Soil Mechanics Laboratory

advertisement

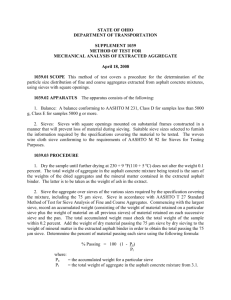

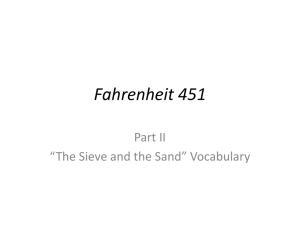

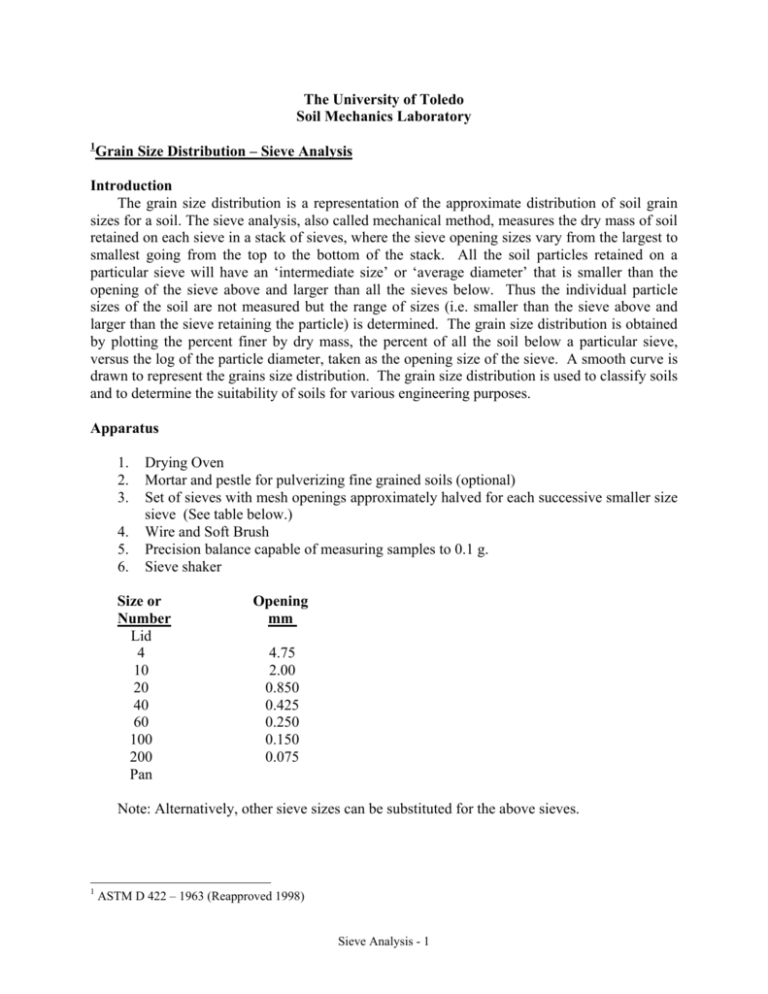

The University of Toledo Soil Mechanics Laboratory 1 Grain Size Distribution – Sieve Analysis Introduction The grain size distribution is a representation of the approximate distribution of soil grain sizes for a soil. The sieve analysis, also called mechanical method, measures the dry mass of soil retained on each sieve in a stack of sieves, where the sieve opening sizes vary from the largest to smallest going from the top to the bottom of the stack. All the soil particles retained on a particular sieve will have an ‘intermediate size’ or ‘average diameter’ that is smaller than the opening of the sieve above and larger than all the sieves below. Thus the individual particle sizes of the soil are not measured but the range of sizes (i.e. smaller than the sieve above and larger than the sieve retaining the particle) is determined. The grain size distribution is obtained by plotting the percent finer by dry mass, the percent of all the soil below a particular sieve, versus the log of the particle diameter, taken as the opening size of the sieve. A smooth curve is drawn to represent the grains size distribution. The grain size distribution is used to classify soils and to determine the suitability of soils for various engineering purposes. Apparatus 1. 2. 3. 4. 5. 6. Drying Oven Mortar and pestle for pulverizing fine grained soils (optional) Set of sieves with mesh openings approximately halved for each successive smaller size sieve (See table below.) Wire and Soft Brush Precision balance capable of measuring samples to 0.1 g. Sieve shaker Size or Number Lid 4 10 20 40 60 100 200 Pan Opening mm 4.75 2.00 0.850 0.425 0.250 0.150 0.075 Note: Alternatively, other sieve sizes can be substituted for the above sieves. 1 ASTM D 422 – 1963 (Reapproved 1998) Sieve Analysis - 1 Procedure A. Preparation (at least 24 hours before test) 1) Measure approximately 250 g. of a coarse-grained soil. The soil should have more than 95% passing the No. 4 sieve and less than 5% passing the No. 200 sieve. (According to ASTM D 422 Standard Test Method for Particle-Size Analysis of Soils, larger samples are required for soils with larger proportions of the plus No. 4 size. Soils with a greater amount of fines must be pulverized with a pestle and washed through sieves.) 2) Dry the soil in the oven. B. Laboratory 1) Carefully brush the sieves to ensure that all loose material is removed. To prevent damage to the sieves, do not use the wire brush on the No. 100 or No. 200 sieve. 2) Obtain the oven dry mass of the sample. 3) Obtain the weight of the pan. 4) Combine the sieves into a stack with the pan on the bottom. 