuart Linksy

for a groupie following the award ceremony.

Photo by Robert M. Brown

14

32

INSIDE AEROSPACE

NOVEMBER/DECEMBER 2015

15

32

Hidehisa Horinouchi, Consul General of Japan,

Los Angeles (left) and Chikara Komiyama, Consul for

Defense Affairs and Security Attaché, Los Angeles,

represented Japan in the ceremonial delivery of the

AX-5 center fuselage.

Photo by Alan Radecki

PERFORMANCE

CENTER FUSELAGE COMPLETED

FOR FIRST JAPANESE-BUILT F-35

By Brooks McKinney

In late September, Aerospace

Systems completed the center

fuselage for the first F-35 Joint

Strike Fighter that Japan will

produce in its new F-35A final

assembly and checkout facility

in Nagoya, Japan.

That center fuselage, designated

AX-5, was presented in early

October to representatives

of the Japanese government

and Lockheed Martin, the F-35

prime contractor, during a brief

ceremony at the Palmdale Aircraft

Integration Center of Excellence.

As part of the visit, the guests

received a tour of the F-35

Integrated Assembly Line, where

the sector will produce all center

fuselages for Japan.

“It’s fitting that today’s delivery

coincides with Manufacturing

Day, a national celebration of our

country’s manufacturing skills

16

32

and capabilities,” said David Tracy,

director of Aerospace Systems

F-35 center fuselage integrated

product team.

“another phase of enhancing the

U.S./Japanese security alliance,”

calling it “a centerpiece of Japan’s

effort to assemble its first F-35.”

“We’re proud of the

manufacturing leadership that Northrop

Grumman brings to

the F-35 program as

we continue to increase

the quality, affordability

and production rate of

the center fuselage.”

“The F-35 program is really a

team sport,” said Joel Malone,

Lockheed Martin’s F-35 business

development manager for Japan,

“And Japan has been an incredible

F-35 customer.” He also thanked

Northrop Grumman for its role in

helping build customer confidence

that every F-35 will be delivered

on time, on cost with the promised

performance.

Hidehisa Horinouchi, Consul

General of Japan, Los Angeles,

spoke during the ceremony of the

growing cooperation between U.S.

and Japanese defense forces. He

described the delivery of AX-5 as

INSIDE AEROSPACE

AX-5 is one of 42 center fuselages that Northrop Grumman will

produce for Japan. It is the 207th

center fuselage that the company

has produced in Palmdale, Calif.,

and one of more than 3,000

that will be produced for the

F-35 program.

NOVEMBER/DECEMBER 2015

WHEN YOU HAVE 35 YEARS

OF EXPERIENCE BUILDING

STEALTH BOMBERS, YOU’RE

INHERENTLY MORE AFFORDABLE.

With over 35 years of experience manufacturing stealth bombers, Northrop Grumman’s

Long Range Strike Bomber is inherently more affordable. Our innovative approach

combines a mature design with our award-winning integrated assembly line for maximum

efficiency. And because we also make the key avionics and stealth components for other

advanced aircraft, we can deliver better-produced stealth systems.

THIS IS WHAT WE DO. AGAIN.

© 2015 Northrop Grumman Corporation

w w w . A m e r i c a s N e w B o m b e r. c o m

COVER STORY

Wes Bush celebrates

Northrop Grumman’s big win with

employees on the West Coast.

Photo by Alyssa Cooper

“Our team has the resources in place

to execute this important program,

and we’re ready to get to work.”

—Wes Bush, chairman, chief executive officer and president

of Northrop Grumman

A

LEGACY

By Ann Carney

18

32

LIKE NO OTHER

Thirty-five years ago, Northrop

Grumman put its passion for innovation and customer satisfaction

to work designing and producing

the B-2, an aircraft unlike the world

had ever seen, for a mission that

would redefine the ground rules

and boundaries of global air power.

Today, the company is applying that

spirit of innovation again, this time

to helping the nation define and

deploy the next generation of

global deterrence.

Bush, chairman, chief executive

officer and president of Northrop

Grumman. Employees heard

from senior leadership that bold

ingenuity and years of hard work

and unprecedented strategic

planning had paid off: Northrop

Grumman will build the nation’s

next stealth bomber.

On Nov. 9, applauding and waving

miniature American flags, 700

employees welcomed Tom Vice,

corporate vice president and sector

president, Aerospace Systems, and

several state and local leaders to

the hangar stage at the Manned

Aircraft Design Center of Excellence in Melbourne, Fla.

