ASTM E2500 A New Approach to Validation

ASTM E2500

A New Approach to Validation

Peter K. Watler, Ph.D.,

Principal Consultant and CTO,

Hyde Engineering + Consulting, Inc.

Where you can find it

Only 5 pages

http://www.astm.org/Standards/E2500.htm

$36.00

-Page 1-

ASTM E 2500 – 07, What is it?

“A risk-based and science-based approach to the specification, design, and verification of manufacturing systems and equipment that have the potential to affect product quality and patient safety .”

“The overall objective is to provide manufacturing capability to support defined and controlled processes that can consistently produce product meeting defined quality requirements.”

¾

¾

¾

Approved June 1, 2007

A voluntary consensus standard

It has legal relevance

Stresses expert analysis of c ritical element that affect product quality

¾

¾

¾

“ quality ”, ( not Quality Assurance or Quality Unit) appears 44 times

“ expert ” appears 21 times

“ critical ” appears 20 times

-Page 2-

The National Technology Transfer Act of 1995

Public Law 104-113

“The Congress finds the following:

¾ (1) Bringing technology and industrial innovation to themarketplace is central to the economic, environmental, and social well-being of the people of the United States.

¾ (2) The Federal Government can help United States business to speed the development of new products and processes”

Provision (12(d)) - Utilization of Consensus Technical

Standards by Federal Agencies;

¾ all Federal agencies and departments shall use technical standards that are developed or adopted by voluntary consensus standards bodies , using such technical standards as a means to carry out policy objectives or activities deemed by the agencies and departments.

-Page 3-

What the Law Looks Like http://www.nist.gov/director/ocla/Public_Laws/PL104-113.pdf

-Page 4-

What ASTM E 2500 Applies To

Pharmaceutical and biopharmaceutical manufacturing systems:

¾ Facility equipment

¾ Process equipment

¾ Supporting utilities

¾ Process monitoring systems

¾ Process control systems

¾ Automation

Systems that have the potential to affect

¾ product quality

¾ patient safety

-Page 5-

ASTM E 2500-07 Highlights

The ASTM standard focuses on

¾

¾

¾

¾

Specification

Design

Verification

Lifecycle

Alternative to ISPE Baseline Guide Vol 5 Commissioning &

Qualification

¾ complexity, cost, time

Replaces Design Qualification with a Design Review by Subject Matter

Experts

Risk Assessments by Subject Matter Experts (SMEs)

¾ Eliminate Impact Assessment

Replaces sequential Commissioning and Qualification with “Verification”

¾ “Fit for intended use” - Not bound by the formal IQ, OQ PQ phases

Lifecycle Change

¾

Continuous process improvements and real-time monitoring (PAT)

-Page 6-

Why is it needed now?

“It is estimated that validation can add up to 25% of the total installation cost for new facilities.”

− M Guyader, LBP

E 2500 – puts focus on

Critical areas that affect

¾ Product Quality

¾ Patient Safety

Let’s Validate

Everything!

I know Nothing!

-Page 7-

What’s Driving us to Consider new Validation

Approaches

“Pharmaceutical manufacturing operations are inefficient and costly .”

dust ry W aste s cien t

“Pha rmac

$50

Billio eutic al In n a Y ear Du e to g”

Ineffi

engineering knowledge.”

• Source:

regulated…

Man ufac turin

Unive rsity,

Octob er 200

"if we change the way both manufacturers and

Pharm aceut ical M cturin earch

Proje ct , G eorge town

the industry could save

g Res

6

10 to 50% of the cost of goods sold.”

average of 15 per cent of manufacturing costs ".

-Page 8-

They Have!

FDA 2004: Pharmaceutical cGMPs for the 21st Century – A Risk

Based Approach

¾ “ Encourage implementation of risk-based approaches”

FDA 2004: PAT — A Framework for Innovative Pharmaceutical

Development, Manufacturing, and Quality Assurance

¾ “ encourage the voluntary development and implementation” of

“Process Analytical Technology”

FDA 2006: A Regulatory Paradigm to Encourage Innovation. Keith

Webber, CDER/OPS, FDA

FDA 2006: Guidance for Industry – Q9 Quality Risk Management

FDA 2007: Pharmaceutical Quality for the 21st Century A Risk-

Based Approach Progress Report

FDA 2009: Guidance for Industry Q8(R1) Pharmaceutical

Development

¾ “ scienceand risk-based submissions” QbD

-Page 9-

Focus on Criticality, Ongoing Verification

3

-Page 10-

Why Now?

