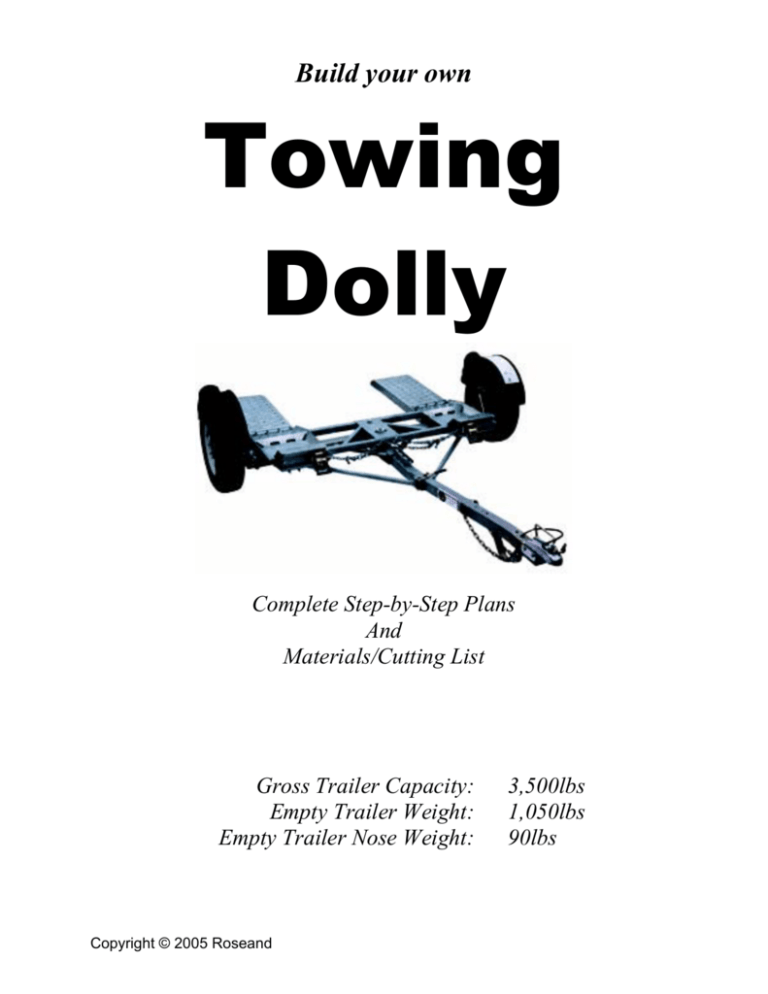

Build your own

advertisement

Build your own Towing Dolly Complete Step-by-Step Plans And Materials/Cutting List Gross Trailer Capacity: Empty Trailer Weight: Empty Trailer Nose Weight: Copyright © 2005 Roseand 3,500lbs 1,050lbs 90lbs Materials List ¼” x 3” x 3” Sq Tubing 3 /16” x 2” x 2” Sq Tubing ¼” x 3” x 3” Angle ¼” x 2” x 2” Angle ¼” Diamond Plate 1 /8” Flat Plate 3 /16” Flat Plate ¼” Flat Plate 3 /8” Flat Plate 3” Channel (5lbs/ft grade) 1 7/16” Round Bar (HRR) ½” Round Bar (HRR) 1 ¼” Schedule 40 Black Pipe 1 ½” Double Heavy Wall Pipe 16 linear feet 11 linear feet 6 linear feet 25 linear feet 8 square feet 7 square feet 10 square feet 25 square feet 5 square feet 17 linear feet 1 linear foot 3 linear feet 9 linear feet 1 linear foot NOTE: The amounts shown above are for the EXACT needs for the plans detailed and do not include any natural wastage incurred during cutting. It is always wise to order slightly more materials at the outset rather than having to re-order small amounts later. Other Items Required SAE Grade 8 Bolts with Lock Washers, Flat Washers & Nuts 3 /8” x 1” /8” x 1½” ½” x 1” ½” x 3½” ½” x 4½” ½” x 6” 3 4 8 4 4 7 2 ½” x 4 ½” high x 1 ½” wide U-Bolt w/washers & Nuts 2” Ball 7,000lb min Coupler Bolt-on Spindle 14” Rims & Tyres 9” x 19” x 32” Mudguards 3 /8” x 150” Safety Chain with 2 Hooks Trailer Lighting Kit Spring Latches with ½” Shanks & Lock DISCLAIMER: As we have no control over the builders abilities or materials, we DO NOT WARRANT these plans for any type of suitability of use and offer them for experimental use only. IT IS HIGHLY SUGGESTED THAT THE FINISHED PROJECT IS CHECKED BY A PROFESSIONAL TRADESMAN BEFORE PUT TO USE. Copyright © 2005 Roseand STEP 1 SPINDLE SELECTION The picture below shows the kind of spindle that this design uses. These could be found by scouring the breakers yards and are commonly found on the rear of front-wheel-drive cars. Many other types could be utilized and new items can be bought from trailer companies such as TrailerTek (www.trailertek.com). 13” or 14” rims should be used and matched to the hubs used. Copyright © 2005 Roseand STEP 2 SPINDLE MOUNTING COMPONENTS Copyright © 2005 Roseand STEP 3 AXLE & SPINDLE ASSEMBLY Copyright © 2005 Roseand Copyright © 2005 Roseand Copyright © 2005 Roseand STEP 4 TONGUE & COUPLER Copyright © 2005 Roseand Copyright © 2005 Roseand Copyright © 2005 Roseand STEP 5 TONGUE MOUNTING HARDWARE Copyright © 2005 Roseand STEP 6 RAMP POCKETS Copyright © 2005 Roseand Copyright © 2005 Roseand STEP 7 RAMP POCKETS (cont.) Copyright © 2005 Roseand Copyright © 2005 Roseand STEP 8 RAMPS Copyright © 2005 Roseand STEP 9 RAMP SPRING LATCH Copyright © 2005 Roseand STEP 10 MUDGUARDS, LIGHTS & NUMBER PLATE BRACKET Copyright © 2005 Roseand STEP 11 PAN PLATE Copyright © 2005 Roseand STEP 12 PAN FRAME Copyright © 2005 Roseand Copyright © 2005 Roseand Copyright © 2005 Roseand Copyright © 2005 Roseand Copyright © 2005 