The purpose of this event, and

several others held across the

country, was to thank and celebrate with employees who helped

to make the selection of Northrop

Grumman for the U.S. Air Force’s

Long-Range Strike Bomber program a reality.

Three hours after the Melbourne

event, another 700 employees in

Palmdale, Calif., joined together

to enthusiastically greet Wes

And in Baltimore, Md., more than

1,000 employees at the Northrop

Grumman Electronic Systems

facility gathered to hear from

sector president Gloria Flach and

leaders from the region on the

impact this program will have on

Northrop Grumman and the nation.

The high level of enthusiasm

and comradery was evident

as dignitaries attended these

celebrations in force. In Melbourne,

guest speakers included Florida

Gov. Rick Scott, Sen. Bill Nelson and

U.S. Rep. Bill Posey. In Palmdale,

U.S. Rep. Mac Thornberry, chairman of the House Armed Services

Committee, and U.S. Rep. Steve

Knight joined Wes Bush in

congratulating employees and

remarking on the company’s

impressive history that made

this military milestone possible.

In Baltimore, Congressman “Dutch”

Ruppersberger, Congressman

John Sarbanes and Congressman

Elijah Cummings shared their deep

appreciation for what our employees

do every day to help keep our warfighters safe from harm.

With more than 35 years of

experience in advanced stealth

technology, Northrop Grumman is

the only company that has designed,

developed and delivered a longrange stealth bomber. That’s quite

an accomplishment and a defining

fact that led to Northrop Grumman’s

selection. Tom Vice told the crowd,

“The only ones who were

surprised that we won is

the team that has never

done this before.”

These employee events were

much more than celebrations—

they were statements. Statements

about how Northrop Grumman

employees consistently approach

their jobs with creativity, scrutiny

and expertise. And statements that

showcased Northrop Grumman

as an exceptional, strong industry

leader and a powerful innovator that

is taking command of its future.

Brooks McKinney also contributed to

this article.

Tom Vice addresses employees

at Melbourne rally celebration.

Photo by Steve Potter

INSIDE AEROSPACE

NOVEMBER/DECEMBER 2015

19

32

INGENUITY

ONE FLEET

By Alan Radecki

“The more we can do with the

Global Hawk, the better off our

country will be.”

—Phil Lo

When Ryan Aeronautical created the original

RQ-4A Global Hawk in the 1990s, it was

designed around specific sensors. It was

so successful that its potential for carrying

payloads for other missions was quickly

recognized.

However, the airframe had to

be partially redesigned each

time a new sensor package was

developed. This resulted in various

Global Hawk versions, commonly

known as “Blocks.”

This design approach meant

that payloads, as a permanent

part of the aircraft, were not

interchangeable. For instance,

when NASA acquired two of the

original Block 0 airframes from

the U.S. Air Force, it took months

to modify it to carry weatherscience payloads.

As sensor technology evolved and

new Global Hawk missions were

identified, a universal payload

adaptor was now mandatory to

meet warfighters’ requirements.

“We needed to reconfigure our

aircraft in a much more affordable

and easier way,” said Alfredo

Ramirez, director and High Altitude Long Endurance (HALE)

chief architect.

Pondering this challenge, a

moment of ingenuity came

to Phil Lo, HALE configuration

design engineer, as he glanced at

tabletops in the Rancho Bernardo,

Calif., laser lab. The surfaces of

these lab benches have a matrix

of threaded holes needed to

mount test equipment in versatile

configurations. “That was the

genius of it,” he explained. “Our

team got together, thought it over,

and asked how we could duplicate

this onto the Global Hawk.”

creativity, enthusiasm and all the

tools you have in solving a very

complex problem.”

Lo’s team innovated a set of small

fittings, each about the size and

shape of a hockey puck, that are

attached to the bottom of the

aircraft in a grid pattern, along

with a large plate mounted to

the various payloads. The system

was named the Universal Payload

Adaptor, or UPA, and it is making it

possible to change Global Hawk’s

“blocks” into One Fleet, where any

Global Hawk can carry any sensor.

Ramirez agrees, “When you can

solve complex problems with

simple solutions … that’s a

great feeling.”