Industry and Regulatory Agencies are striving to be more efficient, reduce costs and improve quality and safety

Decades of pharma & bio manufacturing experience

More knowledge of systems

Solid understanding of operations

Less ‘anything can happen’ philosophy

-Page 11-

Implementing ASTM E 2500

Some will wrongly interpret this as simply shifting validation responsibilities:

¾ “This new approach will significantly shift the current qualification responsibilities and activities associated with facility qualification, equipment qualification, and utility qualification to the company’s corporate engineering group ”

Some will wrongly interpret this as simply changing the terminology:

¾ “Out goes the Design Qualification (DQ) with a Design Review (DR).

Also for those that do them, Impact Assessments are out. Commissioning and

Qualification are replaced by “Verification ”, the qualification phases (IQ, OQ, PQ) are obsolete.”

ASTM E 2500 is a new Concept , requiring new Approaches

¾

¾

It’s more than simply re-naming documents

It’s more than a ‘re-org’ of shifting responsibilities from one group

-Page 12-

Implementing ASTM E 2500

To implement the concepts of E 2500

¾ Approach has to change

¾ Expertise (of the people involved) has to change

¾ Tools have to change

Otherwise there will be no real change

-Page 13-

Is ASTM E 2500 About This?

OLD

NEW?

-Page 14-

GAMP Validation “V” Model

-Page 15-

ASTM E 2500 Is:

A standard approach for validating equipment, facilities, processes

¾ Streamlined process

¾ Risk based – reduce costs

¾ QbD – develop then employ best practices

¾ More consistent qualification

¾ Supports current regulatory guidance (FDA, ICH)

− Knowledge (expert) based

− Risk based

-Page 16-

ASTM E 2500 Process Map

-Page 17-

E2500 System Lifecycle and Validation Approach

Planning

& Documentation

Identify

Subject Matter

Experts

User

Requirements

Specification

Risk

Assessment

Functional

Specifications and Design

Traceability

Matrix

Vendor

Documentation

Verification Plan

Factory

Acceptance

Tests

Site

Acceptance

Tests

Installation/

Operational

Qualification

Tests

Performance

Qualification

Tests

ETOP

Verification Summary Report

GMP Operation and

Change Management

-Page 18-

The New Standard is About Fundamental Change!

To more efficiently and better , design and implement manufacturing systems…

ASTM E 2500 embraces, leverages and brings together the cutting edge concepts of:

RiskBased Approach

Science Based Approach

Quality by Design (QbD)

Process Analytical

Technologies (PAT)

Design Space

Critical Parameters

Critical Quality Attributes (CQA)

Knowledge & Understanding

Subject Matter Experts (SMEs)

Good Engineering Practice,

(GEP)

Lifecycle concepts

Change implementation

Continuous process improvement

Vendor documentation

-Page 19-

E 2500 Key Concepts for Design &

Implementation of Manufacturing Systems

Methodologies

1. Requirements

2. Specification & Design

3. Verification

Toolbox

1. Design Review

2. Subject Matter Experts

3. Risk Management

Process

4. Change Management

Plan

-Page 20-

Benefits of Implementing E 2500

LEANer manufacturing systems

¾ Remove waste

Elevate our industry to more knowledge , better understanding of our manufacturing systems

¾ Data, PAT, Design Space

Focus on what’s important (Critical)

¾ More is not better

Better technical understanding (Subject Matter Experts)

Less waste & repetition

¾ Use vendor doc’s

-Page 21-

Implementing ASTM E 2500

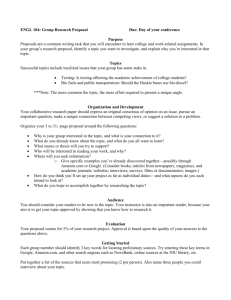

1. Planning and Documentation :

¾

¾

¾

¾

VMP

Verification Team and Responsibilities

Document Matrix (planning, design & verification)