Roseand STEP 13 PIVOT ASSEMBLY Copyright © 2005 Roseand STEP 14 TONGUE, BRACES AND TYRES Copyright © 2005 Roseand STEP 15 CLEAN / PREP / PAINT Before painting, the entire trailer should be cleaned and free from rust and grease. To accomplish this, all surface areas should be wire brushed and/or sanded. If severe rust is present, sandblasting should be considered. The welded areas should be chipped of all slag or residue and wiped clean with paint solvent. One or two coats of primer paint should be applied, and one or two coats of top grade enamel as the final application. Paint according to the manufacturers recommendations and safety guidelines. Alternative finishes to consider are galvanizing and powder coating which will give the trailer a hard, durable finish. STEP 16 WIRING Follow the wiring diagram provided or follow instructions that come with your lighting kit. The suggested routing of the wires is through the 3” square tubing where possible although external routing may be preferred. The routing of wires through or around the mudguards must be done in conduit to protect it from the tyres. STEP 17 WEB RACHET SLIDE BRACKET Copyright © 2005 Roseand STEP 18 PAN INSTALLATION SUPPLY LIST (2) ½” X 3½” NC, SAE GRADE 8 BOLTS WITH WASHERS AND NUTS. GREASE All contact points where pan assembly wear bars meet the wear plates on the ramp pockets are to be cleaned and free of weld spatter etc. Apply grease liberally at all contact points. Clean and liberally grease the pivot pin assembly. Place the pan assembly in alignment with the pivot assembly, and carefully install the pin so that the bolt holes line up. Install the ½” x 3 ½” SAE Grade 8 bolts, washers and nuts to secure pan assembly. Torque bolts to approx. 80 ft/lbs and apply Loctite. Copyright © 2005 Roseand STEP 19 SAFETY CHAINS Copyright © 2005 Roseand STEP 20 ELECTRICAL WIRING The choice of Lamp Clusters is entirely up to you and what you feel looks right, but both Lamp Clusters should have Tail Light, Brake Light and Indicator. Below are some examples of suitable Lamp Clusters: It should also be remembered that the right side light cluster also has to illuminate the number plate unless a separate lamp is used for that. For connecting the trailer electrics to the towing vehicle, a standard 12n trailer plug is used (shown here) and the following diagram MUST be adhered to. 12N Trailer Plug 1 6 2 7 5 3 4 Female PIN COLOUR 1 2 3 4 5 6 7 Yellow Blue White Green Brown Red Black FUNCTION Left Indicator Fog Lamps (if fitted) Ground (chassis) Right Indicator Right Side Tail Lamp Brake Lamps Left Side Tail Lamps Male Care must be taken when routing the wiring. It is suggested that wiring is taken through the frame of the trailer itself, (as shown earlier) and flexible conduit used where it is routed next to the wheels and tyres. If in any doubt, consult a qualified auto electrician and ensure everything works correctly before using on the public road. Copyright © 2005 Roseand