5) Pour the soil into the top sieve and place the lid on the top sieve. 6) Place the sieve on the mechanical shaker and run the shaker for 10 to 15 minutes. 7) Remove the sieves from the shaker and obtain the mass of soil retained on each sieve by carefully transferring the soil retained on each sieve to the pan. Calculations % Mass Retained = (Mass of Dry Soil) / (Sample Dry Mass) X 100% (1) To compute the % Cumulative Retained, add the % Retained on the sieve and all sieves above the sieve. The % Finer is computed using Equation 2. % Finer = 100% - % Cumulative Retained (2) The % Loss computed in Equation 3 should be less 2%. % Loss = (Sample Dry Mass – Total Soil Mass Sieved) / (Sample Dry Mass) X 100% (3) Use the grain size distribution and the following equations to compute the coefficient of uniformity, Cu, and the coefficient of curvature, Cc. Cu = D60 / D10 (4) Sieve Analysis - 2 Cc = (D30)2 / (D60 X D10) where (5) D60 = grain diameter at 60% finer D30 = grain diameter at 30% finer D10 = grain diameter at 10% finer Results Use Table 1 below and Equation 1 to compute the percent finer by weight for each sieve. Compute the percent loss during sieve analysis using Equation 3. Use Figure 1 and Equations 4 and 5 to obtain the coefficients. Use Table 2 to determine the soil classifications. Table 1 – Sieve Analysis SIEVE ANALYSIS Soil Description: Mass of Pan: (g) Mass of Pan + Dry Soil: (g) Sample Dry Mass: (g) Sieve Retained Sieve Opening Soil + Pan Size (mm) (g) #4 4.750 #10 2.000 #20 0.850 #40 0.425 #60 0.250 #100 0.150 #200 0.075 PAN Total Soil Mass Sieved (g) Group ____________ Mass of Dry Soil (g) % Mass Retained Date ____________ % Cumulative Retained % Loss During Sieve Analysis D10: D30: D60: Cu: Cc: Sieve Analysis - 3 mm mm mm % Finer Sample Calculations: Sieve Analysis 100% Percent Finer 80% 60% 40% 20% 0% 10.000 1.000 0.100 Particle Diameter, mm Figure 1 - Grain Size Distribution of Coarse-Grained Soil Sieve Analysis - 4 0.010 Table 2 – Soil Classification Percent Passing No. 10 Percent Passing No. 40 Percent Passing No. 200 Plasticity Index, (IP) AASHTO Classification Percent Passing No. 200 Percent Passing No. 4 Cu Cc USCS Classification NP Conclusions Is the grain size distribution curve representative of the type of soil tested in the laboratory? Would you describe the soil as well graded or poorly graded? Why do you need a larger sample size if the soil sizes are larger? What are some engineering uses for the soil? Would the soil tested in the laboratory meet the specifications listed in the table below? Sieve Min Max. Opening % % (mm) Finer Finer 4.750 100.0 100.0 2.000 100.0 100.0 1.700 90.0 99.0 1.200 60.0 94.0 0.600 1.0 44.0 Sieve Analysis - 5 Sieve Shaker and Sieves Pan Lid No. 40 Sieve Brushes Picture 1 and 2 – Sieve Analysis Apparatus Sieve Analysis - 6