Eligible vendor documentation

Document Matrix prepared by:

HYDE

Task

002

002

002

Title Doc. #

Phase 1 Planning and Definition

Status Doc. # Status

FMECA RISK

ASSESSMENT SOP

VERIFICATION PLAN

PROTOCOL TEMPLATE

HVAC SYSTEM- AIR

HANDLERS

TEC-005

COMMISSIONING PLAN COM-001

URS-50058-

66

APPROVED

19MAY09

APPROVED

24JUL09

APPROVED

04AUG09

APPROVED

29SEP09

RSK-50058-

66

DRAFT

003

004

005

006

007

008

009

AUTOCLAVE (2 DOOR)

BAS- BUILDING

AUTOMATION SYSTEM

CHILLER SYSTEM

URS-50043 APPROVED

13MAY09

URS-50054 APPROVED

08AUG09

URS-50050 APPROVED

02JUL09

CLEAN DRY AIR SYSTEM URS-50049 APPROVED

25JUN09

COOLING TOWER

SYSTEM

URS-50056 APPROVED

09JUL09

ELECTRICAL/ LIGHTING

SYSTEM

EMERGENCY

GENERATORS

URS-50053 APPROVED

03AUG09

RSK-50043 APPROVED

25JUN09

RSK-50054 DRAFT

RSK-50049 APPROVED

18SEP09

RSK-50053 APPROVED

03AUG09

010

Doc. # Status

Phase 2 Design & Development

Doc. # Status FAT SAT

Date: 20-Oct-09

IOQ PQ Enhanced

Comm

Validation

IOQ PQ Summary

Reports

-Page 22-

Implementing ASTM E 2500

2. Identify Subject Matter Experts :

(§6.7) SMEs have primary responsibility for specification, design and verification of the manufacturing systems

“individuals with specific expertise and responsibility in a particular area or field (for example, quality unit, engineering, automation, development, operations.”

CFR21 §211.34 “Consultants advising on the manufacture, processing, packing, or holding of drug products shall have sufficient education, training, and experience , or any combination thereof, to advise on the subject for which they are retained.”

Who are they?

Where do you find them?

-Page 23-

SME Qualifications

Experience

¾ >10 y experience

¾ Designed & implemented systems or practices

Process/System Expertise

¾ Knowledge of GMP, compliance, design elements, risk factors

¾

¾

Applies engineering equations, principles to the design, sizing & scaling of systems.

In-depth knowledge of the subject

Methodology Expertise

¾

¾

Proficient in standard methodologies for design and implementation, such as ICH Quality Guidelines (Q8, Q9, Q10), FDA Guidance, CFRs,

ASME Standards (BPE, E 2500), ISPE Guides (GAMP, Baseline)

Completed formal training courses

Recognized Competence

¾ Recognized by peers and professional associations, published, teaches topic

Professional credentials, license

-Page 24-

Implementing ASTM E 2500

SME

3. Requirements Specification :

Identify specific requirements

Basis for specification, design, and verification of the system (§7.2)

SMEs

¾ product and process knowledge and understanding

¾ based on scientific data (QbD,

Design Space).

This knowledge is the basis of scientific understanding for the system

¾

FDA 2009: Guidance for Industry Q8(R1) Pharmaceutical Development

¾ What is critical

-Page 25-

Implementing ASTM E 2500

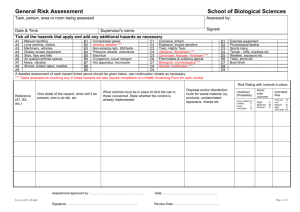

4. Risk Management Process

FDA 2006: Guidance for Industry – [ICH] Q9

Quality Risk Management

¾ Perform risk assessments at appropriate stages to evaluate the risks to product quality and patient safety

Performed by an appropriate SME

Identify controls and verification techniques to manage risk to an acceptable level

-Page 26-

Implementing ASTM E 2500

5. Specification and Design :

Leverage qualified equipment vendor expertise ( SME ) to identify & document elements which affect critical quality attributes

Communicate the factors that impact product quality to the system (e.g. equipment) designer.

Strive to mitigate product quality & patient safety risks through the design

Functional Specifications provide acceptance criteria for functional tests specified in the Verification Plan.

