N-(3-(trimethoxysilyl)propyl)ethylenediamine

advertisement

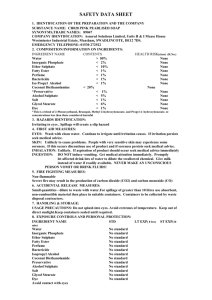

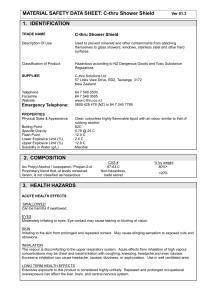

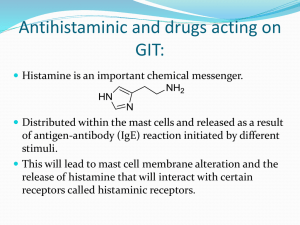

GPS SAFETY REPORT N-(3-(trimethoxysilyl)propyl)ethylenediamine This document is a high-level summary intended to provide the general public with an overview of product safety for this substance. It is not intended to replace the Safety Data Sheet or legally required safety information, which is available from Dow Corning and should be referred to for full details of recommended safety procedures for each type of use. Where there is any inconsistency in the information provided herein and the Safety Data Sheet/legally required information, the latter shall prevail. 1. Substance Name and Chemical Identity Chemical Name: N-(3-(trimethoxysilyl)propyl)ethylenediamine CAS Number: 1760-24-3 Molecular formula: C8H22N2O3Si 2. Uses and Applications N-(3-(trimethoxysilyl)propyl)ethylenediamine is an alkoxysilane that has the following uses: • Use as a monomer (‘building block’) in the production of silicone polymers or silicone resins. Silicone polymers may be oils, greases and rubbers and have a wide range of uses. • Intermediate (starting material) in the production of other organosilicon substances; • Use in sealants and coatings • Use in the production of surface-modified particles or substrates (non-metal surface treatment) • Use in non-polymer preparation • Use in masonry treatment • Laboratory reagent in research and development activities Most of the applications described take place in industrial settings under controlled conditions. The end uses of products made N-(3-(trimethoxysilyl)propyl)ethylenediamine will vary. In coatings, N-(3-(trimethoxysilyl)propyl)ethylenediamine offers improved hardness and scratch-, temperature- solvent and acid-resistance. Examples of typical industrial uses are automotive refinishing and coating of beverage cans. Professional and consumer uses include paints, wood and metal primers and stains and varnishes. In sealants N-(3-(trimethoxysilyl)propyl)ethylenediamine is used as a cross-linking agent and an adhesion promoter during sealant manufacture and sealant application. The use of sealants is widespread with various industrial, professional and consumer end uses, including construction and automotive industry. N-(3-(trimethoxysilyl)propyl)ethylenediamine is also used in non-metal surface treatment and masonry, the uses exploiting the cross-linking capacity of the substance. 1 of 4 3. Physical/chemical properties N-(3-(trimethoxysilyl)propyl)ethylenediamine is a liquid at standard temperature and pressure. When in contact with water, the substance reacts very rapidly to produce N-[3(trihydroxysilyl)propyl]ethylenediamine and methanol. N-(3(trimethoxysilyl)propyl)ethylenediamine is not classified for physicochemical hazards under the Globally Harmonised System (GHS). Property Value Physical state Liquid Colour Clear/yellow Odour None reported Molecular weight 222.36 g/mol Melting/boiling point < -20°C / 240°C Density 1.03 g/cm3 at 20°C Vapour pressure 0.3-0.4 Pa at 20°C Flammability Not flammable Flash point 98°C at 1013 hPa Self-ignition temperature 300-301°C at 1013 hPa Explosive properties Not explosive 4. Health information N-(3-(trimethoxysilyl)propyl)ethylenediamine is classified for human health effects under the Globally Harmonised System (GHS) as: Acute Toxicity Category 4 H332: Harmful if inhaled Eye Damage Category 1 H318: Causes serious eye damage Skin Sensitiser Category 1B H317: May cause an allergic skin reaction 5. Environmental information N-(3-(trimethoxysilyl)propyl)ethylenediamine is not classified for environmental effects under the Globally Harmonised System (GHS). 2 of 4 6. Exposure potential Consumer and Professional exposure: Use of coating and sealant products containing N-(3(trimethoxysilyl)propyl)ethylenediamine by professionals in building construction, furniture coating, decorative coating and vehicle refinishing are representative of exposure to professional exposure. N-(3-(trimethoxysilyl)propyl)ethylenediamine is rarely used in water based decorative coating products meant for the DIY consumer market. In the few cases where it is used, the substance is invariably no longer present in its original form due to a hydrolysis reaction and therefore its end-use in aqueous coating products does not pose an exposure risk to consumers. N-(3-(trimethoxysilyl)propyl)ethylenediamine is also present in some solvent based DIY-coatings, but the frequency of use is expected to be low and once the coating has been applied and has set, there is no further potential for consumer exposure. In sealants, the parent material is negligible at end use. . Regardless of the end use of the coating/sealant the application techniques by consumers and professionals are similar. Masonry products formulated with N-(3(trimethoxysilyl)propyl)ethylenediamine for masonry treatment in building construction and maintenance, by spraying, injection or roller application are also used by professionals and consumers. Workplace exposure: This refers to potential for worker exposure at manufacturing sites or industrial workplaces. Industrial uses include coatings and masonry products formulated with N(3-(trimethoxysilyl)propyl)ethylenediamine, the application of which is typically by spraying, dipping and roll or flow-coating. All aspects of N-(3-(trimethoxysilyl)propyl)ethylenediamine handling, including on-site storage and transfer of the neat substance, are subject to highly controlled conditions, due to its flammability hazard. Further details are given in the Safety Data Sheet. Environmental releases: Releases to the environment can vary depending on the industry and processes used. However, manufacturing occurs under controlled conditions, with minimal releases to air and waste water. Environmental exposure is minimised by applying air and waste water abatement technologies to remove unreacted substance and reaction products. The use of appropriate measures to manage environmental release is described in the Safety Data Sheet. 7. Risk management recommendations Consumer and professional risk management: Adequate ventilation and protective clothing such as rubber type gloves are essential to professional risk management. Masonry products must contain a maximum of 5%-10% of the substance or be diluted to this concentration for safe use of the product by consumers, without additional PPE. Consumers using coatings and sealants should follow the supplier’s/manufacturer’s instructions. Industrial risk management: For more detailed information please refer to the safety data sheet for information on protecting workers and limiting environmental exposure at industrial sites. In summary, when using this chemical, there must be adequate ventilation. Suitable respiratory protection must be worn if the product is handled in large quantities in confined spaces, chemicalresistant clothing and gloves, and safety glasses or other suitable eye protection must be worn. Keep containers tightly closed, in a dry and cool place. In a laboratory setting, local exhaust ventilation must be in place and personal protective equipment must be worn with adherence to good laboratory practice. 8. Conclusions N-(3-(trimethoxysilyl)propyl)ethylenediamine is used under controlled conditions at industrial sites and in consumer applications it does not pose risk to human health if instructions for use are followed. It is therefore concluded that the manufacturing and use of N-(3(trimethoxysilyl)propyl)ethylenediamine does not pose a risk to humans or the environment if instructions in the Safety Data Sheet are followed. 3 of 4 9. Contact Information For further information on this substance or product safety summaries in general, please contact: Dow Corning EH&S Team 4 of 4