“The concept of the UPA is simple,”

says Lo, “But what’s remarkable is

the execution of the design—using

The UPA provides a rapid swap

out of payloads, some types

of which have yet to even be

theorized. In parallel with the

UPA, HALE engineers are

developing an open architecture system that addresses the

payload’s functionality, allowing

a “plug-and-play” payload system.

Consider this: with the UPA

and an open architecture

system, a universal Global

Hawk might fly a SIGINT

payload over hostile territory one day—and a

humanitarian search-andrescue sensor package over

a natural disaster the next.

For Phil Lo, the issue was

more than just solving a

technical problem; it was

contributing to the greater

cause.

The result is an unblocking of

the Blocks.

Phil Lo and the heart of the Universal Payload Adaptor,

which will enable a much wider range of payloads to be

interchangeably carried on the “unblocked” Global Hawks.

Photo by Alan Radecki

20

32

INSIDE AEROSPACE

NOVEMBER/DECEMBER 2015

21

32

WISE:

THE NEXT GENERATION By Ann Carney

ACROSS THE SECTOR

“Women engineers demonstrate every day that they have

the ability to excel in challenging fields such as science and

aerospace. Greater networking opportunities with senior

management will strengthen their potential for discovery

and advancement.”

—Wendy Robello, manager of Engineering Competitive Analysis

worked with executive sponsors

and WIL alumna mentors to tackle

six different business challenges.

The teams’ hard work and research culminated this past

June when the 30-member group

came together from across the

nation to present its solutions

at the inaugural WISE Summit

in Redondo Beach, Calif.

Wendy Robello, manager of

Engineering Competitive Analysis, was one of the protégées

participating at the summit.

Her team researched avenues

of retention and advancement

for women in mid-level technical

positions within the company.

As the first generation and first

female in her family to attend

college, Robello was ideally suited to embrace this topic.

Richa Jolly shares thoughts with guest

speaker during WISE Summit Q&A.

Photos by Daniel Perales

22

Women who excel in science

and engineering needed more

opportunities to glean leadership

skills that would help them grow

and advance in their field. That’s

why Northrop Grumman Aerospace

Systems established Women in

Science and Engineering (WISE)

earlier this year.

“We wanted to create a support

network, strongly linked to the

corporate Women in Leadership

32

(WIL) program, that would foster

professional relationships with

senior management and also lead

to sponsorship opportunities,”

said Karen Tokashiki, director of

Integration, Competitive Analysis

and Materials for Engineering and

Global Product Development.

WISE members were selected,

assigned executive mentors, and

divided into six teams. Over the

following three months, teams

“I’ve always enjoyed math,” said

Robello. “But I never thought

about pursuing it with relation to

a career. The idea of college was

not promoted in my family growing

up. Once I was introduced to physics, I loved the challenge. It was

tough at first, but then it clicked. I

wanted to find a way to integrate

mathematics and physics without

losing my artistic/creative side.”

Robello, who earned a bachelor’s

degree in mechanical engineering

and a master’s in systems architecture and engineering, said that

might not have happened if not for

the encouragement of mentors

along the way.

“One of the themes throughout

our [team’s] research was that

in addition to high performance,

quality mentorships and networking are vital for career growth,”

she said.

Recommendations presented by

Robello’s team included developing a chief engineer pilot program

and holding quarterly virtual panel

discussions led by women with

high-level technical positions at

Northrop Grumman.

Chris Daughters, vice president

of Engineering and Advanced

Development for Special Programs

in El Segundo, Calif., advised

Robello’s team and served as a

mentor to one of its members.

He noted that in many companies,

diversity statistics are satisfactory

for entry-level female engineers

but sharply decline once women

approach 10 years of experience.

“Programs like WIL and WISE are a

positive step in realizing diversity in

the next generation of our technical

leaders, and there are more steps

we could take,” he said.

“Diversity at all levels is essential

for Northrop Grumman because

it makes us a more valuable

company, with more ingenuity,

stronger teams, superior products,

and better relationships with our

customers.”

INSIDE AEROSPACE

Wendy Robello (left) with Halle Horne

during their team’s presentation.

NOVEMBER/DECEMBER 2015

23

32

ONE

ACROSS THE SECTOR

MILLION

HOURS SAVED

By Tom Henson

As it approached its goal of helping save one million

hours of work in 2015, the Busting Bureaucracy

initiative recently paused long enough to mark

one year of success.

