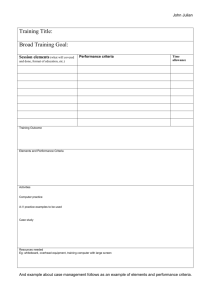

Underpinning Constructability Review (click to view)

advertisement

Leaha Martynuska Construction Management Option Wilsdorf Hall – Materials Science Engineering & Nanotechnology Building University of Virginia 7. Breadth Analysis: Alternate Underpinning System 7.1 MSENT Underpinning Background MSENT is being constructed on a very small site situated between three existing buildings. Construction at this location required the installation of a detailed underpinning system to support the existing foundations. The underpinning system installed on the existing chemistry building failed, cracking the existing foundation, and therefore causing a schedule delay. A structural engineer did not design the underpinning system. The specification section for shoring and underpinning was a ‘performance specification’ wherein an AE indicated what is required, but does not indicate a specific manufacturer or method. Therefore the specification said to underpin the building, don’t let it fail, and the allowable tolerances are…. The chemistry building was underpinned using a mine shaft method in the following steps: • A pit was excavated next to the building footing • A 5’ x 5’ x 5’ hole was dug against the footing • Excavation was completed to 4’ underneath the footing • Wood shoring was installed to shore the inside of the pit • Once completely underneath the building, a shaft was dug down to approximately 33’ with wood boards at the exterior of all four sides • This shaft was then poured solid with concrete up to 2” +/- below the existing footer • Once the concrete was cured the 2” gap was dry packed with grout. 75 The Pennsylvania State University AE Faculty Advisor: Dr. David Riley Leaha Martynuska Construction Management Option Wilsdorf Hall – Materials Science Engineering & Nanotechnology Building University of Virginia 7.2 MSENT Underpinning Constructability Review It is unknown why the building foundation actually cracked. An investigation was conducted by an outside forensic engineering firm who concluded that the design was inadequate and did not comply with project specifications. Yet the contractors who installed and designed the system believe the design was adequate and the building cracked as a result of an unforeseen site condition. There are several different soil/material planes within the height of the excavation. At the intersection of two of the planes there is a slick surface which caused the soil not to be as self supporting as normal and put an unexpected amount of force onto the underpinning pits. This exceeded the values normally used in underpinning design and caused the building to shift and crack. One side claims the failure could have been prevented in either case if the design had been upgraded to comply with the contract documents. Yet the opposing side claims that standard design practice would not have prevented the movement. Currently, it is being accepted that any failure was not the result of faulty installation, but instead of an inadequate design (to support loads under the unforeseen conditions). All required tests were performed on the underpinning system, including the concrete which was tested to ensure it reached the proper compressive strength. The tiebacks (used to resist lateral forces) which were the point of failure were also tested. There were two tests completed, a short test which loaded each tie to alignment, to 0.25 design load, to 0.5 design load, to 0.75 design load, to 1.0 design load, and to 1.2 design load. Each step was tightened, 76 The Pennsylvania State University AE Faculty Advisor: Dr. David Riley Leaha Martynuska Construction Management Option Wilsdorf Hall – Materials Science Engineering & Nanotechnology Building University of Virginia held for a specific duration then its movement was recorded (about 10 minutes total). If movement exceeded an allowable standard then a second test was performed with a more complicated stepping process, longer duration for each step and final step of 1.33 design load (total time about one hour). This test was to be done for any failure (there was none on the project) and 5% of the total number of tiebacks on the job. The 5% selected were the ones with the highest strength requirements, the hardest to install and the rest random. Additional tiebacks were installed to make the system stronger, and each was tested to the more stringent one hour test. Then two were randomly selected to be tested at 1.33 design load and this took a total of 8 hours. 