-Page 27-

Potential Design Requirements

Requirements Definition :

Temperature

Shear

Flow rate

Membrane Area

-Page 28-

Implementing ASTM E 2500

6. Verification Plan (§5.1, §7.4)

Verify the critical aspects of the manufacturing system

¾ Design

¾ Properly installed

¾

¾

¾

Operating correctly

Meets performance requirements

“Fit for intended use”

Identifies all required testing & documentation

¾

¾

¾

Extent of verification and documentation should be based on risk to product quality and patient safety

Criticality, risk factors identified in the URS, FMECA Risk Analysis, and detailed design

Testing occurs from “FAT” to “PQ”

Acceptance criteria:

¾

¾

Developed and approved by subject matter experts

Critical aspects approved by the quality unit

A ‘Traceability Matrix’ summarizes required testing and when it occurs

-Page 29-

Verification Plan Traceability Matrix

Identifies required test functions

Identifies when testing will be executed

FAT, SAT, IQ, OQ, PQ

-Page 30-

Implementing ASTM E 2500

7. Verification Plan Execution :

Subject matter experts perform or oversee activities, and document results (§7.4.3.1)

“Vendor verification documentation may be used” (§7.4.3.2)

Leverage FAT/SAT testing “rather than repeating vendor activities and replicating vendor documentation” (§6.8.2)

Testing occurs across FAT, SAT, IQ, OQ, PQ

¾ The more critical testing or additional testing may occur during IQ/OQ to mitigate risk

-Page 31-

The Role of System Vendors

“The key to a competitive parts supply system is the way the

assembler works with its suppliers”

– Womack, The Story of Lean Production

-Page 32-

Implementing ASTM E 2500

8. Verification Summary Report

Approved FAT, SAT, ETOP, IOQ and PQ Reports collectively provide documented verification that the manufacturing system is fit for intended use (E 2500 §7.5.1)

Summary Report provides an overview of test results and nonconformances with acceptance criteria (§7.5.2)

Completed verification documentation reviewed by qualified and independent subject matter expert(s) (§7.4.4.1)

SME reviews overview of results and any nonconformance with critical acceptance criteria

Systems with critical aspects should be approved by the quality unit .

SME confirms manufacturing system is fit for intended us (§7.5.3)

Approved by SME and Quality Assurance (§7.5.4).

-Page 33-

Implementing ASTM E 2500

9. GMP Operation Acceptance, Release & Change

Management:

After Verification Summary Report approval,

Quality Assurance issues authorization to release the system for GMP operational use (§7.5.5).

As part of the system life-cycle, equipment, and procedures are periodically reviewed.

¾

¾

¾

Modifications are controlled via Change Management throughout the system lifecycle (E 2500 §8.4.3).

Changes are approved by system subject matter experts.

Changes to critical aspects or to aspects that affect system requirements relative to product quality and patient safety are additionally approved by

Quality Assurance (§8.4.2, §8.4.3)

-Page 34-

The Role of QA in ASTM E 2500

7.4.1.3 Acceptance criteria of critical aspects (that is, critical to product quality and patient safety) should be approved by the quality unit.

7.4.2.3 The verification plan should be developed and approved by subject matter experts. Verification plans for systems containing critical aspects should be approved by the quality unit.

al O ver sig ht

7.5.4 Such documentation should be prepared and approved by subject matter experts. Such documentation for systems with critical

wi th A ddi tion te R isk

8.4.2 Before acceptance, change management should be applied. This

Mit iga matter experts. Changes affecting critical aspects of manufacturing systems should be communicated to the quality unit.

8.4.3 After acceptance, prior to manufacturing for commercial use, operational change management should be applied. Under operational change management, all changes related to specific requirements relative to product quality and patient safety require prior approval by the quality unit, unless predefined arrangements are established covering

-Page 35-

What Else is Needed?

Risk Management Process

¾ ICH Q9

¾ Perform risk assessments at appropriate stages to evaluate the risks to product quality and patient safety

Performed by an appropriate SME

Identify controls and verification techniques to manage risk to an acceptable level

-Page 36-

Risk Management Program

ICH Published 09 Nov 2005

FDA Published Federal

Register, June 2, 2006

“Although there are some examples of the use of quality risk management in the pharmaceutical industry today, they are limited and do not represent the full contributions that risk management has to offer.

