1 Chapter Quality Network Asthma Project

advertisement

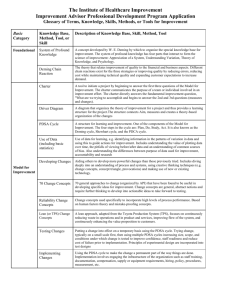

Chapter Quality Network Asthma Project - Quality Improvement Questionnaire Chapter Physician Leader Name ______________________ Chapter: _________________________________________ Date__________________ Instructions: For each skill, method or tool please assess yourself by placing a number from the 1-100 scale provided on the form. Your assessment can be anywhere along this scale and may vary widely from skill to skill (e.g. Aim and Measures 85 and PDSA cycle 37). Refer to the detailed glossary at the end of this document for accurate definitions of terms. Please complete each method, tool, skill & content area. IF YOU ASSESS YOURSELF AT THE: Awareness Stage: You are saying you know what tool is and would rate yourself somewhere between 1 and 20 on the assessment scale based on your familiarity with the method, tool or skill. Skill Stage: You are saying you can apply in identified situations (e.g. if someone tells you that it is appropriate to use a control chart in this situation you could use a control chart). You would rate yourself somewhere between 21 and 40 on the assessment scale. Knowledge Stage: You are saying you know how, when, and where to use the method, skill or tool (you can identify for yourself that a control chart is needed in this situation). You would rate yourself somewhere between 41 and 60 on the assessment scale Understanding Stage: You are saying you have experience with the method, tool, or skill to the point that you can adapt it to a situation and can explain why you are using it to others (e.g. you can explain why you chose a control chart in this situation, and why you chose this specific type of control chart). You would rate yourself somewhere between 61 and 80 on the assessment scale. Expert Stage: You are saying you can teach the theory and the use of the method, skill or tool (e.g. you can teach others when to use a control chart rather than some other tool, which of the several control charts to select in a given situation and the theory behind control charts) . You would rate yourself somewhere between 81 and 100 on the assessment scale. Source: Adapted from instrument developed by Associates in Process Improvement, 2005. 1 Instructions: please assess yourself by placing a number from the 1-100 scale provided on the form. Please reference the glossary at the end of this document. Category Model for Improvement Awareness Do I know what it is? Specific Method, Tool, or Skill Assessment Scale: Select a number anywhere on scale 1 10 20 Skill Can I apply in identified situations with help? 21 30 40 Knowledge Do I know how, when, and where to use? 41 50 60 Understanding Do I have experience? Can I adapt, explain why? 61 70 80 Expert Can teach theory and use of method 81 90 100 Aim and Measures Learning Structure PDSA Cycle Use of Data (basic stats) Developing Changes Testing Changes Designing for Reliability Implementing Changes Spreading Changes Science of Improvement Viewing Systems Research vs. Improvement Flow Diagram Linkage of Processes Gathering Information Operational Definitions Forms for Collecting Data Sampling Methods Source: Adapted from instrument developed by Associates in Process Improvement, 2005. 2 Instructions: please assess yourself by placing a number from the 1-100 scale provided on the form. Please reference the glossary at the end of this document. Category Understanding Variation Awareness Do I know what it is? Specific Method, Tool, or Skill Assessment Scale: Select a number anywhere on scale 1 10 20 Skill Can I apply in identified situations with help? 21 30 40 Knowledge Do I know how, when, and where to use? 41 50 60 Understanding Do I have experience? Can I adapt, explain why? 61 70 80 Expert Can teach theory and use of method 81 90 100 Run Chart Attribute Control Charts (p,c,u,) Continuous Control Charts (X and MR, Xbar and S) Pareto Chart Frequency Plot/Histograms Evidence Based Decision-Making Teamwork Leading teams effectively, Managing group decision-making, etc Leadership of Improvement Quality as a strategy Leading Change Organizational Change, Managing the change process with stakeholders Chronic Care Model Source: Adapted from instrument developed by Associates in Process Improvement, 2005. 3 Glossary Knowledge, Skills, Methods, or Tools for Improvement Category Foundational Knowledge Base, Method, Tool, or Skill System of Profound Knowledge Deming Chain Reaction Model for Improvement Description of Knowledge Base, Skill, Method, Tool A concept developed by W. E. Deming by which to organize the special knowledge required to understand and optimize organizations. The system of profound knowledge has four parts: Appreciation of a System, Understanding Variation, Theory of Knowledge, and Psychology. The theory that relates improvement of quality to the financial and business aspects. Different chain reactions exist for the three strategies or improving quality by reducing errors, reducing cost while maintaining technical quality and expanding customer expectations to increase demand. Charter A tool to initiate a project by beginning to answer the first three questions of the Model for Improvement. The charter communicates the purpose of a team or individual involved in an improvement effort. The charter directly answers the fundamental improvement question, "What are we trying to accomplish and begins to answer the 2nd and 3rd questions (measures and changes). Learning Structure A diagram (version of tree-diagram) that organizes the theory of improvement for a project. The structure connects Aim, measures and creates an organization of the changes PDSA Cycle A structure for learning and improvement. One of the components of the Model for Improvement. The four steps in the cycle are: Plan, Do, Study, Act. Use of the Cycle promotes iterative learning through questions, predictions, actions, data collection, and synthesis. It is also known as the Deming cycle, Shewhart cycle, and the PDSA cycle. Use of Data (including basic statistics) Use of data for learning, e.g. identifying information in the patterns of variation in data and using this to guide actions for improvement. Includes understanding the value of plotting data over time, the pitfalls of viewing before/after data and an understanding of common sources of bias. Also understanding the differences between purpose of data used for improvement, accountability and research Developing Changes Aiding others to develop more powerful changes than those previously tried. Includes diving deeply into an understanding of process and systems, using creative thinking techniques (e.g. change concepts, concept triangle, provocations) and making use of new or existing technology. Testing Changes Putting a change into effect on a temporary basis using the PDSA cycle. Trying change, typically on a small scale first, then using multiple PDSA cycles increasing size, scope, and conditions under which change is tested to improve confidence, staff readiness and reduce cost of failure prior to implementation. Source: Adapted from instrument developed by Associates in Process Improvement, 2005. 