Besides the significant savings,

the program’s website (accessed

by typing ‘busting’ in the browser

window) has logged more than

30,000 visits and 400 ideas

for improvements. Employees

have viewed the ideas more than

100,000 times, often offering

suggestions and solutions. And,

most encouraging of all, a recent

snapshot indicated that 90

percent of ideas were coming

from first-time submitters.

The numbers alone are worth

celebrating and indicate ongoing and increasing interest in

the program among employees.

But numbers only tell part of the

success story; it’s the news behind the numbers that has made

this a remarkable year.

24

32

Working together across functions,

the Busting Bureaucracy team

and volunteers from around the

sector have achieved high-profile,

high-impact results, including

eliminating the requirement

for a pre-travel approval form;

shifting from a paper, event-driven

photo permission form to a onetime, online, clickable form; and

streamlining purchasing processes

across the sector. These and other

“busted” issues led to a President’s

Award for the program in August

and have demonstrated the value

of finding ways to save time.

“When Busting Bureaucracy

launched in late 2014, everyone

involved understood that taking on

something this ambitious would

be met with some skepticism and

would prove to be a real challenge,”

says Sandy McElroy, lead of the

initiative and director of Sector

Affordability and Business Process

Excellence. “And here we are, one

eventful, inspiring year and we’ve

already seen a real benefit—

helping our teammates find time

to do what they came here to do.”

A perfect example is Jon Linch, an

aeroacoustic engineer responsible for implementing new stealth

technologies that facilitate aircraft survivability. Linch works in

research and development, so he

often purchases unusual, one-off

materials. For this, he’d been using

EPS, a program more suited for

purchases of conventional flight

hardware that required additional

hours and personnel to use.

(left to right): Kyle Rahrig, Jon Linch and David Schein, members of

the aeroacoustics team, with some of their flight-test hardware.

Photo by Glen Sakaguchi

This caused delays for Linch and

additional work for purchasers. He

visited the Busting Bureaucracy

website and submitted the idea to

move his purchases from EPS to a

corporate purchasing card, which

makes ordering his items more like

using an online retail store. Linch

has used his saved hours to draft

and submit four new patents. And,

his work on two projects earned

him nominations for two Engineers

Choice “Invention of the Year”

awards this year.

“Engineering is an

iterative process,

and the purchasing

change shortens that

process considerably,”

said Linch. “Now, I can

bring new ideas from

concept to completion

more rapidly. Most

importantly, I’m able

to do what I’ve always

wanted to do as an

engineer—inspire

and create.”

“Saving time certainly is our

goal, but our main objective is to

enable our incredible teammates

to achieve their own ambitions,”

McElroy says. “Imagine what this

talented work force can do with

extra hours to innovate. We can’t

wait to see what happens next year

and beyond.”

Now McElroy and the Busting

Bureaucracy team are turning

their attention to 2016, and an

even more ambitious timesaving

target, with a new focus on sharing

the benefits of reclaiming lost time

as Linch and others have done.

INSIDE AEROSPACE

NOVEMBER/DECEMBER 2015

25

32

ACROSS THE SECTOR

A

SILVER

&GOLD

to work on many critical programs

and activities, classified and unclassified. From administrative

assistants to engineers, from

flight test to fleet support, their

work has contributed to the

success of the company.

TRIBUTE

By Linda Javier

Service anniversaries may not seem important,

or even reachable, until you hit one.

And then it’s time for celebration!

This year alone, more than 300

employees on the West Coast

and East Coast celebrated their

25-year milestone.

On Nov. 7 at the Beverly Hills

Hotel in Southern California, 180

Northrop Grumman West Coast

employees were honored for

reaching their 25-year service

anniversary with the company

this year. Celebrating their

amazing 50th anniversary with

the company were Ann Clark,

Frank Fendell and Ann Linen.

After a welcome and introduction

by Heidi Hendrix, sector vice

26

32

president of Human Resources,

Sector President Tom Vice shared

his memory of his first day on

the job: “a seemingly indefinite

clearance process followed by

a walk through a series of doors

reminiscent of the opening

sequence to the show Get Smart.”

Then, seeing a mockup of an

aircraft so sleek that didn’t look like

anything he had ever seen before,

he realized that “this was going to

be a really cool job.” His first day

was on the B-2.

Acknowledging where we’ve been

and where we came from, Vice

lauded the company’s founders,

dreamers, and innovators.