77 The Pennsylvania State University AE Faculty Advisor: Dr. David Riley Leaha Martynuska Construction Management Option Wilsdorf Hall – Materials Science Engineering & Nanotechnology Building University of Virginia 7.3 Factors Affecting Underpinning Selection Foundations need to be underpinned either when a structure is being disturbed by foundation movements or when proposed new works are likely to cause structural failure if the foundations are not improved. There are many factors to consider when deciding how exactly to underpin an existing structure: • Size and depth of excavation • Soil conditions • Ground water • Surface drainage conditions • Weather and moisture conditions • Routes and depths of existing underground services Size and Depth of Excavation The size and depth of excavation needed to support an existing structure needs to be known to avoid any potential failures. These two factors help to decide which approach to take to underpin a building. Soil Conditions A variation of soil conditions can result in the failure of an installed underpinning system. This is a very important factor to investigate prior to selection of the underpinning system to be used. Any pockets of sand, fissures, or results of previous soil disturbances, etc. prove that the soil is unstable and may be unfit for underpinning. Ground Water Ground water is also very important in the determination of how to go about underpinning an existing structure. The location of the water table needs to be known before excavation can begin. The water table indicates the level to which the ground freezes and thaws. This needs to be known because soil tends 78 The Pennsylvania State University AE Faculty Advisor: Dr. David Riley Leaha Martynuska Construction Management Option Wilsdorf Hall – Materials Science Engineering & Nanotechnology Building University of Virginia to break down and not be as strong and supportive under extreme weather conditions. Surface Drainage Conditions On site surface drainage is very important when installing an underpinning system. It eliminates any problems with additional moisture or flooding during installation. It also improves soil conditions, making soil stronger and more stable. Weather and Moisture Conditions Weather and moisture conditions in areas where underpinning is to be installed are also important factors when choosing which system to install. Soil strength can break down through heavy rain or frost affecting the system. Also, clay has the possibly of shrinking and drying out during extreme conditions. Routes and Depths of Existing Underground Services It is important to know what is underneath the surface, especially where underground utilities are located. Gas, electricity, and telephone lines, are just a few of the many utilities usually located underground. The location of these utilities needs to be known prior to excavation to eliminate any emergency situations. 79 The Pennsylvania State University AE Faculty Advisor: Dr. David Riley Leaha Martynuska Construction Management Option Wilsdorf Hall – Materials Science Engineering & Nanotechnology Building University of Virginia 7.4 Construction Management Role in Underpinning A construction management team, including supervisor play a very important role in the installation of any system. An underpinning system may be very detailed or not depending on the location of the construction site and the structure needing support. Regardless of the size or shape of the underpinning system, the project management team has several tasks: • Safety is the number one concern when on a jobsite, therefore the number one task is to ensure safety during all times. • During installation regular checking is required to ensure the system work is being done correctly. This is also necessary to ensure safety of workers and other people (especially when on a tight site). • Consequences of accidental impact need to be thought about to ensure a safety plan goes into action immediately. No possibilities of accidents can be overlooked. • The sequence of installation needs to be closely watched to ensure the system is being installed correctly. For example the concrete needs to be poured immediately after excavation is complete. 80 The Pennsylvania State University AE Faculty Advisor: Dr. David Riley Leaha Martynuska Construction Management Option Wilsdorf Hall – Materials Science Engineering & Nanotechnology Building University of Virginia 7.5 Conclusion After reviewing the existing underpinning I have determined that the best possible underpinning system was installed. The underpinning system is a sensitive subject on the project and is a fairly new issue; therefore I was advised against contacting any party directly involved in the installation or design of the system. The reason the failure occurred is unclear and measures to keep the failure from happening seem to have been unpreventable. I have evaluated the installation of the underpinning system for MSENT and came up with a number of factors that need to be determined prior to installation. These conditions directly affect the selection and installation of any underpinning system. Also, through research of case studies I have developed a set of guidelines construction managers must follow during the design of and installation of an underpinning system. The number one guideline is to ensure that all safety measures possible are being taken. 81 The Pennsylvania State University AE Faculty Advisor: Dr. David Riley