“

¾

¾

¾

¾

Risk Based Quality Systems

Risk Based Validation

Risk Based Process Monitoring

Risk Based Documentation

-Page 37-

ICH Q9 Describes Several Risk Assessment Tools

Basic Risk Management Facilitation Methods

(Flowcharts, Check Sheets Etc.)

Failure Mode Effects Analysis ( FMEA )

Failure Mode, Effects and Criticality Analysis (FMECA)

Fault Tree Analysis (FTA)

Hazard Analysis And Critical Control Points (HACCP)

Hazard Operability Analysis (HAZOP)

Preliminary Hazard Analysis ( PHA )

Risk Ranking and Filtering

Supporting Statistical Tools

-Page 38-

Risk Management - FMEA Method

Severity

¾ addresses the impact on a process in the event a parameter is out of range.

Occurrence

¾ assesses the likelihood a parameter will be out of range.

Detection

¾ addresses the ability of detecting a defect if a parameter is out of range.

Risk Priority Number

¾ RPN = Severity x Occurrence x Detection

-Page 39-

FMEA Risk Assessment - Identifying Criticality

Assemble multidisciplinary team

¾ Manufacturing, Process Development, Manufacturing Sciences,

Engineering and Quality Assurance

Prepare “FMEA Data Sheet”

¾

¾

¾

All operating inputs and proposed operating ranges

What are the potential failure modes (process, equipment, operators)

Typical sources of failure in systems

¾ What are causes of these failures

Scoring based upon

¾ Knowledge, known equipment capability, maintenance

¾ Previous experience and expertise

-Page 40-

Risk Assessment SOP

-Page 41-

FMEA Worksheet

Severity x Occurrence x Detection = RPN

Process

Unit Operation

Leader

Participants

Failure Modes and Effects Analysis

Healgen

TFF

John Smith

Robert S, Bill E, Fred J, Mary S, Jill R

Operational Parameter Current Range Failure Mode Cause(s) Potential Effect(s)

Preparation

Verify TFF-08207 is within cleaning expiration date

Install dip tubes

Perform pre-use visual inspection

Set-up TFF for processing per MO173

System hose connections

Connect chilled water supply

Conncect AWFI

Conncect CDA

System AWFI flush

30 days

Clean

Drain the system per MO173

Verify Hydraulic Pressure Unit is in the run setting

Open and download file "Automated TFF

Method VER01"

Buffer Manifold Flush

> 1150 psig

Flush valves for > 2 min

Out of date

Incorrect dip tube orientation

Not cleaned

System set-up incorrectly

Incorrect system hose connections

Incorrect connection / utilities failure

Incorrect connection / utilities failure

Incorrect connection / utilities failure

System not drained

Incorrect pressure on membranes

Wrong file downloaded

Valves not flushed for sufficient tim

System not adequately flushed with AWFI

Operator error / Process delay

Operator error / Incorrect alignment of alignment pin

Faulty cleaning cycle

Operator error / Incorrect SOP revision

Operator error

Expired equipment used in process

Foaming / Over concentration /

Yield loss

Dirty equipment used in process

Production delay / Product loss

Utilities failure / Operator error

Utilities failure / Operator error

Utilities failure / Operator error

Operator error / Equipment failure

Wrong setting selected / Faulty

Hydraulic Pressure Unit

Operator error

Incorrect flow rate / Valve failure

Incorrect system connections /

Insufficient volume / Incorrect flow path

Inadequate flushing of system /

Product loss

Temperature spike / Product loss

Inadequate flushing of system /

Product loss

System will not operate / valves will not toggle

System not flushed of storage solution

Membranes not sealed /

Product loss

Product Loss

System not flushed of storage solution

System not flushed of storage solution / Product loss

Severity Occurrence Detection RPN

-Page 42-

FMEA Worksheet

Severity x Occurrence x Detection = RPN

System or Process Name:

Reference Drawings

URS

System/Process

Failure Mode, Effects and Criticality Analysis

(FMECA)

Component Description

& Function

Potential Failure Mode Potential Failure Effects Potential Failure Causes

Compiled by:

System Owner:

Original Date:

Compensating Provisions

Existing Conditions

S

E

V

O

C

C

D

E

T

R

P

N

Team:

Primary SME:

Revision Date:

Recommended

Actions

Resp.