INSIDE AEROSPACE

“You have sacrificed a lot, but for

a good and honorable cause—we

build systems that take men and

women in harm’s way to protect

and project freedom and bring

them back home. We have put

Americans on the moon, and we

intend to be the team that builds

systems that find habitable

planets around distant stars,”

Vice said. “To you, the spouses,

the partners, and the families, I

want to say Thank You.”

Looking back, 50-year honoree

Ann Linen, administrative assistant in San Diego, attributes her

longevity with the company to

“management and the fantastic

people I work with.” She started

with Ryan Aerospace and Teledyne

Ryan before becoming part of

Northrop Grumman.

Ann Clark, senior administrative

assistant in Redondo Beach, who

originally joined TRW as a clerk

in 1965, commented “There was

such a variety of opportunities on

various projects and programs

… but remain with the company.”

She later had the opportunity to

work on the Lunar Module Descent

Engine and the James Webb Space

Telescope program.

Fellow 50-year honoree Frank

Fendell, mechanical engineer in

Redondo Beach, says he was drawn

to TRW’s environment that allowed

him to be as good professionally as

he was capable of being. He also

benefitted from the guidance and

support he received from a series

of mentors throughout his career.

His next milestone? Striving for his

next problem-solving to be better

than any he’s done in the past.

“Applied mathematicians never

exhaust the supply of problems,”

he added, “just the lifespan to

tackle them.”

Fifty years of service: (left to right)

Ann Linen, Frank Fendell and Ann Clark.

“We truly believe our

potential is LIMITLESS

—and we are driven

to build insanely great

products.”

In addition to citing new pursuits

that include the new advanced

jet trainer, the next generation of

surveillance aircraft and resilient

satellites, he reflected on Northrop

Grumman being the first to land an

autonomous aircraft on the deck

of a carrier and the first to refuel

an autonomous aircraft in flight.

The honorees in the room that

evening have worked and continue

NOVEMBER/DECEMBER 2015

Celebrating 25 years with Northrop Grumman

in Beverly Hills, Calif.

Photos by Alex Evers

27

32

ACROSS THE SECTOR

KEVIN

CORPORATE LEAD EXECUTIVE, DAYTON, OHIO

BELL

By Linda Javier

After retiring from the U.S. Air

Force in 2005 with 26 years

of acquisition management

experience, Kevin Bell looked for

another opportunity to use his

business management acumen.

It’s exciting to see all the new

technology and capabilities we

bring to our national defense and

security, specifically to the Air

Force. It makes it exciting to

come into work every day.”

He found it with

Northrop Grumman.

Bell’s involvement in the

community, supported in large

extent by his assistant Lynn

Locke, benefits his engagement

with base personnel and local

industry. As president for the

Wright Brothers Regional Chapter

of the National Defense Industrial

Association, Bell meets monthly

with representatives of all major

defense contractors and some

small businesses to develop and

manage programs to support Air

Force customers.

For more than eight years, Bell

represented Northrop Grumman

in the Dayton region in business

development and as a sector lead

for Aerospace Systems, working

closely with the area’s former

corporate lead executive (CLE)

Jay Jabour. When Jabour retired

last year, this position was a

logical transition for Bell.

“I could now represent all four

sectors and the company in a

broader sense,” says Bell. “It all

seemed to fall into place and is a

capstone for me professionally to

serve as CLE in the Dayton area.”

He interacts primarily with Wright

Patterson Air Force Base, the

Air Force Research Laboratory

and the Air Force Life Cycle

Management Center (LCMC).

The B-2 and Global Hawk

programs are billion-dollar

programs managed at the LCMC.

A number of efforts from across

the company’s sectors are also

done here, including technology

development and future captures.

“I might be dealing with an

Aerospace Systems program

one day, an Electronic Systems

program the next, Information

Systems in the afternoon, and I

really get an appreciation more

broadly about the services and

products this company provides.

The association also supports the

area’s USO chapter, STEM and Air

Force training activities, as well as

special nonprofit organizations,

such as Fisher Nightingale House.

This nationwide organization builds

houses on military installations

(two at Wright Patterson) where

families can stay at no charge

while their loved ones receive

longer-term medical attention.

While he considers becoming a

corporate lead executive as the

highlight of his professional career,

Bell deems the pinnacle of his Air

Force career to be his deployment

to Afghanistan in 2004.