4 Teamwork Viewing Systems Gathering Information Implementing Changes Using the PDSA cycle to make the change a permanent part of the way things are done. Implementation involves engaging the infrastructure of the organization such as staff training, documentation, compensation, supply or equipment requirements, hiring, policy, procedures, measurement, etc. Implementation takes longer than testing and typically involves more resistance to change. Developing strategies to mitigate resistance to change is part of implementation. Conducting Meetings Includes understanding how to structure team meetings so they are more effective and efficient. Includes knowledge related to clarifying roles and responsibilities of team members, team leader, facilitator, technical consultant and management sponsor, clarifying agenda items, timeframes, expected outcomes, decision making methods, meeting documentation and physical environment for the meeting. Group Dynamics Improving team functioning through understanding of how individuals behave when in a group. Includes understanding of the need for clarity of purpose (charter), clarity of behavioral expectations (norms), typical stages of group development, use of discussion and of dialogue, avoidance of “group think” and methods for evaluating, monitoring and improving group interaction in meetings. Flow Diagram A graphic representation of a series of activities that define a process. The diagram shows the stages of a process as inputs are being transformed into outcomes. There are different types of flow diagrams including top-down, complexity, ideal flow, and group-matrix. Linkage of Processes A method to develop a view of a system composed of processes linked together to accomplish the purpose of the system. Operational Definition A definition that gives communicable meaning to a concept by specifying how the concept is applied within a particular set of circumstances. Form for Collecting Data A form for collection of data that provides an organized method to record required data and additional observations to be used in analysis. Often a part of a PDSA Cycle. Surveys A method of collecting information directly from people about their feelings, motivations, plans, beliefs, experiences and backgrounds. Benchmarking The process of measuring products, services, and practices against the best performers or those companies recognized as industry leaders. Sampling Methods Selection of units for study. Different sampling methods include judgment sampling, simple random sampling, proportionate random sampling, systematic sampling, and stratified sampling. Source: Adapted from instrument developed by Associates in Process Improvement, 2005. 5 Organizing Information Understanding Variation Creativity Methods A collection of techniques for tapping into the unconscious mind for new ideas that lead to different ways of attacking a problem or accomplishing a task. Also called lateral thinking methods. Methods include six thinking hats, provocations, random word, and concept triangle. Affinity Diagram A method to summarize qualitative data into groups with a common theme Cause and Effect Diagram A tool for organizing a group’s current knowledge regarding a problem or issue. Useful for recording ideas in a brainstorming session (also called a fishbone diagram or an Ishikawa diagram). Matrix Diagrams Method used to arrange data to help the user understand important relationships. Displays the relationship between two groupings (e.g. criteria for a supply and vendors under consideration, or steps in a process and the departments involved). It is especially useful for developing a change and deciding where to test it. Tree Diagrams Used to visualize the structure of a problem, plan or any other opportunity of interest. Helps in thinking systematically about each aspect of the problem or plan. It has also been called a “systematic diagram”. The tree diagram allows the graphical view of different level of details about a problem or plan Run Chart Control Chart Pareto Chart Relationships A graphical record of a quality characteristic measured over time. A method used to distinguish between variation in a process due to common causes and variation due to special causes. It is constructed by obtaining measurements of some characteristic of a process, summarizing with an appropriate statistic, and grouping the data by time period, location, or other process descriptive variables. There are many different types of control charts, depending on the statistic analyzed on the chart. A tool for helping focus our efforts by identifying how frequently categories of events occur Frequency Plot A tool to display data which presents to the user basic information about the location, shape, and spread of a set of data. (also called histogram or dot plot) Capability A prediction of the individual outputs of a characteristic from a process. If a process is found to be stable, the process capability can be determined. The prediction from a capability calculation can be compared to specifications to determine whether the process can produce outcomes that meet the specs Scatter Plots A tool for showing relationships between two variables. Pairs of data are plotted together on scales set at right angles to each other. Source: Adapted from instrument developed by Associates in Process Improvement, 2005. 6 Two-Way Tables A tabular representation of the relationship between pairs of variables. (Similar to a scatter plot) Source: Adapted from instrument developed by Associates in Process Improvement, 2005. 7