Actions Taken

Revised Conditions

S

E

V

O

C

C

D

E

T

R

P

N

-Page 43-

FMECA Worksheet

Component Description

& Function

3 WFI Distribution System

Potential Failure Mode

WFI distribution pipe

Contamination

Potential Failure Effects Potential Failure Causes Compensating Provisions

S

E

V

WFI water quality out of spec Dead leg, Non-turbulent flow, wrong surface finishing and/or incompatible material (MOC) for

WFI piping

Check design, commissioning, validation, PM & EM program

8

O

C

C

D

E

T

R

P

N

5 5 200

Recommended Actions

Commissioning & Qualification Testing (RPN=200

Undesirable)

1. Verify no dead leg L/D >2.0

2. Verify surface finish

3. Verify MOC (elastomers, SS grade)

4. Verify Reynolds number (circulation flowrate)

5. Verify Design Review

Res

.

p

Actions

Taken

Particle Test

Program

-Yearly by

Intarcia?

S O

E

V

D

C

C

R

E

T

P

N

-Page 44-

Criticality Ranking

Risk Score

Intolerable

Undesirable

Tolerable

Negligible

343-1000

189-336

72-180

1-70

100

80

70

60

50

42

36

30

24

16

12

9

6

1

RISK CRITICALITY

High Risk

Moderate Risk

Low Risk

1 2

Detection Rank

4 6

9

6

1

30

24

16

12

Certain Very High Moderate

100 200 400

80

70

160

140

320

280

60

50

42

36

120

100

84

72

240

200

168

144

60

48

32

24

18

12

2

120

96

64

48

36

24

4

180

144

96

72

54

36

6

Low

600

480

420

360

300

252

216

8 10

Remote Uncertain

800 1000

640

560

800

700

480

400

336

288

600

500

420

360

240

192

128

96

72

48

8

300

240

160

120

90

60

10

Number of

RPN's in Range

37

26

23

34

ACTION

Design modification required to mitigate risk

Qualification testing or design modification required to mitigate risk

Qualification testing may be required to mitigate risk

Commission

-Page 45-

Manufacturing FMEA

RPN’s can range from 1 to 1,000

¾ RPN ≥ 100 indication may be a high risk item

Manufacturing:

¾

¾

¾

Nine unit operations analyzed

FMEA evaluated 445 operational inputs

RPN’s ranged from 3 to 158

Only 6 operational inputs received RPN scores ≥ 100

¾ Indicates robustness, procedural controls and equipment capabilities have minimized the risk of failure

¾

¾

Fewer parameters to validate

More Targeted Validation

¾ Better understanding, better quality, lower cost

-Page 46-

FMEA Results

Unit Operation

Production Fermentation

Production Fermentation

SEC

SEC

SEC

SEC

Parameter

Raw Material Addition

Sampling for Culture Purity Analysis

Elution Buffer (BT018) pH

Elution Buffer (BT018) Conductivity

Load Volume

Remove Bioburden, LAL Samples

Validate only CRITICAL & KEY Parameters

¾

¾

¾

From FMEA

From Severity

From Knowledgebase

RPN

111

102

158

155

144

113

-Page 47-

FMECA Risk Analysis Report

“conduc practice ted in ac

This rec s. ommen cordanc e with…

consist good do cumenta tion ent with al Qua

ICH gu lity Sys

controls idance tem

should

.9 241 be

Nov 18,

2008 for ind ustry,

Decision sufficien dation is

Q10 s and ju tly docu

Pharm stificatio aceutic n of the mented

” –

FDA Gu idance

-Page 48-

E 2500 Implementation Gaps

ASTM E 2500 lays out a ‘standard” roadmap for the overall approach

It is not a ‘how to’ guide,

¾ “ Firms should develop appropriate mechanisms to communicate requirement inputs, including product quality considerations, to those responsible for design”

Firms will need to develop

¾

¾

Processes

Tools & templates suited to their operations

Not one size fits all – needs to address corporate risk, nature of business, expertise of staff, organization resources

-Page 49-

What Else is Needed?