“There’s not a lot of opportunity

in the acquisition career field to

deploy into a combat zone,” Bell

says. “I volunteered while I was a

colonel because I wanted more

direct involvement in the war on

terror before retiring from the

Air Force.”

He became an acquisitions/

logistics mentor and advisor to

the U.S. Major General who led the

Joint Office of Military Cooperation

in Kabul, Afghanistan, and served

as mentor to the Afghan general

in charge of the Afghan National

Army (ANA) acquisition command.

From September 2004-February

2005, Bell directed recruiting,

training and establishment of

a 500-man ANA acquisition

command responsible for acquiring

equipment and supplies, including

thousands of Ford Ranger trucks

and four-wheel drive vehicles

for troop transportation. For his

activity in the war zone, Bell was

awarded the Bronze Star.

Dayton holds a special fascination

for Bell as a city with a rich aviation

heritage. “This is the home of the

Wright Brothers,” he states. “Today,

you can visit Huffman Prairie at the

old Patterson Field where Wilbur

and Orville developed and tested

the first practical airplane.

“I used to live on the Air Force

base, run past Huffman Prairie and

think about how much aviation has

changed the world,” reflects Bell.

“Our company provides some of the

most advanced flying

machines ever created,

and we’re here at this

location where it all

started.”

Kevin Bell in front of the

National Museum of the U.S. Air Force

at Wright Patterson Air Force Base.

Photo by Suzanne Bell

28

32

INSIDE AEROSPACE

NOVEMBER/DECEMBER 2015

29

32

EMPLOYEES GIVING BACK

Featuring Northrop Grumman employees sharing their time,

talent and ideas

BUILD-A-BIKE

El Segundo, Calif.

By Tom Henson

Nearly 150 children in military

services outreach programs will

receive new bicycles this holiday

season thanks to the Build-A-Bike

charity competition.

In October, seven teams from the

El Segundo, Calif., site competed

to see which team could build 21

new children’s bikes right out of

the box. The F/A-18 Structures

group won with a completion time

of 13 minutes.

The Build-A-Bike event was a

joint effort with Aerospace

Systems Corporate Citizenship

and the nonprofit, L.A. Works.

More than 250 employees

participated in the event remotely from Redondo Beach,

Palmdale and San Diego.

COMMUNITY

USO CARNIVAL

AND CAR SHOW

Palmdale, Calif.

By Celina Ramirez

Doing good while having fun

summarizes this year’s USO

Carnival and Car Show held in

early September at the Palmdale

Aircraft Integration Center of

Excellence.

From adult tricycle races to the

impressive car and motorcycle

show, from dunk tanks and live

music to a “cupcake war” bakeoff, this 7th annual event was

attended by more than 800

employees.

Mike Schulte (left) and Damien Smith

pose after pedaling away to victory in

the annual USO Trike Race.

Photo by Aaron Lewis

Six teams of employees, with

representatives from both work

shifts, participated in the tricycle

(trike) race, the most anticipated and humorous of the day’s

competitions. Engineers Damien

Smith and Michael Schulte won

the trike race trophy for first shift.

“Damien and I have done the trike

race for at least five or six years

now,” said Schulte. “It’s fun for

us and fun for others to watch, but

most importantly, it raises money

for the USO to support our troops.”

Race requirements include not only

riding a tricycle, but assembling it

beforehand and decorating it with

a creative flair. Additionally, it has

become a tradition for the teams

to dress in costume, enhancing the

playful spirit of the race.

At the end of the day, more than

$37,000 was raised.

“The Carnival signified the end

of our 2015 USO campaign,” said

Andy Reynolds, vice president,

Manufacturing Operations, and

Palmdale site manager. “I thank

all employees for their generosity

in support of our site fundraising

efforts.”

Northrop Grumman employees hard at

work at the El Segundo, Calif., site

building bikes for children.

30

Photo by Robert M. Brown

32

INSIDE AEROSPACE

NOVEMBER/DECEMBER 2015

31

32

STEALTH

Not all stealth is created equal. For more than 70 years, Northrop Grumman has

been the leader in tailless, blended-wing aircraft—an essential hallmark of true,

low-observable stealth. And to this day, we’re the only ones who have delivered

large-scale, long-range stealth aircraft.

THIS IS WHAT WE DO.

© 2015 Northrop Grumman Corporation

w w w . n o r t h r o p g r u m m a n . c o m /s t e a l t h