Design Review Process

¾ Planned and systematic reviews throughout the system lifecycle:

−

−

−

−

Specifications

Design

Design development

Continuous improvement changes

Ensure product and process requirements are satisfied by the design

Unacceptable risks are mitigated by design or other means

Design is performed by appropriate SMEs

-Page 50-

What Else is Needed?

Change Management Process

¾

¾

Develop a change management plan before releasing the system

Change is good, is expected

¾

¾

Managed by, changes approved by SMEs

Changes affecting critical aspects communicated to the quality unit

Changes related to product quality and patient safety require prior approval by the quality unit, unless predefined plan

PAT – provides scientific data to support changes and manage risk

-Page 51-

ASTM E 2500 – The Role of Vendors

“The key to a competitive parts supply system is the way the assembler works with its suppliers”

¾ (Womack et al., 1990)

Partner with a supplier (LEAN) vs

Bid them against each other (MASS)

“ Preferred Suppliers ”

¾ Few in number, single sourced?

¾

¾

Share information – needs, specifications

Supplier becomes the solution provider

Encourages use good vendor documentation and testing to support qualification

-Page 52-

Implementation Gaps

Gaps

¾

¾

How do you do a risk assessment eg. FMEA SOP?

How often, at what points in the process?

¾

¾

¾

¾

¾

¾

¾

How do you qualify to be an SME?

How many QA staff will be needed? What expertise will they need?

Where will you find them?

How do you manage changes during design & implementation?

How do you manage change to enable improvements to be implemented?

How do you efficiently address deviations from the Verification

Plan?

How do you determine the ‘Critical aspects of the manufacturing system’

How to define & document the verification approach

-Page 53-

E 2500 Implementation Gaps

ASTM E 2500 lays out a ‘standard” roadmap for the overall approach

It is not a ‘how to’ guide,

¾ “ Firms should develop appropriate mechanisms to communicate requirement inputs, including product quality considerations, to those responsible for design”

Firms will need to develop

¾

¾

Processes

Tools & templates suited to their operations

Not one size fits all – needs to address corporate risk, nature of business, expertise of staff, organization resources

-Page 54-

E 2500 Efficiency & Cost Savings

The extent of verification and the level of detail of documentation should be based on risk , including those associated with product quality and patient safety , and the complexity .

“Only companies that achieve a high level of process understanding will have the opportunity to justify a more flexible regulatory path.”

¾ FDA 2004

-Page 55-

Yes, ASTM E 2500 is Being Implemented

Hyde Client, Commercial Device Facility

¾

E2500 Based facility and systems commissioning and qualification

Amgen, Thousand Oaks Clinical Mfg

¾

50-70% reduction in IQ/OQ for chromatography skid

− Phil Bowles, ISPE Tampa 2009

Bristol-Myers Squibb Biologics

¾ “Applying ASTM E2500 to a Greenfield Site”

− E Bramhall, Director Validation, ISPE 2008 Annual Meeting

Perkin Elmer

¾

“Best Practices for Qualification of Laboratory Equipment

Utilizing ASTM E2500”

Major East Bay Pharmaceutical Company

¾

Risk based commissioning & qualification

Major Bay Area Biotech Company

¾ Risk based validation for new facility commissioning

-Page 56-

FDA Guidance

“Guidance for Industry Process Validation:

General Principles and Practices” - FDA Nov 18

2008 Guidance

In keeping with the spirit of ASTM E 2500

Standard, the document uses the term “ verify ” rather than “ validate ” when referring to facility systems.

IQ, OQ, DQ, PQ are industry terms and standards, not FDA mandated.

-Page 57-

Summary

ASTM E 2500-07 provides a cutting edge framework for planning and execution of riskbased approach to designing and implementing reliable manufacturing systems

ASTM E 2500 has many parallels to existing approaches, but relies on more risk management and higher expertise

The challenge is to address the implementation gaps and develop the custom tools

-Page 58-

Contact Info

Peter K Watler, PhD

Principal Consultant and

Chief Technology Officer

Hyde Engineering + Consulting, Inc.

peter.watler@hyde-ec.com

415-235-1911

-Page 59-